Open Die Forging For Large Auto Parts: Where Strength Gets Shaped

What Makes Open Die Forging Essential for Large Auto Parts

When you need automotive components that can withstand punishing loads, relentless vibration, and decades of service, the manufacturing process matters as much as the material itself. For large auto parts like axle shafts, steering knuckles, and heavy-duty drivetrain components, open die forging delivers the structural integrity that keeps vehicles safe and operational under extreme conditions.

Whether you're an automotive engineer specifying materials for a new heavy-duty truck platform, a procurement specialist sourcing reliable suppliers, or a manufacturing decision-maker evaluating production methods, understanding this process helps you make informed choices that impact both performance and bottom-line costs.

The Fundamentals of Open Die Forging Explained

Open die forging, sometimes called free forging or smith forging, shapes heated metal between flat or simple-contoured dies that do not completely enclose the workpiece. Unlike processes that confine metal within a cavity, this method allows the material to flow outward as compressive forces reshape it through repeated hammer or press strokes.

Here's how the process works in practice: An operator positions a heated metal billet between two dies while a hammer or hydraulic press delivers controlled blows. The workpiece is then rotated, repositioned, and struck again. This iterative approach continues until the metal achieves its target dimensions and shape.

What makes this technique particularly valuable for automotive applications? It excels at producing large, robust components that exceed the size limitations of enclosed die cavities. Open die forgings can range from several hundred to thousands of pounds, making the process ideal for oversized drivetrain components, massive axle blanks, and custom suspension parts that simply cannot fit within conventional tooling.

How Open Die Forging Differs from Impression Die Methods

Understanding the distinction between open die and impression die forging helps you select the right approach for your specific application. With impression die forging (also called closed die forging), metal is pressed between two dies that completely enclose the workpiece, forcing material into a precisely shaped cavity.

The key differences affect your manufacturing decisions:

- Part size capability: Open die forging handles substantially larger components that would require prohibitively expensive or physically impossible closed dies

- Tooling investment: Closed die methods require significant upfront investment in custom dies, while open die forging uses simpler, more versatile tooling

- Design flexibility: Open die processes accommodate custom shapes and one-off designs without dedicated die development

- Precision levels: Impression die forging produces near-net shapes with tighter tolerances, whereas open die forgings typically require more post-forging machining

For large automotive components, this tradeoff often favors open die methods. When you're producing axle shafts for commercial trucks, heavy-duty steering components, or specialized drivetrain parts, the ability to create massive, structurally sound blanks outweighs the need for intricate as-forged geometry. The forging process refines the metal's grain structure, improving mechanical properties like toughness and fatigue resistance that are critical for safety-critical automotive applications.

The Open Die Forging Process for Automotive Applications

Ever wondered how a raw steel billet transforms into a massive axle shaft capable of supporting tons of vehicle weight? The open die forging process combines precise thermal control, mechanical force, and skilled craftsmanship to create automotive components with exceptional structural integrity. Understanding each stage helps you appreciate why this method produces superior large auto parts.

Step-by-Step Process Flow for Automotive Forgings

The open die forge operation follows a carefully orchestrated sequence that progressively shapes metal into its final form. Each step builds upon the previous one, refining both dimensions and internal grain structure.

- Heating the Material: The process begins when operators load a billet or ingot into a high-temperature furnace. For automotive-grade steel alloys, temperatures typically reach between 2,000°F and 2,300°F, making the metal malleable enough for deformation. Uniform heating throughout the workpiece is critical—any cold spots can cause cracking or inconsistent material properties in the finished component.

- Positioning on the Die: Once the billet reaches optimal forging temperature, operators transfer it to the open forging station using manipulators or cranes. The heated workpiece is placed on a flat or simple-contoured bottom die, precisely aligned for the first series of blows. For large automotive components, this positioning requires coordination between equipment operators and material handlers.

- Incremental Forging: A hydraulic press or programmable hammer delivers controlled compressive forces to the workpiece. Unlike closed die methods that shape metal in a single stroke, open forging applies multiple successive blows. Each impact displaces material outward, gradually elongating and shaping the billet toward target dimensions.

- Rotation and Repositioning: Between forging passes, operators rotate the workpiece—typically 90 degrees—and reposition it for the next series of blows. This rotation ensures uniform deformation throughout the material and prevents localized stress concentrations. For cylindrical automotive parts like drive shafts and axle blanks, this step creates consistent cross-sectional properties.

- Finishing Operations: After achieving approximate final dimensions, the forging undergoes controlled cooling. Post-forging processes often include heat treatment to optimize mechanical properties, followed by machining to meet precise automotive specifications.

Critical Temperature and Deformation Controls

Why does temperature control matter so much during the open die forging process? When steel is heated to its forging range, the crystalline grain structure becomes plastic and can be reshaped without fracturing. Maintaining proper temperature throughout multiple deformation passes ensures the metal remains workable while the forging action refines its internal structure.

Skilled operators monitor several key variables during each forging cycle:

- Workpiece temperature: Visual inspection and pyrometers track surface temperature, with reheating applied when the material cools below effective forging range

- Deformation rate: Controlled hammer or press speeds prevent surface cracking while maximizing grain refinement

- Reduction ratio: The degree of material displacement per pass affects both dimensional accuracy and mechanical property development

- Die contact time: Minimizing contact between hot metal and cooler dies reduces surface chilling that can cause defects

Modern open die forge facilities combine operator expertise with programmable hammers and hydraulic presses. These systems deliver consistent force profiles across thousands of pounds of striking power, enabling repeatable results on oversized automotive components. The operator's role shifts from purely manual control to supervising automated sequences while making real-time adjustments based on workpiece behavior.

This iterative approach is particularly suited for components exceeding typical closed die size limitations. Imagine trying to create a closed die cavity large enough for a commercial truck axle blank weighing 2,000 pounds—the tooling costs would be astronomical, and the press capacity requirements would limit your supplier options significantly. Open forging sidesteps these constraints entirely, shaping massive automotive parts through progressive deformation rather than single-stroke enclosure.

With a clear picture of how the forging process transforms raw material into shaped blanks, you're ready to explore the metallurgical advantages that make these components outperform alternatives in demanding automotive applications.

Metallurgical Advantages That Enhance Automotive Performance

What happens inside the metal during die forging that makes these components so remarkably strong? The answer lies beneath the surface—literally. When you examine a forged automotive part at the microscopic level, you'll discover a refined internal structure that sets it apart from cast or machined alternatives. This metallurgical transformation is why engineers specify die forged components for applications where failure simply isn't an option.

The forging process doesn't just reshape metal externally. It fundamentally reorganizes the material's crystalline structure, eliminating defects and creating directional properties that align with how the part will actually experience stress in service. For suspension components, drive shafts, and heavy-duty axles, these internal improvements translate directly to longer service life and enhanced safety margins.

Grain Structure Benefits for Fatigue Resistance

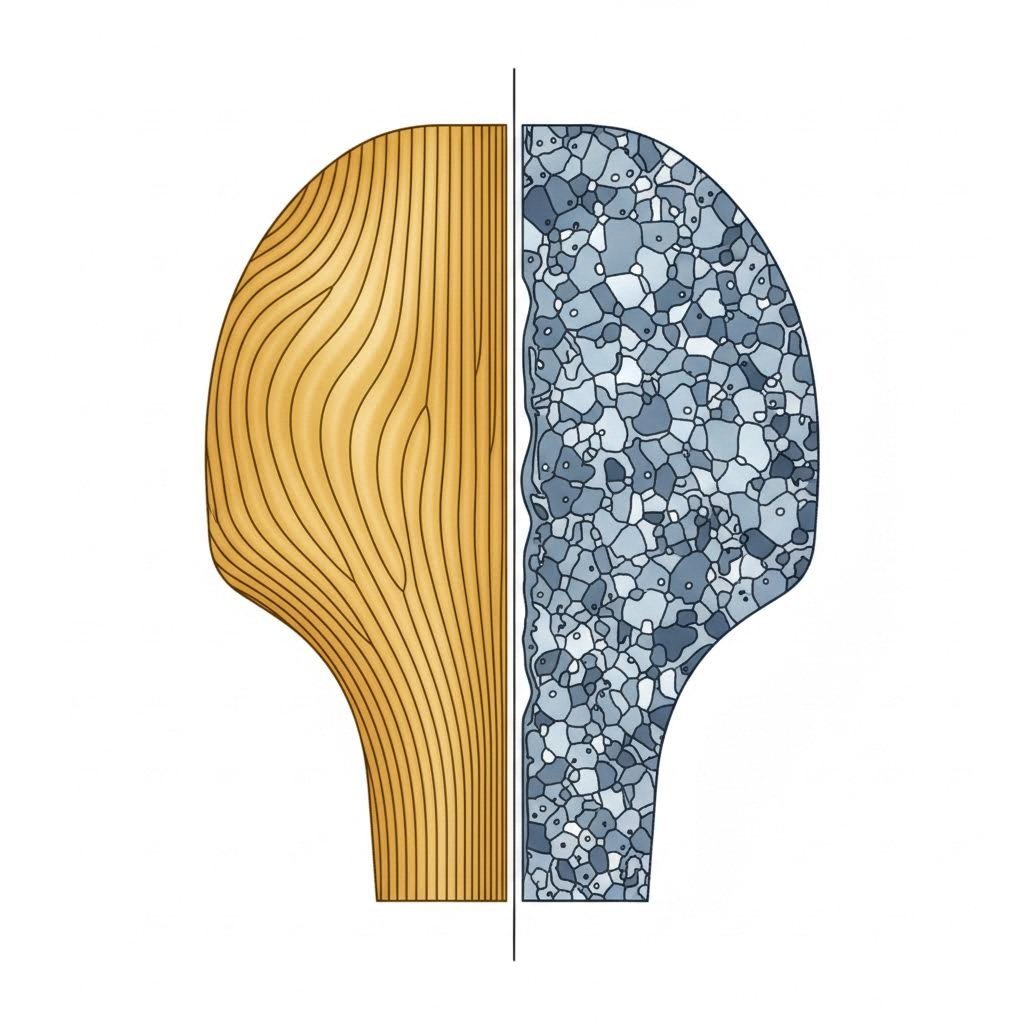

Imagine the internal structure of metal as a bundle of fibers, similar to wood grain. In die forging, controlled deformation aligns these "fibers"—the grain flow—in directions that maximize strength where the component needs it most. According to forging industry research, this directional alignment produces greater metallurgical soundness and improved mechanical properties throughout the material.

Here's what makes grain flow alignment so valuable for automotive applications:

- Continuous grain orientation: The forging action flows grain structure around contours rather than cutting through it, maintaining uninterrupted fiber patterns that resist crack propagation

- Refined grain size: Repeated deformation breaks down coarse grain structures into finer, more uniform crystals that improve toughness and ductility

- Eliminated porosity: The compressive forces of forging collapse internal voids and gas pockets that form during initial metal solidification

- Reduced inclusions: Pre-working during the forging process disperses and minimizes non-metallic inclusions that could act as stress concentrators

Why does this matter for fatigue resistance specifically? Automotive components experience millions of loading cycles during their service life. Every time a truck hits a pothole or a suspension arm absorbs road impact, microscopic stresses accumulate at any internal defect. Closed die forgings and open die forgings both benefit from grain refinement that eliminates the initiation points where fatigue cracks typically begin.

The difference becomes dramatic under cyclic loading conditions. Components with properly aligned grain flow can withstand significantly more stress cycles before failure compared to parts with random or interrupted grain patterns. For safety-critical applications like steering knuckles and axle shafts, this enhanced fatigue life provides the reliability margin that keeps vehicles operating safely.

Why Forged Parts Outperform Cast Alternatives

When comparing manufacturing methods for large automotive components, the contrast between forged and cast parts becomes strikingly clear. Casting produces parts by pouring molten metal into molds, where it solidifies into shape. While this approach offers design flexibility, it cannot match the mechanical properties that die forged components deliver.

The fundamental difference? Cast parts have no grain flow or directional strength. As metallurgical comparisons demonstrate, the solidification process in casting creates random crystal orientation and often traps porosity within the material. Forging, by contrast, pre-works the material to refine internal defects and deliberately orients grain structure for maximum performance.

Consider these specific mechanical property improvements that die forged automotive components provide:

- Superior impact strength: The refined grain structure absorbs shock loads without brittle fracture, critical for components experiencing sudden impacts

- Enhanced load-bearing capacity: Continuous grain flow distributes applied forces throughout the material rather than concentrating stress at weak points

- Improved ductility: Forged components can deform slightly under extreme overload conditions rather than cracking suddenly—a vital safety characteristic

- Better response to heat treatment: The uniform, refined microstructure of forgings responds more consistently to post-forging heat treatment, achieving predictable hardness and strength levels

- Higher reliability over component life: Fewer internal defects mean fewer potential failure initiation sites, resulting in more dependable long-term performance

For automotive engineers specifying materials for heavy-duty applications, these advantages justify the forging process even when casting might appear less expensive initially. A cast axle housing that fails prematurely costs far more in warranty claims, vehicle downtime, and potential safety incidents than the upfront investment in properly die forged components.

The performance gap widens further when you consider real-world operating conditions. Drive shafts transmitting hundreds of horsepower experience torsional fatigue with every acceleration and deceleration cycle. Suspension components absorb continuous impact loading from road surfaces. Heavy-duty axles support massive static loads while simultaneously handling dynamic forces during braking and cornering. In each case, the metallurgical advantages of forging provide the performance margin that separates reliable components from premature failures.

Understanding these material science fundamentals helps you appreciate why the forging process remains the preferred manufacturing method for safety-critical automotive parts—and why selecting the right steel grade and heat treatment protocol further optimizes these inherent advantages.

Material Selection and Steel Grades for Auto Part Forgings

You've seen how the forging process transforms raw billets into structurally superior components. But here's the reality: even the most refined grain structure won't deliver optimal performance if you've selected the wrong base material. Choosing the right steel grade for your forging die application is where metallurgical science meets real-world engineering requirements.

For automotive engineers and procurement specialists, material selection directly impacts component durability, manufacturing costs, and compliance with OEM specifications. The steel grade you specify determines not just initial strength, but how the part responds to heat treatment, how easily it machines to final dimensions, and ultimately how it performs under decades of service stress.

Steel Grade Selection for Automotive Durability

What makes certain alloy steels ideal for automotive open die forgings? The answer lies in their alloying elements—chromium, molybdenum, nickel, and vanadium—that enhance hardenability, toughness, and wear resistance beyond what plain carbon steels can achieve. According to industry specialists, Alloy Steel 4140 is the most commonly used material for open die forging applications, though several grades serve specific automotive needs.

When evaluating forging dies and the materials they'll shape, consider how each steel grade balances these critical factors:

- Tensile and yield strength: Higher strength grades support greater loads but may sacrifice ductility

- Hardenability: Deeper hardening capability ensures consistent properties throughout thick cross-sections

- Fatigue resistance: Critical for components experiencing cyclic loading during vehicle operation

- Machinability: Affects post-forging processing time and costs at your machine shop

- Weldability: Important if the component requires subsequent joining operations

The following table compares common steel grades used in automotive forge die applications, helping you match material properties to your specific component requirements:

| Steel Grade | Typical Automotive Applications | Key Properties | Heat Treatment Requirements |

|---|---|---|---|

| 4140 | Axle shafts, steering components, crankshafts, connecting rods | Good toughness, high fatigue strength, excellent hardenability through thick sections | Normalize and temper or quench and temper; typical pre-hardened range of 28-32 HRC or as specified per heat treatment |

| 4340 | Heavy-duty axles, high-stress drivetrain components, aircraft-quality automotive parts | Superior toughness and fatigue resistance, deep hardening capability, high impact strength | Quench and temper; can achieve 40-44 HRC while maintaining ductility |

| 4150 | Drive shafts, transmission shafts, high-load gears | Higher carbon content for increased surface hardness, good wear resistance | Quench and temper; surface hardness up to 50 HRC possible |

| 4130 | Suspension components, brackets, moderate-stress structural parts | Excellent weldability, good strength-to-weight ratio, easier machinability | Normalize or normalize and temper; 20-25 HRC (or 90-100 HRB) typical |

| 8620 | Gears, pinions, camshafts requiring case hardening | Low carbon core for toughness, carburizes well for hard wear-resistant surface | Carburize, quench, and temper; 58-62 HRC surface with tough core |

Notice how the alloying elements in each grade serve specific purposes. Chromium and molybdenum in the 41xx series improve hardenability and high-temperature strength. The added nickel in 4340 significantly enhances toughness and impact resistance—making it the preferred choice when you need maximum fatigue performance in safety-critical applications. As metallurgical data confirms, elements like nickel and manganese increase toughness, while chromium and molybdenum increase tensile strength and heat resistance.

Heat Treatment Protocols for Optimal Performance

Selecting the right steel grade is only half the equation. The heat treatment you specify determines how those alloying elements translate into actual mechanical properties in your finished component. Think of heat treatment as the final tuning step that unlocks the full potential of your forged material.

According to heat treatment specialists, these processes modify the physical and mechanical properties of steel without altering the part's shape. For automotive forgings, the primary goals are increasing surface strength and wear resistance while maintaining core toughness.

The most common heat treatment sequences for automotive open die forgings include:

- Normalizing: Heating the forging to 830-950°C followed by air cooling refines the grain structure and relieves internal stresses from the forging operation. This process creates a uniform microstructure that improves machinability and prepares the part for subsequent hardening treatments.

- Quenching and Tempering: The workpiece is heated to austenitizing temperature, then rapidly cooled in water or oil to create maximum hardness. Subsequent tempering at controlled temperatures reduces brittleness while retaining strength—achieving the balance between hardness and toughness that automotive applications demand.

- Normalizing and Tempering: A less aggressive approach that provides moderate hardness with excellent toughness. Often specified when extreme hardness isn't required but consistent mechanical properties throughout the cross-section are essential.

The heat treatment you choose directly affects both performance and cost. Quenching and tempering produces higher strength levels but requires more process control and can introduce distortion that increases machining allowances. Normalizing is less expensive but achieves lower hardness ranges—typically 163-300 BHN depending on grade and section size.

OEM Specification Requirements and Material Certifications

When supplying forgings to automotive OEMs, material selection extends beyond mechanical properties to encompass comprehensive documentation and traceability requirements. Every steel grade must meet industry standard specifications including AISI, ASTM, SAE, and international equivalents that define chemistry, mechanical properties, and testing protocols.

What documentation should you expect with automotive-grade forgings? Material certifications typically include:

- Chemical analysis certificates verifying alloy composition

- Mechanical test reports documenting tensile strength, yield strength, elongation, and reduction of area

- Hardness certifications confirming heat treatment effectiveness

- Heat lot traceability linking each forging to its source material

- Non-destructive testing reports when specified

These certifications integrate directly with automotive quality systems, providing the documentation trail that tier suppliers need for IATF 16949 compliance. Your forging supplier should maintain ISO 9001 or AS9100 quality systems that ensure consistent material handling from raw material receipt through final shipment.

Material choice also affects your total project economics beyond the per-pound steel cost. Higher-alloy grades like 4340 cost more than 4140, but their superior properties may allow lighter-weight designs or extended service intervals that offset the initial premium. Similarly, grades with better machinability reduce secondary processing costs at your machine shop. The right selection balances material cost, processing efficiency, and in-service performance requirements for your specific application.

With your material grade and heat treatment specified, the next critical step involves ensuring your forging supplier meets the rigorous quality standards that automotive OEMs demand throughout the manufacturing process.

Quality Standards and Certifications for Automotive Forgings

Sounds complex? When you're supplying forged components to automotive OEMs, quality isn't just a checkbox—it's an entire ecosystem of standards, documentation, and verification processes that trace every part from raw material to final installation. For open die forging companies serving the automotive sector, meeting these requirements separates qualified suppliers from those who simply cannot participate in this demanding market.

Modern vehicles contain over 30,000 parts sourced from hundreds of suppliers across multiple countries. A single faulty component can trigger widespread recalls, safety hazards, and significant reputational damage. That's why the automotive industry has developed rigorous quality frameworks that every open die forging company must navigate to maintain supplier status with major manufacturers.

IATF 16949 Compliance in Forging Operations

When automotive engineers evaluate potential forging suppliers, IATF 16949 certification is often the first qualification hurdle. This international standard builds upon ISO 9001 foundations while adding automotive-specific requirements for defect prevention, waste reduction, and continuous improvement throughout the supply chain.

What does IATF 16949 compliance actually mean for open die forging operations? The standard mandates comprehensive quality management systems that cover every aspect of production:

- Process control documentation: Detailed work instructions for each forging operation, including heating parameters, deformation sequences, and cooling protocols

- Measurement system analysis: Validation that inspection equipment and methods provide accurate, repeatable results

- Statistical process control: Ongoing monitoring of critical dimensions and properties to detect variation before it produces nonconforming parts

- Corrective and preventive action: Systematic approaches to identify root causes of quality issues and implement permanent solutions

- Internal auditing: Regular assessments ensuring quality systems remain effective and aligned with customer requirements

For closed die forged parts and open die forgings alike, IATF 16949 compliance demonstrates that a supplier has implemented the systematic controls automotive OEMs require. Certification involves rigorous third-party audits that verify not just documentation, but actual shop floor practices and results.

Meeting OEM Quality Specifications

Beyond industry-wide standards, each automotive OEM maintains proprietary quality specifications that suppliers must satisfy. These customer-specific requirements often exceed baseline IATF standards, reflecting each manufacturer's unique engineering philosophies and historical quality priorities.

Imagine you're a tier supplier providing forged axle blanks to a major truck manufacturer. You'll need to demonstrate compliance with their specific:

- Material specifications defining acceptable chemistry ranges and mechanical property targets

- Process approval requirements including production part approval process (PPAP) documentation

- Inspection protocols specifying measurement techniques, sampling frequencies, and acceptance criteria

- Packaging and shipping standards protecting parts during transit

- Supplier portal systems for electronic data exchange and quality reporting

Meeting these varied requirements demands flexibility and robust quality infrastructure. An open die forging company serving multiple automotive customers must maintain parallel documentation systems while ensuring consistent manufacturing excellence across all programs.

The Complete Documentation Trail

Traceability—the ability to track every component back to its origins—has become a regulatory necessity in automotive manufacturing. As industry analysts note, digital traceability helps ensure automated compliance, simplifies audits, and provides proof-of-origin documentation that protects both suppliers and OEMs.

For open die forgings, the documentation trail begins before the first hammer blow and extends through final customer delivery. Critical quality checkpoints include:

- Incoming material verification: Chemical analysis certificates, mechanical test reports, and heat lot identification confirm raw materials meet specifications before processing begins

- In-process dimensional checks: Measurements during and after forging operations verify that parts remain within tolerance as they progress through manufacturing

- Non-destructive testing: Ultrasonic, magnetic particle, or liquid penetrant inspections detect internal or surface defects invisible to visual examination

- Mechanical property validation: Tensile testing, hardness measurements, and impact testing on sample pieces confirm heat treatment achieved target properties

- Final documentation packages: Complete certification packages accompanying shipments include material certs, dimensional reports, NDT results, and any customer-required attestations

This traceability infrastructure delivers measurable benefits beyond compliance. When field issues arise, manufacturers can limit recall scope to specific production lots rather than entire product lines—potentially saving millions in containment costs. Root cause analysis connects field failures to specific component batches, enabling faster corrective action.

Statistical Process Control for Automotive Customers

You'll notice that automotive OEMs don't just want inspection reports—they want evidence that your processes consistently produce conforming parts. Statistical process control (SPC) provides this evidence by tracking variation in critical characteristics over time and triggering intervention before nonconformances occur.

For open die forging operations, SPC typically monitors:

- Critical dimensions at key process stages

- Forging temperature consistency

- Heat treatment results including hardness distribution

- Surface quality indicators

Process capability indices (Cpk values) quantify how well your process performs relative to specification limits. Most automotive OEMs require minimum Cpk values of 1.33 or higher for critical characteristics, demonstrating that normal process variation stays well within acceptable bounds. Achieving and maintaining these capability levels requires disciplined process control, regular equipment calibration, and prompt response to any signals of increasing variation.

Working with IATF 16949-certified suppliers like Shaoyi (Ningbo) Metal Technology ensures your forged components meet these rigorous automotive quality standards from initial prototyping through high-volume production. With your quality framework established, the next consideration involves determining whether open die forging is the optimal manufacturing method for your specific large component application.

Choosing Open Die Forging Versus Alternative Methods

When you're specifying manufacturing methods for large automotive components, the decision extends far beyond simple cost comparisons. Should you choose open-die forging, closed die methods, casting, or machining from solid stock? Each approach offers distinct advantages depending on your part size, production volume, performance requirements, and budget constraints.

Making the right choice requires understanding where each method excels—and where it falls short. A manufacturing approach that's perfect for prototype steering knuckles might prove economically disastrous for high-volume axle production. Conversely, the method that dominates at 50,000 units annually could be completely impractical for specialty low-volume applications.

When to Choose Open Die Over Closed Die Forging

The fundamental question many engineers face: when does open-die forging make more sense than impression die methods? The answer typically comes down to three interconnected factors—part size, production volume, and tooling economics.

Open die forging becomes the clear choice when:

- Component dimensions exceed closed die capabilities: Parts weighing hundreds to thousands of pounds simply cannot fit within economically feasible enclosed die cavities. Commercial truck axle blanks, large marine drivetrain components, and oversized industrial vehicle parts often default to open die methods by necessity.

- Production volumes remain relatively low: When you're producing fewer than several hundred pieces annually, the tooling investment for closed dies rarely justifies itself. Open die forging's simpler tooling spreads costs more favorably across limited production runs.

- Design flexibility matters: Prototype development, custom specifications, and one-off engineering projects benefit from open die forging's adaptability. You can adjust dimensions between forgings without scrapping expensive dedicated dies.

- Cross-sectional simplicity prevails: Round, square, or rectangular profiles with gradual transitions suit open die methods perfectly. Complex near-net shapes with intricate features favor closed die approaches.

Closed die forging wins when you need tight as-forged tolerances, complex geometry, or production volumes reaching into the thousands. According to manufacturing economics research, closed-die forging becomes competitive in the low thousands of units as tooling costs amortize across higher volumes.

For specialty automotive applications—think custom performance vehicles, low-volume commercial platforms, or aftermarket heavy-duty components—open-die forging often provides the optimal balance between metallurgical quality and economic practicality.

Cost-Benefit Analysis for Large Component Production

Understanding manufacturing economics helps you make informed sourcing decisions. The total cost equation for any forging method includes tooling investment, per-piece processing costs, material utilization, and post-forging machining requirements.

Here's a critical insight: the cheapest method at 100 units might be the most expensive at 10,000 units. Your production volume fundamentally shifts which approach delivers the best value.

The following comparison table helps you evaluate manufacturing methods across key decision factors:

| Manufacturing Method | Ideal Part Size Range | Tooling Costs | Per-Piece Cost Trend by Volume | Best Applications |

|---|---|---|---|---|

| Open Die Forging | 50 lbs to 10,000+ lbs | Low ($5,000-$25,000 for simple dies) | Moderate at low volumes; less competitive at high volumes | Large axle shafts, heavy drivetrain blanks, prototype components, custom low-volume parts |

| Closed Die Forging | Under 50 lbs typical; up to several hundred lbs | High ($50,000-$500,000+ for complex dies) | High at low volumes; most competitive at 5,000+ units | Connecting rods, crankshafts, gears, high-volume suspension components |

| Casting | Ounces to several tons | Moderate ($10,000-$100,000 for molds) | Competitive at low-medium volumes; varies by complexity | Complex housings, engine blocks, transmission cases, decorative components |

| Machining from Solid | Limited by bar/plate stock availability | Minimal (programming and fixtures only) | Very high per piece; practical only for prototypes or very small quantities | Prototypes, one-off replacements, small precision parts where forging isn't justified |

Notice how the economics shift dramatically with volume. At 50 units, machining from solid or open-die forging likely wins on total cost despite higher per-piece expenses, simply because you avoid major tooling investments. At 50,000 units, closed die forging's lower per-piece costs overwhelm its tooling premium.

Break-Even Points and Volume Considerations

Where exactly do these methods cross over economically? While specific break-even points depend on part complexity, material costs, and supplier capabilities, general guidelines help frame your analysis:

- Open die vs. closed die forging: For moderately complex automotive components, closed die methods typically become more economical somewhere between 500 and 2,000 units annually. Larger parts push this break-even higher; simpler geometries lower it.

- Forging vs. casting: When mechanical properties drive the decision, forgings justify their premium even at lower volumes. As comparative studies indicate, forged parts often exhibit around 26% higher tensile strength and 37% higher fatigue strength than cast equivalents—performance advantages that matter for safety-critical automotive applications.

- Forging vs. machining from stock: Unless you're producing fewer than 10-20 pieces, forging almost always proves more economical than hogging material from solid bar or plate. The material waste in machining—often 50-80% of starting weight—makes this approach impractical for production quantities.

How Part Geometry Influences Method Selection

Beyond volume and cost, your component's shape plays a decisive role in method selection. Think about what the die forge process can achieve versus what requires alternative approaches.

Open-die forging excels with:

- Cylindrical or prismatic shapes (shafts, bars, blocks)

- Stepped profiles with gradual transitions

- Parts where subsequent machining defines final geometry

- Components requiring maximum grain flow orientation control

Consider closed die methods when your design includes:

- Complex three-dimensional contours

- Thin webs, ribs, or intricate features

- Near-net shapes minimizing machining requirements

- Tight as-forged dimensional tolerances

Casting becomes attractive when geometry complexity reaches levels impractical for any forging method—internal passages, hollow sections, or extremely intricate external features. However, remember the performance tradeoff: cast parts generally have inferior mechanical properties compared to forged ones due to internal porosity and weaker grain structure.

Guidance for Commercial Vehicle and Specialty Applications

For heavy-duty commercial vehicle applications—Class 7 and 8 trucks, construction equipment, agricultural machinery—open-die forging frequently emerges as the optimal choice. These applications typically feature:

- Large component sizes exceeding closed die practicality

- Moderate annual volumes (hundreds to low thousands)

- Demanding fatigue and impact requirements

- Long product lifecycles justifying premium manufacturing methods

Specialty automotive uses—racing components, custom performance vehicles, restoration parts, prototype development—similarly favor open-die forging's flexibility. When you're forging small parts quantities or developing new designs, the ability to iterate without major tooling investments accelerates development timelines.

The bottom line? Match your manufacturing method to your specific combination of size, volume, geometry, and performance requirements. Open-die forging delivers exceptional value for large automotive components produced in quantities where closed die tooling investments cannot be justified—while still providing the superior metallurgical properties that set forgings apart from cast alternatives.

With your manufacturing method selected, understanding the dimensional capabilities and tolerance expectations helps you specify appropriate requirements for your forging supplier.

Technical Specifications and Dimensional Capabilities

What size and weight ranges can open die forging actually handle for automotive applications? When you're specifying large drivetrain components or heavy-duty axle blanks, understanding the practical limits of the process helps you set realistic expectations and communicate effectively with your forging supplier.

The open die forging specifications for automotive work span an impressive range—from components weighing a few hundred pounds to massive forgings exceeding 70,000 pounds. According to industry capability data, leading forging facilities can produce shafts up to 57 feet in length, discs reaching 135 inches in diameter, and milled forgings with cross-sections approaching 3,700 square inches. These automotive forging capabilities far exceed what closed die methods can economically achieve.

Size and Weight Capabilities for Auto Components

Imagine you're sourcing forged blanks for commercial truck axles or heavy equipment drivetrain components. The physical dimensions you can specify depend on both the forging equipment capacity and the specific part geometry you need. Here's what modern open die forging facilities can deliver:

| Forging Type | Minimum Dimensions | Maximum Dimensions | Weight Range |

|---|---|---|---|

| Solid Bars | 6 in. (152 mm) diameter | Various lengths based on weight | 1,500 lbs minimum (682 kg) |

| Shafts/Eccentrics | 6.25 in. (160 mm) diameter | 57 ft. length (17,400 mm); 70 in. diameter (1,800 mm) | 10,000 - 60,000 lbs (4,536 - 27,215 kg) |

| Milled Forgings | 6 in. (152 mm) width/thickness | 40 ft. length (12,192 mm); 140 in. max cross-section dimension | 4,000 - 70,000 lbs (1,814 - 31,800 kg) |

| Hollow Forgings (Sleeves) | 3 in. (76 mm) wall thickness minimum | 72 in. OD (1,828 mm) | 10,000 - 70,000 lbs (4,540 - 31,800 kg) |

| Discs | 7 in. (178 mm) thickness | 135 in. diameter (3,429 mm) | 10,000 - 70,000 lbs (4,540 - 31,800 kg) |

Notice the length-to-diameter ratios achievable with shaft forgings. A 57-foot shaft with diameters up to 70 inches demonstrates the process flexibility that makes open die forging essential for oversized automotive and industrial components. These ratios would be physically impossible to achieve with closed die methods, where cavity depth and press capacity impose strict geometric limits.

For typical automotive applications, you'll most commonly specify forgings in the 500 to 5,000 pound range—axle blanks, large steering components, and drivetrain elements that require substantial material cross-sections for strength while remaining within practical handling limits.

Tolerance Expectations and Surface Finish Standards

Here's a reality check that every automotive engineer needs to understand: open die forgings are blanks, not finished parts. The as-forged dimensions include machining allowances that get removed during subsequent finishing operations. Forging dimensional tolerances reflect this reality—they're intentionally looser than final part specifications because the forging serves as raw material for precision machining.

According to DIN 7527 standards, machining allowances and permissible variations for open die forged bars apply to parts up to 1000 mm in thickness or width and 6000 mm in length. These standards define the relationship between forging dimensions and finished dimensions, ensuring adequate material remains for final machining while minimizing waste.

What tolerance ranges should you expect before machining? Standard practice for open die automotive forgings typically includes:

- Diameter tolerances: +/- 1% to 3% of nominal dimension, depending on size and cross-section

- Length tolerances: +/- 0.5 to 1 inch on shorter forgings; proportionally larger on extended lengths

- Straightness: 0.1 to 0.25 inches per foot of length for shaft-type components

- Surface finish: As-forged surfaces typically range from 250 to 500 microinches Ra; machined surfaces achieve 32-125 microinches Ra

The machining allowance you specify directly affects both forging cost and machining time. Too little allowance risks exposing forging scale or surface defects in your finished part. Too much allowance wastes material and increases machining hours. For most automotive applications, machining allowances of 0.25 to 0.50 inches per side on critical surfaces provide adequate cleanup margin without excessive waste.

When planning your forging specifications, communicate both the as-forged dimensions you need and the final machined dimensions you're targeting. This allows your forging supplier to optimize the starting billet size and forging sequence, ensuring adequate material throughout while minimizing the blank weight you're purchasing. Understanding these dimensional relationships from the outset streamlines the complete lifecycle from initial design through production integration.

Complete Lifecycle From Design Through Production

You've selected open die forging as your manufacturing method and understand the dimensional capabilities available. But how do you actually move from a concept sketch to production-ready components installed in vehicles? The journey from initial design requirements through forging to final integration involves multiple interconnected stages—each requiring careful coordination between your engineering team and forging partners.

Successfully navigating this lifecycle separates projects that deliver on time and on budget from those plagued by delays, rework, and cost overruns. Whether you're developing heavy-duty axle shafts for a new truck platform or prototyping custom drivetrain components, understanding each phase helps you anticipate challenges and accelerate your development timeline.

Design Considerations for Forgeable Geometries

Ever designed a beautiful component only to discover it couldn't be economically forged? Design-for-forging principles prevent this frustration by aligning your engineering requirements with manufacturing realities from the earliest concept stages.

When developing geometries for open die forging, keep these forging design guidelines in mind:

- Favor gradual transitions: Sharp corners and abrupt cross-section changes create stress concentrations during forging and in service. Generous radii and tapered transitions improve material flow and final part performance.

- Consider grain flow direction: Orient your design so the forging process aligns grain structure with primary load paths. An axle shaft's grain should run longitudinally, parallel to applied torsional and bending stresses.

- Allow adequate machining stock: As-forged surfaces require cleanup. Design your blank dimensions with 0.25 to 0.50 inches of additional material on surfaces requiring precision machining.

- Minimize aspect ratio extremes: While open die forging handles impressive length-to-diameter ratios, extremely long thin sections or very flat wide shapes increase forging difficulty and cost.

- Simplify where possible: Features like undercuts, internal cavities, or intricate external profiles should be machined after forging rather than formed during the forging operation.

The fundamental question to ask: does this geometry work with progressive deformation between flat or simple-contoured dies? If your design requires metal to flow into enclosed cavities or form complex three-dimensional shapes during forging, you may need to reconsider your manufacturing approach or simplify the as-forged geometry.

The Project Lifecycle: From Concept to Components

Understanding the complete automotive forging development sequence helps you plan realistic timelines and allocate resources appropriately. Here's how a typical project progresses from initial requirements through production integration:

- Requirements Definition: Your engineering team establishes performance specifications, material requirements, dimensional tolerances, and quality standards. This phase defines what the component must achieve in service—load ratings, fatigue life targets, environmental resistance, and interface dimensions with mating parts.

- Preliminary Design Review: Initial geometry concepts are evaluated against forging feasibility. This is where design-for-forging principles get applied, potentially modifying your ideal geometry to accommodate manufacturing constraints while maintaining functional requirements.

- Supplier Engagement: You share preliminary designs with potential forging suppliers for manufacturability assessment and quotation. According to forging industry specialists, die design and tooling considerations are critical aspects of scaling from prototype to production, requiring careful attention to material flow and durability.

- Design Optimization: Based on supplier feedback, final forging dimensions, material specifications, and heat treatment requirements are established. This collaborative refinement often identifies opportunities to reduce cost or improve quality.

- Forging Prototype Production: First article forgings are produced, typically in small quantities for validation testing. Lead times from design approval to first article commonly range from 6 to 12 weeks, depending on material availability and supplier capacity.

- Testing and Validation: Prototype forgings undergo dimensional inspection, mechanical testing, metallurgical evaluation, and potentially functional testing in vehicle prototypes. Results may trigger design revisions.

- Production Approval: Once prototypes meet all specifications, production part approval process (PPAP) documentation is completed and the design is released for volume production.

- Volume Production and Integration: Ongoing forging production feeds your machining and assembly operations, with continuous quality monitoring ensuring consistent component performance.

Why Early Supplier Involvement Improves Outcomes

Imagine discovering after months of development that your carefully specified geometry requires tooling modifications costing $50,000 and adding eight weeks to your timeline. Early supplier collaboration prevents exactly these scenarios.

When you engage forging suppliers during preliminary design rather than after specifications are locked, several benefits emerge:

- Manufacturability feedback: Experienced forging engineers identify potential issues—difficult material flow patterns, challenging heat treatment requirements, or geometric features that increase scrap rates—before your design is finalized.

- Material optimization: Suppliers can recommend steel grades and heat treatments that meet your performance requirements while improving cost or lead time. They may suggest alternatives you hadn't considered based on their production experience.

- Process alignment: Understanding your final machining requirements helps the forging supplier optimize blank dimensions, potentially reducing material costs and machining time.

- Realistic timeline planning: Suppliers provide accurate lead time estimates based on actual material availability and production capacity, preventing schedule surprises later in development.

As manufacturing research indicates, process parameter optimization becomes essential when scaling production, involving factors such as forging temperature, strain rate, and lubricant selection. Suppliers who understand your end requirements from the start can tune these parameters appropriately during initial prototype runs.

From Prototype to Production Integration

The transition from forging prototype production to sustained volume manufacturing introduces its own challenges. What worked for 10 prototype forgings may require adjustment when you're producing 500 monthly.

Post-forging operations that follow the open die forging step typically include:

- Heat treatment: Normalizing, quenching and tempering, or other thermal processes that develop final mechanical properties

- Rough machining: Removing forging scale and bringing dimensions within tolerance ranges for finish machining

- Non-destructive testing: Ultrasonic, magnetic particle, or other inspections verifying internal and surface integrity

- Finish machining: Precision operations that create final dimensions, surface finishes, and features like threads, keyways, or splines

- Surface treatment: Coatings, plating, or other protective treatments as required by your specifications

- Final inspection and documentation: Comprehensive verification that finished components meet all requirements

For time-sensitive automotive programs, rapid prototyping capabilities become crucial. Some suppliers can deliver first-article forgings in as few as 10 days when material is available and standard processes apply. Shaoyi (Ningbo) Metal Technology offers rapid prototyping turnaround combined with IATF 16949-certified quality systems, enabling accelerated development timelines without sacrificing the documentation rigor automotive OEMs require.

Accelerating Development for Time-Sensitive Programs

When market pressures demand compressed development schedules, several strategies help accelerate your forging timeline:

- Parallel processing: Begin supplier qualification and material procurement while design details are being finalized, rather than waiting for complete specifications

- Standard materials: Specify commonly stocked steel grades when possible, avoiding extended lead times for specialty alloys

- Simplified geometries: Designs that minimize forging complexity reduce production time and potential for quality issues

- Co-located operations: Suppliers with in-house heat treatment and machining capabilities eliminate transit time between process steps

- Risk-based testing: Prioritize critical validation tests and defer less essential evaluations when schedules demand

The investment in upfront planning and supplier collaboration pays dividends throughout the development cycle. Projects that rush into forging production without adequate design-for-manufacturing review often experience delays, rework, and cost overruns that far exceed the time saved by skipping preliminary steps.

With a clear understanding of the development lifecycle, the final consideration involves selecting and building effective partnerships with forging suppliers who can consistently deliver the quality and responsiveness your automotive programs demand.

Working With Open Die Forging Suppliers Successfully

You've mapped out your component requirements, selected appropriate materials, and confirmed that open die forging delivers the metallurgical advantages your application demands. Now comes a decision that can make or break your project: choosing the right forging supplier evaluation criteria and building a partnership that delivers consistent results over time.

Selecting an open die forging vendor isn't like purchasing commodity materials where price dominates the decision. For automotive applications where component failure carries safety implications and supply disruptions halt production lines, your supplier relationship becomes a strategic asset. The right automotive forging partners understand your quality requirements, respond quickly to engineering changes, and scale seamlessly from prototype quantities to volume production.

Evaluating Supplier Capabilities and Certifications

When you begin your forging supplier evaluation, what criteria separate qualified vendors from those who simply claim capability? According to industry research, selecting a forging supplier is not a straightforward process, with quality concerns, cost management, and lead time reliability representing the most common challenges buyers face.

Start your assessment by examining these key supplier evaluation criteria:

- Certifications held: IATF 16949 certification is essential for automotive work, demonstrating compliance with industry-specific quality management requirements. Look also for ISO 9001 as a baseline, plus any customer-specific certifications your OEM partners require. As supplier evaluation guides note, suppliers with ISO 9001 certification have demonstrated their ability to meet strict quality control standards.

- Equipment capabilities: Verify that press capacity, furnace sizes, and material handling equipment match your component requirements. A leading open die forging company must invest heavily in modern machinery, with presses ranging from 200 to over 5,000 tons capacity, according to forging industry specialists.

- Quality systems: Beyond certifications, examine actual quality practices—statistical process control implementation, non-destructive testing capabilities, and traceability systems that track each forging from raw material through shipment.

- Engineering support: Does the supplier offer design-for-forging guidance, material selection expertise, and collaborative problem-solving? True excellence in open die forging comes through comprehensive engineering services that extend from initial part design considerations through final quality assurance.

- Geographic location: Proximity affects shipping costs, lead times, and your ability to conduct site visits or audits. For global supply chains, consider suppliers located near major shipping ports.

- Logistics capabilities: Evaluate packaging standards, shipping options, and the supplier's track record for on-time delivery. Lead time concerns often arise from inefficient production scheduling or limited production capacity.

Don't overlook production capacity alignment with your volume requirements. Some open die forging vendors specialize in small batch runs, while others are equipped to handle large volumes. The best forging supplier should be able to scale production according to your project needs without compromising quality or delivery schedules.

Building Effective Forging Partnerships

Once you've identified qualified suppliers, how do you structure relationships that deliver long-term value? The distinction between transactional purchasing and true partnership becomes evident when challenges arise—and in manufacturing, challenges always arise.

Effective automotive forging partners share several characteristics:

- Transparent communication: Reliable suppliers keep buyers informed at every stage, providing updates on production progress and addressing concerns quickly. When communication becomes unclear or delayed, misunderstandings lead to mistakes and frustration.

- Technical collaboration: Beyond execution capabilities, your supplier should offer expert guidance throughout the development process. Full-service forging companies are staffed with experts in metallurgy, material science, and process engineering who can optimize your forging processes.

- Predictable pricing: The cost of a forged part should be transparent and predictable. Suppliers with unclear pricing structures or hidden fees create budget uncertainty that compounds across multiple orders.

- Flexibility for changing requirements: Automotive programs evolve, and your supplier should adapt. Traditional suppliers may not be flexible enough to accommodate design changes quickly, leaving you struggling with rework and delays.

Structuring Relationships for Prototype and Production Needs

Your relationship structure may differ depending on project phase. During prototype development, you need rapid response, engineering collaboration, and flexibility to iterate designs quickly. Shaoyi (Ningbo) Metal Technology exemplifies this approach, offering rapid prototyping in as little as 10 days combined with in-house engineering support that accelerates development timelines.

For high-volume production, priorities shift toward capacity assurance, cost optimization, and supply chain reliability. Consolidating multiple stages of the forging process with one provider reduces overhead costs and streamlines logistics. According to partnership research, businesses working with full-service providers can see lead time reductions of up to 30 percent.

The strategic advantage of suppliers located near major ports—such as Ningbo Port in China—becomes apparent when you're managing global supply chains. Reduced transit times, lower shipping costs, and simplified logistics coordination all contribute to more competitive total landed costs.

Pros and Cons of Open Die Forging for Automotive Applications

As you finalize supplier partnerships, maintain a balanced perspective on what open die forging delivers and where challenges may arise:

Pros

- Handles component sizes far exceeding closed die capabilities

- Lower tooling investment compared to impression die methods

- Superior metallurgical properties from grain refinement

- Design flexibility for custom and low-volume applications

- Excellent mechanical properties for safety-critical components

Cons

- Looser as-forged tolerances requiring more post-forging machining

- Less competitive per-piece costs at very high volumes

- Limited ability to produce complex near-net shapes

- Requires skilled operators and process expertise

- Surface finish typically requires machining for final applications

Understanding these tradeoffs helps you set appropriate expectations and communicate effectively with both your forging suppliers and internal stakeholders. The advantages overwhelmingly favor open die forging for large automotive components where metallurgical quality and size capability outweigh the need for tight as-forged tolerances.

Building effective relationships with qualified open die forging vendors positions your organization to deliver high-performance automotive components that meet the demanding requirements of modern vehicles. Whether you're sourcing heavy-duty axle blanks for commercial trucks or custom drivetrain components for specialty applications, the right supplier partnership transforms manufacturing challenges into competitive advantages.

Frequently Asked Questions About Open Die Forging for Large Auto Parts

1. What is the difference between open die and closed die forging for automotive parts?

Open die forging shapes heated metal between flat or simple-contoured dies without complete enclosure, allowing material to flow outward through repeated hammer strokes. This method excels at producing large automotive components like axle shafts and heavy drivetrain parts that exceed closed die size limitations. Closed die forging presses metal into precisely shaped cavities, producing near-net shapes with tighter tolerances but requiring significantly higher tooling investments. For components weighing hundreds to thousands of pounds, open die forging offers superior economics and metallurgical quality.

2. What materials are best for open die forging automotive components?

The most common steel grades for automotive open die forgings include 4140, 4340, 4150, 4130, and 8620. AISI 4140 is the industry standard for axle shafts and steering components due to its excellent hardenability and fatigue strength. For heavy-duty applications requiring maximum toughness, 4340 with its added nickel content delivers superior impact resistance. Material selection depends on your specific requirements for tensile strength, hardenability, fatigue resistance, and machinability, with heat treatment protocols further optimizing final mechanical properties.

3. What size and weight capabilities does open die forging offer for auto parts?

Open die forging handles automotive components ranging from several hundred to over 70,000 pounds. Leading facilities can produce shafts up to 57 feet in length, discs reaching 135 inches in diameter, and hollow forgings with 72-inch outer diameters. For typical automotive applications, components commonly fall in the 500 to 5,000 pound range. These capabilities far exceed closed die limitations, making open die forging essential for commercial truck axles, large steering components, and oversized drivetrain elements.

4. What certifications should an open die forging supplier have for automotive work?

IATF 16949 certification is essential for automotive forging suppliers, demonstrating compliance with industry-specific quality management requirements. Additional certifications include ISO 9001 as a baseline and customer-specific OEM certifications. Suppliers should maintain comprehensive traceability systems, statistical process control capabilities, and non-destructive testing equipment. IATF 16949-certified suppliers like Shaoyi (Ningbo) Metal Technology provide the documentation trail and quality assurance automotive OEMs demand, from rapid prototyping through high-volume production.

5. When should I choose open die forging over casting or machining for large auto parts?

Choose open die forging when you need superior mechanical properties for safety-critical components, parts exceeding closed die size capabilities, or moderate production volumes where tooling investments cannot be justified. Forged parts exhibit approximately 26% higher tensile strength and 37% higher fatigue strength than cast equivalents due to refined grain structure and eliminated porosity. For production quantities above 10-20 pieces, forging proves more economical than machining from solid stock, which wastes 50-80% of starting material.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —