PPAP Documents Explained: 18 Elements, Levels One–Five, Tools

PPAP Documents Explained Without the Fluff

When you’re launching a new automotive part, or even making a small change to an existing one, how do you prove to your customer that you can deliver quality parts—every time? That’s where PPAP documents come in. If you’ve ever wondered, “what is PPAP?” or searched for a clear PPAP definition that makes sense in real-world manufacturing, you’re in the right place.

PPAP definition and purpose

PPAP is the Production Part Approval Process—a structured set of documents and evidence that demonstrates a supplier’s ability to consistently meet customer engineering and quality requirements before and after changes to a product or process.

In plain terms, PPAP documents are the proof package that suppliers present to customers—often in the automotive and aerospace industries—to show they understand all design requirements and their processes are capable of producing compliant parts. These documents aren’t just paperwork; they’re essential to building trust and enabling smooth launches, especially when supply chains are global and stakes are high.

How PPAP documents reduce risk

Imagine a customer receiving a shipment of parts that don’t fit, function, or last as intended. The cost—in time, money, and reputation—can be huge. PPAP documents help prevent these headaches by:

- Proving design intent: Confirming that all drawings, specifications, and requirements are fully understood and agreed upon.

- Validating process capability: Showing that manufacturing processes can reliably produce parts within tolerance and quality limits.

- Controlling changes: Ensuring that any engineering or process change is reviewed, documented, and approved before implementation.

- Confirming supplier readiness: Demonstrating that the supplier’s systems, controls, and teams are prepared to launch or resume production without surprises.

By focusing on these goals, PPAP documents serve as a risk-reduction tool for both suppliers and customers, reducing the chance of costly errors after product launch (1factory).

APQP and PPAP connection

So, how do PPAP documents fit into the bigger picture of quality planning? Enter APQP—Advanced Product Quality Planning. APQP is a structured methodology for planning, developing, and validating new products and processes. Think of APQP as the roadmap, and PPAP as the final checkpoint where you prove you followed that roadmap and achieved the intended results.

During APQP, teams use tools like FMEA (Failure Mode and Effects Analysis), control plans, and process flow diagrams to identify risks and put controls in place. PPAP documentation then captures the evidence that these controls work in real production, bridging the gap between planning and execution.

Where PPAP fits in the approval process

PPAP documents are usually required at two key moments:

- Before the start of series production for a new or significantly changed part

- After any change to design, materials, process, supplier, or location

This means suppliers must maintain their systems and documentation so they’re always ready to submit a PPAP when requested. The production part approval process is not a one-time event, but an ongoing commitment to quality and transparency throughout the product lifecycle.

Why this guide goes further

If you’re searching for clear answers to “ppap meaning in manufacturing” or want a practical resource for preparing PPAP documents, this article is designed for you. We’ll move beyond simply listing the 18 elements of PPAP and instead provide you with summary tables, annotated examples, timelines, and troubleshooting tips—so you can confidently navigate the entire process and avoid common pitfalls.

Your Complete PPAP Elements Reference Table

Ever stare at a PPAP checklist and wonder, “What does each document really do—and who’s responsible for it?” You’re not alone. Whether you’re new to the 18 elements of PPAP or just want a smarter way to prep for your next submission, this section gives you a practical, at-a-glance guide you’ll actually use. Bookmark this table as your working index for ppap documentation—and keep it handy as you prepare, review, or audit your next package.

The 18 PPAP Elements Explained

| Element | Purpose | Prepared By | Typical Format | Reference | Common Pitfall |

|---|---|---|---|---|---|

| 1. Design Records | Confirms all part requirements and specs are understood | Design Engineer | Drawing, specs, PO copy | AIAG PPAP manual | Outdated drawings or missing revision match |

| 2. Engineering Change Documents | Documents any requested/approved changes | Engineering/Change Owner | ECN, technical change note | AIAG PPAP manual | Omitting change approval or latest ECN |

| 3. Customer Engineering Approval | Evidence of customer’s engineering sign-off | Supplier, Customer | Approval form, deviation waiver | AIAG PPAP manual | Missing trial results or deviation documentation |

| 4. Design FMEA (DFMEA) | Analyzes risks in the part design | Cross-functional team | DFMEA worksheet/report | AIAG PPAP manual | Not updated after design changes |

| 5. Process Flow Diagram | Maps the manufacturing process steps | Process/Manufacturing Engineer | Flowchart/diagram | AIAG PPAP manual | Missing steps or nonconformance flow |

| 6. Process FMEA (PFMEA) | Identifies risks in the manufacturing process | Cross-functional team | PFMEA worksheet/report | AIAG PPAP manual | Controls not linked to actual risks |

| 7. Control Plan | Lists controls for special characteristics and process steps | Quality/Process Engineer | Table or matrix | AIAG PPAP manual | Inconsistent with PFMEA or missing special characteristics |

| 8. Measurement System Analysis (MSA) | Validates that gaging systems are accurate and repeatable | Quality Engineer | Gage R&R study, calibration records | AIAG PPAP manual | Incomplete Gage R&R or missing calibration |

| 9. Dimensional Results | Verifies all dimensions meet print requirements | Quality/Inspection | Spreadsheet/table | AIAG PPAP manual | Not all print dimensions reported |

| 10. Material/Performance Test Results | Confirms material and performance compliance | Lab/Test Engineer | Test summary, certs | AIAG PPAP manual | Missing test certs or incomplete results |

| 11. Initial Process Studies | Shows process stability and capability | Process/Quality Engineer | SPC charts, study report | AIAG PPAP manual | Not covering all critical characteristics |

| 12. Qualified Laboratory Documentation | Proof that labs are certified for testing | Quality/Lab Manager | Lab certs, accreditation | AIAG PPAP manual | Expired or missing lab certifications |

| 13. Appearance Approval Report (AAR) | Confirms customer has approved part appearance | Quality/Customer Rep | AAR form/report | AIAG PPAP manual | Omitted for appearance-critical parts |

| 14. Sample Production Parts | Physical samples for customer review/storage | Supplier | Physical part, photos | AIAG PPAP manual | Not matching documentation or missing storage info |

| 15. Master Sample | Benchmark sample for ongoing comparison | Supplier, Customer | Signed sample part | AIAG PPAP manual | Not signed/approved or not available for training |

| 16. Checking Aids | List and calibrate tools used for inspection | Quality/Process Engineer | Tool list, calibration schedule | AIAG PPAP manual | Uncalibrated aids or incomplete list |

| 17. Customer-Specific Requirements | Documents any special requirements from the customer | Supplier/Account Manager | CSR checklist, forms | AIAG PPAP manual | Missed or misunderstood customer-specific details |

| 18. Part Submission Warrant (PSW) | Summary, declaration, and approval of the whole PPAP | Quality Manager | PSW form | AIAG PPAP manual | Incorrect submission level or missing signatures |

Who Prepares Each PPAP Document?

Most ppap elements require cross-functional teamwork. For example, the PFMEA and Control Plan are best developed by a team including engineering, quality, and manufacturing. Lab documentation and test results should always be coordinated with qualified labs and quality managers. Keeping your team aligned with the AIAG PPAP manual and customer requirements is critical for smooth approvals.

Purpose and Typical Format at a Glance

- Reports: Used for FMEAs, MSA, and process studies—often in tabular or worksheet form.

- Tables/Spreadsheets: Common for dimensional results, control plans, and checking aids.

- Narratives/Forms: Needed for PSW, engineering change documentation, and appearance approval report.

- Physical Evidence: Includes master samples and sample production parts.

Referencing the aiag ppap manual pdf or your organization’s standards library helps ensure you use the right templates and formats every time.

Where to Find Official Guidance

- AIAG PPAP manual: The authoritative source for definitions, sample forms, and expectations for all 18 elements of ppap (Quality-One).

- IATF 16949: For broader quality system requirements that reinforce PPAP documentation.

- Customer-specific manuals: Always check for unique requirements or formats from your customer.

Tips for Linking Elements and Avoiding Pitfalls

- Make sure your PFMEA drives your control plan—review both together for consistency.

- Use your MSA studies to support both dimensional results and ongoing process controls.

- Never submit outdated prints or ignore customer-specific requirements—they’re common rejection triggers.

- Double-check that all special characteristics are clearly identified and flow through every relevant document.

Now that you have a comprehensive reference for the 18 elements, the next section will show you how to match these documents to the right PPAP submission level—so you’re not over- or under-preparing for your customer’s needs.

Understand PPAP Levels and Choose the Right Scope

Ever wonder why some PPAP submissions are a breeze while others feel like a mountain of paperwork? The answer often lies in choosing the right PPAP level for your project. When you understand the levels of PPAP, you can match your documentation to your customer’s needs—saving time, reducing risk, and building trust. Let’s break down the five levels, so you’ll always know what’s expected and how to negotiate the right submission scope.

PPAP Submission Levels at a Glance

| PPAP Level | What to Submit | What to Retain | Typical Triggers | Customer Expectations | When to Use |

|---|---|---|---|---|---|

| Level 1 | Part Submission Warrant (PSW) only | All supporting documentation kept at supplier | Low-risk, simple parts with proven history | Fast approval, minimal review | Basic fasteners, non-critical plastic caps |

| Level 2 | PSW + selected samples and limited data (e.g., dimensional, material certs) | Full package retained at supplier | Moderate complexity, minor changes, or new supplier with good track record | Some evidence required, but not full documentation | Brackets, simple machined parts, minor design updates |

| Level 3 | PSW + full supporting data + product samples | Copy at supplier; all documents submitted to customer | New parts, high complexity, safety/critical items, or regulatory requirements | Comprehensive review of all 18 elements | Engine components, safety systems, new product launches |

| Level 4 | PSW + other documents as specified by customer | Defined by customer; may require special forms or tests | Unique customer needs, special regulatory or operational requirements | Tailored submission, customer defines evidence | Medical devices, parts with special compliance needs |

| Level 5 | PSW + full package, all data available for on-site review | All documents and samples ready at supplier’s site | Highest risk, critical applications, or customer audit required | On-site audit, deep dive into process and controls | Aerospace, critical engine parts, or by special request |

When Level 3 Is Appropriate

Level 3 PPAP is by far the most common—and for good reason. It’s the go-to for new parts, major changes, and anything with significant risk or complexity. If you’re supplying a safety-related item or a part that’s new to your process, expect your customer to require level 3 ppap. This means submitting the PSW, all 18 elements, and physical samples for review. The ppap level 3 requirements give your customer full confidence before production ramps up (Six Sigma Development Solutions).

Evidence Required by Level

- Level 1: Just the PSW—fast and light, but only for low-risk parts.

- Level 2: PSW plus targeted evidence (like a few test results or samples). This is often called level 2 ppap and is a good fit for moderate changes or when your customer wants a little more assurance.

- Level 3: The full package—PSW, all 18 elements, and product samples. This is the default unless otherwise specified.

- Level 4: PSW plus whatever the customer asks for. Level 4 ppap is flexible and used for custom requirements.

- Level 5: Everything from Level 3, but all documents and samples must be ready for an on-site customer review or audit.

Remember, every PPAP level includes the Part Submission Warrant. The difference is in how much supporting evidence is submitted versus retained at the supplier—and whether special forms or audits are involved.

Choosing the Right Level with Your Customer

Sounds complex? It doesn’t have to be. Here’s how to navigate the decision:

- Start with risk: Higher risk, complexity, or regulatory scrutiny usually means a higher submission level.

- Ask early: Clarify with your customer which level of PPAP they require—don’t assume.

- Check for customer-specific requirements: Some OEMs or Tier 1s have their own rules that override the default levels. Always review their supplier manuals or quality agreements.

- Negotiate when appropriate: If your part is low-risk but the customer requests Level 3, present your case for a lighter level, especially if you have a strong quality history.

- Document the agreement: Always confirm the agreed level in writing to avoid confusion later.

"The right PPAP level balances risk, complexity, and customer expectations—while never compromising on quality or compliance."

By understanding and applying the correct ppap levels, you’ll streamline your submissions, avoid overwork, and build stronger customer relationships. Next, we’ll dive into annotated examples of key PPAP documents—so you can see what successful submissions look like in practice.

Annotated PPAP Document Examples That Pass Review

When you’re staring down a PPAP deadline, the difference between a smooth approval and a round of rework often comes down to how clearly your documents demonstrate compliance. Wondering what a strong ppap template or psw template looks like? Let’s walk through annotated, standards-aligned examples for the most scrutinized PPAP documents—so you can build your next submission with confidence, not guesswork.

How to Complete a Part Submission Warrant (PSW)

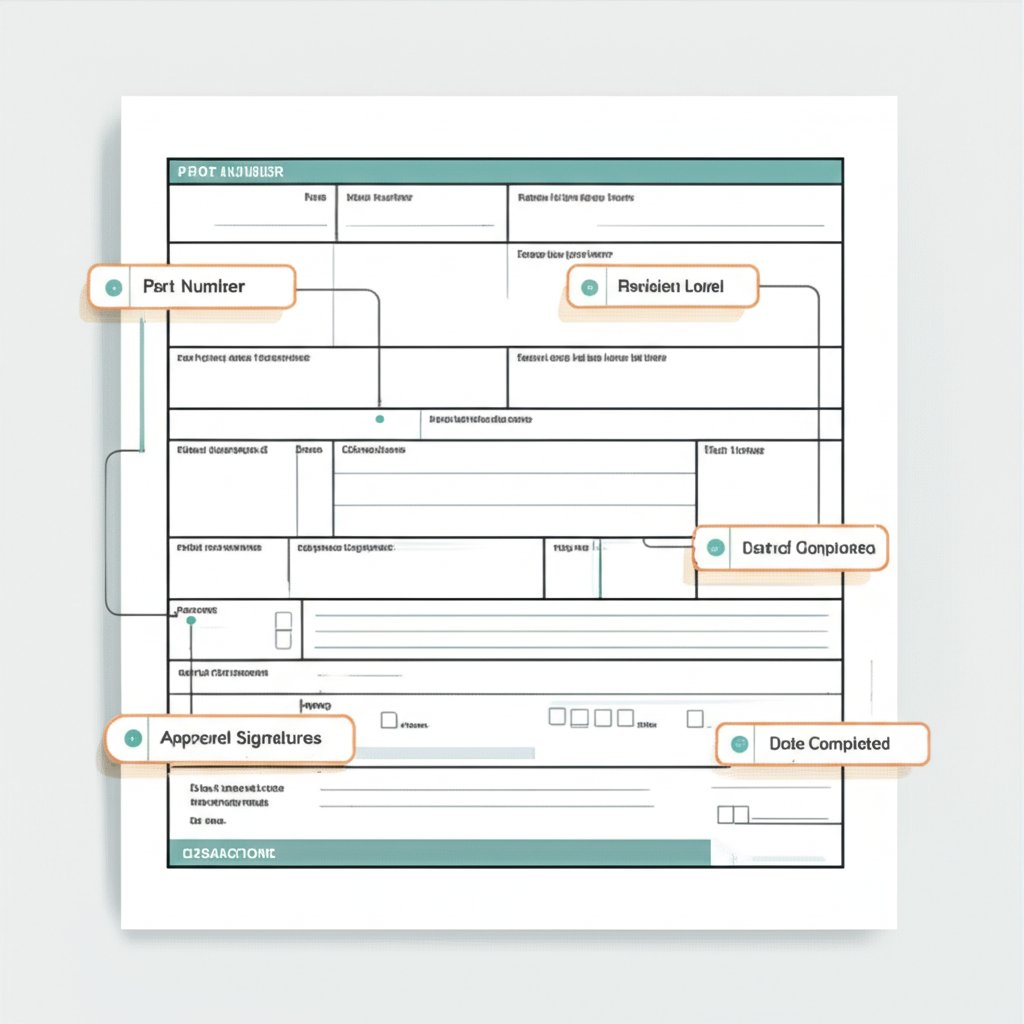

The PSW is the capstone of your PPAP package. It summarizes your declaration that all requirements have been met—and it’s required for every part number unless your customer says otherwise. If you’ve ever asked, what is a part submission warrant or searched for a part submission warrant template, here’s a simplified, annotated example based on industry best practice and reference forms (InspectionXpert):

[Part Number] — Identifies the specific part submitted.

[Drawing Revision] — Shows which drawing version was used; must match supporting docs.

[Reason for Submission] — New part, engineering change, supplier change, etc.; buyer checks for correct trigger.

[Submission Level] — Level 1–5; signals how much supporting evidence is included.

[Organization Manufacturing Information] — Plant/location, ensuring traceability.

[Declaration] — Supplier’s formal sign-off that requirements are met and evidence is available.

- Common errors: Mismatched part numbers/revisions, missing reason for submission, incorrect level, unsigned declaration.

Remember, the part submission warrant meaning is your official statement that your entire PPAP package is accurate and complete. Always double-check alignment with the rest of your documentation and your customer’s requirements.

PFMEA to Control Plan Linkage: Ensuring Traceability

One of the most common reasons for PPAP rejection? Risks identified in the PFMEA aren’t addressed in the Control Plan. Every significant failure mode should have a corresponding control and reaction plan. Here’s a simplified table to show how these documents connect, based on best practices and standards guidance (Plexus International):

| Failure Mode (PFMEA) | Control Method (Control Plan) | Reaction Plan |

|---|---|---|

| Incorrect part dimension | 100% inspection with digital caliper | Stop production, segregate nonconforming parts, notify supervisor |

| Surface defect | Visual inspection at final assembly | Quarantine, rework, review operator training |

| Improper hardness | Periodic hardness testing (lab-certified) | Hold lot, initiate corrective action, inform customer if needed |

- Tip: Review every PFMEA risk and ensure a matching control exists in your Control Plan. Consistency is key.

- Common pitfalls: Missing controls for special characteristics, vague reaction plans, or sampling frequency that doesn’t match risk.

Dimensional Results Essentials: Reporting with Clarity

Dimensional results are a core part of ppap documents with example value. They prove your parts physically match the print. Here’s a simple structure for reporting, adapted from industry templates:

| Characteristic ID | Nominal | Tolerance | Result | Gage Used | Reference |

|---|---|---|---|---|---|

| 1 | Ø10.1 | -0.02 | 10.09 | Micrometer | Print Rev L4/d |

| 2 | 6.3 Ra | Max | 5.8 | Roughness Tester | Print Rev L4/d |

| 3 | 192 | ±0.5 | 192.2 | VHG | Print Rev L4/d |

- Best practice: Include all drawing-required dimensions, note the gage used, and reference the correct drawing revision.

- Common errors: Omitting dimensions, using uncalibrated gages, or referencing the wrong print version.

MSA and Initial Process Studies: What to Include

Measurement System Analysis (MSA) and initial process studies build confidence in your measurement and production stability. While the formats vary, your narratives should always include:

- Scope of Study: Which characteristics, gages, or processes were evaluated?

- Rationale: Why were these selected—are they special characteristics, high risk, or customer-specified?

- Method Reference: Which standard or method was followed (e.g., AIAG MSA manual)?

- Summary of Results: Were the gages found capable? Is the process stable and capable for key features?

For example, your MSA narrative might read: “Gage R&R studies were performed on the digital caliper used for outer diameter measurement, following the AIAG MSA manual. All results met acceptance criteria for repeatability and reproducibility.” For process studies, summarize capability for each special characteristic, referencing control charts or study reports as needed.

- Common pitfalls: Missing rationale for gage selection, incomplete method references, or not covering all critical features.

Why Examples and Templates Matter

When you use clear, standards-aligned templates—like those above—you make it easier for buyers to review your PPAP submission and reduce the risk of costly rework. Whether you’re searching for a psw template, a part submission warrant template, or a full ppap template, always tailor your documents to the latest customer and AIAG requirements.

Next, we’ll show you how to plan and stage your PPAP submission step by step, so you can move from document prep to on-time approval with fewer surprises.

Stepwise PPAP Preparation with Checklists and Timelines

Ever find yourself wondering where to start—or what to double-check—when preparing your next PPAP submission? The ppap process can feel overwhelming, but breaking it into clear, practical steps makes it manageable and audit-ready. Whether you’re supporting a new product launch or responding to a change, this guide gives you a sequenced ppap checklist that integrates seamlessly with your APQP activities and sets you up for a smooth review.

Pre-launch PPAP Checklist

Before you compile your PPAP package, staging the right artifacts and aligning with your customer is crucial. Here’s a step-by-step approach you can adapt for any project:

- Confirm design records and latest revisions—ensure drawings, specifications, and customer requirements are up to date and match your internal documentation.

- Identify special characteristics—create or update your matrix for features requiring extra controls or traceability.

- Develop or update PFMEA and Control Plan—make sure risks and controls are consistent and reflect the current process flow.

- Prepare process flow diagrams—verify every manufacturing and inspection step is mapped, including non-conformance flows.

- Lock gaging strategies and create an MSA plan—define which gages are used for critical features and schedule Gage R&R studies.

- Stage capability evidence—plan for initial process studies (SPC, capability indices) on key characteristics.

- Arrange for material and performance testing—coordinate with qualified labs for any required certifications or reports.

- Align on submission level and customer-specific requirements—confirm with your customer which ppap level is required and any unique evidence or formats.

- Schedule run-at-rate (if needed)—plan for production trials to prove process capacity and stability.

- Compile documentation and complete the Part Submission Warrant (PSW)—summarize your submission, ensuring all supporting evidence is organized and ready for review.

- Submit package and retain originals as required—deliver the agreed evidence to your customer and keep copies for audit or future reference.

- Artifacts to stage early:

- Drawings and design records

- Special characteristics matrix

- PFMEA and Control Plan drafts

- MSA plan and gage list

- Initial process study templates

- Material/performance test requests

- Packaging and labeling approvals

Delta PPAP After Engineering Changes

Change is a constant in manufacturing, but it doesn’t always mean starting your PPAP from scratch. When you’re dealing with a design update, process tweak, or supplier switch, a delta PPAP is the tool for the job. Here’s how to scope and document it:

- Identify the affected elements—pinpoint which of the 18 PPAP elements are impacted by the change (e.g., updated drawing, revised PFMEA, new material cert).

- Maintain traceability—reference the original approved PPAP and clearly mark the revised documents and their effective dates.

- Engage your customer—align early on what needs to be resubmitted, and confirm if a full or partial package is required.

- Document the change rationale—include engineering change notices and any supporting validation or testing that demonstrates continued compliance.

Delta PPAP keeps your documentation lean and relevant, ensuring only the necessary updates are reviewed while preserving the integrity of your original approval. For more on integrating change control with the apqp and ppap process, reference your organization’s APQP procedures or seek targeted ppap training for your team.

Timeline and Responsibilities

Planning your PPAP activities alongside the broader apqp process helps avoid last-minute scrambles and missed deadlines. Here’s a sample timeline template you can adapt:

| Week | Owner | Deliverables | Risks/Blocks |

|---|---|---|---|

| 1 | Design Engineer | Confirm drawing and special characteristics | Pending customer clarification |

| 2 | APQP Lead | Update PFMEA and process flow | Incomplete process details |

| 3 | Quality Engineer | Lock MSA plan and gage selection | Gage availability or calibration delays |

| 4 | Lab Manager | Initiate material/performance testing | Lab capacity, sample readiness |

| 5 | Process Engineer | Conduct initial process studies, capability analysis | Process instability, data gaps |

| 6 | Quality Manager | Compile PPAP package, complete PSW | Missing signatures, unresolved nonconformances |

| 7 | Supplier Quality | Submit to customer and retain originals | Customer review feedback |

Adapting this template lets you clarify roles, spot risks early, and keep your submission on track. You’ll notice that integrating apqp ppap activities throughout the timeline supports readiness and reduces fire drills at launch.

By following a structured ppap procedure—from checklist to delta updates and timeline management—you’ll not only meet your customer’s requirements but also build a culture of proactive quality planning. Up next, we’ll look at how buyers evaluate your PPAP package and what you can do to avoid common rejection triggers.

Acceptance Decisions and How to Avoid Rejections

Imagine you’ve put weeks into your PPAP package, only to hear back from your customer: “Submission rejected—please resubmit.” Frustrating, right? Understanding how buyers evaluate ppap documents and what triggers acceptance or rejection is the key to smoother approvals and fewer delays. Let’s break down the ppap approval process so you know exactly what to check—and how to fix the most common pitfalls before you submit.

How Buyers Evaluate PPAP Submissions

When a customer receives your PPAP package, their review is both systematic and detail-oriented. They’re not just looking for completed checkboxes—they want to see that your evidence is consistent, traceable, and aligned with their requirements as well as the AIAG PPAP manual. Here’s what most buyers scrutinize:

- Drawing alignment: Do your design records, dimensional results, and sample parts match the latest customer drawings and revisions?

- Special characteristic flow-down: Are all special characteristics clearly identified and controlled throughout the PFMEA, Control Plan, and inspection results?

- Evidence coherence: Do all 18 elements of your submission tell a consistent story—no mismatched specs, missing signatures, or outdated forms?

- MSA adequacy: Are your gage R&R studies and calibration records complete, current, and relevant to the key measurements?

- Process study rationale: Do your initial process studies (SPC, capability analysis) cover all critical and special characteristics?

- Packaging verification: Have you validated and documented that packaging meets customer requirements and protects the product?

- Change traceability: Are engineering changes clearly documented, and are affected PPAP elements updated accordingly?

- Customer-specific requirements: Have you addressed any unique forms, data, or evidence your customer expects, beyond the standard?

For ppap requirements level 3, buyers expect a full, detailed submission with every element carefully prepared and internally consistent. Any gaps or misalignments can lead to delays or outright rejection.

Common Rejection Triggers and Fixes

Even experienced teams run into avoidable issues. Here are the most frequent rejection triggers—and how to address them before they become roadblocks:

- Mismatched revisions: If your dimensional results or control plans reference a different drawing revision than what the customer expects, update all documents to the correct version and double-check for consistency.

- Incomplete special characteristic controls: Make sure every special characteristic is identified in the PFMEA, controlled in the Control Plan, and measured in your results. Missing even one can prompt a resubmission.

- Unsigned or outdated PSW: The Part Submission Warrant must be fully completed, signed by the authorized representative, and reflect the current submission reason and level.

- Insufficient gage rationale or MSA: If your measurement system analysis is missing for a key dimension, perform and document a Gage R&R study or include calibration records as required.

- Omitted or incomplete process studies: For critical characteristics, always include capability studies or SPC charts. If process capability is not yet achieved, document interim controls and improvement plans.

- Customer-specific forms or data missing: Review your customer’s supplier manual for any extra requirements—and include them in your submission package.

Establishing a structured internal workflow and regular cross-functional reviews, especially before submitting ppap requirements level 3 packages, can catch most of these issues early.

Decision Outcomes and Next Steps

"PPAP approval decisions typically fall into three categories: full approval (all requirements met), interim approval (limited production allowed with conditions), or rejection (resubmission required with corrective action)."

- Full approval: Your package is complete and consistent; you’re cleared for full production.

- Interim approval: Some requirements are not fully met, but the customer allows limited shipments while you address specific issues—usually with a clear action plan and timeline.

- Rejection: Significant gaps, inconsistencies, or missing elements require you to revise and resubmit the entire or partial package.

To improve your ppap approval rate, focus on internal consistency, traceability, and proactive communication with your customer. Always reference the AIAG PPAP manual and, where applicable, IATF 16949 clauses for the most current and precise acceptance criteria. If you’re ever unsure, ask your customer for clarification or examples of best-in-class submissions—many organizations will share templates or checklists to help you align with their approval process.

Ready to apply these lessons? Next, we’ll show you how to tailor your PPAP documentation strategy for different part types—so you never miss an essential detail, no matter what you’re manufacturing.

Tailor PPAP by Part Type Without Missing Essentials

When it comes to ppap manufacturing, one size rarely fits all. The core requirements of the production part approval process stay the same, but the way you document and emphasize key risks can shift dramatically depending on the part you’re making. So, how do you ensure ppap quality for everything from fasteners to high-tech connectors? Let’s break it down by part type, so you never miss a critical detail—no matter what’s on your shop floor.

Fasteners and Cold Formed Parts

- Material certifications: Always provide full traceability back to melt source and lot, since material mix-ups are a common risk.

- Thread gauging rationale: Clearly document why you chose a particular thread gage and show calibration evidence—buyers scrutinize this for automotive industry process parts.

- Dimensional results: Cover all print features, but pay extra attention to critical thread and head dimensions.

- PFMEA focus: Highlight risks like tool wear, die breakage, and material hardness variation.

- Control plan detail: Ensure frequent checks for special characteristics and document reaction plans for out-of-tolerance threads.

- Documenting labs: Use only accredited labs for material and hardness testing, and include their certifications in your package.

Machined Components

- Capability narratives: For critical dimensions (e.g., bores, threads, surfaces), provide robust initial process studies and explain your approach to process capability.

- Gage strategy: Document gage selection rationale and include MSA (Gage R&R) studies for all custom or high-risk measurements.

- PFMEA depth: Address risks like tool breakage, setup errors, and surface finish defects.

- Control plan: Map every special characteristic from PFMEA and define clear reaction plans for each.

- Packaging/handling: Specify how you prevent nicks, dings, or contamination after machining—often a buyer concern for high-value parts.

- Documenting labs: If using outside labs for dimensional or metallurgical verification, attach their accreditations and test methods to your PPAP package.

Electronic Connectors and Assemblies

- Functional validation: Include evidence of electrical continuity, insulation resistance, and mating/de-mating cycles as required by the drawing.

- Layered process audits: Show how you audit assembly steps and operator training, since human error is a key risk.

- ESD/handling controls: Document your electrostatic discharge protection measures and packaging protocols.

- PFMEA emphasis: Focus on risks like solder joint failure, pin misalignment, and housing cracks.

- Control plan: Detail in-process and end-of-line functional tests, with reaction plans for failures.

- Lab documentation: For environmental or electrical tests, ensure all results come from certified, documenting labs and reference their qualifications.

Comparative Table: PPAP Focus by Part Type

| Part Type | Key Risks | Documentation Emphasis | Typical Buyer Concerns |

|---|---|---|---|

| Fasteners/Cold Formed | Material mix-up, thread quality, tool wear | Material certs, thread gage rationale, lab accreditations | Traceability, thread fit, hardness consistency |

| Machined Components | Dimensional accuracy, surface finish, tool breakage | Process capability studies, MSA, packaging/handling | Critical feature control, gage traceability, damage prevention |

| Connectors/Assemblies | Electrical function, ESD, assembly errors | Functional test evidence, ESD protocols, layered audits | Performance validation, operator training, environmental robustness |

Don’t Forget: Customer-Specific and Special Characteristics

No matter your part type, always check for customer-specific requirements and pay close attention to any special characteristics flagged on the drawing. These override generic PPAP templates and often require extra documentation, controls, or third-party documenting labs for verification. By tailoring your PPAP approach to the realities of your production part approval and the unique risks of each product, you’ll meet both industry and customer expectations—and avoid costly surprises during review.

Next, we’ll help you compare tools and services that can streamline your PPAP documentation process, so you can focus more on manufacturing and less on paperwork.

Compare PPAP Tools and Services for the Right Fit

When you’re tasked with building a PPAP package, do you rely on your in-house team, try a digital solution, or partner with a manufacturer who handles everything from parts to paperwork? The answer depends on your project’s complexity, timing, and the resources you have on hand. Let’s break down the main options for ppap services—so you can confidently choose the support that matches your needs and customer expectations.

Choosing PPAP Support: What Are Your Options?

Imagine you’re launching a new automotive component with a tight deadline. You need not only compliant documentation but also parts that are delivered on time and meet every quality standard. Here’s where your PPAP support choices come into play:

- One-stop manufacturing partners who can handle both production and PPAP documentation, streamlining the whole process.

- Dedicated PPAP software that automates document management, approvals, and workflow tracking.

- Specialized PPAP consulting services that guide your team through documentation, audits, and customer communication.

- Internal teams using manual or digital tools to manage the process in-house.

When a One-Stop Manufacturer Helps

For suppliers who need both part realization and fully compliant PPAP documentation—especially when rapid prototyping and IATF 16949 discipline are critical—a one-stop partner can be a game-changer. Shaoyi Metal Technology stands out here, offering end-to-end solutions for high-precision automotive components. Their services span stamping, cold forming, CNC machining, and welding, all under one roof, with PPAP documentation support integrated at every step. This approach streamlines evidence gathering for PFMEA, Control Plan, MSA, and dimensional results, minimizing the risk of missing or inconsistent documentation.

PPAP Software vs. Service Providers

Maybe you’re considering digital tools to manage your submission. Modern ppap software platforms can automate document management, enable electronic approvals, and keep all your records in a centralized, cloud-accessible location. This is especially helpful for teams juggling multiple projects or remote approvals. Some solutions even offer a ppap software free download or trial, so you can test features before committing.

On the other hand, specialized PPAP consulting services offer hands-on guidance, from document preparation to on-site audits and customer communication. These experts are particularly valuable if your team is new to the process, facing complex customer requirements, or needs to ensure compliance with the latest standards—such as those covered in AIAG PPAP training.

Comparative Table: PPAP Support Options

| Provider/Tool | Key Features | Turnaround | Certification/Expertise | Best For |

|---|---|---|---|---|

| Shaoyi Metal Technology | One-stop part manufacturing, integrated PPAP documentation, rapid prototyping, IATF 16949 certified, global OEM/Tier 1 experience | As fast as 7 days for prototypes | IATF 16949, extensive automotive track record | Suppliers needing both parts and compliant PPAP packages fast |

| SafetyCulture PPAP Software | Document management, workflow automation, compliance tracking, mobile app | Immediate (cloud-based) | Industry-agnostic, digital compliance tools | Teams needing digital workflow and remote approvals |

| ComplianceQuest | Compliance management, analytics, collaboration | Immediate (cloud-based) | QMS expertise | Organizations focused on compliance analytics |

| EHSInsight | Quality and safety management, reporting | Immediate (cloud-based) | QMS/EHS experience | Large enterprises with environmental/quality needs |

| QT9 QMS | Quality management, document control, audits | Immediate (cloud-based) | QMS focus | Companies seeking robust document control |

| TPT PPAP Services | Guided PPAP documentation, audits, supplier-customer communication | Project-based | PPAP process expertise | Suppliers needing process coaching and audit support |

Pros and Cons: Choosing Your Approach

-

Shaoyi Metal Technology

-

Pros

- Integrated part and documentation delivery—reduces handoffs and errors

- Rapid prototyping and launch support for urgent timelines

- IATF 16949 certified, trusted by leading automotive customers

-

Cons

- Best fit for suppliers needing both manufacturing and documentation; not ideal for documentation-only projects

-

-

PPAP Software (e.g., SafetyCulture, QT9 QMS)

-

Pros

- Speeds up document management and approvals

- Centralizes records for easy access and audit

- Some offer ppap software free download or trial

-

Cons

- May not address physical part or process validation

- Requires upfront setup and training

-

-

Specialized PPAP Services (e.g., TPT)

-

Pros

- Hands-on guidance for complex or first-time submissions

- Support for audits, capability studies, and customer negotiations

-

Cons

- May not provide manufacturing or digital workflow tools

- Project-based, so ongoing support may require additional engagement

-

Making Your Decision

Ultimately, the best PPAP support depends on your organization’s resources, the complexity of your parts, and your customer’s requirements. If you need a single partner who can deliver both parts and compliant documentation with speed and quality, consider Shaoyi Metal Technology. If you’re focused on digitalizing your workflow, a ppap software solution with a free trial might be your best first step. For teams new to the process or facing demanding customers, investing in aiag ppap training or consulting services can pay dividends in smoother approvals and fewer surprises.

Next, we’ll wrap up with actionable steps to turn your PPAP strategy into confident execution—no matter which support option you choose.

Turn PPAP Guidance into Action with Confidence

Key Takeaways on PPAP Documents

- Always ensure coherence across every PPAP document—from design records to the PSW—so your submission tells a complete, consistent story.

- Never overlook customer-specific requirements; these can override standard templates and often make or break your approval.

- Confirm your submission level early and align all evidence to what the customer expects—whether it’s Level 1 or a full Level 3 package.

At its core, the production part approval process ppap is about building trust and clarity between supplier and customer. Understanding what does PPAP stand for and the ppap full form—Production Part Approval Process—helps you see that it’s more than paperwork: it’s a disciplined system for risk reduction, change control, and launch readiness. The ppap acronym is recognized across automotive and precision manufacturing for its role in ensuring every part meets quality expectations before full production.

Action Plan for Your Next Submission

Ready to put these lessons into practice? Use this checklist to move from planning to successful submission—no matter your industry or part type:

- Confirm all drawing revisions and special characteristics—check for the latest specs and make sure every unique requirement is clearly identified.

- Align on submission level with your customer—clarify if you’re submitting Level 1, Level 2, Level 3, or higher, and document this agreement.

- Stage your MSA plan and select gages—identify which measurements need gage R&R or calibration evidence early in the process.

- Schedule process studies—plan capability studies for all critical features and ensure data is ready before compiling your package.

- Prepare the Part Submission Warrant (PSW) early—populate it as you go, so it’s consistent with the rest of your documentation and ready for final review.

Imagine you’re facing a tight launch window or a complex assembly with multiple special characteristics. This is where having a single accountable partner can make all the difference. Shaoyi Metal Technology offers a one-stop solution for both part realization and compliant PPAP documentation—ideal for projects where speed, quality, and IATF 16949 discipline are non-negotiable. Their experience in stamping, cold forming, CNC machining, and welding means you can focus on your core business while they manage both the manufacturing and the paperwork, accelerating your path to approval.

Of course, every project is unique. The best approach is to compare your options using the earlier tools and services framework—consider your internal resources, the complexity of your parts, and your customer’s expectations. Whether you need a complete manufacturing partner, a digital PPAP workflow, or targeted process training, choose the path that best matches your timeline and risk profile.

By applying these actionable steps and leveraging the right support, you’ll not only define PPAP for your organization but also build a track record of smooth approvals and lasting customer trust. Ready to take your next PPAP submission from checklist to confident delivery?

Frequently Asked Questions about PPAP Documents

1. What are the 5 levels of PPAP submission?

The 5 PPAP submission levels define how much documentation you must provide to your customer. Level 1 requires only the Part Submission Warrant (PSW), while Level 3—most common—demands the PSW plus all 18 supporting elements and product samples. Levels 2 and 4 require varying amounts of evidence as specified by the customer, and Level 5 involves an on-site review of all documentation. Choosing the right level depends on part complexity, risk, and customer requirements.

2. What does PPAP stand for in manufacturing?

PPAP stands for Production Part Approval Process. It is a standardized method used in manufacturing—especially automotive and aerospace—to demonstrate that a supplier can consistently meet customer engineering and quality requirements before and after changes. PPAP documents provide the evidence needed for approval prior to production.

3. What documents are included in a PPAP package?

A complete PPAP package contains 18 elements, such as design records, engineering change documents, FMEAs, control plans, measurement system analyses, dimensional results, material and performance test results, and the Part Submission Warrant (PSW). Each document serves to prove design intent, process capability, and compliance with customer and industry standards.

4. How does PPAP relate to APQP?

APQP (Advanced Product Quality Planning) is the overall quality planning process, while PPAP is the evidence package submitted at the end of APQP. PPAP documents confirm that all APQP activities—like risk analysis, process validation, and control planning—were successfully completed and the part is ready for production approval.

5. When should a delta PPAP be submitted?

A delta PPAP is required whenever there is a significant change to the product or process, such as design updates, material changes, or supplier/location shifts. Only the affected elements of the original PPAP need to be updated and submitted, but all changes must be clearly documented and traceable to maintain approval status.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —