Why Choose IATF 16949 Certified Aluminum Extrusion Suppliers For PPAP

Why Certification Matters for Extrusion Buyers

When you’re sourcing aluminum extrusions for automotive applications, the stakes are high. Imagine launching a new vehicle program—only to be tripped up by late PPAP approvals, inconsistent part quality, or a supplier who can’t trace a defect back to its source. Sound familiar? In 2025, OEMs and Tier 1s are raising the bar, demanding not just reliable parts, but evidence of robust, automotive-grade processes from every link in the supply chain. That’s where IATF 16949 certification becomes your risk-reduction tool and competitive advantage.

What IATF 16949 Means for Aluminum Extrusions

Let’s break it down. IATF 16949 is the global quality management standard for automotive production. It builds on ISO 9001—the baseline for quality systems—by adding layers of discipline specifically for the automotive sector. This includes Advanced Product Quality Planning (APQP), Production Part Approval Process (PPAP), full traceability, strict change management, and supplier development. For extrusion aluminum, this means every step—from billet selection and die design to heat treatment, machining, and finishing—operates under a documented, repeatable process. No shortcuts, no guesswork.

Why does this matter? Because the aluminum extrusion process is complex, with many variables that can affect dimensional stability, surface finish, and mechanical properties. A certified supplier’s system ensures that every profile, whether structural or decorative, meets your design intent and customer-specific requirements—every time. As Hydro’s Supplier Handbook notes, IATF 16949-certified suppliers are expected to follow the full suite of AIAG core tools (APQP, PPAP, FMEA, MSA, SPC), providing a proven framework for defect prevention and continuous improvement.

Proof Points Buyers Should Request in 2025

How do you know if a supplier truly lives up to these standards? Don’t just take their word for it. Insist on concrete evidence during your sourcing process. Here’s what you should expect from a partner with aluminum extrusion suppliers who are IATF 16949 certified:

- Consistent lot traceability from billet to finished part

- Validated control plans and process FMEAs for every extrusion profile

- Documented die maintenance and tool ownership registers

- Disciplined change management and formal approval for any process or product changes

- Timely, complete PPAP submissions aligned with AIAG standards

- Evidence of supplier development and continuous improvement activities

These aren’t just nice-to-haves—they’re the foundation for fewer launch delays, cleaner PPAP submissions, and better issue containment if problems arise.

Choosing an IATF 16949 certified extrusion partner is the single most effective way to reduce launch risk and ensure your aluminum profiles meet both technical and customer-specific requirements from day one.

Why Most Supplier Shortlists Miss Critical Scope

It’s tempting to focus only on price or lead time when building your supplier shortlist. But here’s the catch: many suppliers claim quality but lack the full IATF 16949 discipline across all relevant processes—especially when it comes to secondary machining, finishing, or sub-supplier management. That’s a recipe for hidden risk. As the automotive industry continues to evolve, you’ll notice that the most resilient supply chains are built on partners who can demonstrate end-to-end compliance, not just a certificate on the wall.

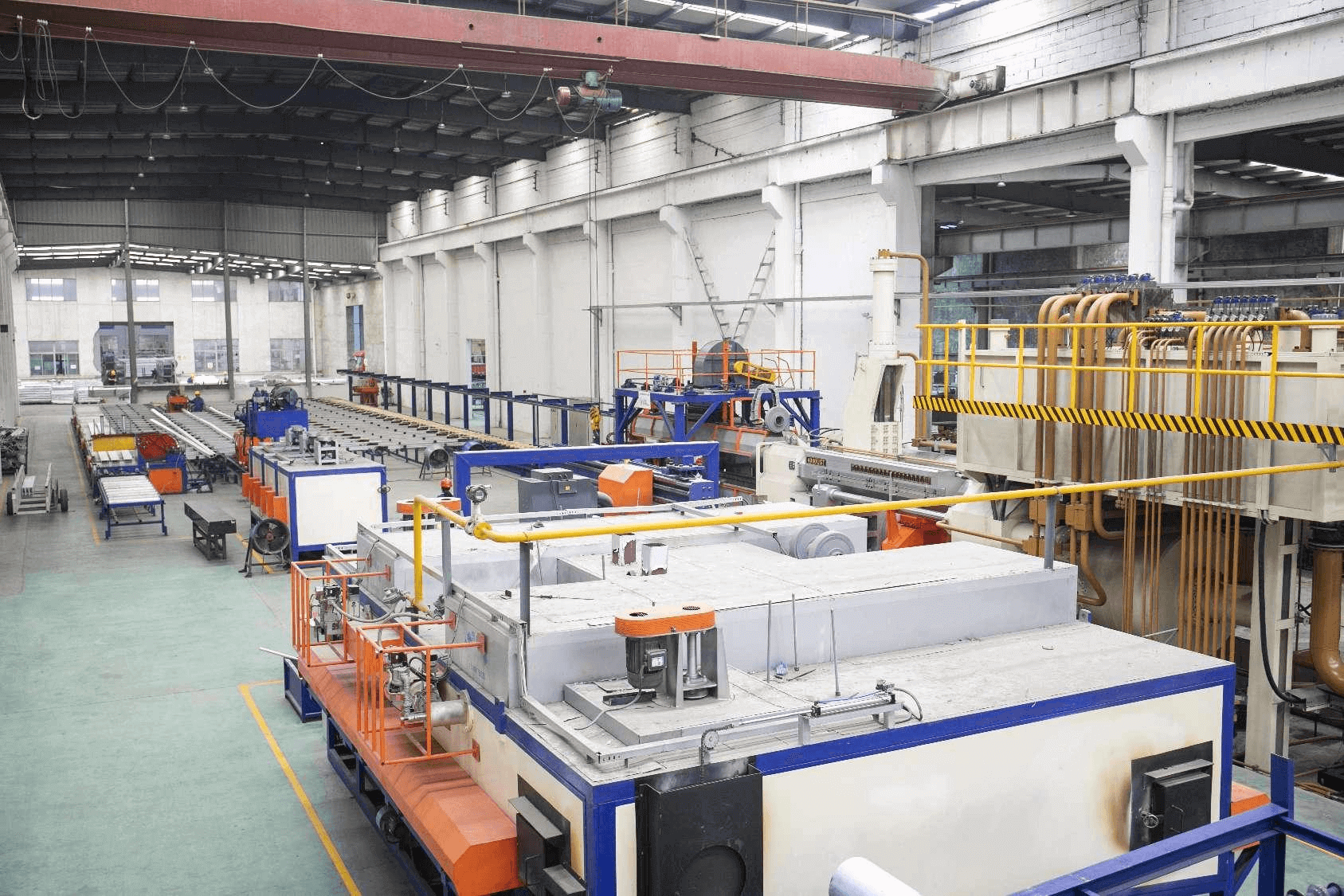

For automotive-grade extrusion programs, consider Shaoyi Metal Parts Supplier—a leading integrated precision auto metal parts solutions provider in China. Explore their aluminum extrusion parts for evidence of IATF-aligned processes, robust traceability, and a proven track record with global OEMs. It’s a vetted option for buyers who want peace of mind and a smoother path to PPAP approval.

In short, when you ask, “what is aluminum extrusion” or seek to optimize your aluminum extrusion process, remember that certification isn’t just a box to tick. It’s your insurance against costly surprises and your key to launching on time, every time.

How Does Aluminum Extrusion Work?

Ever wondered how lightweight, complex aluminum parts are made for automotive and industrial applications? If you’re new to sourcing or need to get non-technical colleagues up to speed, understanding the aluminum extrusion process is essential. Let’s break down what aluminum extrusions are, how the process works, and why disciplined controls matter for quality outcomes—especially when working with IATF 16949-certified suppliers.

What Is Aluminum Extrusion Explained Simply?

Picture squeezing toothpaste from a tube—that’s the basic idea behind aluminum extrusion. In industrial terms, aluminum extrusion is a process where heated aluminum billets are pushed through a specially shaped die to create long profiles with consistent cross-sections. These profiles can be solid, hollow, or semi-hollow and come in shapes ranging from simple bars to highly intricate designs.

How Does Aluminum Extrusion Work: From Billet to Profile

Sounds complex? Here’s a step-by-step outline of the typical aluminum extrusion process steps, each requiring its own set of controls to ensure repeatability and quality:

- Billet Preparation: Aluminum alloy billets are preheated to the optimal temperature for extrusion.

- Extrusion: The heated billet is forced through a steel die under high pressure, shaping it into the desired profile.

- Quenching: The extruded profile is rapidly cooled (quenched) to lock in mechanical properties.

- Stretching: Profiles are stretched to straighten and relieve internal stresses, ensuring dimensional accuracy.

- Cutting: Long profiles are cut to the required lengths for further processing.

- Aging (Heat Treatment): Profiles may undergo heat treatment to achieve specific tempers and enhance strength.

- Finishing: Optional processes like anodizing, painting, or powder coating improve appearance and corrosion resistance.

- Fabrication: Additional machining, drilling, or punching brings parts to their final dimensions and specifications.

Every step in this sequence can affect the final product’s dimensional stability and surface integrity. Factors such as die design, press tonnage, temperature control, and pull speed all play a role in ensuring profiles meet tight tolerances and visual standards.

Common Extrusion Defects Buyers Should Know

Even with a robust process, things can go wrong. Here are some typical aluminum extrusion defects and the process controls that help prevent them:

- Twist: Profile warps along its length; mitigated by proper die alignment and tension control.

- Bow: Curvature in the profile; controlled by balanced cooling and stretching.

- Die Lines: Surface marks from die wear or contamination; addressed by regular die maintenance and cleaning.

- Pick-up: Surface roughness from material sticking to the die; minimized by optimizing lubrication and die temperature.

- Dimensional Drift: Profiles out of spec; prevented through real-time monitoring and capability studies.

Process Controls and Evidence: What Auditors Look For

Wondering what kind of documentation backs up a supplier’s quality claims? Here’s a quick reference table mapping extrusion process stages to typical control evidence required by IATF 16949-certified suppliers:

| Process Stage | Typical Control Evidence |

|---|---|

| Billet Preparation | Alloy certification, preheat logs |

| Extrusion | Die design records, press logs, dimensional inspection reports |

| Quenching & Stretching | Quench rate records, straightness checks |

| Heat Treatment/Aging | Oven cycle records, temper certification |

| Finishing | Surface inspection standards, coating logs |

| Fabrication | Machining records, final dimension checks |

Disciplined process controls like these are the backbone of reliable PPAPs and serial production readiness. When you partner with a supplier who systematizes every step, you gain confidence that your extruded parts will meet both technical and customer-specific requirements—consistently and at scale.

Now that you know how the aluminum extrusion process works and the kinds of defects and controls involved, the next step is understanding the difference between ISO 9001 and IATF 16949 certification—and when each is appropriate for your program.

IATF 16949 or ISO 9001 for Your Program

Ever looked at a supplier’s website and wondered, “Does that ISO 9001 badge mean they’re ready for my automotive extrusion program?” Or maybe you’ve seen both ISO 9001 and IATF 16949 on a certificate and thought, “Which one really matters for what I need?” If you’re sourcing aluminum extrusions for demanding applications, especially in the automotive sector, understanding the difference is crucial. Let’s break it down so you can make the right call for your next project.

When ISO 9001 May Be Acceptable

ISO 9001 is the foundational quality management standard recognized worldwide. For an aluminium extrusion section manufacturer, ISO 9001 certification means they’ve established basic process discipline—documented procedures, regular audits, corrective actions, and a commitment to continuous improvement. If you’re running early-stage prototyping, sourcing non-automotive parts, or working with suppliers who only provide tooling or basic profiles, ISO 9001 may be sufficient—if you clarify risk controls and customer-specific requirements up front.

For example, if you’re developing a new consumer electronics enclosure or architectural profile, ISO 9001 ensures a baseline of quality. You’ll want to define aluminum extrusion requirements clearly and request supporting documentation, but the stakes are generally lower than in regulated automotive launches.

When You Should Require IATF 16949

But what if your project involves what are aluminum extrusions used for in automotive body structures, chassis, or safety-critical systems? Here’s where IATF 16949 comes in. This standard builds on ISO 9001 but adds rigorous, automotive-specific requirements—think APQP, PPAP, traceability from billet to finished part, strict change management, and robust supplier development (Amtivo).

For series production or any program where a Production Part Approval Process (PPAP) is required, IATF 16949 is the industry expectation. It’s not just about paperwork: it’s about a culture of defect prevention, risk mitigation, and meeting customer-specific requirements every time. Without IATF 16949, you risk launch delays, nonconforming parts, and, ultimately, unhappy customers.

| Aspect | ISO 9001 | IATF 16949 |

|---|---|---|

| Scope | General quality management for any industry | Automotive-specific, covers all manufacturing and supply chain steps for parts |

| Documentation Rigor | Standardized procedures, basic records | Detailed APQP, PPAP, FMEA, control plans, traceability, and change control |

| Customer-Specific Requirements | Handled if defined by contract | Integrated into QMS, mandatory for automotive customers |

| Production Launch Readiness | General process validation | Formal PPAP submission, evidence-based approval for serial production |

How to Read Multi-Site Certificate Scopes

Sounds complex? Here’s what you need to know. Many extrusion suppliers operate multiple sites or have complex value chains. When reviewing a certificate, don’t just check for the logo—look at the details:

- Site Address: Is the physical location that will ship your parts listed?

- Scope Wording: Does it explicitly mention aluminum extrusion, machining, finishing, or other downstream processes?

- Certification Body: Is it an IATF-recognized registrar for automotive programs?

- Expiry Date: Is the certificate current and valid for your production timeline?

For multi-site certificates, make sure the specific plant handling your order is included in the certificate’s scope. If your supplier subcontracts finishing or machining, those processes should be covered as well.

Key insight: A certificate’s scope must explicitly include extrusion and any downstream processes at the site that ships your parts—otherwise, your risk controls may not be as robust as you think.

In summary, choosing between ISO 9001 and IATF 16949 isn’t just a checkbox—it’s about matching your certification requirements to your program’s risk profile and customer expectations. Next, let’s translate these standards into the specific APQP and PPAP deliverables you should expect for aluminum extrusion programs.

APQP and PPAP Essentials for Extrusion Programs

When you’re launching a new aluminum extruding program, the path from concept to serial production is paved with quality gates and deliverables. But what do terms like APQP, PPAP, FMEA, and control plan actually mean for your day-to-day sourcing and how do they help you avoid costly missteps? Let’s break down these automotive quality processes into clear buyer expectations—so you know exactly what to ask for and why it matters.

APQP Milestones Every Extrusion Program Needs

Think of APQP for aluminum extrusion as your structured roadmap for a successful product launch. Advanced Product Quality Planning (APQP) brings together cross-functional teams to plan, assess, and validate every step, ensuring customer requirements are met from the first part to full production (QAD).

- Kick-off & Customer Requirements: Define all technical specs, including drawing reviews and customer-specific requirements (CSR).

- Feasibility Assessment: Evaluate if the extrusion process, tooling, and downstream steps can meet requirements—before investing in dies or machinery.

- Control Plan Draft: Develop a preliminary control plan, mapping out process controls for critical features and risks.

- Tooling Readiness: Complete die design, manufacturing, and validation, ensuring tools are up to spec.

- Pre-Launch Production Run: Run initial batches to validate process stability and product conformity, collecting data for capability studies.

- PPAP Submission: Deliver the full package of evidence to the customer for approval before serial production begins.

Each milestone is a checkpoint where risks are identified and mitigated, not just a box-ticking exercise. Miss one, and you risk delays, rework, or even rejected parts at launch.

PPAP Documentation Checklist for Extrusions

What’s inside a PPAP for aluminum extrusions? The Production Part Approval Process (PPAP) is your proof that the process is robust and repeatable. While the exact submission level may vary, here’s what you should expect in a typical extrusion program (Discus Software):

- Drawing and customer-specific requirements (CSR) review record

- Process flow diagram for extrusion, heat treatment, and finishing

- Process Failure Mode and Effects Analysis (PFMEA)

- Control plan tailored to extrusion and downstream steps

- Material and heat treatment certifications

- Capability studies on critical-to-function dimensions

- Gage R&R / measurement system analysis evidence

- Initial process study summaries

- Appearance approval report (if surface finish is critical)

- Part submission warrant (PSW)

Having these documents in place doesn’t just satisfy a requirement—it gives you insight into process stability, measurement reliability, and the supplier’s attention to detail. Clean, well-organized PPAP documentation also speeds up customer approvals and reduces the risk of launch delays.

FMEA and Control Plan Expectations

If you’ve ever wondered how suppliers anticipate and prevent defects before they reach your line, the answer is FMEA and the control plan. Extrusion control plan FMEA is all about risk analysis: identifying potential failure modes in the extrusion process (like dimensional drift, die wear, or inconsistent heat treatment), then putting controls in place to catch or prevent them (The Center).

For buyers, here’s what to look for:

- PFMEA that covers the full extrusion process, including secondary operations

- Control plan linked directly to the PFMEA, showing controls for each identified risk

- Clear evidence of ongoing monitoring and continuous improvement

First article inspection reports—where the supplier measures initial parts against all specs—should align with the control plan and PPAP data. This objective verification ensures the process window is set correctly before mass production ramps up.

Buyer tip: Align measurement methods and datum schemes with your supplier before capability studies begin. This avoids costly rework and ensures your PPAP data matches your product’s real-world requirements.

By understanding and requesting the right APQP and PPAP deliverables, you de-risk your aluminum extruding program and set the stage for a smoother launch. Up next, we’ll look at how these quality disciplines impact project timelines and where the real payback comes from.

Cost and Timeline Tradeoffs You Should Anticipate

When you’re under pressure to launch a new product, every extra day or dollar in your aluminum extrusion program can feel like a hurdle. So, is all the documentation and discipline that comes with IATF 16949 certification worth the added effort? Let’s dig into what really adds time and cost—and why these investments pay off with fewer disruptions and higher reliability in your extrusion aluminum supply chain.

What Adds Time in Certified Extrusion Projects?

Sounds complex? It can be, but every added step serves a purpose. Certification-driven projects include rigorous planning and validation activities that go beyond basic production. Here’s what typically extends timelines in IATF 16949-certified aluminum extrusion applications:

- Die validation evidence: Proving the die consistently produces profiles within specification before mass production.

- Heat treatment parameter verification: Documenting that every batch meets required temper and strength standards.

- Traceability trials: Ensuring lot traceability from billet to finished profile, which is essential for issue containment and recalls.

- Capability confirmation on critical-to-function dimensions: Running capability studies (Cp, Cpk) and Measurement System Analysis (MSA) to verify that key dimensions are stable and measurement methods are reliable.

- Appearance standard alignment: Aligning on surface finish and cosmetic standards through documented approval samples and inspection routines.

- Pre-launch production runs: Conducting controlled pilot runs to validate process stability before full ramp-up.

- Controlled change management: Implementing formal processes for reviewing and approving any process or design changes, reducing the risk of unexpected variation.

While these steps may add days or even weeks to the project schedule, they are proven to prevent costly launch issues, field failures, and the kind of firefighting that can derail a program.

Common Audit Findings in Extrusion Shops

Ever wondered what auditors actually find when they visit extrusion suppliers? Even experienced shops can stumble on the basics. Here are some typical nonconformities that can delay approvals or trigger corrective actions:

- Incomplete die maintenance records, making it hard to verify tool condition or root cause die-related defects.

- Unclear or missing lot traceability from billet to finished profile, limiting the ability to contain quality issues.

- Inconsistent quench documentation, which can lead to undetected variations in mechanical properties.

- Missing control plan linkages to PFMEA, meaning risks identified in the risk analysis aren’t properly controlled in production.

- Insufficient change control records, increasing the chance of undocumented process shifts or supplier-induced variation.

These findings can stall a program, especially when automotive customers require strict evidence for every process step. By addressing these areas proactively, you’ll notice smoother audits and fewer surprises down the road (InTouch Quality).

Elements of an Effective 8D Response

But what happens if something still goes wrong? That’s where a disciplined problem-solving approach comes in—most notably, the 8D corrective action process. Here’s what automotive customers expect from a robust 8D response when nonconformities are found:

An effective 8D corrective action includes: a clear problem statement tied to evidence, root cause analysis verified with data, immediate containment to protect customers, systemic corrective action linked to control plan updates, verification of effectiveness, and prevention steps that extend to upstream suppliers and future programs (Siemens).

Imagine receiving a batch of extruded profiles with a surface defect. The supplier’s 8D team would:

- Document the problem and affected lots.

- Contain all suspect material to prevent further shipment.

- Analyze why the defect occurred (occur cause) and why it wasn’t caught earlier (escape cause).

- Implement and verify a corrective fix—such as updating die maintenance schedules or inspection routines.

- Update the control plan and PFMEA to ensure the issue doesn’t recur.

- Communicate lessons learned to upstream suppliers or related processes.

This structured approach not only satisfies automotive customer requirements but also builds trust and reduces the risk of repeat issues—key reasons why more buyers are choosing IATF 16949 certified aluminum extrusion suppliers for critical applications.

Understanding these tradeoffs helps you set realistic expectations for timeline and cost, while also appreciating the long-term value of disciplined, certification-driven programs. Next, we’ll explore how to verify a supplier’s certification status and documentation before you issue an RFQ, so you can avoid surprises and build a more resilient supply chain.

Practical Steps to Verify IATF 16949 Certification and Supplier Scope

Ever wondered if a supplier’s IATF 16949 certificate really covers your extrusion program—or if it’s just a logo in the email signature? When you’re under pressure to partner with reliable aluminum extrusion suppliers, a little due diligence up front can save you from costly surprises later. Here’s how to confidently verify certification, interpret scope details, and request the right supplier quality documentation before you issue an RFQ.

Where to Verify IATF Certification Status

First, don’t just take a PDF certificate at face value. The official IATF certified organization directory is your go-to source for verification. This registry lists all valid IATF 16949 certificates worldwide, including the scope of certification, site addresses, certification body, and expiry dates. If a supplier’s certificate isn’t listed here, that’s a red flag—no matter how convincing their paperwork looks.

- Visit the IATF certified organization directory and search by company name or certificate number.

- Check that the site address matches the facility shipping your aluminum extrusions.

- Review the scope wording: Does it specify aluminum extrusion and any secondary processes (machining, finishing) you require?

- Note the certification body and ensure it’s IATF-recognized.

- Confirm the expiry date is valid for your project timeline.

- Request the latest audit report overview or a nonconfidential summary of findings and status.

- Ask for a PPAP sample package—such as a control plan and PFMEA for a similar profile—to assess quality documentation depth.

- Verify that the supplier’s APQP/PPAP process aligns with current AIAG and OEM requirements (especially if you’re supplying major automakers).

How to Interpret Scope, Expiry, and Site Addresses

Sounds overwhelming? Here’s what matters most: the certificate’s scope must explicitly mention aluminum extrusion and any downstream steps performed at the certified site. If the certificate only covers billet casting, or a different plant, your risk controls may be incomplete. Also, check for multi-site certificates—make sure the physical location handling your parts is listed, not just a corporate headquarters or unrelated facility. Expiry dates matter, too; an expired or soon-to-expire certificate could delay your project if the supplier must undergo recertification or address major audit findings.

Documents to Request Before RFQ

Before you send out a request for quote, arm yourself with the right questions and documentation requests. Here’s a buyer’s checklist to ensure you’re covered:

- Verify the IATF 16949 certificate via the official directory and cross-check all site and scope details.

- Request a summary of the last audit report (nonconfidential version) to identify any open findings or improvement actions.

- Ask for a PPAP sample package—control plan, PFMEA, and measurement system analysis for a comparable extrusion profile.

- Confirm the supplier’s APQP/PPAP documentation matches AIAG and customer-specific requirements.

- Inquire about traceability systems and evidence of lot tracking from billet to finished part.

- Unverifiable or missing certificates in the IATF directory

- Mismatched scope (e.g., certificate says "aluminum profiles" but site only does machining)

- Expired or suspended certification status

- Claims of "in progress" certification for active automotive series production

- Reluctance to share sample supplier quality documentation or PPAP evidence

If you spot any of these red flags, pause and dig deeper—don’t risk your launch on unchecked assumptions. As supplier due diligence experts recommend, independent verification and regular re-evaluation are your best defense against costly disruptions (SafeCoze).

Need a quick outreach template? Here’s wording you can copy:

“To support our sourcing process, please provide a copy of your current IATF 16949 certificate (including scope and site address), confirmation of scope coverage for aluminum extrusion and any secondary processes, and representative quality documentation such as a control plan and PFMEA for a similar profile. We also request a summary of your most recent audit findings and status. Thank you for your support.”

By following these steps, you’ll notice greater confidence in your supplier selection and fewer surprises as your program moves from RFQ to PPAP approval. Next, we’ll look at how to translate these verification steps into a transparent, defensible supplier scoring matrix for your team.

A Weighted Scoring Matrix for Supplier Selection

Faced with a stack of RFQs and several promising extrusion suppliers, how do you make a choice that stands up to scrutiny? Relying on gut feeling or the lowest price rarely leads to the best long-term outcome. Instead, imagine having a clear, structured supplier selection matrix—one that helps your team compare apples to apples, document decisions, and justify your final pick with confidence. Let’s explore how a weighted scoring approach can transform your supplier evaluation process for aluminum extrusion programs, especially when PPAP readiness and IATF 16949 discipline are non-negotiable.

Criteria to Score Extrusion Suppliers

Sounds complex? It doesn’t have to be. Start by identifying the key criteria that matter most for your project. These often include quality, delivery, cost, and risk management factors—each mapped to your program’s requirements and customer expectations.

| Criterion | Definition | Suggested Weight Tier | Evidence to Review |

|---|---|---|---|

| Certification Scope Robustness | Does the supplier’s current certificate explicitly cover aluminum extrusion and all downstream processes at the shipping site? | High | IATF 16949 certificate, scope wording, site address |

| Process Capability on Critical Features | Ability to consistently meet key dimensional and surface requirements for your extrusion profiles | High | Capability studies, first article reports, historical data |

| PPAP Readiness | Depth, completeness, and organization of PPAP documentation for similar products | High | Sample control plans, PFMEA, PSW, prior submission records |

| Change Management Discipline | How rigorously process and product changes are documented, approved, and communicated | Medium | Change request logs, approval workflows, version control records |

| Traceability Depth | Extent of lot, material, and process traceability from billet to finished part | High | Traceability matrix, lot tracking reports, barcode/RFID records |

| Lead Time and Logistics Flexibility | Ability to meet required delivery windows and adapt to schedule changes | Medium | Historical on-time delivery data, logistics plans, surge capacity evidence |

| Cost Structure Transparency | Clarity and predictability of pricing, including breakdowns for tooling, material, and secondary operations | Low/Medium | Quotation breakdowns, cost models, escalation clauses |

| Capacity and Surge Ability | Ability to handle volume increases or urgent orders without compromising quality | Medium | Capacity charts, overtime policies, contingency plans |

| Customer-Specific Requirement Compliance | History of meeting unique OEM or Tier 1 requirements (e.g., labeling, packaging, documentation) | High | CSR compliance logs, customer feedback, audit reports |

How to Weight Quality Versus Cost and Delivery

When building your supplier selection matrix, resist the urge to treat all criteria equally. For automotive extrusion programs, quality and PPAP readiness often outweigh cost—because a late or failed launch can erase any savings. Here’s a simple approach:

- Assign “High” weight to criteria that are critical for program success—like certification scope, process capability, traceability, and PPAP documentation.

- Use “Medium” weight for important but less critical factors—such as change management and logistics flexibility.

- Apply “Low” weight to criteria that, while relevant, won’t make or break your launch—such as minor cost differences or non-critical capacity.

Involve cross-functional stakeholders (quality, engineering, purchasing, logistics) to agree on these weightings up front. This ensures your extrusion supplier evaluation criteria reflect both technical needs and business realities (Graphite Connect).

Sample Rationale for Scoring a Shortlist

Scoring is just the start—documenting your rationale is what makes the process transparent and defensible. Here are examples of rationale language you can use for each criterion:

- "Rated High because control plan directly links to PFMEA and historical extrusion capability data are available for similar alloys and wall thicknesses."

- "Rated Medium: Supplier has robust change management, but evidence of recent process escapes requires closer monitoring."

- "Rated Low: Quotation lacks breakdown of tooling and finishing costs, which may impact price predictability."

- "Rated High: Traceability system demonstrated billet-to-finished-part tracking during audit, with barcode scans at each process stage."

- "Rated High: Supplier provided a complete PPAP package for a comparable profile, with all 18 elements documented and approved by a major OEM."

Encourage your team to use specific evidence, not just opinions, and to record narrative justifications for each score. This creates an audit trail for award decisions and helps defend your choice if challenged by stakeholders or customers.

A weighted scoring matrix built on clear extrusion supplier evaluation criteria and documented rationale transforms supplier selection from a guessing game into a transparent, defendable process—one that supports your program’s success from RFQ to PPAP approval.

With your shortlist scored and rationales in place, you’ll be ready to compare supplier types and make a confident, risk-based selection in the next stage.

A Pragmatic Shortlist and Supplier Type Comparison

When you’re ready to act on your supplier evaluation, the next step is translating your weighted scoring matrix into a practical shortlist. But how do you compare different types of extrusion suppliers—and what’s the smartest way to structure your sourcing approach for 2025? Let’s break it down, so you can make confident, risk-based decisions that align with your program’s needs.

Recommended IATF Ready Shortlist for 2025

Not all extrusion suppliers are created equal. Below is a ranked shortlist, starting with a proven IATF 16949 aluminum extrusion supplier that covers the full spectrum of process scope, quality, and launch support:

- Shaoyi Metal Parts Supplier — A leading integrated precision auto metal parts solutions provider in China. Explore their proven aluminum extrusion parts and IATF-aligned launch practices for automotive programs.

- Other IATF 16949 certified extrusion suppliers with strong automotive references and robust process controls.

- ISO 9001-only extrusion suppliers, suitable for non-automotive or early prototype projects where full automotive rigor is not required.

Comparison of Supplier Types

To help you visualize the differences, here’s a comparative table outlining key dimensions for each supplier class:

| Supplier Type | IATF Status | Process Scope Coverage | PPAP Depth | Scalability |

|---|---|---|---|---|

| Shaoyi Metal Parts Supplier | IATF 16949 Certified | Extrusion, Machining, Finishing (Anodizing, Plating, Phosphating) | Full AIAG-compliant PPAP, rapid prototyping, robust documentation | High – Proven with global OEMs, digital production management, surge capacity |

| Other IATF 16949 Certified Suppliers | IATF 16949 Certified | Typically Extrusion, may include Machining/Finishing (varies by supplier) | Full PPAP, though depth and responsiveness may vary | Medium to High – Depends on supplier’s size and experience |

| ISO 9001-Only Suppliers | ISO 9001 Certified | Extrusion, sometimes basic Machining/Finishing | Limited PPAP, may not meet full automotive requirements | Medium – Best for prototypes or non-automotive projects |

When to Pilot with Two Suppliers: Dual Sourcing Strategy

Still not sure which path to take? For high-risk automotive launches, a dual sourcing strategy can be a smart move. By qualifying both a primary and a secondary supplier—ideally in different regions—you hedge against disruptions like capacity shortfalls, logistics delays, or quality escapes (Procurement Tactics). This approach helps maintain a steady flow of compliant parts and keeps both suppliers engaged and ready to scale if needed.

-

Shaoyi Metal Parts Supplier

Pros

- End-to-end IATF 16949 discipline, full process traceability, and rapid PPAP support

- Integrated engineering and digital production management for faster, more reliable launches

- Proven track record with global automotive OEMs; reduces supplier risk

Cons

- May require higher initial engagement for complex, custom projects

-

Other IATF 16949 Certified Suppliers

Pros

- Meet core automotive requirements and offer some flexibility on process scope

- Often locally based for faster logistics

Cons

- Process depth and documentation can vary; may not offer full integration or digital transparency

-

ISO 9001-Only Suppliers

Pros

- Suitable for prototypes or non-automotive programs with lower risk

- Often cost-competitive for basic profiles

Cons

- Lack of automotive-grade controls, limited PPAP, and weaker risk management

- May not meet OEM or Tier 1 requirements for serial production

The right extrusion supplier type should always be matched to your program risk and customer requirements. For automotive launches where quality, traceability, and PPAP discipline are non-negotiable, partnering with a top-tier IATF 16949 aluminum extrusion supplier like Shaoyi drastically reduces launch risk and ensures compliance from day one.

As you finalize your shortlist, keep these distinctions in mind. Next, we’ll equip you with practical RFQ checklists and audit questions to help you take the next step with confidence—whether you’re piloting with one trusted partner or pursuing a dual sourcing strategy for extra resilience.

Practical Tools and Your Next Move

When it’s time to turn your supplier shortlist into a real-world sourcing decision, having the right tools at your fingertips can make all the difference. Ever found yourself wishing for a concise, copy-paste checklist for your aluminum extrusion RFQ, or wondered which audit questions truly separate a certified extrusion supplier from the rest? Let’s break down the essential steps and questions so you can move forward with confidence—no guesswork required.

Copy Paste RFQ Checklist for Extrusion Programs

Before you send out your next RFQ, imagine how much smoother the process will be if you ask for the right details up front. Here’s a practical aluminum extrusion RFQ checklist you can use to ensure suppliers are aligned with your requirements and ready to deliver on APQP PPAP next steps:

- Certificate and scope confirmation (IATF 16949 preferred for automotive, with explicit mention of extrusion and relevant downstream processes)

- Alloy and temper capability (e.g., 6061-T6, 6063-T5, 6005A-T6—match to application needs)

- Tolerance and surface specification feasibility (request evidence of meeting your critical dimensions and finish requirements)

- Heat treatment and finishing process control evidence (oven logs, anodizing/powder coating process records)

- Capability data for similar profiles (historical Cp/Cpk studies, first article inspection reports)

- Measurement method agreement (clarify datum schemes, gage R&R, and inspection frequencies)

- PPAP deliverables commitment (list specific documentation and submission level required)

- Lead time windows and logistics flexibility (standard and expedited options)

- Change control process (request sample change request and approval workflow)

Using this aluminum extrusion RFQ checklist helps you gather apples-to-apples proposals and minimizes costly back-and-forth or surprises during launch (Shengxin Aluminum).

Audit Questions Focused on Extrusion Risks

Ever wondered what to ask on a supplier audit to really get at the heart of extrusion quality and process discipline? Here are actionable extrusion audit questions tailored to the unique risks of aluminum profile production:

- Can you demonstrate billet-to-finished-part traceability for a recent production lot?

- Show evidence of die maintenance scheduling and actual maintenance logs.

- How are quench parameters and cooling rates monitored and recorded?

- What checks are in place for aging oven uniformity and heat treatment certification?

- How do you track, analyze, and reduce scrap and rework rates?

- Provide a recent corrective action report for a nonconforming lot—what was the root cause and systemic fix?

- How do you manage supplier quality for outsourced processes like anodizing or machining?

Asking these targeted extrusion audit questions will help you uncover the depth of your supplier’s quality systems and whether they’re truly ready to serve as a certified extrusion supplier for demanding programs.

Next Steps with a Certified Partner

So, what’s the smart way to move from evaluation to partnership? Here’s a proven path you can follow—whether you’re piloting with one supplier or dual sourcing for added security:

Verify certification and scope, align on APQP/PPAP expectations, pilot a controlled pre-launch run, and award business based on documented evidence of process capability and quality discipline.

This approach ensures you’re not just checking boxes, but building a foundation for reliable supply and fewer launch disruptions.

For an IATF-aligned partner ready to support automotive launches, review Shaoyi Metal Parts Supplier’s aluminum extrusion parts and request program-specific documentation. Their integrated, certified approach can help you de-risk your next extrusion program and streamline your path from RFQ to successful PPAP approval.

Frequently Asked Questions About IATF 16949 Certified Aluminum Extrusion Suppliers

1. What is IATF 16949 certification and why is it important for aluminum extrusion suppliers?

IATF 16949 is a global automotive quality management standard that builds on ISO 9001 with additional requirements for risk management, traceability, and process control. For aluminum extrusion suppliers, this certification ensures robust controls throughout production, minimizes defects, and aligns with strict automotive customer demands. Choosing certified suppliers helps buyers reduce launch risks, meet PPAP requirements, and achieve consistent part quality for automotive programs.

2. How does the aluminum extrusion process benefit from IATF 16949 certified suppliers?

IATF 16949 certified suppliers apply systematic process controls at every stage of aluminum extrusion, from billet preparation to finishing. This discipline prevents common defects, ensures dimensional stability, and guarantees that each part meets required specifications. Buyers benefit from better traceability, cleaner documentation, and fewer production delays, making certification a key factor for reliable automotive launches.

3. How can buyers verify if an aluminum extrusion supplier is truly IATF 16949 certified?

Buyers should check the official IATF certified organization directory to confirm a supplier's certification status, ensuring the site address and scope cover aluminum extrusion and any downstream processes. Requesting recent audit summaries and sample quality documentation, such as control plans and PFMEA, provides further assurance of compliance and process maturity.

4. When is it acceptable to use ISO 9001 certified extrusion suppliers instead of IATF 16949 certified ones?

ISO 9001 certified suppliers may be suitable for non-automotive projects, early prototypes, or when risk is lower and customer-specific requirements are clearly defined. However, for automotive serial production or when PPAP is required, IATF 16949 certification is the industry standard to ensure full compliance, risk reduction, and seamless production part approval.

5. What are the key advantages of partnering with a supplier like Shaoyi Metal Parts Supplier for automotive aluminum extrusions?

Shaoyi Metal Parts Supplier offers a one-stop solution with IATF 16949 certification, ensuring end-to-end process control, rapid prototyping, and full traceability. Their experience with global automotive brands, digital production management, and comprehensive quality processes drastically reduce supply chain risk and help buyers achieve reliable, on-time launches for critical vehicle components.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —