CNC Machining Die Castings: A Guide to Precision & Cost

TL;DR

CNC machining is often a crucial secondary process applied to die-cast components to achieve precision that casting alone cannot. While die casting excels at producing complex, net-shape parts in high volumes at a low per-unit cost, CNC machining provides the final, high-tolerance features like threaded holes and smooth mating surfaces. The decision to use one or a combination of both hinges on a trade-off: die casting is for mass production, while CNC machining adds essential precision at an additional cost.

CNC Machining vs. Die Casting: A Head-to-Head Comparison

Understanding the core differences between CNC machining and die casting is fundamental for any engineering or product team. These two manufacturing methods represent distinct approaches to metal fabrication: one carves away material, and the other shapes it from a molten state. Choosing the right one depends entirely on the project's requirements for volume, cost, speed, and precision.

CNC (Computer Numerical Control) machining is a subtractive process. It begins with a solid block of material (a billet) and uses computer-controlled cutting tools—like mills, drills, and lathes—to remove material layer by layer until the final part is formed. As described by Zetwerk, the process is automated by a computer program, ensuring high accuracy and repeatability. This method is highly versatile and can work with a vast range of materials, making it ideal for prototypes and low-to-medium volume production runs where precision is paramount.

In contrast, die casting is a molding process. It involves melting non-ferrous metals like aluminum or zinc and injecting the molten material into a custom-made steel mold, known as a die, under high pressure. Once the metal cools and solidifies, the die is opened, and the part is ejected. This method is incredibly efficient for producing large quantities of identical parts with complex geometries. While the initial investment in creating the die can be substantial, the per-part cost drops significantly at high volumes, making it a go-to for mass production in consumer and automotive industries.

While die casting and CNC machining are often compared, other methods like forging also play a key role in manufacturing. For instance, companies such as Shaoyi (Ningbo) Metal Technology specialize in automotive forging, another process that shapes metal using compressive forces, ideal for creating exceptionally strong and durable components. Understanding the full spectrum of manufacturing options ensures the best process is chosen for a part's specific performance requirements.

| Factor | CNC Machining | Die Casting |

|---|---|---|

| Process Type | Subtractive (Material Removal) | Molding (Material Injection) |

| Best For (Volume) | Low to Medium (1-5,000) | High to Very High (5,000+) |

| Tooling Cost | Low to None | High (Requires custom die) |

| Per-Part Cost | High (constant) | Low (decreases with volume) |

| Lead Time | Short (no tooling required) | Long (due to die creation) |

| Material Waste | High (generates scrap chips) | Low (uses only needed material) |

The Synergy: Using CNC Machining as a Finishing Process for Die Castings

While often presented as competing methods, CNC machining and die casting are frequently partners in a sequential manufacturing process. Many high-performance components leverage the strengths of both. The process begins with die casting to efficiently create the part's primary, complex shape (its near-net shape), and then moves to CNC machining for finishing touches that require a higher degree of precision than casting can achieve on its own.

As explained by G&M Die Casting, this hybrid approach is a single-source solution for creating assembly-ready parts. Die casting can produce features with tolerances around ±0.005 inches, which is sufficient for many applications. However, when a design calls for tighter tolerances, perfectly flat mating surfaces, or complex features like threaded holes, secondary machining is necessary. This is where CNC centers take over, refining the die-cast part to meet exact specifications.

This synergistic relationship allows manufacturers to achieve the best of both worlds: the cost-effectiveness and speed of high-volume die casting for the bulk of the part, combined with the surgical precision of CNC machining for its most critical features. This ensures both economic viability and functional performance.

Common secondary CNC machining operations on die-cast parts include:

- Drilling and Tapping: Creating precise threaded holes for screws and bolts.

- Milling: Machining flat surfaces for gaskets or mating with other components.

- Boring: Creating perfectly round and precisely located holes for bearings or shafts.

- Turning: Machining cylindrical features to tight diametrical tolerances.

- Creating O-ring Grooves: Machining precise channels for seals to prevent leaks.

Key Considerations for Machining Die-Cast Components

Machining a die-cast part is not the same as machining a solid block of billet material. The casting process introduces unique material characteristics and challenges that engineers and machinists must account for to ensure a successful outcome. Proper planning and technique are essential to avoid damaging the part or compromising its integrity.

One of the primary challenges is material porosity. Microscopic gas pockets can sometimes form within a casting as the molten metal solidifies. When a cutting tool encounters these voids, it can lead to a poor surface finish or even tool breakage. Machinists must use sharp tools and optimized cutting parameters to mitigate the effects of porosity. Another critical factor is fixturing, or workholding. Die-cast parts are created in a near-net shape, often with complex, non-uniform surfaces and thin walls. A custom fixture is usually required to hold the part securely and repeatably without distorting or damaging it during the machining process.

Furthermore, the alloys used in die casting, such as aluminum A380, have different properties than common billet alloys like 6061 aluminum. Cast aluminum often has a higher silicon content, which makes it more abrasive and causes faster tool wear. Specialized tool coatings and geometries are often necessary for efficient machining.

Best practices for machining die-cast components include:

- Use Sharp, Coated Tooling: Polycrystalline diamond (PCD) or coated carbide tools are often recommended to resist the abrasive nature of high-silicon aluminum alloys.

- Optimize Speeds and Feeds: Cutting parameters must be carefully controlled to prevent melting low-temperature alloys and to achieve a clean cut without smearing the material.

- Implement Proper Workholding: Design fixtures that support the part's unique geometry, clamping on strong, stable areas to prevent deflection or damage.

- Manage Chips Effectively: Use high-pressure air blasts or minimal coolant to clear chips, as traditional flood coolant can sometimes infiltrate material porosity and cause issues later.

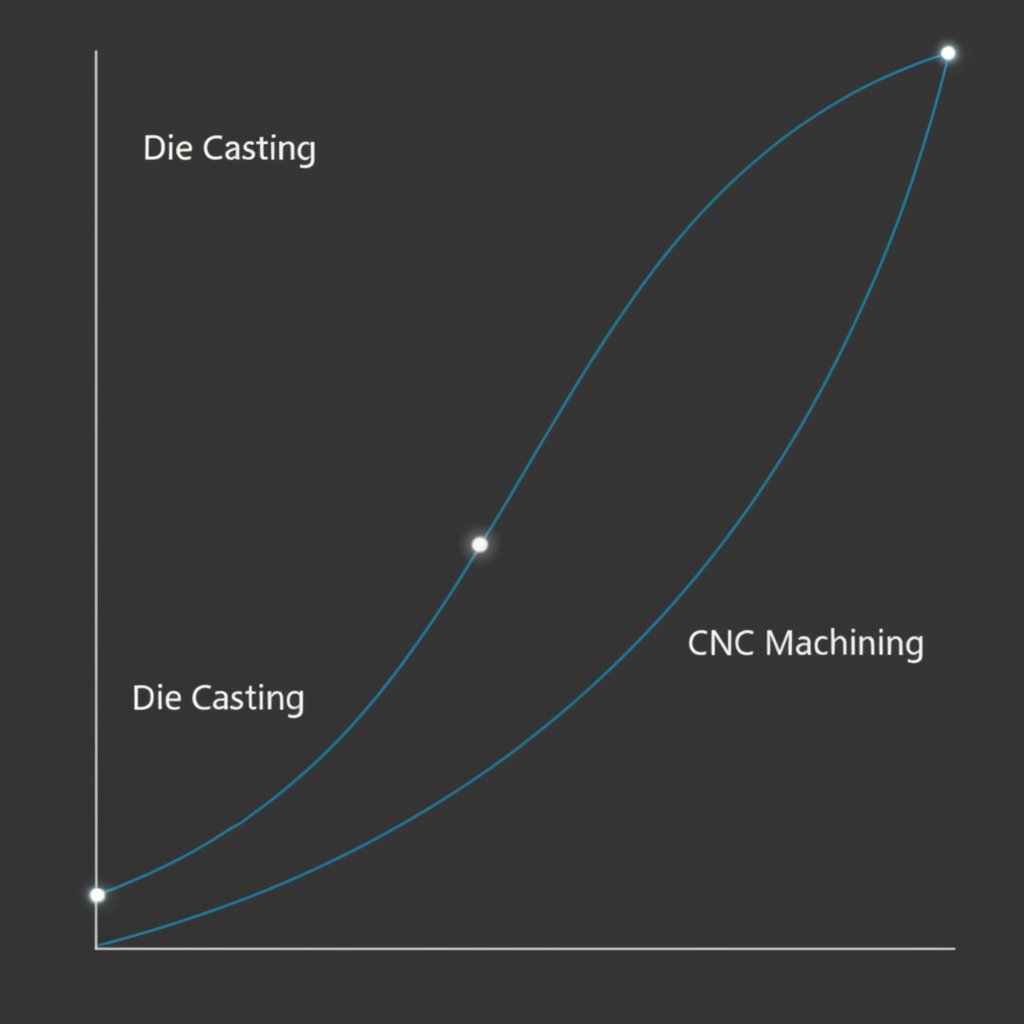

Cost Analysis: When is Die Casting + CNC More Economical?

The decision between CNC machining alone versus a combined die casting and machining process is almost always driven by production volume and cost. While CNC machining offers flexibility and avoids high upfront tooling costs, die casting provides unparalleled efficiency at scale. Understanding the cost crossover point is critical for making a sound financial decision for a manufacturing project.

For low volumes, such as prototypes or runs of a few hundred parts, CNC machining is almost always cheaper. As SyBridge Technologies points out, there is no need to invest tens of thousands of dollars in a steel die. The cost is primarily driven by machine time and material. However, this per-part cost remains relatively constant regardless of how many units are produced. Die casting, on the other hand, has a very high initial cost due to the design and fabrication of the die. But once that tool is made, parts can be produced for pennies on the dollar in material and cycle time.

A compelling case study from Dynacast highlights this trade-off. For the Light L16 camera, producing the complex chassis via CNC machining was five times more expensive than die casting it. For a mass-market consumer product, this cost difference made CNC machining impractical for large-scale production. The initial investment in the die was quickly offset by the massive savings in the per-part cost, making the hybrid approach the only viable path forward.

As a general guideline, the crossover point where die casting becomes more economical typically falls between 2,000 and 5,000 units. Below this range, the tooling cost is too high to justify. Above it, the low per-part cost of die casting creates significant savings that compound with every part produced, making it the clear winner for mass production.

Frequently Asked Questions

1. What is the difference between CNC machining and die casting?

CNC machining is a subtractive process that starts with a solid block of material and cuts it away to create a part. Die casting is a molding process that injects molten metal into a steel mold (a die) to form the part. CNC is best for low-to-medium volumes and high precision, while die casting is ideal for high-volume production of complex parts at a low per-unit cost.

2. What are the 7 major parts of a CNC machine?

The major components of a typical CNC machine include the Machine Control Unit (MCU), which is the brain of the system; Input Devices for loading the program; a Drive System with motors to move the axes; the Machine Tool itself (e.g., spindle and cutting tools); a Feedback System to ensure accuracy; the Bed and Table which form the machine's structure; and a Cooling System to manage heat.

3. Is die casting cheaper than CNC?

It depends on the production volume. For low quantities (prototypes to a few thousand parts), CNC machining is cheaper because it avoids the high upfront cost of creating a die. However, for large production runs (typically over 5,000 units), die casting becomes significantly more cost-effective due to its extremely low per-part cost, which quickly offsets the initial tooling investment.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —