Brushed Finish On Forged Wheels: From Raw Aluminum To Showroom Shine

What Makes Brushed Finish Unique on Forged Wheels

A brushed finish on forged wheels is a hand-crafted surface treatment that creates distinctive linear patterns across the aluminum face through controlled abrasive techniques. Unlike mirror-polished or painted surfaces, brushed aluminum wheels feature fine directional lines that catch light at varying angles, producing a subtle yet sophisticated metallic texture. This finishing method has become one of the most sought-after options among automotive enthusiasts who want their wheels to balance raw industrial appeal with refined elegance.

The Signature Look of Brushed Aluminum

What sets brushed finish rims apart from other wheel treatments? Imagine the difference between a sleek stainless steel appliance and a chrome faucet. That same contrast exists in the wheel world. According to Turismo Wheels, hand brushing is a meticulous process where the surface is worked manually, resulting in a subtle pattern that gives wheels a distinctive and luxurious appearance.

This finish stands in deliberate contrast to other popular options:

- High Gloss: Mirror-like shine that requires frequent cleaning but delivers maximum reflectivity

- Matte/Satin: Subtle sheen without directional texture, easier maintenance than gloss

- Diamond Cut: Precision-machined surfaces with exposed bare aluminum accents

- Powder Coated: Durable painted finish with excellent corrosion resistance

Brushed wheels occupy a unique middle ground, offering textural depth without the high-maintenance demands of polished surfaces. Much like how brushed nickel ceiling fans have become a design staple in modern homes for their timeless appeal, brushed aluminum wheels bring that same understated sophistication to automotive applications.

Understanding Linear Surface Patterns on Forged Metal

The magic of brushed wheels lies in their directional grain pattern. When light hits the surface, those fine parallel lines create a soft, diffused reflection rather than a harsh mirror effect. This characteristic makes them particularly forgiving when it comes to hiding minor imperfections, water spots, and everyday road grime.

Car enthusiasts appreciate this finish because it delivers what Velgen Wheels describes as a "high-end industrial look" that feels custom and intentional. The texture adds depth and dimension to wheel designs while maintaining a premium aesthetic that works equally well on sports cars, luxury sedans, and performance builds.

Whether you're drawn to the visual complexity or the practical benefits of concealing minor wear over time, understanding what makes this finish special is the first step toward determining if brushed aluminum wheels are the right choice for your vehicle.

Why Forged Aluminum Excels for Brushed Finishes

Ever wondered why premium wheel manufacturers insist on forged aluminum when creating brushed finishes? The answer lies deep within the metal itself. Not all aluminum wheels are created equal, and the manufacturing process fundamentally determines how well a wheel accepts and retains that distinctive linear texture you're after.

Forged Density and Finish Quality

When aluminum undergoes the forging process, something remarkable happens at the molecular level. According to CEX Casting, forged aluminum develops a continuous grain flow structure that makes the metal dense and virtually defect-free. This creates an ideal canvas for brushed finishing work.

Think of it like woodworking: you'll get far better results sanding a piece of solid hardwood than particleboard. The same principle applies here. Cast aluminum, while perfectly suitable for many applications, contains microscopic pores and inclusions that can create inconsistencies when abrasive brushing techniques are applied. These tiny voids may appear as pits, uneven texture, or interruptions in those clean directional lines that define a quality brushed finish.

Forged polished wheels and their brushed counterparts share this same advantage. The forging process applies tremendous pressure to solid aluminum billets, often accompanied by heat treatment, which refines the grain structure and eliminates the porosity issues common in cast alternatives. Research from the ASM Handbook on Metalworking confirms that forging creates extremely low porosity and high consistency in the final product, making it far superior for demanding surface treatments.

Why Grain Structure Matters for Surface Treatments

Here's where things get interesting for anyone considering brushed aluminium wheels. The grain structure of forged aluminum isn't just denser; it's directionally aligned. During forging, metal flows in specific patterns that create what metallurgists call a "wrought structure." This aligned grain makes the surface respond uniformly to brushing, producing those consistent linear patterns that catch light so beautifully.

Cast aluminum, by contrast, has a more random crystalline structure formed as molten metal cools in a mold. When you apply abrasive brushing to this type of surface, the varying grain orientations can cause uneven material removal. Some areas may scratch deeper than others, creating an inconsistent appearance that's difficult to correct.

The mechanical stress of brushing also demands a robust substrate. Here's why forged aluminum stands up to the challenge:

- Superior tensile and yield strength: Forged aluminum withstands the mechanical forces of brushing without developing micro-cracks or surface defects

- Enhanced fatigue resistance: The dense structure and continuous grain flow make forged wheels extremely resistant to the repeated stress of finishing processes

- Consistent material density: Uniform hardness across the surface ensures even abrasive action and predictable results

- Reduced risk of subsurface defects: Unlike cast wheels prone to shrinkage cavities and air inclusions, forged wheels present a clean, uniform surface for finishing

- Better strength-to-weight ratio: Thinner sections can be achieved without compromising structural integrity, allowing for more refined wheel designs

This metallurgical superiority explains why discerning enthusiasts specifically seek out forged wheels when they want a brushed finish. The investment in forged construction pays dividends not only in performance and durability but also in the quality and longevity of the surface treatment itself.

Understanding these material differences sets the foundation for what comes next: the actual brushing process that transforms raw forged aluminum into that stunning showroom finish.

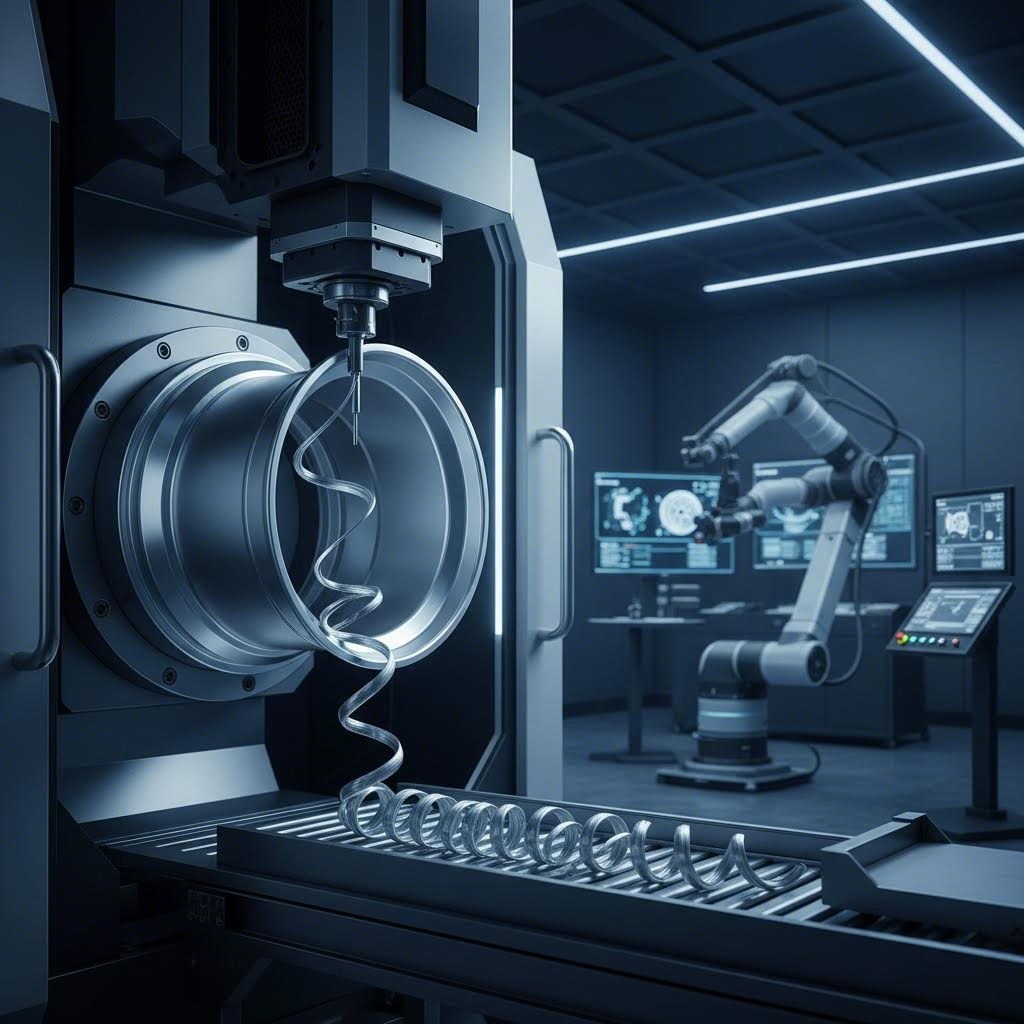

The Complete Brushing Process Explained

Ready to understand exactly how professionals transform raw forged aluminum into those stunning brush finish wheels? The process involves far more precision than simply rubbing sandpaper across metal. Each step builds upon the previous one, and skipping stages or rushing through them will compromise the final result. Whether you're curious about how your wheels were made or considering a refinishing project, this comprehensive breakdown reveals the expert techniques behind flawless brushed finishes.

Surface Preparation and Cleaning Protocols

Before any abrasive touches the aluminum, meticulous preparation is essential. Think of it like painting a car: the prep work determines 90% of the outcome. According to Sasa Aluminum's finishing guide, cleaning is critical to prevent particles from scratching the aluminum during brushing.

The preparation sequence follows a strict protocol:

- Initial Decontamination: Wash the forged wheel thoroughly using a mild detergent and warm water to remove surface dirt, brake dust, and road grime

- Complete Drying: Allow the surface to dry completely, as moisture trapped under abrasives can cause inconsistent scratching patterns

- Solvent Wipe-Down: Clean with acetone or rubbing alcohol to eliminate oil residues, fingerprints, and any remaining contaminants

- Surface Inspection: Examine the wheel under good lighting for defects, pits, or previous coating remnants that need addressing before brushing begins

This isn't the time for shortcuts. Any contamination left on the surface will embed into the aluminum during brushing, creating permanent imperfections that no amount of subsequent work can fix. Much like how you wouldn't skip surface prep when using JB Weld for a critical repair, proper cleaning ensures the brushing process bonds correctly with the base material.

Grit Progression for Optimal Results

Here's where the artistry meets science. Professional wheel finishers follow a deliberate grit progression that gradually refines the surface texture. Jumping straight to fine grits won't work; you need to systematically remove material and scratches from each previous stage.

The typical professional progression looks like this:

| Stage | Grit Range | Purpose | Result |

|---|---|---|---|

| Initial Correction | 120-180 | Remove surface imperfections, casting marks, or old finishes | Coarse, visible brush lines |

| Refinement | 240-320 | Reduce scratch depth from coarse grit, establish uniform pattern | Medium texture with consistent grain |

| Final Brushing | 400-600 | Create the finished brushed appearance with fine, subtle lines | Smooth satin sheen with professional finish |

The key principle: each successive grit removes the scratches from the previous one while creating finer scratches of its own. If you skip a step, the coarser scratches remain visible beneath the finer pattern, ruining the uniform appearance that defines quality brushed aluminum wheels.

For wheels with significant surface defects or old coatings, professionals may start even coarser, around 80-100 grit, before beginning the standard progression. High-quality forged wheels typically require less initial correction due to their superior surface consistency.

Directional Brushing Techniques

This is where polishing brushed aluminum becomes an art form. Unlike random orbital sanding used for other finishes, brushed wheels demand unidirectional stroke patterns. Every pass must follow the same direction to create that characteristic linear grain.

Critical technique elements include:

- Consistent Direction: Move the abrasive in one direction only, typically following the spoke contours or wheel face geometry

- Even Pressure: Maintain uniform pressure throughout each stroke to prevent deep gouges or light spots

- Overlapping Passes: Slightly overlap each stroke to avoid visible transition lines between passes

- Clean Abrasives: Wipe the surface and check your sandpaper or pad frequently; aluminum particles can build up and cause inconsistent scratching

- Single-Use Sections: Replace worn abrasive materials regularly, as dull media creates uneven results

Whether using hand sanding blocks, orbital sanders locked in linear mode, or specialized belt sanding equipment, the directional discipline remains paramount. For how to polish forged wheels with a brushed pattern, circular motions are strictly prohibited unless you're intentionally creating a swirl or cross-hatch design.

Final Refinement and Pre-Coating Preparation

After completing the grit progression, one final step elevates the finish from good to exceptional. Professional finishers use non-woven abrasive pads, commonly known as Scotch-Brite pads, for this critical refinement stage.

The process involves:

- Direction Matching: Rub the non-woven pad in the exact same direction as your previous sanding strokes

- Scratch Removal: This step eliminates fine scratches left by the final grit sandpaper

- Surface Uniformity: Evening out any remaining inconsistencies in the brushed pattern

- Final Cleaning: Wipe the surface with a dry microfiber cloth, then perform one last solvent wipe to ensure complete cleanliness before clear coating

At this stage, the wheel displays that coveted smooth, satin sheen with perfectly uniform directional lines. However, the brushed surface remains vulnerable until protected with an appropriate clear coat, which we'll explore in the next section. The unprotected aluminum, while beautiful, will quickly oxidize and lose its refined appearance without proper sealing.

Understanding this complete process helps you appreciate the craftsmanship behind quality brush finish wheels and sets realistic expectations for anyone considering DIY refinishing projects. It also explains why professionally finished wheels command premium prices: the skill, patience, and attention to detail required at each stage cannot be rushed or automated without compromising results.

Clear Coat Selection and Its Visual Impact

You've invested hours achieving that perfect brushed pattern on your forged wheels. Now comes a decision that will define how your wheels look and perform for years: which clear coat do you apply? This choice isn't merely cosmetic. The protective layer you select dramatically influences everything from visual depth to long-term durability. Surprisingly, many wheel enthusiasts overlook this critical step, yet it's arguably the most important factor in preserving your brushed clear wheels.

High Gloss Clear Coat Characteristics

When you want maximum visual impact, high gloss clear coat delivers that mirror-like shine that makes brushed aluminum pop. This finish creates a deep, wet-look appearance that intensifies the metallic character of your wheel gloss clear coat while adding substantial depth to the brushed pattern beneath.

What makes gloss clear coat stand out?

- Enhanced reflectivity: Light bounces off the surface more intensely, making brushed lines appear more pronounced

- Color depth: The aluminum's natural silver tones appear richer and more dimensional

- Showroom presence: Perfect for display vehicles, show cars, and weekend drivers where appearance matters most

However, that stunning shine comes with trade-offs. According to Painting Drive's finish comparison research, glossy finishes exhibit all small scratches and swirl marks, requiring repeated polishing to look impeccable. For daily-driven vehicles exposed to road debris, brake dust, and frequent washing, maintaining that pristine gloss becomes a demanding commitment.

Satin Finish Protection Options

Imagine getting the protection your brushed finish needs without the high-maintenance demands of gloss. That's exactly what satin clear coat offers. This finish provides a low-luster sheen that complements the brushed texture rather than competing with it, creating a more understated yet equally sophisticated appearance.

The same research from Painting Drive reveals that satin finishes demonstrate superior fingerprint and scratch resistance compared to their glossy counterparts. Industry testing indicates satin finishes last 30-40% longer in terms of appearance during scratch tests. For clear rims that see regular street duty, this durability advantage translates to wheels that look better, longer.

Satin clear coat benefits include:

- Improved UV resistance: Less color fade over time from sun exposure

- Concealed imperfections: Minor scratches and swirl marks remain far less visible

- Reduced maintenance: Studies indicate glossy surfaces require 3-5 times more cleaning effort than satin alternatives

- Modern aesthetic: The subdued sheen aligns with contemporary automotive design trends

Comparing Your Clear Coat Options

Choosing between these finishes depends on your priorities. Are you building a show car that spends weekends at exhibitions? High gloss might be your answer. Daily driving a performance vehicle through all seasons? Satin provides practical advantages that matter over time.

| Factor | High Gloss Clear Coat | Satin Clear Coat |

|---|---|---|

| Appearance | Mirror-like, deep reflections | Subtle sheen, muted elegance |

| Durability | Shows scratches immediately | Conceals minor imperfections |

| UV Protection | Moderate; may degrade faster | Superior; resists fading longer |

| Maintenance | Daily wiping often needed | Weekly dusting typically sufficient |

| Best Application | Show cars, garage queens | Daily drivers, all-weather use |

Application Thickness and Curing Requirements

Regardless of which finish you select, proper application determines long-term success. Clear coat thickness matters significantly for both protection and appearance. Too thin, and you sacrifice durability. Too thick, and you risk runs, orange peel texture, or extended curing times that leave the surface vulnerable.

Professional wheel finishers typically apply clear coat in multiple thin passes rather than one heavy coat. This approach:

- Ensures even coverage without pooling in recessed areas

- Allows proper solvent flash-off between coats

- Creates a uniform film thickness across complex spoke geometries

- Reduces the risk of trapped solvents that cause cloudiness or delamination

Curing requirements vary by product chemistry. Solvent-based clear coats may require 24-48 hours before handling, while two-part catalyzed systems cure faster but demand precise mixing ratios. Heat-accelerated curing in controlled environments produces the hardest, most durable finish but requires specialized equipment.

One critical point: never subject freshly clear-coated wheels to water, chemicals, or heavy use before full cure. Premature exposure can cause hazing, softening, or adhesion failure that ruins all your previous work.

With your clear coat selection understood, the next consideration becomes equally important: how will your chosen finish hold up against the real-world challenges of brake dust, road salt, and UV exposure over months and years of use?

Durability and Longevity Compared to Other Finishes

So you've fallen in love with the look of brushed finish wheels. But here's the question that really matters: how will they hold up after a year of daily driving, harsh winters, or scorching summers? Understanding durability isn't just about protecting your investment. It's about choosing the right finish for your specific driving conditions and maintenance commitment. Let's break down exactly how brushed rims stack up against the competition in real-world scenarios.

Real-World Durability Expectations

When it comes to longevity, brushed finish wheels occupy an interesting middle ground in the wheel finish hierarchy. They're more forgiving than mirror-polished surfaces yet require more attention than powder-coated alternatives. According to Kipardo Racing's finish guide, brushed finishes deliver a midpoint between ruggedness and elegance, giving discerning buyers a high-end look without the higher costs or lead times associated with chrome plating.

What does this mean in practice? The linear texture that defines brushed aluminum actually works in your favor for everyday use. Those fine directional lines naturally camouflage minor scratches, water spots, and light abrasions that would be glaringly obvious on polished surfaces. Think of it like the difference between a pristine hardwood floor and one with a distressed finish. The textured surface tells a story while hiding imperfections.

However, the clear coat protecting your brushed finish becomes the critical factor in long-term durability. Once that protective layer fails, the exposed aluminum oxidizes rapidly, dulling that distinctive satin sheen you paid for. Much like how proper garage door insulation protects your home's interior from temperature extremes, quality clear coat shields your brushed surface from environmental assault.

Environmental Factors Affecting Finish Longevity

Your driving environment dramatically impacts how long any wheel finish survives. Brushed finish wheels face three primary enemies: road salt, brake dust, and UV radiation. Understanding each threat helps you make informed decisions about maintenance and finish selection.

Road Salt Exposure: Winter driving presents significant challenges for all wheel finishes. Salt accelerates corrosion, attacking any breach in the clear coat barrier. Brushed finishes with quality clear coats resist salt intrusion effectively, but require prompt cleaning after exposure. The textured surface can trap salt residue in the linear grooves, making thorough rinsing essential.

Brake Dust Accumulation: Hot brake dust particles embed themselves into wheel surfaces, causing chemical etching if left untreated. The Kipardo Racing research emphasizes that regular cleaning to remove brake dust and salt, followed by protective sealant application, ensures wheels don't corrode prematurely. Brushed surfaces hide dust buildup better than gloss finishes, but this can be deceptive. Just because you can't see the contamination doesn't mean it isn't causing damage.

UV Radiation: Prolonged sun exposure degrades clear coat integrity over time, leading to yellowing, chalking, and eventual failure. Satin clear coats typically outperform gloss versions in UV resistance, making them the smarter choice for vehicles parked outdoors or driven in sun-intensive climates.

Finish Comparison Matrix

How do brushed finish wheels compare to other popular options? This breakdown helps you weigh your priorities:

| Finish Type | Scratch Visibility | Corrosion Resistance | UV Durability | Maintenance Level | Touch-Up Difficulty |

|---|---|---|---|---|---|

| Brushed | Low (texture hides minor marks) | Moderate (clear coat dependent) | Good with satin coat | Moderate | High (extremely difficult to match directional pattern) |

| Polished | Very High (every mark shows) | Low (oxidizes quickly) | Poor without coating | High | Difficult (full refinish often needed) |

| Painted | Moderate | High | Moderate | Low | Easy (touch-up paint available) |

| Powder Coated | Low | Excellent | Excellent | Very Low | Difficult (requires recoating) |

Touch-Up and Refinishing Considerations

Here's something most buyers don't consider until it's too late: what happens when your finish eventually needs attention? Brushed wheels present unique refinishing challenges that differ significantly from other finish types.

Minor clear coat damage on brushed surfaces can sometimes be addressed with spot application, but achieving invisible repairs requires matching the exact sheen level and application technique. Unlike painted wheels where touch-up is straightforward, brushed finishes demand directional consistency that's difficult to replicate in small areas.

When damage extends to the brushed aluminum itself, refinishing becomes more complex. You'll need to:

- Strip the damaged area completely down to bare aluminum

- Re-brush using the same grit progression and directional technique

- Blend the new brushing pattern seamlessly with surrounding areas

- Reapply clear coat to the entire wheel face for uniform appearance

This process explains why professional refinishing of brushed wheels costs more than painted alternatives. The skill and time investment is significantly higher. For vehicles stored in controlled environments, like temperature-regulated garages with proper garage door insulation, brushed finishes can last many years without intervention. Daily drivers in harsh climates should budget for periodic professional assessment.

The durability question ultimately comes down to this: are you willing to perform moderate, consistent maintenance in exchange for that distinctive linear aesthetic? If the answer is yes, brushed finish wheels deliver excellent value. If you prefer truly set-and-forget durability, powder coating may better suit your lifestyle. Understanding these trade-offs now prevents disappointment later and helps you enjoy your wheels for years to come.

Maintenance and Care for Brushed Wheel Finishes

Now that you understand durability expectations, let's tackle the question that drives countless forum debates: can you polish brushed aluminum wheels without ruining them? Whether you're dealing with surface oxidation, considering a finish change, or simply want to keep your wheels looking pristine, understanding proper maintenance techniques protects your investment and preserves that distinctive linear aesthetic.

Can You Polish Brushed Wheels Without Damage

Here's the honest answer that many enthusiasts don't want to hear: traditional polishing will destroy your brushed finish. The circular buffing motions and abrasive compounds used in conventional metal polishing work against everything that makes brushed wheels special. Those directional lines you paid for? They'll disappear under a swirled, mirror-like surface within minutes of aggressive polishing.

Think of it this way: brushing and polishing are fundamentally opposite surface treatments. Brushing creates texture through controlled linear scratches, while polishing removes scratches to create smoothness. You can't have both simultaneously. Attempting to "refresh" a brushed finish with polishing compounds is like trying to preserve wood grain by sanding it completely smooth.

However, there's an important distinction to understand. Light cleaning and conditioning isn't the same as polishing. You can safely:

- Clean the clear coat surface: Gentle washing and waxing maintain protection without affecting the underlying brushed pattern

- Remove light contamination: Clay bar treatment on the clear coat lifts embedded contaminants safely

- Apply sealants: Protective coatings add UV resistance and hydrophobic properties without altering texture

The key is never penetrating through the clear coat layer to the brushed aluminum beneath during routine maintenance. Once you breach that barrier with abrasives, you've committed to refinishing the entire surface.

Restoration Options for Worn Brushed Finishes

What happens when your brushed finish genuinely needs restoration? Perhaps the clear coat has failed, oxidation has set in, or physical damage has compromised the surface. You have two paths forward, and understanding both helps you make the right decision for your situation.

Option One: Re-Brushing

If you want to maintain the brushed aesthetic, the damaged area must be stripped to bare aluminum and re-brushed using the same grit progression and directional technique as the original finish. This requires matching stroke direction, pressure, and final grit to achieve seamless blending. It's similar to restoration projects in other areas. Just as popcorn ceiling removal requires careful technique to avoid damaging the underlying surface, brushed wheel restoration demands patience and proper methodology to preserve the intended appearance.

Option Two: Conversion to Polished

Some owners decide worn brushed wheels present an opportunity to switch finishes entirely. Converting to a mirror-polished surface is technically possible on forged aluminum, but requires completely removing the brushed texture through progressive polishing stages. This is a labor-intensive process that changes the wheel's character entirely.

Daily and Weekly Maintenance Protocols

Prevention beats restoration every time. Proper ongoing care extends the life of your brushed finish dramatically while keeping your wheels looking their best between professional detailing sessions.

Recommended Cleaning Products:

- pH-neutral wheel cleaners specifically formulated for coated surfaces

- Soft microfiber wash mitts that won't scratch clear coat

- Dedicated wheel brushes with soft bristles for spoke crevices

- Spray-on ceramic sealants for added protection between washes

- Distilled water for final rinsing in hard water areas

Products to Avoid:

- Acidic wheel cleaners that can attack clear coat integrity

- Abrasive polishing compounds or rubbing compounds

- Steel wool, scotch-brite pads, or aggressive scrubbing tools

- Automatic car washes with harsh brush systems

- Pressure washers at close range or extreme settings

- Petroleum-based tire dressings that may sling onto wheel surfaces

The goal is simple: keep contaminants off the surface before they cause damage, and clean gently when removal becomes necessary. Brake dust should be removed weekly for daily drivers, as its metalite particles become increasingly difficult to remove the longer they remain embedded in the clear coat.

Following these maintenance guidelines keeps your brushed finish on forged wheels looking showroom-fresh while avoiding the costly refinishing that results from neglect or improper cleaning techniques. The effort is modest compared to high-gloss alternatives, and the payoff is years of that distinctive linear aesthetic that caught your attention in the first place.

Choosing Brushed Finish for Your Application

You've learned the process, understood the durability factors, and know how to maintain brushed wheels properly. Now comes the most personal decision: is this finish actually right for your specific situation? Not every vehicle, driving style, or lifestyle pairs equally well with brushed aluminum. Making the wrong choice means either excessive maintenance frustration or missing out on a finish that could perfectly complement your build.

Matching Finish Choice to Your Driving Style

How you use your vehicle day-to-day should heavily influence your finish selection. According to Aura Forged's consultation insights, finish selection is deeply personal and reflects how you see yourself, how you want your car to present itself, and what kind of attention you're comfortable attracting.

Consider brushed finish ideal for these scenarios:

- Weekend enthusiasts: Vehicles that see regular spirited driving but aren't daily commuters benefit from the forgiving texture that hides minor road wear

- Show car builds: The distinctive linear pattern photographs exceptionally well and stands out at meets and exhibitions

- Performance-focused drivers: Those who prioritize function appreciate that brushed finishes require less obsessive cleaning than mirror-polished alternatives

- Moderate climate regions: Areas without extreme salt exposure or year-round intense UV bombardment maximize finish longevity

When might alternatives serve you better? Daily drivers in harsh winter climates may find powder coating's superior corrosion resistance more practical. Owners who rarely wash their vehicles should consider that even forgiving finishes need periodic attention. And if you genuinely enjoy the ritual of weekly polishing, mirror-finished wheels might satisfy that maintenance preference better.

Aesthetic Considerations for Different Vehicle Types

The relationship between wheel finish and body color creates your vehicle's overall visual impact. Some combinations enhance each other beautifully, while others create unintended tension that diminishes the build's cohesion.

White, Silver, and Light-Colored Vehicles: These platforms offer maximum flexibility with brushed wheels. The linear metallic texture creates subtle contrast without overwhelming lighter body colors. Brushed aluminum reads as refined and technical rather than aggressive, complementing modern European sports cars and luxury sedans particularly well.

Black and Dark-Colored Vehicles: Here's where brushed finishes truly shine. The lighter aluminum tones create necessary separation, defining wheel outlines clearly against dark paint. This contrast prevents the visual flatness that occurs when matte black wheels disappear into black bodywork. The textured surface catches light in ways that add dimension to overall appearance.

Red, Blue, and Saturated Colors: Brushed aluminum serves as a neutral foundation that doesn't compete for attention with vibrant body colors. Unlike polished chrome that might clash with bold paint, brushed finishes complement without overwhelming. The subdued metallic character allows your paint to remain the visual focus.

Electric Vehicles and Modern Designs: Contemporary EVs with progressive styling often pair exceptionally well with brushed finishes. The industrial-yet-refined aesthetic aligns with the tech-forward character these vehicles already possess. Tesla's minimalist design language, for example, harmonizes naturally with brushed aluminum's clean lines.

Ultimately, your finish choice should feel intentional every time you see your vehicle. Brushed aluminum rewards those who appreciate texture, understand its maintenance requirements, and value the distinctive character it brings to their build. When the match is right, you'll know it. That confident satisfaction each time you approach your car confirms you've made the correct decision for your specific application.

Manufacturing Quality and Finish Excellence

You've selected the perfect brushed finish, understand the maintenance requirements, and know it suits your application. But here's what separates wheels that look stunning for years from those that disappoint within months: manufacturing quality. The precision behind forged wheel production directly determines how well that brushed surface will turn out and how long it will last. Think of it like comparing a handcrafted timepiece to a mass-produced watch. Both tell time, but the underlying quality defines the ownership experience.

Quality Control in Wheel Finishing

What happens before the brushing process even begins matters enormously. According to Kipardo Racing's manufacturing analysis, reputable wheel manufacturers conduct rigorous testing including load simulation, concentricity tests, and dimensional checks using Finite Element Method analysis to identify weak spots before wheels ever hit the road.

Why does this matter for brushed finishes specifically? Consider what you've learned about the brushing process. Consistent grit progression, uniform pressure, and directional precision all depend on starting with a flawless substrate. Manufacturing defects hidden beneath the surface will reveal themselves during brushing as:

- Inconsistent texture patterns: Porosity variations cause uneven material removal during abrasive passes

- Visible inclusions: Foreign particles embedded during casting or forging create pits that interrupt linear patterns

- Surface waviness: Dimensional inconsistencies from poor machining translate to visible high and low spots after brushing

- Premature clear coat failure: Subsurface defects create stress points where protective coatings crack or delaminate

Much like how precision matters when using an oscillating tool for detailed work, wheel manufacturing demands exacting standards at every production stage. CNC machining tolerances, heat treatment consistency, and surface preparation all contribute to final finish quality.

What Separates Premium Brushed Wheels from Budget Options

The difference between premium forged wheels and budget alternatives often isn't visible until finishing reveals underlying quality disparities. As Flexiforge Wheel's certification guide emphasizes, selecting manufacturers with comprehensive certifications demonstrates thorough dedication to quality, safety, and industry standards.

Premium manufacturers distinguish themselves through:

- Material traceability: 6061-T6 aluminum billets sourced from certified suppliers with documented metallurgical properties

- Process control: Documented procedures ensuring every wheel receives identical treatment through forging, heat treatment, and machining

- Inspection protocols: Multiple quality checkpoints catching defects before finishing operations begin

- Consistent metallurgy: Uniform grain structure across production batches enabling predictable brushing results

IATF 16949:2016 certification is vital for wheel manufacturers supplying major automakers. It covers the entire production process, ensuring high-quality standards at every stage with focus on continuous improvement and defect prevention.

This automotive industry quality standard matters because it demands the systematic approach that produces consistently excellent base materials for brushed finishes. Companies like Shaoyi (Ningbo) Metal Technology exemplify this commitment through IATF 16949 certification combined with in-house engineering capabilities that ensure precision hot forging meets exact specifications. Their rigorous quality control throughout the forging process creates the kind of uniform, defect-free aluminum substrate that takes brushed finishes beautifully.

The connection between forging expertise and finish quality isn't coincidental. When manufacturers control every variable from billet selection through final machining, the resulting wheel surface presents an ideal canvas for brushed finishing. Conversely, budget wheels often sacrifice quality control steps that seem unrelated to appearance but directly impact how finishes perform long-term.

Certification Standards That Matter

How can you identify manufacturers committed to quality before purchasing? Look for these key certifications that indicate proper manufacturing discipline:

| Certification | What It Indicates | Relevance to Finish Quality |

|---|---|---|

| ISO 9001 | Quality management system compliance | Consistent processes produce uniform surfaces |

| IATF 16949 | Automotive industry quality standards | Defect prevention and continuous improvement |

| JWL/JWL-T | Japanese safety and quality requirements | Structural integrity supporting finish longevity |

| TÜV | European safety and durability testing | Rigorous stress testing validates substrate quality |

An oscillating tool in the hands of a skilled craftsman produces different results than the same tool wielded carelessly. Similarly, certified manufacturing processes in the hands of experienced engineers produce forged wheels that accept and retain brushed finishes far better than those from facilities cutting corners on quality control.

When evaluating brushed wheel options, don't focus solely on price or appearance in photographs. Investigate the manufacturer's certifications, production capabilities, and quality control documentation. This due diligence pays dividends in finish quality, longevity, and overall satisfaction with your investment. The wheels that look best after years of use invariably come from manufacturers who never compromised on the production standards that made premium brushed finishes possible in the first place.

Essential Insights for Brushed Wheel Selection

You've journeyed from understanding what makes brushed finish on forged wheels unique through the intricate manufacturing and finishing processes that create them. Now it's time to consolidate everything into actionable guidance you can apply when making your purchase decision. Whether you're upgrading a weekend track car or refining a daily driver's appearance, these takeaways will help you evaluate options confidently and avoid common pitfalls.

Key Takeaways for Wheel Enthusiasts

After exploring every aspect of brushed forged wheels, certain principles emerge as non-negotiable for making a smart purchase. Keep these fundamentals front and center when shopping:

- Forged construction matters: The denser grain structure and reduced porosity of forged aluminum create superior brushing results compared to cast alternatives. Never compromise on this foundation.

- Clear coat selection defines longevity: Satin clear coats offer better scratch concealment and UV resistance for daily drivers, while high gloss maximizes visual impact for show vehicles.

- Manufacturer certifications indicate quality: Look for IATF 16949, ISO 9001, or JWL certifications that demonstrate commitment to consistent production standards affecting finish quality.

- Maintenance requirements are moderate: Brushed finishes forgive more than polished surfaces but still require regular cleaning with pH-neutral products to prevent brake dust etching.

- Refinishing costs exceed painted alternatives: Understand that restoring damaged brushed surfaces demands skill and time, making quality initial finishing worth the investment.

Making an Informed Finish Decision

The decision to choose brushed aluminum wheels ultimately comes down to matching your priorities with what this finish delivers. Ask yourself these questions before committing:

- Does your driving environment expose wheels to extreme salt, heat, or UV radiation that might favor powder coating instead?

- Are you comfortable with weekly brake dust removal to maintain appearance and prevent surface damage?

- Does the distinctive linear texture complement your vehicle's color and design language?

- Have you verified the manufacturer's quality certifications and material specifications?

- Do you understand both clear coat options and which suits your intended use?

When you can answer these questions confidently, you're ready to purchase. The knowledge you've gained about grit progression, directional brushing techniques, and protective coating options positions you to evaluate wheel quality far beyond surface appearance. You'll recognize when manufacturers have invested in proper finishing versus those cutting corners on the steps that determine long-term satisfaction.

Brushed finish on forged wheels represents a compelling balance between raw metallic character and refined sophistication. For enthusiasts who appreciate texture, understand the care requirements, and value wheels that improve with age rather than demanding constant attention, this finish delivers exactly what it promises: distinctive style backed by the engineering excellence that forged construction provides.

Frequently Asked Questions About Brushed Finish on Forged Wheels

1. How do you fix a brushed finish on forged wheels?

Fixing a brushed finish requires stripping the damaged area to bare aluminum, then re-brushing using the same grit progression (typically 120-600 grit) and directional technique as the original. You must match stroke direction and pressure precisely to blend seamlessly with surrounding areas. After re-brushing, apply clear coat to the entire wheel face for uniform appearance. For minor clear coat damage, spot treatment may work, but matching sheen levels requires professional skill. IATF 16949-certified manufacturers like Shaoyi Metal Technology produce wheels with consistent metallurgy that refinish more predictably.

2. Should I add clear coat to brushed forged aluminum wheels?

Yes, clear coat is essential for protecting brushed forged wheels. Without it, exposed aluminum oxidizes rapidly, dulling the distinctive satin sheen. Choose between high gloss clear coat for maximum visual impact and mirror-like reflections, or satin clear coat for better scratch concealment and UV resistance. Satin finishes last 30-40% longer in appearance tests and require less frequent cleaning. Ceramic coating can still be applied over clear coat for additional hydrophobic protection. Apply clear coat in multiple thin passes for even coverage.

3. Can you polish brushed aluminum wheels to make them polished?

Converting brushed wheels to polished is possible but requires completely removing the brushed texture through progressive polishing stages. Traditional polishing destroys the linear pattern that defines brushed finishes. The process involves heavy wet sanding to eliminate directional lines, followed by compound polishing to achieve mirror smoothness. This is labor-intensive and fundamentally changes the wheel's character. If your wheels were originally polished before brushing, restoration is easier. For maintenance without conversion, use pH-neutral cleaners and avoid abrasive compounds that penetrate the clear coat.

4. What is the difference between brushed wheels vs polished wheels?

Brushed wheels feature fine directional lines created through controlled abrasive techniques, producing a subtle satin sheen that catches light at varying angles. Polished wheels have mirror-smooth surfaces with maximum reflectivity. Key differences include maintenance level (brushed hides minor scratches while polished shows every mark), durability (brushed finishes are more forgiving for daily driving), and aesthetics (brushed offers industrial refinement versus polished's showroom brilliance). Brushed finishes require moderate cleaning effort while polished surfaces need obsessive maintenance to remain pristine.

5. How much does a brushed finish on forged wheels cost?

Brushed finish costs vary based on wheel size, manufacturer quality, and clear coat selection. Premium forged wheels with brushed finishes typically command higher prices than painted alternatives due to the hand-finishing process requiring skilled craftsmanship. Professional refinishing of existing wheels costs more than painted options because matching directional brushing patterns demands significant skill and time. Quality-certified manufacturers with IATF 16949 certification may charge premium prices but deliver superior base materials that accept brushing better and maintain appearance longer, representing better long-term value.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —