Automotive Die Casting: The Future of Chassis Components

TL;DR

Automotive die casting is a high-pressure manufacturing process where molten metal, typically aluminum, zinc, or magnesium alloys, is injected into a steel mold to create strong, lightweight, and complex chassis components. This technology is critical for modern vehicle design, as it enables significant weight reduction, consolidates multiple parts into a single component, and enhances overall structural integrity and performance.

The Fundamentals of Automotive Die Casting Technology

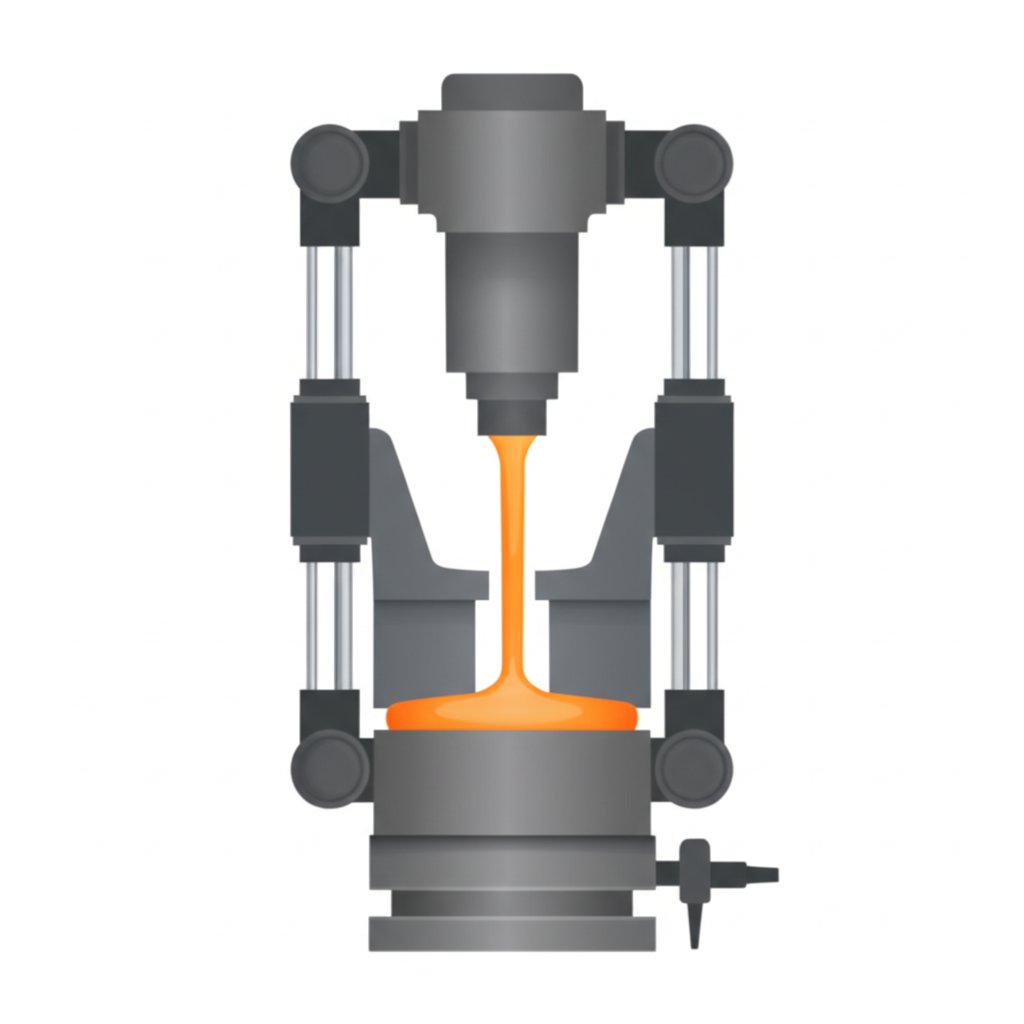

At its core, automotive die casting is a highly automated and efficient manufacturing process designed for high-volume production of intricate metal parts. The technique involves forcing molten non-ferrous metal into a reusable steel mold, known as a die, under immense pressure. This pressure is maintained as the metal cools and solidifies, resulting in a part that precisely matches the mold's complex geometry. This method is especially suited for producing a large quantity of small- to medium-sized castings, making it one of the most prolific casting processes in the automotive industry.

The components of a die casting setup are crucial to its success. The primary elements include the two-part steel die (a cover die and an ejector die), the molten metal alloy, and the injection machine. These machines are categorized into two main types: hot-chamber and cold-chamber. Hot-chamber machines, used for lower melting point alloys like zinc, have an integrated furnace. Cold-chamber machines are used for high-melting-point alloys like aluminum, where the metal is melted in a separate furnace and then transferred to the injection system. The choice between them depends on the material being cast and the specific requirements of the component.

The high-pressure die casting process follows a precise sequence to ensure quality and consistency. This automated cycle allows for rapid production rates, which is essential for meeting the demands of automotive manufacturing. The key steps are as follows:

- Die Preparation: The internal surfaces of the two die halves are cleaned and sprayed with a lubricant. This lubricant helps control the die's temperature and facilitates the easy removal of the finished part.

- Die Closing: The two halves of the die are securely closed and clamped together by the powerful hydraulic press of the casting machine.

- Injection: Molten metal is injected into the die cavity at high speed and under extreme pressure, typically ranging from 1,500 to 25,400 psi. This rapid filling ensures that even thin-walled sections of the component are completely formed before the metal solidifies.

- Cooling and Solidification: Once the cavity is filled, the pressure is held constant while the molten metal cools and hardens, taking the shape of the die.

- Ejection: The die halves are opened, and the solidified casting, known as a shot, is pushed out of the ejector die half by a series of ejector pins.

- Shakeout: The finished part is separated from any excess material, such as the runners, gates, and flash, which is then recycled by being remelted for future use.

This method stands in contrast to other manufacturing techniques like stamping and welding, which require assembling multiple separate pieces. By creating a single, integrated component, die casting reduces assembly time and potential points of failure. For other critical components requiring immense strength, processes like forging are also used. For instance, some manufacturers specialize in precision-engineered automotive forging parts to produce components where extreme durability is paramount.

Core Materials for Chassis Components: A Comparative Analysis

The selection of the right material is fundamental to the success of automotive die casting for chassis components. The most commonly used materials are non-ferrous metals, prized for their unique combination of properties that align with the industry's goals of lightweighting and performance. The primary alloys used are aluminum, zinc, and magnesium, each offering distinct advantages for specific applications within the vehicle's chassis and body.

Aluminum alloys are the most prevalent choice in automotive die casting due to their excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity. These properties make them ideal for structural components like chassis frames, suspension brackets, and engine blocks, where reducing weight without compromising strength is critical. As noted by industry experts, specialized processes like squeeze die-casting are particularly effective for producing high-density aluminum chassis frames and front steering knuckles.

Zinc alloys are valued for their exceptional fluidity, which allows them to be cast into very thin-walled and intricate shapes with a high degree of precision and a smooth surface finish. According to Bruschi, a leader in zinc die casting, this material also offers high impact strength and ductility, making it suitable for components that require durability and a fine finish, such as housings for sensors and electronic modules within the chassis assembly. Its ease of casting and ability to promote long die life also make it an economical choice for smaller, complex parts.

Magnesium stands out as the lightest of the common structural metals, offering the best strength-to-weight ratio. This makes it a premium choice for applications where weight reduction is the absolute priority, such as in high-performance vehicles or electric vehicle components where offsetting heavy battery packs is essential. Magnesium is easily machined and provides good dimensional stability, making it suitable for complex parts like steering wheel frames and instrument panel supports.

To aid in material selection, the following table provides a direct comparison of these key alloys:

| Material | Key Properties | Relative Weight | Relative Cost | Common Chassis Applications |

|---|---|---|---|---|

| Aluminum Alloys | Excellent strength-to-weight ratio, corrosion resistance, high thermal conductivity. | Moderate | Low | Chassis frames, suspension components, engine blocks, transmission cases. |

| Zinc Alloys | High ductility and impact strength, excellent fluidity for thin walls, superior surface finish. | High | Low | Sensor housings, electronic covers, retractor gears, brackets. |

| Magnesium Alloys | Lightest structural metal, highest strength-to-weight ratio, excellent machinability. | Very Low | High | Instrument panel frames, steering components, transfer cases. |

Key Benefits: How Die Casting Revolutionizes Chassis Performance and Efficiency

The adoption of die casting for automotive chassis components offers transformative advantages that directly address the industry's most pressing challenges: improving fuel efficiency, enhancing performance, and increasing manufacturing speed. By enabling the production of lightweight, strong, and geometrically complex parts, this technology has become indispensable for modern vehicle engineering. The benefits extend from the design phase through to the vehicle's on-road performance and overall durability.

The most significant benefit is substantial weight reduction. Lighter vehicles require less energy to accelerate and maintain speed, directly translating to better fuel economy in internal combustion engines and extended range in electric vehicles (EVs). Die casting allows engineers to replace heavy, multi-part steel assemblies with single, lighter aluminum or magnesium components. According to Proterial America, Ltd., adopting high-vacuum aluminum die castings has led to a vehicle mass decrease of approximately 30% compared to traditional manufacturing methods. This reduction is a critical factor in meeting stringent emissions standards and consumer expectations for efficiency.

Another revolutionary advantage is component consolidation. Traditional chassis frames are often constructed by stamping and welding numerous individual steel parts together. This multi-step process is labor-intensive and creates multiple potential points of weakness at the joints. Die casting allows designers to create a single, complex component that integrates the functions of many smaller parts. Proterial also notes that the number of component items in a front frame can be considerably reduced, simplifying assembly, lowering manufacturing costs, and improving the structural integrity and rigidity of the chassis. This leads to better vehicle handling, ride comfort, and safety.

The key benefits of automotive die casting for chassis components can be summarized as follows:

- Improved Fuel Efficiency and EV Range: Significant weight reduction directly leads to lower energy consumption.

- Enhanced Structural Performance: Single-piece components offer superior strength, stiffness, and dimensional stability compared to welded assemblies.

- Design Flexibility: The process allows for the creation of intricate and complex geometries that would be impossible or cost-prohibitive with other methods, optimizing parts for strength and weight.

- Cost-Effective Manufacturing: High automation, fast cycle times, and reduced assembly needs lower the overall cost per part in high-volume production.

- Increased Durability: Die-cast parts are highly resistant to wear and tear, contributing to the long-term reliability of the vehicle, as detailed by Autocast Inc.

Ultimately, these advantages combine to create a superior vehicle. A lighter, more rigid chassis improves handling and acceleration, while the precise dimensions of die-cast parts ensure consistent quality and fit. This technology empowers automakers to build safer, more efficient, and better-performing vehicles that meet the evolving demands of the global market.

Market Trends and the Future of Die Casting in the Automotive Sector

The automotive die casting market is not just a mature manufacturing process; it is a dynamic and growing sector poised for significant expansion, driven largely by transformative shifts within the automotive industry itself. The rise of electric vehicles (EVs) and the relentless pursuit of manufacturing efficiency are creating powerful tailwinds for die casting technology. As the industry moves forward, several key trends are shaping its future trajectory, promising further innovation in materials, processes, and applications.

Market growth projections reflect this positive outlook. A report from Metastat Insight forecasts that the Automotive Parts Aluminium Die Casting Market is estimated to reach $45,249.2 million by 2031, growing at a compound annual growth rate (CAGR) of 6.9%. This growth is fueled by increasing vehicle production globally and the escalating demand for lightweight components to enhance fuel economy and EV battery range. The need to offset the substantial weight of battery packs in EVs has made aluminum die casting a critical enabling technology for the electric mobility revolution.

Technological advancements are also pushing the boundaries of what is possible. Emerging techniques like vacuum-assisted and squeeze die-casting are gaining traction. These advanced methods minimize porosity in the final product, resulting in components with superior mechanical properties and structural integrity. As highlighted by Mordor Intelligence, squeeze die-casting is particularly adept at producing high-density parts like aluminum chassis frames, which combine strength and low weight. These innovations are allowing die-cast parts to be used in even more safety-critical applications that were previously the domain of heavier, forged, or machined components.

Furthermore, the concept of integrated die casting is revolutionizing vehicle architecture. Pioneered by companies like Tesla with its "Giga Press," this approach uses massive die casting machines to produce very large single-piece components, such as the entire front or rear underbody of a vehicle. This consolidates dozens or even hundreds of smaller stamped and welded parts into one. The benefits include drastically simplified assembly lines, reduced manufacturing costs, lower vehicle weight, and improved structural rigidity. This trend toward large-scale integration represents a paradigm shift in automotive manufacturing and is likely to be adopted more widely across the industry.

Looking ahead, the future of automotive die casting will be defined by the continued development of advanced alloys, the integration of smart manufacturing (Industry 4.0) principles for real-time process control, and a greater focus on sustainability through recycling and energy-efficient operations. These trends ensure that die casting will remain a cornerstone technology for building the next generation of efficient, high-performance, and sustainable vehicles.

The Road Ahead for Automotive Structural Components

In summary, automotive die casting for chassis components is far more than a simple manufacturing technique; it is a foundational technology that enables the core objectives of the modern automotive industry. By facilitating the production of lightweight, strong, and intricate parts at scale, it directly contributes to enhanced vehicle performance, improved fuel efficiency, and greater design freedom. The ability to consolidate numerous parts into a single, cohesive structure not only streamlines manufacturing but also builds a stronger, more reliable vehicle from the ground up.

The continuous innovation in materials from aluminum to magnesium and advancements in processes like high-vacuum and integrated die casting demonstrate the industry's commitment to pushing the envelope. As market trends indicate, the demand for these technologies is set to grow, particularly with the global transition to electric mobility. For automotive engineers and designers, mastering the principles of die casting is essential for developing the next generation of vehicles that are safer, more efficient, and more sustainable than ever before. The future of automotive chassis design is inextricably linked to the evolution of this powerful process.

Frequently Asked Questions

1. What are the components of die casting?

The primary components of the die casting process include the die casting machine (either hot-chamber or cold-chamber), the two-part steel mold or die, and the molten metal alloy. The main die casting alloys are typically non-ferrous metals such as zinc, aluminum, and magnesium, as noted in Wikipedia's overview. The process also requires lubricants to aid in part ejection and control die temperature.

2. What automobile parts are made by casting?

A wide variety of automotive parts are made using casting processes. Die casting is particularly used for components requiring precision and complexity, such as engine blocks, transmission cases, suspension brackets, steering knuckles, and various housings for electronics and sensors. Other casting methods are used for parts like pistons, while valve covers are often die-cast.

3. What are the major components of an automobile chassis?

An automobile chassis is the vehicle's foundational frame. Its major components typically include the main frame structure, suspension system (including control arms, knuckles, and shock absorbers), the steering system, and the braking system. Many of these structural and suspension components are increasingly being produced using advanced die casting techniques to reduce weight and improve rigidity.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —