Outsourcing Automotive Forging: A Strategic Cost-Saving Solution

TL;DR

Outsourcing automotive forging is a strategic manufacturing decision where car makers contract external specialists to produce forged metal parts. This approach significantly reduces production costs, provides access to advanced technologies and specialized expertise without major capital investment, and allows automotive original equipment manufacturers (OEMs) to concentrate on their core competencies, such as design, innovation, and assembly.

The Strategic Advantages of Outsourcing Forging for Automotive OEMs

In the highly competitive automotive industry, efficiency, cost-control, and innovation are paramount. Outsourcing automotive forging has emerged as a critical strategy for OEMs looking to gain a competitive edge. By partnering with a specialized supplier, companies can shift from the capital-intensive reality of in-house production to a more flexible and often more cost-effective model. This move is not merely about delegation; it's a strategic decision to leverage external expertise and resources to achieve key business objectives.

One of the most compelling reasons to outsource is significant cost reduction. As noted in a case study by Presrite Corporation, a forging solution for an automotive OEM reduced machining cycle times and costs by up to 67%. Outsourcing eliminates the need for substantial upfront investment in heavy machinery, facility maintenance, and a specialized workforce. External suppliers achieve economies of scale by serving multiple clients, which translates into lower per-unit costs for forged components. This allows OEMs to reallocate capital towards research and development, marketing, and other core activities that drive brand value.

Access to specialized technology and expertise is another primary benefit. Forging is a complex process that requires deep metallurgical knowledge and sophisticated equipment. Top-tier suppliers invest continuously in the latest technologies and employ teams of highly skilled engineers. As VPIC Group highlights, outsourcing provides access to full teams of trained technicians focused on optimizing manufacturing processes, which improves the quality of parts. This ensures that components meet stringent automotive standards for strength, durability, and safety without the OEM bearing the full cost of innovation.

Furthermore, outsourcing enhances production flexibility and capacity. An external partner can scale production up or down in response to market demand, helping OEMs avoid the costs associated with underutilized facilities during downturns or the bottlenecks that occur during production spikes. This agility is crucial in a market characterized by fluctuating consumer preferences and supply chain complexities. By entrusting production to a reliable partner, companies can shorten lead times, maintain appropriate inventory levels, and ultimately focus on what they do best: designing and selling vehicles.

Understanding Key Automotive Forging Processes

Choosing to outsource requires a foundational understanding of the available forging processes, as different automotive components have unique structural and performance requirements. The selection of a specific technique depends on the part's size, complexity, material, and required strength. The primary types of forging include open-die, impression (or closed-die), cold, and seamless rolled ring forging. Each method offers distinct advantages for various automotive applications.

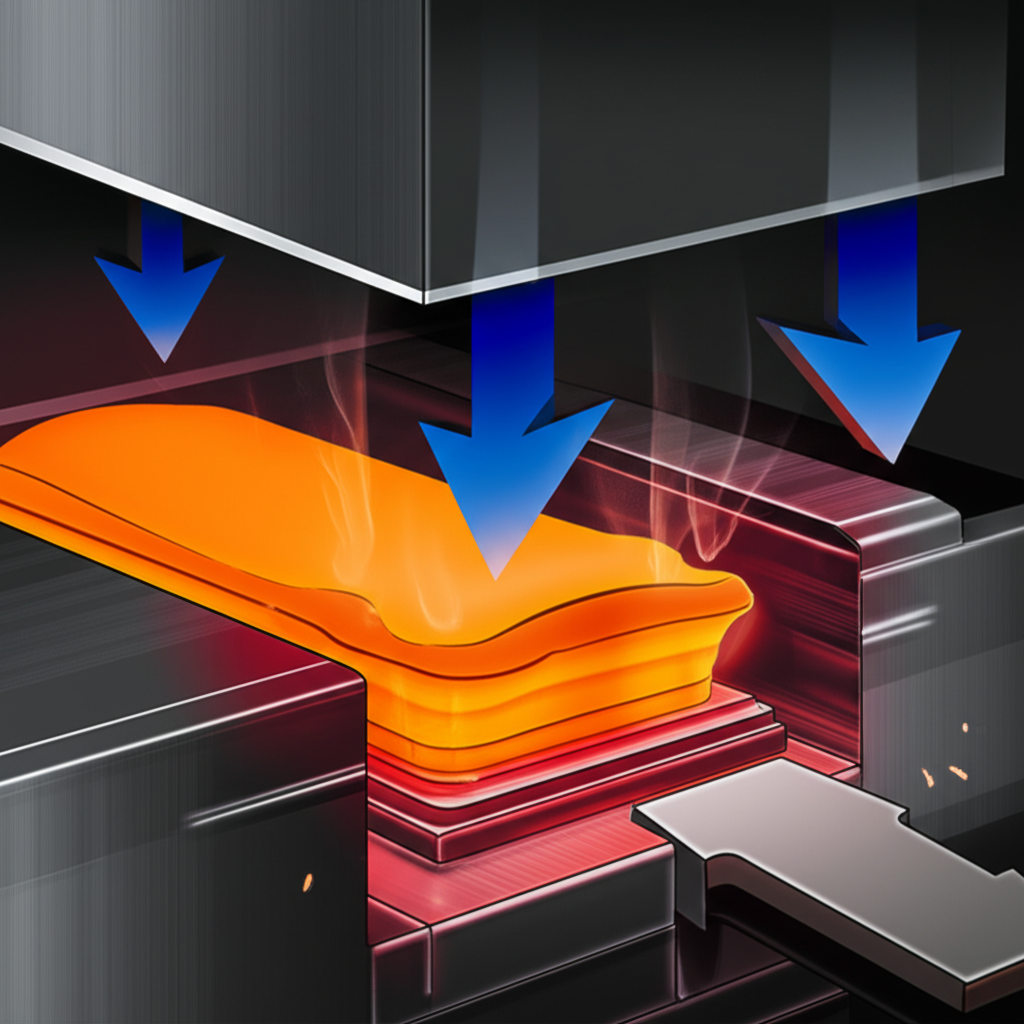

Closed-Die Forging, also known as impression-die forging, is the most common process for automotive components. In this method, heated metal is placed between two dies that contain a precise impression of the final part. As the dies press together, the metal flows and fills the cavity, creating a strong, near-net-shape component with excellent dimensional accuracy. This process is ideal for producing intricate parts like connecting rods, gears, and suspension components where strength and reliability are critical. According to Sun Fast USA, closed-die forging can produce parts ranging from a few ounces to many tons, making it highly versatile for the automotive sector.

Open-Die Forging involves shaping metal between two flat or simply shaped dies that do not fully enclose the workpiece. The process relies on the skilled manipulation of the workpiece by an operator. While less precise than closed-die forging, it is highly effective for large components like axles and shafts or for initial shaping before further machining. It offers greater flexibility for custom or low-volume parts and improves the metal's grain structure, enhancing its strength.

Another key process is Upset Forging, which is particularly suited for creating long parts with a forged end, such as high-strength bolts, engine valves, and piston rods. As explained by Compass & Anvil, this technique involves heating a metal bar and then applying pressure to its end to form a larger, more complex shape. The process maintains the integrity of the component while creating parts that are highly resistant to deformation, making it essential for critical fasteners and powertrain components in vehicles.

How to Select the Right Outsourcing Partner for Automotive Forging

Selecting the right forging supplier is a critical decision that directly impacts product quality, supply chain reliability, and overall cost-effectiveness. A thorough vetting process is essential to establish a successful long-term partnership. OEMs should evaluate potential suppliers based on a clear set of criteria that goes beyond just the price per part.

First, assess the supplier's technical capabilities and specialization. Do they have proven experience with the specific materials (e.g., aluminum, carbon steel, nickel alloys) and forging processes your components require? Review their equipment list, engineering expertise, and portfolio of past projects within the automotive sector. For robust and reliable automotive components, you might consider a specialist like Shaoyi Metal Technology, which offers high-quality hot forging and has in-house die manufacturing to ensure precision from start to finish. Their ability to handle everything from prototypes to mass production demonstrates the kind of comprehensive capability to look for.

Quality control and certifications are non-negotiable. A credible supplier must have a robust quality management system in place. Look for certifications that are critical to the automotive industry, such as IATF 16949, which ensures adherence to the highest standards for quality and continuous improvement. Ask for documentation on their quality assurance processes, including material traceability, in-process inspections, and final part validation. This diligence prevents costly defects and ensures components will perform safely and reliably under demanding conditions.

Finally, evaluate their supply chain and logistics infrastructure. A supplier's ability to deliver high-quality parts on time is paramount. Consider their geographic location, shipping capabilities, and inventory management strategies. A partner with a strategic location and established logistics can help reduce lead times and shipping costs. Analyze their overall value proposition, weighing their technical expertise, quality systems, and logistical support against their pricing to ensure you are securing a partner that contributes to your long-term success, not just short-term savings.

Mitigating the Risks of Outsourcing Manufacturing

While outsourcing automotive forging offers substantial benefits, it is not without potential risks. Acknowledging and proactively managing these challenges is key to a successful partnership. The most common concerns revolve around quality control, communication barriers, intellectual property protection, and supply chain disruptions. A strategic approach can transform these potential liabilities into manageable aspects of the business relationship.

Quality control is a primary concern when production is moved off-site. A negative outcome of outsourcing in auto manufacturing can be a dependency on external partners that leads to quality control issues. To mitigate this, establish clear, detailed quality standards and inspection protocols in your contract from the outset. Regular site audits, third-party inspections, and requiring certifications like IATF 16949 are essential. Implementing a collaborative quality management system where data is shared transparently can help identify and resolve potential issues before they escalate into major problems.

Communication barriers, whether due to language differences, time zones, or cultural norms, can lead to misunderstandings and production delays. Establish a clear communication plan with designated points of contact on both sides. Regular meetings, shared project management tools, and detailed documentation can bridge these gaps. Investing time in building a strong relationship with your supplier fosters a sense of shared purpose and makes navigating challenges much smoother.

Supply chain disruptions are another significant risk, as events like geopolitical instability, natural disasters, or shipping crises can halt production. Diversifying your supplier base, even if it's just having a qualified backup, can provide a crucial safety net. Work with your primary partner to understand their own supply chain vulnerabilities and develop contingency plans. Maintaining a reasonable level of safety stock for critical components can also provide a buffer against unexpected delays, ensuring your assembly lines continue to run smoothly.

Frequently Asked Questions

1. What are the 4 types of forging?

The four main types of forging processes are open-die forging, impression-die forging (also known as closed-die forging), cold forging, and seamless rolled ring forging. Each method is chosen based on the desired shape, size, material, and performance characteristics of the final component.

2. What are the three types of outsourcing?

The three primary types of outsourcing are onshore (hiring a provider in the same country), nearshore (partnering with a company in a neighboring country), and offshore (working with a supplier in a distant country). The choice often depends on a balance of cost, logistics, communication, and strategic goals.

3. What is a negative outcome of outsourcing in auto manufacturing?

A significant negative outcome can be a loss of control over quality and production schedules. Other challenges include dependency on external partners, communication difficulties, potential supply chain disruptions, and risks to intellectual property if not properly managed. These issues can lead to production delays, increased costs, and compromised component quality.

4. Is it cheaper to outsource manufacturing?

Outsourcing manufacturing is often cheaper due to lower labor costs, economies of scale, and avoiding the high capital investment required for specialized equipment and facilities. Specialized suppliers can frequently produce parts more efficiently, leading to reduced overall production costs for the hiring company.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —