Choosing Carbon Fiber Vs Forged Aluminum Wheels For Your Superbike

The Ultimate Wheel Material Showdown

You've finally decided to upgrade your wheels. Whether you're pushing a liter bike through canyon twisties or chasing lap times at your local track, the question inevitably surfaces: carbon fiber vs aluminum—which one deserves your investment?

This isn't just about aesthetics or bragging rights. Your wheel choice directly impacts acceleration, braking distances, cornering response, and how much you'll spend over the lifetime of ownership. Get it right, and your S1K feels transformed. Get it wrong, and you're left questioning every dollar spent.

Why This Wheel Decision Matters More Than You Think

Wheels represent some of the most critical unsprung mass on any vehicle. Unlike components supported by your suspension, wheels rotate at high speeds while absorbing road impacts directly. This means every gram saved translates into measurable performance gains—faster spin-up during acceleration, quicker direction changes, and more responsive suspension behavior.

For S1K bike owners and superbike enthusiasts alike, the carbon vs aluminum wheels debate touches everything from weekend spirited rides to dedicated track sessions. The stakes extend beyond pure performance too, encompassing crash resistance, repair costs, and long-term reliability.

The Real Performance Stakes at Play

Here's what makes this decision particularly challenging: both materials sit at the top of the performance pyramid. Carbon fiber wheels offer extreme weight savings and exceptional stiffness-to-weight ratios. Forged aluminum delivers remarkable strength and durability at more accessible price points. Neither is universally "better"—context determines everything.

The performance implications ripple through your entire riding experience. Lighter wheels improve how quickly you can accelerate out of corners, reduce braking distances, and sharpen turn-in response. But durability matters equally when you're navigating imperfect roads or the occasional debris strike.

What Most Buyers Get Wrong About Wheel Materials

Forum discussions reveal widespread confusion about wheel terminology. Many riders conflate standard cast aluminum with forged aluminum—two vastly different products. Others overlook magnesium options entirely or misunderstand how manufacturing processes affect final performance characteristics.

Cast wheels are made by pouring molten aluminum into molds, resulting in heavier, less durable components. Forged wheels undergo intense pressure that compresses the metal's grain structure, creating superior strength-to-weight ratios and enhanced durability. This distinction alone changes everything about how you should evaluate your options.

This guide takes a vehicle-agnostic approach, covering applications across motorcycles, cycling, and automotive platforms. The physics remain consistent regardless of what you ride or drive—only the specific weight savings and cost calculations shift.

- Weight Savings: Actual measurements and percentage reductions across applications

- Durability: Impact resistance, failure modes, and real-world survival rates

- Repairability: What damage can be fixed versus requiring full replacement

- Heat Dissipation: Brake performance implications during aggressive use

- Cost of Ownership: Purchase price plus long-term maintenance and replacement expenses

- Use-Case Suitability: Matching wheel choice to your actual riding conditions

By the end of this guide, you'll understand exactly which wheel material aligns with your performance goals, budget constraints, and riding reality.

How We Evaluated Each Wheel Type

Before diving into specific product recommendations, you need to understand how we approached this comparison. Manufacturer marketing materials rarely tell the complete story—especially when thousands of dollars hang in the balance. Our evaluation framework strips away the promotional spin and focuses on what actually matters when your wheels hit the pavement.

Our Neutral Evaluation Framework

Here's the uncomfortable truth about wheel comparisons: most published content comes directly from manufacturers or retailers with financial incentives to steer your decision. Carbon fiber wheel makers emphasize weight savings while downplaying durability concerns. Forged aluminum producers highlight crash resistance while glossing over the weight penalty.

We approached this differently. Rather than accepting manufacturer claims at face value, we cross-referenced real-world owner experiences from enthusiast forums, analyzed independent testing data where available, and considered the physics underlying each material's properties. When examining whether is carbon fiber lighter than aluminum, we looked beyond simple weight figures to understand the practical implications of that weight difference.

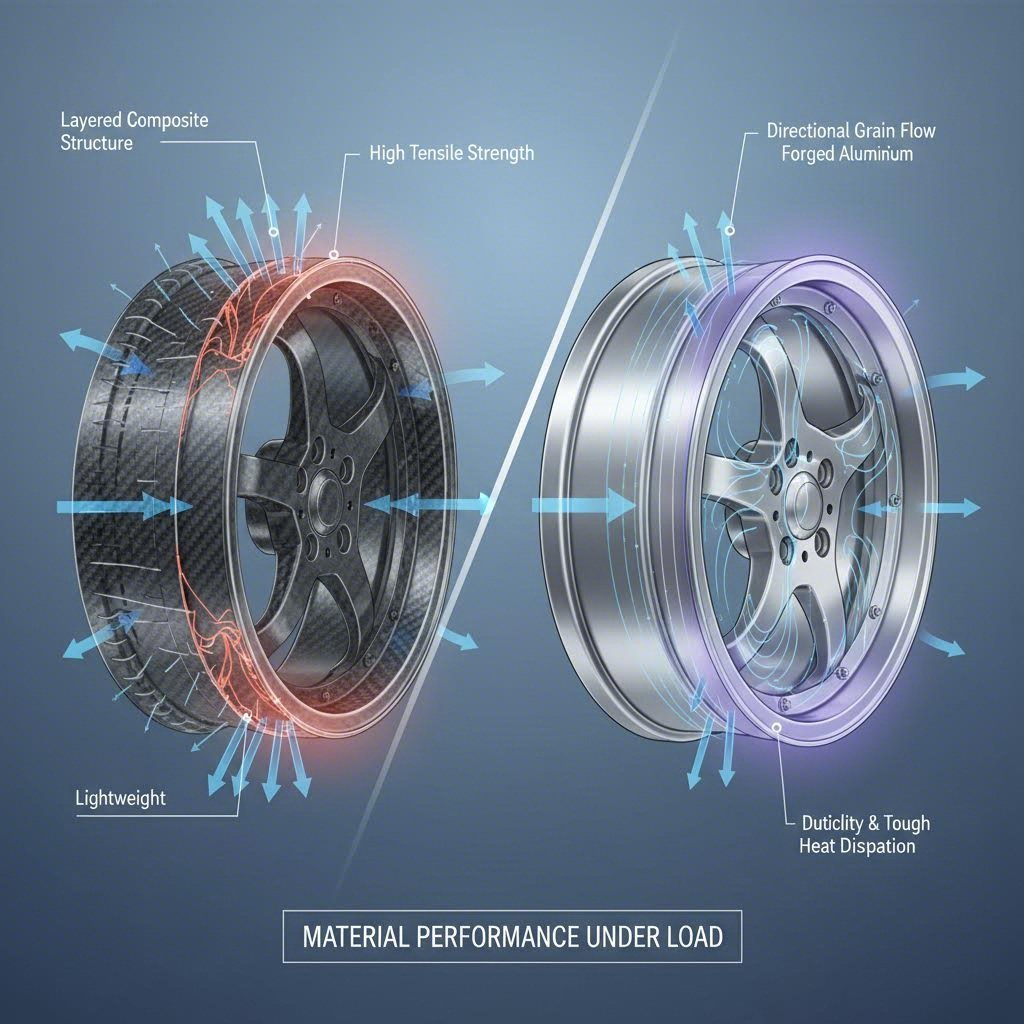

The carbon fiber density vs aluminum comparison reveals interesting nuances. Carbon fiber composites typically range from 1.5 to 1.6 g/cm³, while aluminum alloys used in forged wheels sit around 2.7 g/cm³. This density difference explains why carbon fiber wheels can achieve 40-50% weight reductions—but density alone doesn't determine real-world performance. Manufacturing quality, layup techniques, and structural design all influence the final product.

The Six Critical Performance Metrics

After analyzing countless forum discussions, owner testimonials, and technical specifications, we identified six dimensions that truly separate exceptional wheels from mediocre ones. These criteria apply whether you're evaluating track-focused options or street-riding solutions.

- Real-World Weight Measurements: Manufacturer-stated weights often represent idealized conditions. We prioritized verified weights from independent sources and owner reports. The weight of carbon fiber vs aluminum matters most at the outer diameter where rotational inertia has maximum effect.

- Crash Resistance and Failure Modes: How does each material behave during impacts? Forged aluminum typically bends or cracks in predictable patterns, often providing warning signs before catastrophic failure. Carbon fiber tends toward more sudden, complete failures—though modern designs have improved significantly.

- Manufacturing Process Quality: Not all forged aluminum wheels are created equal, and carbon fiber layup quality varies dramatically between manufacturers. We examined what separates premium offerings from budget alternatives.

- Heat Management Under Braking: Extended aggressive braking generates significant heat. How each material conducts and dissipates thermal energy affects brake performance and wheel longevity—critical for track days or spirited canyon riding.

- Repairability Scenarios: When damage occurs, can you repair it or must you replace the entire wheel? This consideration dramatically affects long-term ownership costs.

- Total Cost of Ownership: Purchase price represents only part of the equation. We factored in potential repair costs, replacement likelihood, and expected service life to calculate true ownership expenses.

Why Manufacturer Claims Need Verification

Is carbon fibre stronger than aluminium? The answer depends entirely on how you define "stronger" and which specific products you're comparing. Tensile strength, impact resistance, fatigue life, and stiffness all represent different aspects of strength—and each material excels in different areas.

This is precisely why independent verification matters. When a manufacturer claims their carbon wheels offer "superior strength," they might be referencing stiffness rather than impact resistance. When another boasts about "unmatched durability," they might be ignoring failure mode characteristics that matter during real-world incidents.

Safety certification standards provide one layer of verification. According to Velgen Wheels, the three most recognized standards—SAE, JWL, and VIA—each require specific testing protocols including radial fatigue tests, cornering fatigue tests, impact tests, and torsion tests. However, as Konig Wheels notes, a wheel can be stamped as JWL without third-party certification, meaning manufacturers can self-certify based on internal testing.

The VIA standard stands apart because it requires independent third-party verification and tests wheels with different tire sizes and vehicles. For buyers seeking maximum confidence in wheel quality, VIA certification provides the most rigorous validation available. That said, absence of VIA certification doesn't automatically indicate inferior quality—particularly for manufacturers outside Japan where this standard originated.

When evaluating any wheel purchase, ask manufacturers directly about their testing protocols and certifications. Reputable companies will readily share this information.

For riders who push hard enough to eliminate their moto chicken strips entirely, these verification considerations become especially important. The margins between aggressive street riding and track-level demands shrink considerably when you're regularly approaching the limits of tire adhesion—and your wheels need to handle those stresses reliably.

Understanding this evaluation framework prepares you to assess each wheel type on its genuine merits. With these criteria established, we can now examine forged aluminum wheels in detail—starting with the manufacturing process that creates their legendary strength characteristics.

Forged Aluminum Wheels

What transforms a simple block of aluminum into a wheel capable of withstanding extreme forces while remaining remarkably lightweight? The answer lies in a manufacturing process that has been refined over decades—forging. Unlike cast alternatives where molten metal simply fills a mold, forged aluminium wheels undergo intense mechanical transformation that fundamentally changes the material's internal structure.

For superbike enthusiasts considering upgrades for machines like the HP4 or similar high-performance platforms, understanding this manufacturing distinction is essential. The forging process doesn't just shape aluminum—it strengthens it at the molecular level.

The Forging Process That Creates Superior Strength

Imagine taking a solid aluminum billet and subjecting it to pressures exceeding 10,000 tons. That's essentially what happens during the forging process. The billet is first heated to a precise temperature—hot enough to become malleable but not so hot that it loses structural integrity. Then, massive hydraulic presses force the material into dies, compressing and shaping it simultaneously.

This extreme pressure accomplishes something remarkable: it aligns the aluminum's grain structure along the wheel's contours. Think of it like wood grain—when aligned properly, the material becomes dramatically stronger in the directions that matter most. The result is a billet rim with superior tensile strength, fatigue resistance, and impact tolerance compared to cast alternatives.

Following the initial forging, wheels undergo heat treatment processes that further enhance material properties. Precision CNC machining then removes excess material to achieve final specifications, often shaving significant weight while maintaining structural requirements. The entire process demands exceptional quality control—any inconsistency in temperature, pressure, or timing can compromise the final product.

This is precisely why manufacturing certification matters. IATF 16949 certified manufacturers like Shaoyi (Ningbo) Metal Technology ensure precision hot forging meets exact specifications through rigorous quality control protocols. Their in-house engineering capabilities—from rapid prototyping in as little as 10 days to high-volume mass production—exemplify the manufacturing standards that separate premium forged components from inferior alternatives.

When comparing aluminium wheels vs alloy wheels, remember that "alloy" typically refers to cast aluminum products. Forged wheels represent an entirely different tier of engineering and performance. The aluminium vs steel wheels comparison is similarly one-sided for performance applications—steel simply cannot match the weight savings forged aluminum delivers.

Heat Management and Brake Performance Benefits

Here's something many riders overlook: your wheels play a significant role in brake performance. During aggressive riding—whether you're attacking canyon roads or pushing hard on track—brakes generate enormous heat. That thermal energy needs somewhere to go.

Aluminum excels at heat dissipation. Its thermal conductivity allows heat from brake rotors to transfer into the wheel structure and radiate into the surrounding air. This heat-sink effect helps maintain consistent brake performance during extended aggressive use, preventing the fade that occurs when brake components overheat.

For riders who spend time at the track or enjoy spirited street riding, this thermal management capability provides tangible benefits. Your brakes remain more consistent lap after lap or corner after corner. The practical implications extend beyond pure performance too—better heat dissipation means reduced thermal stress on brake components, potentially extending their service life.

While upgrading components like an S1000RR 2024 radiator guard addresses engine cooling, your wheel material choice directly influences braking thermal management. Both considerations matter for riders pushing their machines toward the limits.

When Damage Happens - Repair vs Replace Reality

No matter how carefully you ride, wheel damage remains a possibility. Potholes, debris strikes, and the occasional curb encounter can all leave their marks. This is where forged aluminum demonstrates another significant advantage: repairability.

According to Tree Wheels, the distinction between cosmetic and structural damage determines your repair options. Cosmetic issues like curb rash, minor scratches, and light scuffs can typically be professionally repaired—their data shows curb rash accounts for nearly 30% of all cosmetic claims. Professional refinishing can restore these surface-level damages to near-original condition.

Structural damage presents a different scenario. Forged aluminum's ductility means the material typically bends or cracks in predictable patterns when overloaded, often providing visible warning signs before catastrophic failure. This characteristic differs significantly from carbon fiber's tendency toward sudden, complete failures.

Pros of Forged Aluminum Wheels

- Superior repairability: Cosmetic damage can often be professionally restored

- Predictable failure modes: Visible deformation typically warns of structural compromise

- Excellent heat dissipation: Enhanced brake performance during aggressive use

- Consistent quality: Well-established manufacturing processes deliver reliable results

- Strong impact resistance: Handles road hazards better than cast alternatives

- Moderate weight savings: Typically 15-25% lighter than cast aluminum

Cons of Forged Aluminum Wheels

- Heavier than carbon fiber: Cannot match carbon's extreme weight reductions

- Higher cost than cast: Premium manufacturing commands premium pricing

- Structural repairs limited: Significant impact damage still requires replacement

- Finish vulnerability: Some finishes show damage more readily than others

The failure mode analysis deserves special attention. When forged aluminum wheels sustain serious impact damage, even without obvious deformation, internal microcracks or metal fatigue may develop. These invisible flaws can compromise safety over time. Laboratory testing demonstrates that structurally damaged wheels may function normally initially before suddenly failing under stress.

Warning signs of structural damage include vibrations at speed, visible bending or deformation, cracks near spoke bases or bead seats, and difficulty maintaining tire pressure. Any of these symptoms warrant immediate professional inspection.

For riders weighing the carbon fiber vs forged aluminum wheels decision, this repairability advantage often proves decisive. The ability to restore a wheel after minor incidents rather than facing full replacement costs significantly affects long-term ownership economics. Now let's examine how carbon fiber wheels approach these same challenges differently.

Carbon Fiber Wheels

When riders first experience carbon fiber wheels, the difference is immediately apparent. That initial acceleration feels sharper. Direction changes happen with less effort. The bike responds to inputs with an eagerness that forged aluminum simply cannot replicate. This transformation stems from one fundamental advantage: dramatic weight reduction at the outer diameter where it matters most.

But understanding why carbon fiber delivers these benefits—and where its limitations lie—requires examining how these wheels are actually made. The carbon fiber vs aluminium debate ultimately comes down to understanding what you gain and what you sacrifice with each choice.

Carbon Fiber Layup - Where Art Meets Engineering

Unlike forged aluminum's mechanical transformation process, carbon fiber wheel manufacturing resembles something closer to skilled craftsmanship. According to November Bicycles, what we call "carbon fiber" is actually a composite—thin strands of carbon atoms woven into fabric, then set in a resin matrix. Both components depend on each other, and their properties must be carefully correlated to maximize system performance.

The traditional manufacturing process begins with mold preparation. Technicians place pre-cut carbon sheets into or onto precisely engineered molds, carefully orienting each layer to optimize strength in specific directions. This orientation matters tremendously—carbon fiber's strength characteristics vary dramatically depending on fiber alignment relative to applied forces.

These carbon sheets arrive "pre-impregnated" (called pre-preg) with resin. The raw carbon sheets are laid onto tables where measured amounts of resin are poured and spread to saturate the material. Industry standards typically target around 63% carbon to 37% resin—deviations from this tight band in either direction create problems. Pre-pregged materials must be refrigerated to prevent premature curing and have limited shelf life before going bad.

After layup completion, the assembly enters curing cycles involving precise temperature and pressure control, often in autoclaves. This thermic reaction catalyzes the resin, transforming flexible sheets into rigid, seamless structures. The result is a wheel rim capable of enduring racing rigors and everyday use—assuming everything was executed correctly.

Alternative manufacturing methods exist. Resin infusion involves loading molds with fiber sheets, then using vacuum suction to pull resin into the material. This technique works well for relatively straightforward geometries but can create dry spots in tight corners and complex curves. Dry spots ruin entire parts, making quality control critical.

Filament winding represents another approach, using mandrels instead of molds and wetting fibers as they come off spools. Some manufacturers also produce braided rims—essentially carbon and resin socks molded into wheel shapes. Each method offers distinct advantages for process control, resin ratio consistency, and contamination prevention.

The Weight Savings That Transform Performance

Numbers tell a compelling story. According to AutoMod Express, high-performance carbon fiber cycling wheels can weigh as little as 1,692g to 1,750g per wheelset—savings of up to 500g compared to alloy equivalents. For automotive applications, carbon wheels on vehicles like the Ford GT500 weigh around 17 pounds for fronts and up to 19 pounds for larger rears, representing 20-30% reductions versus stock alloys.

This aluminium vs carbon fiber weight difference explains the performance transformation riders experience. Light bicycle carbon options have revolutionized competitive cycling, where every gram matters during climbs and sprints. Similar principles apply to motorcycles—reduced rotational mass means engines work less hard overcoming inertia during acceleration.

But weight savings alone don't tell the complete story. Carbon fiber's exceptional stiffness-to-weight ratio provides additional handling benefits. The material resists deflection under cornering loads, maintaining precise tire contact patches and delivering more predictable responses. This rigidity translates to better power transfer during acceleration and more confident braking feel.

Carbon fiber mtb rims and carbon fiber cycling wheels have demonstrated these advantages across competitive cycling disciplines for years. Bicycle wheels carbon fiber construction offers both weight savings and aerodynamic benefits, giving riders measurable performance edges. These same physics apply to motorcycle applications, though specific weight savings vary based on wheel dimensions and construction techniques.

The Durability Truth Nobody Wants to Discuss

Here's where honest assessment becomes essential. Carbon fiber vs forged carbon debates often gloss over durability concerns, but enthusiast forums consistently raise legitimate questions about crash resistance and failure modes.

Carbon fiber behaves fundamentally differently than metals when overloaded. According to AutoMod Express's damage guide, the material is highly resistant to heat, chemicals, and corrosion—unlike metal wheels, carbon fiber doesn't bend easily under normal conditions. However, when it does sustain damage, the failure characteristics differ dramatically from forged aluminum's predictable bending.

Carbon fiber tends toward more sudden, complete failures rather than gradual deformation. While the material withstands tremendous forces without deforming or cracking under normal use, severe impacts can cause immediate structural compromise. More concerning: tiny fractures or stress points may not be visible, risking catastrophic failure if not professionally inspected.

The tap test provides one detection method. A healthy wheel produces consistent, clear rings when tapped gently with a coin or plastic tool. Dull or dead spots may indicate internal delamination or void formation compromising structural integrity. However, this technique cannot identify all damage types—professional inspection using ultrasonic testing or other non-destructive evaluation methods offers more reliable assessment.

Manufacturing quality significantly influences durability outcomes. Pre-preg carbon fiber construction generally offers superior performance and durability compared to wet layup techniques, providing more consistent resin distribution and better curing process control. Wheels from reputable manufacturers employing rigorous quality control typically exhibit more predictable performance and longer service life than budget alternatives.

Pros of Carbon Fiber Wheels

- Dramatic weight reduction: Typically 40-50% lighter than equivalent aluminum options

- Exceptional stiffness-to-weight ratio: Superior handling response and power transfer

- Corrosion immunity: No rust or oxidation concerns regardless of conditions

- Reduced rotational inertia: Faster acceleration, braking, and direction changes

- Vibration damping: Smoother ride quality on rough surfaces

- Aerodynamic optimization: Design flexibility enables aerodynamic profiling

Cons of Carbon Fiber Wheels

- Limited repairability: Most structural damage requires complete wheel replacement

- Invisible damage risk: Internal failures may not be visually apparent

- Sudden failure modes: Less warning before catastrophic structural compromise

- Significant cost premium: Prices of $10,000-$20,000 for full automotive sets

- Manufacturing quality variance: Performance varies dramatically between manufacturers

- Impact vulnerability: Severe strikes cause more complete damage than aluminum

Repairability represents perhaps the starkest contrast with forged aluminum. Minor surface damage like scratches or small clear coat chips may be professionally refinished, but structural damage typically mandates replacement. Delamination—where bonds between carbon layers fail—rarely allows safe repair since compromised inter-layer bonds affect overall structural integrity. Many manufacturers void warranties if unauthorized repairs are attempted.

The total cost of ownership equation must account for this replacement reality. While carbon fiber wheels deliver undeniable performance advantages, buyers should budget for potential replacement costs rather than assuming repairs will address all damage scenarios. Insurance considerations become important for these high-value components—some policies may not adequately cover aftermarket wheels.

Despite these durability considerations, carbon fiber wheels continue gaining popularity among serious performance enthusiasts. The key lies in matching wheel choice to intended use—and understanding that different applications demand different risk calculations. Track-focused riders accept different trade-offs than street commuters, which is exactly what we'll explore next.

Carbon Fiber for Track Warriors and Racers

When milliseconds separate podium finishes from mid-pack results, professional racing teams leave nothing to chance. So why do countless championship-winning operations choose carbon fiber wheels despite their substantial cost premium? The answer lies in understanding how rotational mass reduction transforms every aspect of track performance—from corner entry to race-winning acceleration.

For riders maximizing their sportbike track time, the carbon wheels vs aluminum wheels decision carries particularly significant implications. What works brilliantly on Sunday spirited rides may not deliver optimal results when you're chasing lap records at venues like Jennings GP.

Why Racing Teams Bet on Carbon

Professional motorsport operates under brutal economics: teams invest wherever measurable advantages exist. Carbon fiber wheels have earned their place in this equation through quantifiable performance gains that justify their premium pricing.

According to testing conducted by MotoIQ with Carbon Revolution, the advantages extend far beyond simple weight savings. Their back-to-back comparison on a $100K+ sports car revealed that carbon fiber wheels affect everything from steering feel to overall grip and noise/vibration/harshness characteristics. The extremely stiff Carbon Revolution CR-9 wheels delivered significantly better tire wear, zero blistering, and consistently faster lap times compared to high-end OEM aluminum alternatives.

Ultra-lightweight aluminum wheels can flex and lose over 1-degree of camber for every cornering G-force the car generates—a stiffness deficit that carbon fiber effectively eliminates.

This camber compliance issue proves particularly significant during aggressive track use. When aluminum wheels flex under cornering loads, tire contact patches distort, reducing available grip precisely when you need it most. The testing showed high-end OEM aluminum wheels severely blistered tire outer edges due to wheel flexing and insufficient static camber. Meanwhile, carbon's exceptional stiffness maintained consistent tire contact geometry throughout aggressive cornering sequences.

Because carbon fiber wheels run stiffer than aluminum alternatives, riders and drivers can actually run less static camber while maintaining optimal tire contact. This seemingly minor adjustment improves braking performance, acceleration traction, and overall consistency—advantages that compound across race distances.

Rotational Mass - The Hidden Performance Multiplier

Physics dictates that reducing rotational inertia requires less energy to change wheel speed, effectively increasing available power for vehicle acceleration. But the benefits extend well beyond simple straight-line speed improvements.

When comparing carbon rims vs aluminum rims for track applications, consider three critical performance dimensions:

- Acceleration Response: Lighter wheels spin up faster, delivering more immediate throttle response out of corners. The weight advantage proves most pronounced during initial acceleration and gear changes where engines must overcome rotational resistance.

- Braking Efficiency: Reduced rotational mass requires less braking force to achieve equivalent deceleration rates. This means later braking points, shorter stopping distances, and reduced stress on brake pads, rotors, and hydraulic systems.

- Direction Changes: Lower rotational inertia reduces gyroscopic forces resisting directional changes during cornering and chicane sequences. Wheels change direction more readily, translating rider inputs more directly to vehicle movement.

According to GVICHN's technical analysis, vehicles equipped with carbon fiber wheels consistently achieve faster 0-60 mph times than identical vehicles with standard wheels. The cumulative effect of reduced rotational mass creates synergistic improvements exceeding the sum of individual benefits.

For riders preparing for track days—whether browsing sportbiketrackgear for protective equipment or fine-tuning suspension settings—wheel choice represents one of the most impactful single upgrades available. The transformation in how your bike changes direction and accelerates out of corners is immediately apparent.

Track Day Ownership Realities

Extended track sessions create thermal conditions that street riding rarely approaches. Repeated heavy braking into corners, followed by aggressive acceleration, generates significant heat in both brake systems and wheel assemblies. How carbon fiber handles this thermal stress differs meaningfully from aluminum.

Carbon fiber's lower thermal conductivity actually provides advantages in certain scenarios. While aluminum conducts heat more readily—functioning as a heat sink for brake components—carbon fiber's thermal isolation helps maintain more consistent brake rotor temperatures. This characteristic can reduce brake fade during extended sessions by keeping thermal energy concentrated where braking actually occurs rather than dissipating through the wheel structure.

However, forum discussions among track day enthusiasts reveal nuanced perspectives. Some riders report that carbon wheels perform optimally once reaching operating temperature, delivering their best feel and response after initial warmup laps. Others emphasize the importance of gradually building speed during initial sessions rather than immediately attacking at maximum pace.

Real owner experiences consistently highlight one critical consideration: inspection protocols between sessions become essential. Unlike aluminum wheels that often show visible deformation after significant impacts, carbon fiber damage may not be immediately apparent. Many dedicated track riders develop the habit of performing tap tests and visual inspections between sessions, checking for any changes in sound characteristics or visible damage.

For serious track enthusiasts calculating cost-per-session economics, the equation requires honest assessment. A premium carbon fiber wheelset for motorcycles might cost $4,000-$8,000 depending on application. Amortized across 50 track days, that represents $80-$160 per session—potentially worthwhile if the performance advantages translate to meaningful lap time improvements and enhanced riding enjoyment.

Riders investing in top-tier safety equipment like the Supertech R10 boots understand that performance and protection both command premium pricing. Carbon fiber wheels represent a similar philosophy: investing in components that maximize your capabilities while accepting the associated ownership costs.

The real question isn't whether carbon fiber wheels improve track performance—the physics and testing data confirm they do. The question is whether those improvements justify the investment for your specific track goals and budget.

Professional racing teams answer this question affirmatively because their competitive environment demands every available advantage. Dedicated amateur track enthusiasts often reach similar conclusions after experiencing the transformation firsthand. But riders who split time between street and occasional track use face more complex calculations—which brings us to evaluating forged aluminum's advantages for mixed-use applications.

Forged Aluminum for Street and Touring Applications

Track performance is exhilarating, but let's be honest—most superbike miles happen on public roads. Potholes lurk around blind corners. Construction debris scatters across lanes without warning. That perfect parking spot requires threading between curbs that seem designed to destroy expensive components. For riders who spend significant time navigating real-world conditions, forged aluminum wheels offer compelling advantages that carbon fiber simply cannot match.

When evaluating aluminium bike wheels for street applications, the conversation shifts from maximum weight savings to practical durability and long-term ownership economics. What happens when your front wheel finds that crater the road crew hasn't patched yet?

Street Survival - Where Forged Aluminum Shines

Imagine hitting a substantial pothole at speed—a scenario every street rider eventually faces. According to XZ Forged Wheels, forged alloy rims demonstrate superior resistance to pothole impacts due to their aligned grain structure. The forging process creates denser, more uniform material that distributes impact stress more evenly across the wheel surface.

When a vehicle hits a pothole, wheels experience sudden, intense impact forces. These forces can cause bending, cracking, or complete failure depending on severity. Forged aluminum's ductile nature means it typically absorbs these impacts by flexing slightly rather than fracturing catastrophically. This characteristic provides crucial advantages for street riders:

- Predictable deformation: When overloaded, forged aluminum bends rather than shattering, often providing visible warning signs before structural failure

- Impact absorption: The aligned grain structure distributes stress more effectively than cast alternatives or carbon fiber composites

- Curb damage recovery: Minor curb strikes typically result in cosmetic damage that can be professionally refinished rather than requiring complete replacement

- Debris strike tolerance: Road debris impacts that might crack carbon fiber often leave forged aluminum merely scratched

The alloy versus aluminum wheels distinction matters here. When people reference "alloy wheels," they typically mean cast aluminum—a fundamentally different product. Cast wheels contain microscopic voids and random grain structures that create weak points under stress. Forged aluminum wheels bike applications demand address these limitations through the compression process that eliminates internal voids and aligns molecular structure.

For riders who commute daily or tour extensively, this durability advantage compounds over thousands of miles. Every pothole avoided represents luck; every pothole survived without wheel damage represents engineering.

The Long-Haul Reliability Factor

What do high-mileage owners actually experience? Forum discussions consistently reveal that well-manufactured forged aluminum wheels often outlast the motorcycles they're mounted on. Riders report 50,000+ mile ownership without structural issues—a longevity that justifies premium pricing when calculated on a per-mile basis.

According to Kipardo Racing, forged wheels offer exceptional resistance to fatigue—essential for high-mileage applications. The solution heat treatment and aging processes that follow initial forging lock in strength characteristics that resist degradation over time. Unlike cast wheels that may develop fatigue cracks after years of service, quality forged aluminum maintains structural integrity through repeated stress cycles.

Heat dissipation advantages extend reliability benefits further. During varied riding conditions with frequent braking—think urban traffic, mountain descents, or loaded touring—forged aluminum's thermal conductivity helps manage brake system temperatures. This heat-sink effect reduces thermal stress on brake components while maintaining consistent stopping performance.

Practical ownership considerations for touring and daily use include:

- Tire mounting simplicity: Standard aluminum wheels require no special mounting procedures or equipment

- Wide service availability: Any competent wheel shop can inspect, balance, and service forged aluminum

- Insurance simplicity: Standard replacement values and claims processes apply

- Resale value retention: Well-maintained forged wheels command strong prices on the secondary market

When you use a motorcycle front wheel chock for garage storage between rides, you're protecting an investment. Forged aluminum wheels represent durable investments that reward proper care with decades of reliable service. Similarly, when you lock motorcycle helmet to bike during stops, you're managing valuable equipment—forged wheels deserve similar consideration as long-term assets rather than consumable components.

Maintenance and Longevity Expectations

Forged aluminum ownership requires remarkably little specialized maintenance. Regular cleaning prevents brake dust and road grime accumulation that can eventually damage finishes. Periodic inspection for cracks, bends, or unusual wear patterns catches potential issues before they become safety concerns. Beyond these basics, quality forged wheels simply continue performing.

Longevity expectations depend significantly on manufacturing quality and use conditions. Premium forged wheels from reputable manufacturers with proper certifications—like JWL, VIA, or TUV standards—typically deliver trouble-free service measured in decades rather than years. Budget alternatives may cut corners on heat treatment, machining tolerances, or quality control, potentially compromising long-term reliability.

The value proposition crystallizes for riders prioritizing durability over maximum weight savings. Consider the total ownership equation:

- Initial cost: Premium forged aluminum costs significantly less than carbon fiber—often 50-70% less for comparable applications

- Repair costs: Cosmetic damage from curb strikes or minor impacts typically costs $100-300 to professionally refinish

- Replacement likelihood: Structural damage requiring full replacement occurs far less frequently than with carbon fiber

- Service life: Quality forged wheels routinely exceed 15-20 years of active use

For street-focused riders, pants for riding might wear out annually while quality forged aluminum wheels continue performing flawlessly. This longevity advantage—combined with superior real-world durability—makes forged aluminum the practical choice for riders who prioritize reliability over extracting every possible gram of weight savings.

The carbon fiber vs forged aluminum wheels decision ultimately hinges on honest assessment of your actual riding. Track warriors chasing lap times benefit from carbon's weight advantages. Street riders navigating unpredictable conditions benefit from aluminum's forgiveness. But how do these materials truly compare when evaluated head-to-head across all critical dimensions? Let's examine the complete comparison.

Carbon Fiber vs Forged Aluminum Direct Comparison

You've seen the individual strengths and weaknesses of each material. Now let's put them side by side—no marketing spin, just honest evaluation across every dimension that matters for your riding reality. Whether you're building a dedicated track weapon or upgrading your daily rider, this head-to-head breakdown reveals exactly where each material excels and where it falls short.

The carbon vs aluminum rims debate ultimately comes down to understanding trade-offs. Neither material wins across every category, but one will align better with your specific priorities, budget, and intended use.

Weight Savings Breakdown by Application

Weight reduction represents carbon fiber's most dramatic advantage—but context matters enormously. According to GVICHN's technical analysis, carbon fiber wheels typically achieve weight reductions of 40-50% compared to equivalent cast aluminum wheels, while forged aluminum wheels offer weight savings of 20-30% over cast alternatives.

When directly comparing carbon fiber to forged aluminum, expect carbon to deliver approximately 15-25% additional weight savings. For a typical performance motorcycle wheelset, this translates to roughly 2-4 pounds of total reduction. Sounds modest? Remember that this weight sits at the outer diameter where rotational inertia has maximum effect—the performance impact exceeds what simple weight numbers suggest.

The carbon fiber density vs aluminum comparison explains this advantage. Carbon fiber composites average around 1.6 g/cm³ while aluminum alloys used in forged wheels sit near 2.7 g/cm³. This fundamental density difference allows carbon manufacturers to build lighter structures while maintaining comparable strength characteristics.

For cycling applications, similar principles apply. A road bike carbon wheel set can save 300-500 grams compared to quality aluminum alternatives. Carbon 29 mountain bike wheels deliver meaningful weight reductions that translate to faster climbing and more responsive handling on technical terrain. These savings compound with rider fatigue—lighter wheels require less energy to accelerate, leaving more in the tank for demanding rides.

However, weight savings alone don't determine the best choice. An aluminum versus carbon fiber bikes comparison must also consider durability, cost, and intended use patterns. Maximum weight reduction matters most for competitive applications where every gram affects results.

Durability Under Real-World Stress

How each material handles impacts, stress cycles, and real-world hazards differs fundamentally. Understanding these differences helps you assess risk appropriately for your riding conditions.

Forged aluminum demonstrates superior impact resistance for typical road hazards. The material's ductile nature means it absorbs impacts by deforming gradually rather than fracturing suddenly. According to Top-Fire's comparison guide, aluminum rims often endure 10,000-20,000 kilometers before fatigue becomes a concern—nearly double carbon's typical 5,000-8,000 kilometer fatigue life under mixed riding conditions.

Carbon fiber excels in different stress scenarios. Its exceptional fatigue resistance handles repeated high-stress cycles well—ideal for racing applications with consistent, controlled conditions. The material resists corrosion completely and maintains structural integrity across temperature extremes. But severe impacts create different failure patterns: where aluminum bends, carbon fiber may crack or delaminate without visible warning.

For carbon vs aluminum road bike applications, these durability considerations shift the equation. Competitive cyclists pushing equipment limits in controlled environments benefit from carbon's performance advantages. Riders navigating unpredictable road conditions—potholes, debris, unexpected obstacles—gain security from aluminum's forgiving failure modes.

A 2024 wheel lab study found that 85% of aluminum rims maintained structural integrity after 15,000 km, whereas only 60% of carbon rims did the same under identical stress tests.

This durability gap narrows significantly with premium carbon fiber construction. Quality control during manufacturing, proper carbon fiber layup orientation, and rigorous curing processes all influence final durability. Budget carbon wheels may exhibit concerning failure rates, while premium options from established manufacturers demonstrate impressive longevity. Manufacturing quality matters far more for carbon fiber than for forged aluminum, where the forging process itself provides inherent consistency.

The True Cost of Ownership Calculation

Purchase price tells only part of the story. Calculating true ownership costs requires factoring in repairability, replacement likelihood, and expected service life. This comprehensive view often surprises riders focused solely on initial pricing.

According to GVICHN's cost analysis, carbon fiber wheel sets for performance vehicles often range from $5,000 to $15,000 or more depending on size, design complexity, and manufacturing quality. Forged aluminum wheels offer quality sets typically ranging from $1,500 to $4,000 for most applications—a 3-5x price differential for comparable fitments.

Repairability dramatically affects long-term economics. Forged aluminum's cosmetic damage—curb rash, minor scratches, light scuffs—typically costs $100-300 to professionally refinish. Even moderate damage from impacts can often be addressed through straightening, welding, or machining processes at specialized facilities. This repairability extends useful service life significantly.

Carbon fiber presents starkly different repair economics. Minor surface scratches may be professionally addressed, but any structural damage typically mandates complete replacement. Delamination, cracks near spoke holes, or impact damage affecting the carbon matrix cannot be safely repaired. A single significant pothole strike that might cost $200 to repair on aluminum could require $2,500+ wheel replacement for carbon.

RPM carbon and similar premium brands offer exceptional performance, but ownership requires accepting these replacement realities. Insurance considerations become important—some policies don't adequately cover aftermarket wheels, leaving owners exposed to significant out-of-pocket replacement costs after damage incidents.

| Feature | Forged Aluminum | Carbon Fiber |

|---|---|---|

| Weight Savings vs Cast | 20-30% lighter | 40-50% lighter |

| Weight Savings vs Each Other | Baseline | 15-25% lighter than forged |

| Impact Resistance | Excellent - bends before breaking | Moderate - may crack suddenly |

| Fatigue Life | 100,000+ km (Street) / 20,000 km (Race) | 5,000-8,000 km typical |

| Repairability | High - cosmetic and some structural | Low - replacement usually required |

| Heat Dissipation | Excellent - natural heat sink | Limited - thermal isolation |

| Brake Performance | Consistent under extended use | Requires warm-up; consistent once hot |

| Initial Cost | $1,500-$4,000 typical | $5,000-$15,000+ typical |

| Repair Costs | $100-$500 typical | Full replacement usually required |

| Failure Warning Signs | Visible deformation, cracks | May fail without visible warning |

| Best Use Case | Street, touring, mixed use | Track, racing, dedicated performance |

Safety certification differences warrant attention when evaluating specific products. Both wheel types should meet established standards—SAE, JWL, VIA, or manufacturer-specific requirements—but verification methods differ. VIA certification requires independent third-party testing, providing maximum assurance. JWL allows manufacturer self-certification based on internal testing. When investing significant money in either material, verify what certifications apply and whether independent testing validates manufacturer claims.

For riders weighing carbon fiber vs forged aluminum wheels, this comprehensive comparison reveals no universal winner. Carbon fiber delivers undeniable performance advantages for dedicated track use where weight savings justify premium pricing and replacement risks. Forged aluminum offers superior practical value for street applications where durability, repairability, and cost-effectiveness matter more than extracting maximum performance. Your ideal choice depends entirely on matching wheel characteristics to your actual riding patterns—which is exactly what we'll address in our final recommendations.

Which Wheel Material Wins for Your Riding Style

You've seen the data, weighed the trade-offs, and understand how each material performs across critical dimensions. Now comes the decision that actually matters: which wheel material matches your specific riding reality? Forget generic recommendations—your ideal choice depends on honest assessment of how you actually ride, what risks you're willing to accept, and how much you're prepared to invest.

The carbon fiber vs forged aluminum wheels debate doesn't have a universal answer. But it absolutely has a right answer for you—once you identify which rider profile fits your situation.

Match Your Wheels to Your Riding Reality

Different riders demand different characteristics from their wheels. A weekend track warrior prioritizes entirely different qualities than a daily commuter navigating urban obstacles. Here's how each rider profile should approach this decision:

- Dedicated Track Enthusiasts: Carbon fiber delivers measurable advantages that justify premium pricing. If you're logging 15+ track days annually, chasing lap records, or competing in organized racing, the rotational mass reduction translates directly to performance gains. Forged carbon wheels offer the ultimate combination of lightweight construction and stiffness for serious competitors. Budget $5,000-$10,000 for quality carbon fiber rims for motorcycles and plan for potential replacement costs. The performance transformation is immediately noticeable—sharper turn-in, faster acceleration response, and reduced braking distances.

- Street Performance Riders: Forged aluminum represents the sweet spot for aggressive street riding. You'll enjoy meaningful weight savings over cast wheels while retaining the durability needed for unpredictable road conditions. That pothole hiding around a blind corner? Forged aluminum handles it far better than carbon alternatives. Alloy vs aluminium wheels comparisons consistently favor forged construction for this application—the aligned grain structure provides superior impact resistance without the fragility concerns.

- Touring and Commuting Users: Forged aluminum wins decisively for high-mileage applications. Long-term reliability, service availability at any competent wheel shop, and forgiving behavior during inevitable road hazard encounters make forged wheels the practical choice. The weight penalty versus carbon is negligible when you're carrying luggage and covering continental distances. Focus your upgrade budget on comfort and reliability rather than maximum weight savings.

- Budget-Conscious Upgraders: Quality forged aluminum delivers the best performance-per-dollar ratio. You'll gain 20-30% weight reduction over stock cast wheels at a fraction of carbon fiber pricing. This leaves budget available for other meaningful upgrades—suspension components, brake systems, or protective equipment. Consider this approach if you're building comprehensive capability rather than optimizing a single dimension.

When Carbon Fiber Investment Pays Off

Carbon fiber wheels make financial and performance sense under specific circumstances. Understanding when the premium investment actually delivers proportional returns helps avoid both overspending and undershooting your potential.

The investment equation favors carbon fiber when you're genuinely exploiting weight savings—meaning regular track use where lap times matter, competitive racing where every advantage counts, or specific applications like carbon fiber wheels for bike climbing specialists where reduced rotational mass directly affects performance metrics you care about.

Premium brands like Zipp wheels carbon offerings have demonstrated that quality construction delivers both performance and reasonable durability when used appropriately. Bike carbon fiber wheels from established manufacturers undergo rigorous testing and quality control that budget alternatives simply cannot match.

However, carbon fiber investment rarely makes sense for occasional track users, riders who prioritize street practicality, or those unable to absorb potential replacement costs after damage incidents. The hybrid approach deserves consideration: maintain forged aluminum wheels for street duty while owning a dedicated carbon set for track days. This strategy provides optimal performance in each environment while protecting your expensive carbon investment from road hazards.

The smartest wheel strategy often involves owning multiple sets matched to different purposes rather than compromising with a single all-purpose solution.

The Smart Upgrade Path for Every Budget

Regardless of which material you choose, sourcing from quality manufacturers dramatically affects long-term satisfaction. For forged aluminum wheels, seek manufacturers with established quality certifications and proven track records. IATF 16949 certified manufacturers like Shaoyi (Ningbo) Metal Technology demonstrate the manufacturing standards that ensure consistent quality—their precision hot forging capabilities and in-house engineering represent exactly what buyers should seek when evaluating forged wheel sources.

When inspecting used wheels of either type, specific warning signs indicate problems worth avoiding:

Used Forged Aluminum Inspection Checklist

- Run fingers along spoke surfaces feeling for cracks or irregularities

- Check bead seats for visible damage or unusual wear patterns

- Look for evidence of prior repairs—welding marks, refinishing inconsistencies

- Inspect spoke-to-hub junction areas where stress concentrates

- Verify the wheel spins true without wobble or vibration

- Ask about impact history—potholes, curb strikes, crashes

Used Carbon Fiber Inspection Checklist

- Perform tap tests across entire wheel surface listening for dead spots

- Examine carefully for hairline cracks, especially near spoke holes

- Look for discoloration or exposed carbon weave indicating wear

- Check for delamination at edges where layers might separate

- Verify manufacturer authenticity—counterfeits exist and pose safety risks

- Request any crash or impact history—even minor incidents matter

The alloy vs aluminium wheels decision for street applications should favor forged construction when budget permits. Cast wheels sacrifice too much durability and performance for the price savings they offer. Motul 300V lubricants might keep your engine protected, but quality forged wheels protect your safety during every rotation.

Ultimately, the carbon fiber vs forged aluminum wheels decision comes down to matching material characteristics to your actual riding patterns. Track warriors benefit from carbon's weight advantages. Street riders benefit from aluminum's forgiveness and repairability. Honest self-assessment about how you ride—not how you imagine riding—leads to the choice you'll appreciate for years to come.

Whatever you choose, invest in quality from reputable manufacturers, inspect regularly for damage, and understand the maintenance requirements your selection demands. Your wheels connect you to the road—they deserve thoughtful selection and proper care.

Frequently Asked Questions About Carbon Fiber vs Forged Aluminum Wheels

1. Are carbon fiber wheels stronger than aluminum?

Strength depends on how you define it. Carbon fiber offers superior stiffness-to-weight ratios and exceptional tensile strength, making it ideal for controlled track conditions. However, forged aluminum demonstrates better impact resistance for road hazards—it bends predictably under stress rather than cracking suddenly. Aluminum absorbs energy and deforms during impacts, providing warning signs before failure, while carbon fiber may crack without visible warning. For street applications with potholes and debris, forged aluminum's ductile properties offer practical durability advantages.

2. What are the disadvantages of carbon fiber rims?

Carbon fiber wheels present several ownership challenges. The primary disadvantage is limited repairability—most structural damage requires complete wheel replacement at costs of $2,500 or more per wheel. Manufacturing is labor-intensive, making prices 3-5x higher than forged aluminum. Carbon fiber can fail suddenly without visible warning signs, unlike aluminum which bends first. Quality varies dramatically between manufacturers, and budget options may exhibit premature failure. Additionally, specialized inspection equipment is needed to detect internal delamination that visual inspection cannot reveal.

3. Can you feel a difference with forged wheels?

Yes, the difference is noticeable. Forged wheels are 20-30% lighter than cast aluminum, delivering improved handling, faster acceleration response, and better ride quality. Compared to cast wheels, forged options offer superior steering feedback and reduced unsprung mass. When upgrading from cast to carbon fiber, the transformation is even more dramatic—40-50% weight reduction creates sharper turn-in, quicker direction changes, and noticeably faster throttle response. Most riders report the difference is immediately apparent during their first ride.

4. How much do carbon fiber wheels cost compared to forged aluminum?

The price gap is substantial. Quality forged aluminum wheelsets typically range from $1,500-$4,000 for most motorcycle and automotive applications. Carbon fiber wheels command $5,000-$15,000 or more depending on size, design complexity, and manufacturer reputation. This 3-5x price premium reflects the labor-intensive manufacturing process, specialized materials, and precision required for carbon fiber construction. Factor in replacement costs after damage—carbon usually requires full replacement while aluminum can often be repaired for $100-$500.

5. Which wheel material is better for street riding versus track use?

For street riding, forged aluminum is the superior choice. Its impact resistance handles potholes and debris better, cosmetic damage can be professionally repaired, and the material provides visible warning signs before structural failure. For dedicated track use, carbon fiber delivers measurable performance advantages—40-50% weight reduction translates to faster lap times through improved acceleration, braking, and direction changes. Many serious enthusiasts maintain both: forged aluminum for street duty and carbon fiber reserved for track sessions where conditions are controlled.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —