PPAP Production Levels Mapped: What To Submit, When, And Why

Demystifying PPAP Production for Manufacturers

What is PPAP and Why It Matters in Manufacturing

When you’re sourcing automotive or industrial components, you’ll often hear about “ppap production.” But what does PPAP stand for, and why is it so critical? PPAP means “Production Part Approval Process,” a structured method used to confirm that both the product and the manufacturing process can reliably meet the customer’s requirements. This process is widely adopted in the automotive sector and increasingly in aerospace, electronics, and other high-spec industries.

Imagine launching a new part only to discover, after production starts, that it doesn’t meet your customer’s needs. Sounds complex and risky? That’s exactly the kind of scenario PPAP is designed to prevent. The ppap production part approval process formalizes how suppliers prove—through a package of documents—that their parts and processes are ready for serial production.

PPAP Meaning vs Everyday Quality Checks

It’s easy to confuse PPAP with routine inspections or quality checks, but there’s a big difference. While everyday quality checks focus on catching defects in individual batches, the PPAP process is about demonstrating up front that the entire system—design, materials, manufacturing, and testing—can consistently deliver conforming parts over time. In other words, PPAP isn’t just a checklist; it’s a comprehensive evidence package reviewed and signed off by both supplier and customer, culminating in the Part Submission Warrant (PSW).

- Confirms design and process readiness before mass production (SOP)

- Aligns supplier and customer expectations on requirements and quality

- Reduces risk of costly recalls, rework, and launch delays

- Ensures documentation traceability and clear communication

- Supports supplier approval and ongoing relationship management

PPAP validates both the product and the manufacturing process, ensuring readiness for mass production as outlined in the AIAG PPAP-4 standard.

How PPAP Production Fits Supplier Approval

PPAP production is triggered in several scenarios: launching a new part, making an engineering change, switching suppliers, or even when a customer requests it during a product’s lifecycle [Capvidia]. The process is collaborative, with suppliers assembling the PPAP package and customers (often OEMs or Tier 1s) reviewing and approving it before full-scale production starts.

Unlike everyday inspections, PPAP is not a one-and-done activity. It’s a living set of documents that must be updated whenever there are changes to the part or process. The ultimate goal? To provide confidence that every part delivered will meet all engineering, quality, and safety requirements—right from the start.

Key Objectives and Outcomes of PPAP

- Provide documented evidence that parts meet customer specifications

- Demonstrate process capability and control

- Enable smooth and confident product launches

- Facilitate supplier-customer alignment and trust

By understanding the ppap meaning in manufacturing and how the ppap production part approval process works, you can better align your teams, prepare for customer audits, and avoid costly missteps. Remember, PPAP is your roadmap to launch readiness and long-term supplier success.

Connect APQP to PPAP and Clarify FAI Differences

APQP and PPAP Relationship Explained

When you hear about quality planning in the automotive or industrial world, you’ll notice two acronyms come up again and again: APQP and PPAP. But what’s the real difference—and why does it matter for your next project?

Let’s break it down. APQP stands for Advanced Product Quality Planning. Think of the apqp process as your roadmap for developing a new product, ensuring every design and manufacturing detail is planned, validated, and controlled. It’s a collaborative effort, involving engineering, manufacturing, quality, and supply chain experts working together to prevent problems before they arise [InspectionXpert].

PPAP, or Production Part Approval Process, is one key milestone inside APQP. It’s the evidence package you submit to your customer at the end of the planning cycle—proof that your team can consistently produce parts that meet all requirements. In other words, APQP is the journey, and PPAP is the checkpoint that confirms you’re ready for production.

| Process | Purpose | Timing | Output | Owner |

|---|---|---|---|---|

| APQP | Plan and control product and process development | Start to launch (phases 1–5) | Design FMEA, Process FMEA, Control Plan, Process Flow, MSA, Capability studies, validation results | Cross-functional team (Engineering, Quality, Manufacturing, Procurement) |

| PPAP | Demonstrate process and product readiness for production | End of APQP (Phase 4) | PPAP submission package (including DFMEA, PFMEA, Control Plan, PSW, evidence of capability) | Supplier (submitted to customer for approval) |

| FAI | Verify conformance of first production build | Before or during early production | FAI report (dimensional, material, and process checks on first article) | Supplier or manufacturer (often for internal or customer review) |

PPAP vs FAI: What Changes and What Stays

It’s easy to confuse PPAP with First Article Inspection (FAI), but they serve different roles. FAI is like a snapshot: it verifies that the very first build of a part matches drawings and specifications. This is especially common in aerospace, but also appears in automotive for new or significantly changed parts. FAI is typically a one-time, detailed inspection of one part or lot before mass production starts.

PPAP, on the other hand, is a comprehensive package that not only includes dimensional results (sometimes using FAI data) but also process capability studies, material certifications, and control plans. It’s about proving that your entire process—not just one part—can repeatedly deliver quality over time. Some OEMs may ask for FAI data as part of the PPAP evidence, but PPAP always goes further, requiring ongoing validation and documentation updates if changes occur.

Advanced Product Quality Planning in Action

So, how do APQP and PPAP work together in the real world? Imagine you’re launching a new automotive component. During APQP, your team builds out all the foundational documents—DFMEA, PFMEA, Process Flow, Control Plan, Measurement Systems Analysis (MSA), and capability studies. These deliverables are not just paperwork; they’re the backbone of your quality system and feed directly into your PPAP submission.

- APQP ensures the process is robust and risks are managed before production.

- PPAP is the formal checkpoint—your customer’s assurance that everything is ready for launch.

- FAI is a supporting tool, providing detailed evidence for one build, but does not replace the ongoing, systemic validation required by PPAP.

APQP and PPAP are two sides of the same coin: APQP stands for planning and process discipline, while PPAP confirms that discipline results in production-ready, conforming parts.

By understanding the difference between apqp vs ppap and how FAI fits in, you’ll be better equipped to meet customer expectations, negotiate requirements, and ensure your launch goes smoothly. Ready to dive deeper? Next, we’ll map out the specific PPAP levels and document requirements so you can select the right approach for your next submission.

PPAP Levels and Document Mapping Made Usable

Understanding PPAP Levels and Submission Triggers

Ever wondered why your customer requests a specific PPAP level, or what those levels of PPAP really mean for your project? The answer lies in balancing risk, complexity, and trust. The PPAP process uses five submission levels to define exactly what evidence and ppap documents you need to provide for part approval. These levels aren’t just bureaucracy—they ensure the right amount of oversight for each part, from simple fasteners to safety-critical components.

Submission triggers include new part launches, engineering changes, supplier changes, or customer requests. The selected PPAP level determines the scope and depth of documentation you’ll submit. Let’s break down each level and when it’s typically used.

PPAP Levels 1–5: What to Submit and When

- Level 1 PPAP: Only the PSW (Part Submission Warrant) is submitted. Used for catalog or low-risk standard parts, or where the supplier’s track record is proven. Fast and simple, but rarely used for complex components [Six Sigma Development Solutions].

- Level 2 PPAP: PSW plus limited samples and supporting data (such as basic dimensional or material results). Chosen for moderately complex parts or when the customer needs more assurance than Level 1, but not the full package.

- Level 3 PPAP: PSW, product samples, and the complete set of supporting data. This is the most common submission level—think of it as the gold standard for ppap level 3 submissions. Customers expect full transparency and robust evidence here.

- Level 4 PPAP: PSW plus whatever else the customer requests. This is a fully customized level, often used for parts with unique regulatory or operational requirements.

- Level 5 PPAP: PSW, samples, and all supporting data must be available for review at your manufacturing site. The customer may conduct an onsite audit to verify everything firsthand—reserved for high-risk or critical parts.

Level 3 PPAP: When Customers Expect Full Evidence

Why is level 3 ppap so important? For most automotive and high-reliability applications, Level 3 is the default unless the customer explicitly waives it. This approach ensures that every aspect of your process and product is documented, traceable, and reviewable. If you’re ever in doubt, assume Level 3 requirements and check with your customer for exceptions. This mindset helps avoid costly rework or resubmissions down the line.

Always confirm customer-specific requirements before finalizing your PPAP level—some customers may promote or demote the level based on risk, history, or unique needs.

Document Mapping by Level Made Simple

Choosing the right ppap level is only half the battle. You also need to assemble the correct documents for your submission. Use the table above to create your checklist, and always coordinate with your customer to clarify any special requirements. This approach keeps your submission on track and your launch on schedule.

Ready to put this into practice? Next, we’ll walk through a step-by-step PPAP submission workflow—so you can confidently manage roles, timelines, and customer expectations from start to finish.

End to End PPAP Submission Workflow and Timeline

From Design Freeze to PSW Signoff: The Step-by-Step PPAP Process

When you’re gearing up for a new product launch, the production approval process can seem like a maze of documents, meetings, and checklists. But with a clear workflow, you’ll keep your team aligned—and avoid last-minute surprises that delay ppap approval. Here’s a practical, step-by-step guide to the ppap documentation and milestones that drive a successful submission:

- Customer Requirements Intake: Gather all customer specifications, drawings, and contractual expectations. Clarify what triggers the production part approval—is it a new part, a process change, or a supplier switch?

- Risk Planning: Conduct risk assessments (DFMEA, PFMEA) to identify potential design and manufacturing issues before they become roadblocks.

- Process Design: Map out the manufacturing process, create process flow diagrams, and develop the control plan to ensure quality at every stage.

- Pre-Production Build: Run a pilot or initial production batch to validate the process under real-world conditions. Collect samples for testing and measurement.

- Evidence Collection: Gather all required documentation—dimensional results, material certifications, MSA studies, capability data—aligned to the latest design revision.

- Internal Review: Cross-functional teams (Design, Manufacturing, Quality) review the complete package to catch gaps or misalignments before customer submission.

- Customer Submission: Submit the PPAP documentation to the customer, following their portal or format requirements. Include the completed Part Submission Warrant (PSW).

- Feedback Loops: Address any customer questions, requests for clarification, or required corrections. Update documents as needed and resubmit.

- Final PSW Approval: Receive customer signoff on the PSW, confirming that your process and product are cleared for mass production.

Milestones, Owners, and Deliverables

| Milestone | Responsible Role | Typical Duration |

|---|---|---|

| Customer Requirements Intake | Program Manager, Sales Engineer | Short |

| Risk Planning (DFMEA, PFMEA) | Design, Quality | Medium |

| Process Design & Control Plan | Manufacturing, Quality | Medium |

| Pre-Production Build | Manufacturing | Medium |

| Evidence Collection | Quality, Manufacturing | Medium |

| Internal Review | Cross-functional Team | Short |

| Customer Submission | Supplier Quality, Program Manager | Short |

| Feedback Loops | Supplier Quality, Program Manager | Varies |

| Final PSW Approval | Customer Quality | Short |

What to Ask Your Customer Before You Start

Imagine investing weeks in a submission, only to discover your customer expected a different approval process or data format. Avoid rework by clarifying these points up front. Here’s a copy-and-paste checklist for your kickoff call or email:

- What is the required PPAP submission level? (Level 1–5, or customer-specific)

- Which drawing or model is the authority? (Include revision/date)

- What tolerance scheme and special characteristics apply?

- What are the acceptance criteria for process capability (CpK, PpK, etc.)?

- Which formats are acceptable for MSA and dimensional results?

- Are there any customer portal instructions or submission templates?

- Is partial or staged submission allowed?

- Are there any customer-specific requirements not covered in AIAG PPAP?

Building Your PPAP Package: Order and Signoff

Now, how do you assemble and route your ppap documentation for signoff? Follow this typical order for your submission package:

- Cover page or index

- Design records (drawings, specs)

- Engineering change documents (if applicable)

- DFMEA and PFMEA

- Process Flow Diagram

- Control Plan

- Measurement Systems Analysis (MSA)

- Dimensional results

- Material/performance test results

- Capability studies

- Appearance approval report (if needed)

- Records of compliance (material, regulatory, etc.)

- Completed Part Submission Warrant (PSW)

Each document should be reviewed and signed by the responsible department lead (Design, Manufacturing, Quality), with the PSW signed by the supplier’s authorized representative. The PSW is the formal declaration of compliance and is required for production part approval—so double-check all details before submission [1factory].

"A disciplined PPAP workflow, with clear roles and sequenced milestones, is the backbone of a smooth production approval process. Don’t leave signoffs or document order to chance—clarity up front prevents costly delays and rework."

With this workflow, you’ll be ready for any customer audit or review. Next, we’ll dive into how to present your MSA and capability evidence to pass even the toughest customer scrutiny.

MSA and Capability Evidence That Earns Approval

MSA Essentials for PPAP Confidence

When you’re preparing a PPAP submission, have you ever wondered why so much emphasis is placed on Measurement Systems Analysis (MSA)? Imagine your measurement system is off by just a little—suddenly, good parts might get rejected or, worse, non-conforming parts slip through. That’s why MSA is a cornerstone of ppap manufacturing and a required ppap element for quality assurance.

MSA ensures your measurement tools and methods are accurate, precise, and reliable. In the context of what is ppap in quality, it’s about proving to your customer that your data is trustworthy—that your process control decisions are based on sound evidence, not guesswork.

- Measurement method: Describe the type of measurement (e.g., caliper, CMM, go/no-go gauge).

- Gauges and calibration status: List all devices used and confirm calibration is up to date.

- Study type: Specify if it’s a Gauge R&R, attribute study, linearity, or stability assessment.

- Study scope: Indicate which characteristics, samples, and operators were included.

- Summary of findings: Present key results—are the systems capable, and what’s the measurement error?

- Limitations: Note any restrictions (e.g., operator variability, environmental factors).

- Corrective actions: Outline steps taken if the measurement system didn’t meet requirements.

Always cite AIAG PPAP-4 for formal acceptance criteria and only include specific values when provided by your customer or the official standard.

How to Summarize Capability Without Overpromising

Summarizing process capability can feel like walking a tightrope—promise too much, and you risk customer pushback; too little, and your submission gets delayed. The goal is to clearly connect each special characteristic to its corresponding study, using real data and transparent logic.

Here’s a simple table format to present capability results that stands up to audit scrutiny:

| Characteristic | Method | Sample Description | Result Summary | Notes on Stability |

|---|---|---|---|---|

| Critical Diameter | CMM Measurement | 30 parts, 3 operators | CpK = 1.45, meets customer target | No drift detected over initial run |

| Surface Hardness | Rockwell Test | 10 samples, 2 shifts | All within spec; GR&R < 10% | Stable over 2-week period |

Be direct about any borderline results. If a characteristic’s capability is close to the minimum requirement, flag interim controls in your Control Plan and document plans for future process improvement. This risk-based approach shows you’re proactive—not hiding problems.

Presenting Results That Withstand Audits

Audit-ready evidence isn’t just about numbers; it’s about traceability and alignment. Make sure all dimensional, material, and performance data are tied to the same revision level as the approved drawing or model. If you’re documenting labs (internal or external), provide their accreditation and scope of work as part of your PPAP package.

- Cross-reference every study to the drawing or BOM revision.

- Include calibration certificates and lab accreditations where required.

- Use a logical document order and clear labeling—make it easy for reviewers to trace each result back to its source.

- Flag any interim controls and update your Control Plan as process improvements are verified.

Remember, what does ppap mean in manufacturing? It means building trust—through data, transparency, and readiness for scrutiny. By following these practices, you’ll shorten review cycles and build a reputation for reliable ppap quality.

Next, we’ll explore how digital thread practices and model-based definitions are transforming how you document and submit PPAP deliverables—so your evidence package stays robust, even as manufacturing evolves.

Digital Thread and MBD Mapped to PPAP Deliverables

How Model-Based Definition (MBD) Changes the PPAP Package

When you hear about the digital thread or Model-Based Definition (MBD) in manufacturing, it might sound like a buzzword—but in the context of the production part approval process ppap, these concepts are rapidly changing how evidence is created, submitted, and reviewed. Imagine replacing stacks of static PDFs and spreadsheets with a single, connected set of digital files that flow directly from engineering through quality and into your PPAP submission. That’s the promise of a digital thread: faster updates, fewer errors, and greater traceability.

With MBD, your 3D CAD model becomes the primary source of truth—not just for design, but for manufacturing and inspection as well. This means that Product Manufacturing Information (PMI)—like tolerances, surface finishes, and special characteristics—are embedded directly into the model, eliminating the need for manual data re-entry and reducing the risk of human error. When an engineering change occurs, the digital thread ensures every downstream PPAP document is updated automatically, keeping your submission package in sync and audit-ready.

Digital Artifacts Mapped to Classic PPAP Documents

So, how do digital artifacts actually map to the classic ppap document requirements? Let’s break it down with a practical table that shows common PPAP deliverables alongside their digital equivalents, submission notes, and customer acceptance considerations:

| Classic PPAP Artifact | Digital Equivalent | Submission Format Notes | Customer Acceptance Notes |

|---|---|---|---|

| Design Records | 3D CAD model (native or STEP), PMI annotations | Include model format and revision; reference drawing if required | Confirm if model or drawing is the authority; some OEMs require both |

| Ballooned Drawing | Digital ballooning output, QIF or PDF with traceable characteristics | Link balloons to model features; provide digital bill of characteristics | Some customers require both digital and static versions for traceability |

| Dimensional Results | QIF file, CMM output linked to 3D model and PMI | Reference PMI callouts in results; align sample IDs with model features | Check if customer portal accepts QIF or requires Excel/PDF summary |

| Control Plan | ePLM record, digital workflow document | Include ePLM record ID in PSW remarks; export PDF if needed | Confirm acceptance of digital signatures and revision tracking |

| PFMEA | ePLM or quality software record | Export summary for submission; maintain live version for audits | Verify if customer will review in-platform or requires static file |

| Process Flow | Interactive flowchart (software), PDF export | Ensure flow matches digital Control Plan and PFMEA | Some OEMs accept only static PDF for official record |

| MSA | Digital study files, linked to measurement equipment database | Include calibration traceability and digital signatures | Check customer requirements for data format and evidence |

| Capability | Statistical software output, ePLM summary | Reference data source and revision; export as required | Align capability summary with digital bill of characteristics |

| Material/Performance Results | Lab certificates (PDF), ePLM linked records | Attach digital certs to submission; reference lot and test IDs | Some customers require original lab files for traceability |

For example, instead of submitting a static spreadsheet of dimensional results, you might provide a QIF file that’s directly traceable to the 3D model’s PMI. In your Part Submission Warrant, you can reference the ePLM record ID for your Control Plan, giving the customer a direct link to the live, revision-controlled document. This not only satisfies the ppap approval process but also streamlines future updates when engineering changes occur [Action Engineering].

Ensuring Model and Drawing Authority Alignment

One of the most common sources of confusion—and rework—in digital PPAP submissions is misalignment between the model and the drawing. Before you submit, always confirm with your customer which artifact is the official authority. Some OEMs accept the 3D model with PMI as the single source of truth, while others still require a signed 2D drawing for regulatory or legacy reasons. Include a clear statement in your submission that all evidence is aligned to the specified revision of the model or drawing, and cross-reference this in every digital artifact.

- State the model/drawing authority and revision in your PPAP cover page and PSW remarks.

- Ensure all digital files (QIF, ePLM records, PDFs) reference the same revision/date.

- Coordinate with your customer’s quality or engineering contact if there’s any uncertainty.

When in doubt, provide both the native model and a PDF version of the drawing, and keep a record of all correspondence about authority and format. This approach minimizes the risk of costly delays or rejection during the production part approval process ppap.

The digital thread transforms PPAP from a static, manual process into a dynamic, traceable workflow—reducing errors, speeding up approvals, and making compliance with aiag ppap guidelines easier than ever.

As digital platforms and ppap software become more common, you’ll notice that the boundaries between engineering, manufacturing, and quality are blurring. By mapping your digital artifacts to classic PPAP requirements and confirming customer authority up front, you’ll ensure your next submission is both compliant and future-ready. Next, we’ll look at how to avoid common PPAP rejection pitfalls and provide ready-to-use corrective action templates.

Avoidance and Remediation for PPAP Rejections

Most Common Reasons PPAP Gets Rejected

Ever felt that sinking feeling when your carefully assembled PPAP package comes back with a rejection notice? You’re not alone. Even experienced teams can stumble over details that seem minor but have major consequences for production approval. So, what are the usual suspects that trip up a psw ppap submission?

- Missing signatures on the Part Submission Warrant or supporting documents

- Mismatched revisions between drawings, FMEAs, and control plans

- Incomplete MSA summaries or missing calibration evidence

- Undocumented special characteristics or unclear control methods

- Unlinked capability studies—results not tied to specific control plan features

- Unsupported material or performance results (e.g., missing lab certificates)

- Outdated or recycled FMEAs that don’t reflect current design/process risks

- Gaps in traceability—unsigned, undated, or untraceable part approval documents

Imagine spending weeks preparing your level 3 ppap requirements only to miss a signature or upload the wrong revision. These simple oversights can result in costly delays, rework, and even loss of customer trust.

CAPA Summaries You Can Paste and Adapt

When a rejection happens, acting fast—and documenting your response—is key. That’s where CAPA (Corrective and Preventive Action) summaries come in. Here are ready-to-use templates you can adapt for any PPAP issue:

Problem Statement: The submitted PFMEA was not updated to match the latest engineering change (Revision D).

Immediate Containment: Halted production and notified all affected departments.

Root Cause Summary: Engineering change was not communicated to the quality team before PPAP submission.

Corrective Action: Updated PFMEA to Revision D, retrained team on change control process.

Verification of Effectiveness: Cross-check of all PPAP documents now included in pre-submission checklist.

Preventive Controls: Implemented digital workflow for engineering change notifications.

Problem Statement: MSA study missing calibration certificate for primary measurement device.

Immediate Containment: Withheld affected dimensional results from submission.

Root Cause Summary: Calibration status not verified before data collection.

Corrective Action: Device calibrated; results resubmitted with certificate.

Verification of Effectiveness: Added calibration check to MSA preparation SOP.

Preventive Controls: Scheduled quarterly calibration audits for all critical gauges.

These CAPA summaries help you respond quickly, demonstrate operational discipline, and show your customer that issues are addressed at the root—not just patched over. They’re especially valuable for recurring issues tied to ppap level 3 requirements, where submission completeness is critical.

Staying Aligned with Customer-Specifics

Every customer has their own quirks—sometimes requiring extra evidence, unique document formats, or additional signoffs. That’s why it’s essential to cross-check your package against customer-specific requirements and contract clauses before you hit submit. Don’t forget to document any interim controls or resubmission plans if a gap is found during internal review.

- Review customer submission guidelines and special instructions

- Confirm required submission level (especially for level 3 ppap)

- Verify document order, index page, and evidence traceability

- Double-check revision alignment across all documents

- Ensure all signatures and dates are present on every part approval document

- Attach all supporting evidence (lab certs, calibration records, etc.)

- Maintain an internal checklist for recurring customer-specific needs

| Preflight Review Checklist |

|---|

| All documents reviewed for correct revision and authority |

| Index page matches actual document order |

| All required signatures and dates present |

| Traceability links (e.g., drawing numbers, part numbers) are consistent |

| Supporting evidence attached for all test results and studies |

| Customer-specific requirements checked and documented |

Understanding part submission warrant meaning and what is part submission warrant is vital here: the PSW is your formal declaration that all requirements have been met. Any gaps or errors risk not just rejection, but also your credibility as a supplier.

"Treat every PPAP submission as a reflection of your organization’s quality mindset. A disciplined, checklist-driven approach minimizes rejections and builds trust with even the most demanding customers."

With these strategies and templates, you’ll be ready to prevent common pitfalls, respond to rejections with confidence, and keep your ppap production process running smoothly. Next, we’ll provide copy-ready artifact samples and annotations to further streamline your documentation process.

Copy Ready PPAP Artifact Samples and Annotations

When you’re building your PPAP package, having clear, ready-to-use templates can save hours of drafting and help ensure consistency across submissions. Below you’ll find practical examples for the most requested PPAP documents—with each field annotated so you know exactly how it ties into your overall evidence package. These samples are based on best practices and real-world formats, so you can adapt them for your next ppap production project.

Filled Part Submission Warrant (PSW) Text Example

Part Submission Warrant (PSW)

Part Name: [Part Name] (Matches drawing and BOM)

Part Number: [Part Number] (Unique identifier for traceability)

Engineering Change Level: [Revision/ECN] (Indicates latest approved design)

Organization Name: [Your Company Name] (Supplier of record)

Manufacturing Location: [Plant/Address] (Where the part is produced)

Submission Level: [Level 1–5] (Aligns with customer request)

Reason for Submission: [New part, Engineering Change, etc.] (Why PPAP is triggered)

Declaration: "We certify that the samples and documentation meet all specified requirements. All supporting data is retained per customer and AIAG PPAP-4 guidelines."

Remarks: [Any clarifications or customer-specific notes]

Tip: The PSW is the formal summary of your PPAP package and is required for each part number unless otherwise specified by the customer. Always double-check that all fields match your supporting documents and the latest engineering revision.

Dimensional Results Table with Annotations

| Balloon No. | Characteristic | Spec Reference | Method/Tool | Result Summary | Disposition |

|---|---|---|---|---|---|

| 1 | Outer Diameter | Ø10.10–0.02 | Micrometer | 10.08 / 10.09 / 10.10 | Pass |

| 2 | Surface Roughness | 6.3 Ra | Roughness Tester | 6.1 / 6.2 / 6.3 | Pass |

| 3 | Chamfer | 1 x 30° | Visual | OK | Pass |

- Balloon No.: Links to the ballooned drawing for traceability.

- Characteristic: The feature measured, as specified on the drawing.

- Spec Reference: The tolerance or requirement for the feature.

- Method/Tool: The measurement device or inspection method used.

- Result Summary: Sample results or range of values measured.

- Disposition: Indicates if the results meet requirements (Pass/Fail).

Use this format to quickly communicate compliance for each key feature. For more extensive ppap documents with example tables, you can expand to include operator, date, or additional notes as needed [Reference].

PFMEA and Control Plan Excerpt Templates

Ever wonder how to align your PFMEA and Control Plan so that special characteristics and controls are clearly mapped? Here’s a paired example to help you get started:

- Process Step: Shaft Machining

- Potential Failure Mode: Out-of-spec diameter

- Effect: Assembly interference

- Cause: Tool wear

- Current Control: Periodic micrometer check

- Detection: 100% in-process inspection

- Severity/Occurrence/Detection: Severity 8, Occurrence 3, Detection 4, RPN = 96

- Recommended Action: Increase inspection frequency

- Process Step: Shaft Machining

- Characteristic: Outer Diameter

- Spec/Tolerance: Ø10.10–0.02

- Control Method: Micrometer measurement every 30 minutes

- Reaction Plan: Stop production, replace tool if out of spec

- Sample Size/Frequency: 1 part per interval

- Responsible: Operator, QA Inspector

Annotation: The PFMEA identifies risks and control gaps, while the Control Plan documents the specific monitoring and reaction steps. Consistency in terminology and feature naming across both documents is crucial for a robust part submission warrant ppap package.

Quick Tips for Consistency and Adaptation

- Replace all placeholders (e.g., [Part Name], [Spec/Tolerance]) with your customer’s exact terms and latest revisions.

- Keep nomenclature consistent across all documents—especially between the PSW, dimensional results, and control plans.

- For each ppap part submission warrant, ensure supporting evidence is referenced and traceable.

- Maintain an index page in your package so reviewers can easily find each artifact.

By using these annotated templates, you’ll streamline your documentation process, reduce the risk of omissions, and deliver a professional, audit-ready PPAP submission. Next, we’ll tie it all together with guidance on choosing the right manufacturing partner to accelerate your PPAP journey.

Choose the Right Partner to Accelerate PPAP Production

What to Look for in a PPAP-Ready Manufacturing Partner

When the difference between a smooth launch and costly delays comes down to supplier performance, choosing the right partner for ppap production is critical. Imagine you’re facing a tight deadline for an automotive project—would you rather juggle multiple vendors or rely on a single, integrated team that’s fluent in the entire automotive industry manufacturing process? The answer is clear: the right partner can make or break your submission timeline and quality outcomes.

So, what should you look for when evaluating potential suppliers for your next PPAP-driven program? Here’s a practical checklist to guide your automotive industry procurement decisions:

| Partner Criteria | Why It Matters for PPAP |

|---|---|

| IATF 16949 Certification | Demonstrates robust quality management aligned with automotive standards—essential for ppap certification and customer confidence. |

| Multi-Process Capability Under One Roof | Reduces handoffs, simplifies traceability, and keeps all ppap services coordinated—especially for complex assemblies. |

| Rapid Prototyping and Short Lead Times | Accelerates the apqp and ppap process by enabling fast iterations and quick evidence generation for dimensional and material validation. |

| Documented APQP Discipline | Ensures process rigor, risk management, and clear documentation from design through production—minimizing surprises at the PPAP stage. |

| Experience with OEM/Tier 1 Portals | Facilitates seamless submissions, compliance with customer-specific requirements, and fast feedback cycles. |

How Integrated Processes Shorten Submission Cycles

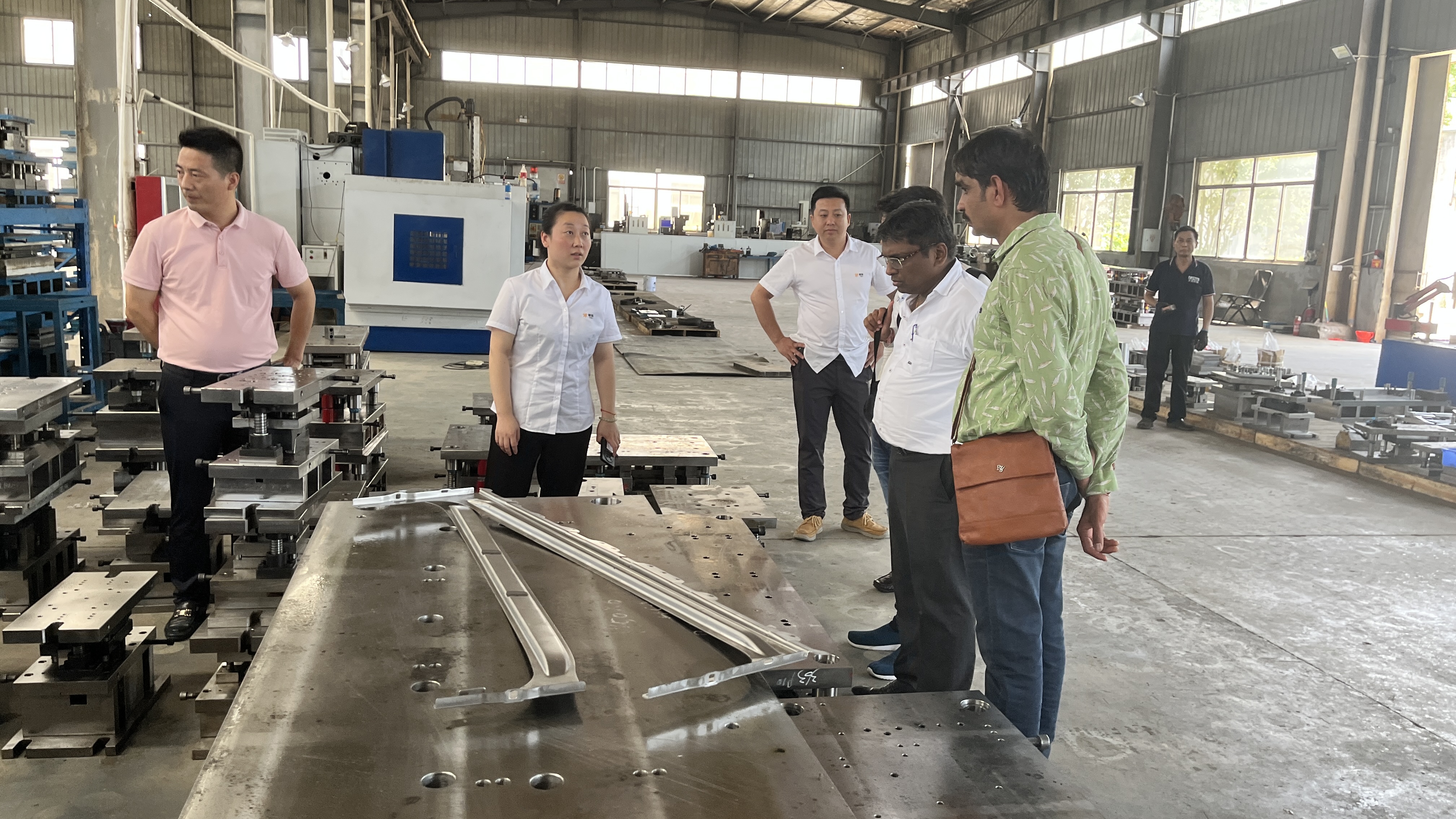

When you partner with a supplier who checks all these boxes, you’ll notice a significant difference in speed and reliability. For example, Shaoyi Metal Technology is an IATF 16949 certified manufacturer offering end-to-end solutions for high-precision automotive components. Their one-stop approach—combining stamping, cold forming, CNC machining, and welding—means every step from design to final inspection happens under one roof. This integration reduces the risk of errors, speeds up communication, and ensures that every PPAP artifact is traceable to a single source.

Rapid prototyping is another game-changer. Imagine compressing the time from initial design to first article approval from weeks to just days. With the ability to produce dimensional evidence quickly, you can iterate on process controls and address customer feedback before it becomes a delay. This is especially valuable for teams navigating the rigorous demands of the automotive industry process—where every day counts, and every detail matters.

- One-stop production: Reduces communication gaps and misaligned documentation.

- Single-source traceability: Simplifies evidence gathering for audits and customer reviews.

- Faster PPAP cycles: Rapid prototyping and in-house process control mean quicker turnarounds and fewer resubmissions.

- Consistent training: Teams with documented APQP and ppap training can adapt to new requirements and customer standards with agility.

One-stop suppliers streamline the PPAP journey by reducing handoffs, minimizing rework, and delivering consistent, audit-ready documentation—so you can focus on innovation, not paperwork.

From Prototype to PSW with Minimal Friction

Think about the last time you faced a late-stage PPAP rejection. Was it due to missing evidence, unclear traceability, or delays from third-party vendors? A partner with integrated capabilities and automotive experience can help you avoid these pitfalls. They’ll understand the nuances of ppap production, anticipate customer-specific quirks, and ensure that every artifact—from prototype samples to the final Part Submission Warrant—is aligned and ready for approval.

By prioritizing these selection criteria, you’ll not only reduce project risk but also accelerate your time to market. In a competitive landscape where the automotive industry manufacturing process is always evolving, the right partner is your strongest asset for delivering on quality, compliance, and speed.

PPAP Production FAQs

1. What are the 5 levels of PPAP and when are they used?

The five PPAP levels define the scope of documentation required for part approval. Level 1 requires only the Part Submission Warrant (PSW), typically for standard parts. Level 2 adds limited supporting data, while Level 3, the most common, demands a complete evidence package. Levels 4 and 5 are tailored to customer needs or involve onsite reviews. The chosen level depends on part complexity, risk, and customer requirements.

2. How does PPAP differ from First Article Inspection (FAI)?

PPAP is a comprehensive approval process confirming both product and process readiness for mass production, requiring a full set of documents. FAI verifies a single build against specifications, focusing on initial conformance. While FAI may be included in PPAP as dimensional evidence, PPAP covers broader process validation and ongoing requirements.

3. Is PPAP required for CAD files and digital submissions?

Yes, modern PPAP submissions often require CAD files and digital artifacts. Design records may include 3D models with Product Manufacturing Information (PMI), and digital outputs can be mapped directly to classic PPAP documents. Always confirm with your customer which digital formats are accepted and whether the model or drawing is the authority.

4. What is a Part Submission Warrant (PSW) and why is it important?

The PSW is the formal declaration in PPAP that all parts and processes meet customer requirements. It summarizes the submission, references supporting evidence, and is signed by the supplier's authorized representative. Approval of the PSW is essential for production release and ongoing supplier-customer alignment.

5. How can the right manufacturing partner accelerate PPAP production?

A partner with IATF 16949 certification, in-house multi-process capabilities, and rapid prototyping streamlines the PPAP process. Integrated teams reduce handoffs, improve traceability, and deliver faster, more consistent documentation. For example, Shaoyi Metal Technology offers one-stop solutions that help compress development cycles and enhance submission quality.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —