8 Essential Points About Custom Forged Gears For Racing Transmissions

Understanding Custom Forged Gears in Racing Applications

When milliseconds separate winners from the rest of the pack, every component in your car transmission matters. Custom forged gears for racing transmissions represent the pinnacle of drivetrain engineering—precision components designed to handle extreme torque, survive punishing heat cycles, and deliver power with remarkable efficiency. But what exactly makes these gears so special, and why do serious racers consider them essential investments?

At its core, a custom gearbox built around forged components offers something that off-the-shelf solutions simply cannot match: purpose-built performance tailored to your specific racing application. Whether you're building a dedicated drag car or a road racing machine, understanding the engineering behind these components helps you make smarter decisions about your drivetrain.

What Makes Forged Gears Different from Standard Components

Imagine the difference between a handcrafted blade and a mass-produced knife. That's essentially the distinction between forged and cast gears. During the forging process, manufacturers heat metal billets and apply extreme compressive pressure to shape them. This intense pressure does something remarkable—it aligns the metal's internal grain structure along the contours of the gear teeth.

Cast gears, by contrast, are formed by pouring molten metal into molds. While this method offers flexibility in design and lower production costs, it often introduces microscopic voids and porosity as the metal solidifies. These imperfections become stress concentrators under racing loads, potentially leading to premature failure.

Machined gears cut from solid billet stock offer excellent precision, but the cutting process actually disrupts the metal's natural grain flow. According to industry research, forged components can deliver up to 26% greater tensile strength and 37% better fatigue life compared to their cast counterparts.

The Engineering Foundation of Racing Transmission Performance

Why does grain structure matter so much in racing applications? Think about what custom transmission gears actually experience during competition. They endure repeated shock loads during aggressive shifts, sustained high-RPM operation, and torque spikes that would destroy lesser components. The continuous, aligned grain structure in forged gears creates natural resistance to these forces.

Custom gears designed for racing also allow engineers to optimize gear ratio selection for specific tracks, power curves, and racing disciplines. Unlike production gearbox gears designed for broad applications and longevity under normal driving conditions, racing components prioritize maximum performance within their intended operational envelope.

Throughout this technical deep-dive, we'll explore the metallurgical science behind forging, examine heat treatment processes, and help you understand exactly what separates championship-caliber drivetrain components from the rest. The concepts might sound complex, but we'll break everything down into accessible explanations that give you genuine insight into the engineering—not just marketing claims.

The Forging Process and Metallurgical Advantages

So what actually happens when a gear blank transforms into a race-ready component? The answer lies in the forging process itself—a controlled, violent reshaping of metal that fundamentally changes its internal structure. Understanding this process helps you appreciate why custom gear manufacturing for racing applications demands such precision and expertise.

When manufacturers produce gear forgings, they start with a metal billet heated to temperatures between 1000°C and 1200°C for steel alloys. At this temperature, the metal becomes malleable without melting. Massive hydraulic presses then apply extreme compressive force—we're talking thousands of tons of pressure—forcing the metal to flow into precision dies that define the gear's final shape.

Grain Structure and Why It Matters for Durability

Here's where things get interesting. Every piece of metal contains a crystalline grain structure—think of it like wood grain in timber. When you forge a gear, that intense pressure doesn't just reshape the exterior. It compresses and realigns the internal grain structure to follow the contours of the gear teeth.

Why does this matter for racing? According to research from the University of Toledo's engineering departments, forged parts demonstrate:

- 26% higher tensile strength – the gear can handle greater pulling and twisting forces

- 37% higher fatigue strength – significantly longer service life under repeated stress cycles

- 44% greater yield strength – parts resist deformation under extreme loads

- Greater deformation area before failure – the component will show warning signs before catastrophic failure

When a high precision gears manufacturer uses forging, the grain fibers remain continuous and uninterrupted throughout the component. This creates natural load paths that efficiently distribute stress across the entire gear tooth, rather than concentrating it at weak points.

Compare this to machined gears cut from solid billet. While machining offers excellent dimensional accuracy, the cutting process literally slices through the metal's grain structure. Those interrupted grain boundaries become potential crack initiation sites under the repeated loading that racing transmissions experience.

From Raw Billet to Race-Ready Component

The journey from raw material to finished custom made gears involves several critical stages. First comes heating—achieving uniform temperature distribution throughout the workpiece ensures consistent material properties. Uneven heating creates internal stresses that can cause warping or cracking later.

Next, preforming roughly shapes the heated metal into a form approximating the final geometry. This step distributes material efficiently and minimizes waste during finish forging. For racing applications, a skilled custom gear manufacturer typically uses closed-die forging, where precision dies contain the exact negative impression of the desired gear shape.

During finish forging, hydraulic presses force the preformed blank into these dies under tremendous pressure. The metal flows to fill every detail of the die cavity, creating the tooth profiles, splines, and other features. This near-net-shape process means less machining later—and less machining means fewer opportunities to introduce surface defects.

The optimized grain flow and absence of porosity in forged gears dramatically enhances fatigue strength, allowing them to endure many more stress cycles before crack initiation.

The key metallurgical advantages of forging versus casting and machining include:

- Elimination of porosity – casting traps gases and creates shrinkage voids as metal solidifies; forging compresses these out completely

- Aligned grain flow – fibers follow gear contours, maximizing strength in the direction of loading

- Increased density – compressed metal structure provides superior hardness and wear resistance

- Better fatigue resistance – continuous grain boundaries resist crack propagation under cyclic loading

- Improved impact resistance – interlocked grain structure absorbs shock loads more effectively

- Superior heat treatment response – uniform microstructure ensures consistent hardening results

For custom gearbox gears designed to handle racing stresses, these advantages translate directly to real-world reliability. When you're applying 1,000+ horsepower through a transmission, launching hard off the line, or running at sustained high RPM, forged components provide the metallurgical foundation for consistent performance.

Understanding this foundation sets the stage for exploring how heat treatment further enhances these properties—transforming an already strong forged gear into a truly race-ready component.

Heat Treatment and Its Impact on Gear Performance

You've got a perfectly forged gear blank with optimized grain structure—but it's not race-ready yet. Without proper heat treatment, even the finest forged component lacks the surface hardness to resist wear and the core toughness to absorb shock loads. Think of heat treatment as the final transformation that unlocks your gear's full potential.

Here's the challenge engineers face: surface hardness and core toughness pull in opposite directions. Maximize one, and you often compromise the other. Racing transmission gears need both—hard surfaces to prevent wear during thousands of gear mesh cycles and tough cores to survive aggressive launches and missed shifts. Getting this balance wrong is one of the most common failure points in racing drivetrain components.

Surface Hardness Versus Core Toughness Trade-offs

Imagine your gear tooth as having two distinct zones. The outer layer—called the case—needs to be armor-plated against the grinding friction of gear mesh contact. Meanwhile, the inner core must remain relatively soft and ductile, able to flex slightly under heavy loads without cracking.

According to Crown Race Gears' technical documentation, automotive gears use mild steel with relatively low carbon content (less than 0.25%) specifically because it provides excellent toughness. This allows teeth to flex slightly under heavy loads and absorb energy without fracturing. The drawback? Soft material wears away quickly under friction.

High-performance racing gears solve this dilemma through case hardening—adding carbon to the outer surface while preserving the tough, ductile core. The result is a gear with:

- Surface hardness of 58-62 HRC – extremely resistant to wear, pitting, and surface fatigue

- Core hardness of 25-40 HRC – tough enough to absorb shock loads and prevent tooth breakage

- Gradual transition zone – prevents stress concentration between hard and soft regions

When steel is heated in the presence of carbon and then rapidly cooled (quenched), the internal crystalline structure transforms from austenite to martensite. This martensitic structure allows for much higher carbon concentration, creating extreme hardness. The rapid quenching—happening at approximately the speed of sound—causes microscopic dislocations throughout the structure that block shear stresses, scratches, and dents.

Heat Treatment Methods for Racing Applications

Different racing disciplines demand different heat treatment approaches. Your choice depends on load requirements, dimensional tolerances, operating temperatures, and budget constraints. Let's examine the primary methods:

Carburizing operates at high temperatures (1,400°F to 1,700°F) inside a carbon-rich environment. The gear absorbs additional carbon atoms, then undergoes oil quenching to lock in that carbon. This process delivers deep case depths (1-2mm or more) and maximum load capacity—research indicates carburized gears handle 30-50% more load than through-hardened alternatives.

The tradeoff? Carburizing causes significant dimensional changes (0.05-0.15mm), requiring post-treatment grinding. It also limits operating temperatures to about 150°C continuous. For high-torque racing applications like drag racing, these compromises are worthwhile.

Nitriding works at lower temperatures (500-550°C), using nitrogen diffusion rather than carbon to harden the surface. According to Nitrex's technical analysis, nitriding produces harder surfaces (55-65 HRC) with minimal distortion—typically under 0.025mm. The process also creates compressive stress that improves bending fatigue resistance without requiring additional shot peening.

Nitrided gears excel in applications requiring dimensional stability and can operate at temperatures up to 455°C. However, case depths remain shallower (0.2-0.6mm), making them better suited for precision applications with moderate loads.

Through-hardening creates uniform hardness (28-45 HRC) throughout the entire gear—no separate case and core. This approach offers faster processing times and lower costs but provides less surface durability than case-hardened alternatives. It works well for moderate-load applications and prototyping.

| Heat Treatment Method | Surface Hardness (HRC) | Case Depth | Dimensional Change | Ideal Racing Application |

|---|---|---|---|---|

| Carburizing | 58-62 | 0.5-2.0mm | 0.05-0.15mm | Drag racing, high-torque applications |

| Nitriding | 55-65 | 0.2-0.6mm | <0.025mm | Road racing, precision assemblies |

| Through-Hardening | 28-45 (uniform) | Full depth | 0.025-0.076mm | Moderate loads, prototyping |

| Induction Hardening | 50-60 | 1.5-6mm (selective) | Localized | Selective tooth hardening |

Premium manufacturers like Crown Race Gears take heat treatment even further with cryogenic treatment—freezing gears below -300°F to complete the austenite-to-martensite transformation that standard quenching leaves incomplete. This additional step maximizes case hardness and uniformity.

The thoroughly hardened case depth matters enormously for durability. Quality racing gears maintain 0.028-0.030 inches of fully hardened case, while lower-quality alternatives may run as thin as 0.010 inches. When aggressive finishing operations remove too much material, they can compromise this protective layer entirely.

Getting heat treatment right requires matching your steel alloy to the appropriate process. Low-carbon steels like 8620 and 9310 are designed for carburizing, while medium-carbon steels like 4140 and 4340 pair with nitriding or through-hardening. Mismatching—like attempting to carburize 4140—creates excessive surface carbon and leads to cracking during quench.

With a solid understanding of how heat treatment transforms gear performance, you can better appreciate how different racing disciplines place unique demands on these carefully engineered components.

Racing Discipline Requirements and Gear Specifications

Not all racing is created equal—and neither are the gears that power different disciplines. A transmission that thrives in quarter-mile drag racing would likely fail catastrophically in a 24-hour endurance event. Understanding these discipline-specific demands helps you specify the right custom forged gears for your application and avoid expensive mismatches between component capabilities and racing requirements.

Each motorsport discipline places unique stresses on drivetrain components. The torque converter in a drag car experiences vastly different loads than one in a road racing machine. Similarly, the transmission valve body must respond to shifting patterns that vary dramatically between a rally stage and a road course. Let's examine what makes each discipline unique—and how gear specifications must adapt accordingly.

Drag Racing Gear Requirements and Torque Considerations

Drag racing represents the most extreme instantaneous loading scenario in motorsport. When a 3,000+ horsepower Top Fuel car launches, the transmission experiences torque spikes that would shatter components designed for any other application. Even in sportsman classes, launches regularly subject gears to forces far exceeding continuous operation limits.

What makes drag racing uniquely challenging? Consider the math: you're applying maximum engine torque through a stationary drivetrain, often with sticky slicks gripping a prepared surface. That initial moment of engagement creates shock loads several times higher than steady-state operation. Many competitors running modified th400 transmission setups or turbo 400 transmission builds understand this reality—it's why these robust platforms remain popular despite their age.

- Extreme torque capacity – gears must handle momentary loads 3-5 times rated continuous torque during launches

- Limited cycle life requirements – a drag gear might see 1,000 passes versus millions of cycles in road racing

- Wider tooth profiles – increased contact area distributes shock loads more effectively

- Deep case hardening – carburized surfaces resist the crushing forces of high-torque mesh contact

- Aggressive dog engagement – instant, positive shifts without synchro delay

- Optimized first and second gear ratios – maximizing acceleration off the line matters most

Gear ratio selection in drag racing follows a distinct philosophy. According to Grassroots Motorsports' technical analysis, drag applications prioritize the lowest possible first gear ratio for aggressive launches, with carefully spaced steps from there. The goal is keeping the engine in its peak torque band throughout the run while minimizing shift points.

Material choices reflect these priorities. Drag gears typically use alloys like 9310 aerospace steel with deep carburizing—sometimes exceeding 0.040 inches of case depth—to handle repeated shock loading. The gearbox box itself often requires reinforcement to contain these forces without case distortion.

Road Racing Versus Rally Transmission Demands

Road racing flips the script entirely. Instead of brief, violent passes, road racing transmissions endure sustained high-RPM operation across hours of competition. Heat management becomes paramount, and cycle life requirements jump from thousands to potentially millions of gear mesh engagements.

Think about what a road racing transmission experiences during a typical session. The valve body orchestrates countless shifts as drivers work through corners, the engine screaming near redline lap after lap. Many road racers building serious platforms evaluate options like the 700r4 transmission for its overdrive capability and relative compactness—though racing applications typically require extensive modification.

- Sustained high-RPM operation – gears must maintain precision at 7,000+ RPM for extended periods

- Superior heat dissipation – friction generates significant thermal load during continuous running

- Fatigue resistance priority – components must survive millions of loading cycles

- Closer ratio spacing – keeping the engine in its powerband through varying corner speeds

- Lighter weight construction – reducing rotating mass improves acceleration and deceleration

- Nitriding-friendly alloys – dimensional stability matters when tolerances are measured in microns

The technical analysis from Your Data Driven explains why road racing gear ratio optimization gets complex: "You want gearbox ratios that ensure you hit maximum speed on the straights, whilst ensuring you have the best possible acceleration at launch and coming out of each corner." This requires analyzing speed traces from data acquisition and plotting tractive force curves against track-specific velocity profiles.

Rally transmissions face yet another set of challenges. These gearboxes must survive brutal shock loads from jumps and rough terrain, resist damage from debris ingestion, and deliver consistent performance across wildly varying conditions—from frozen tundra to desert heat.

- Extreme shock load resistance – landing jumps creates instantaneous forces exceeding normal racing loads

- Debris and contamination tolerance – dust, mud, and water intrusion are constant threats

- Wide ratio spread – covering everything from hairpin turns to high-speed stages

- Robust synchronizer design – repeated downshifts on challenging surfaces demand durability

- Enhanced sealing requirements – keeping contaminants out under adverse conditions

- Thick case depth – protecting against surface damage from particle ingestion

The tooth profile itself changes between disciplines. Drag racing often uses wider, stubbier teeth that maximize contact area for torque transfer. Road racing favors finer-pitch teeth with optimized involute profiles for smooth, quiet operation at sustained high speeds. Rally specifications typically fall somewhere between—balancing strength against operational refinement.

Understanding these discipline-specific requirements is essential before approaching any custom gear manufacturer. The more precisely you can define your application's demands—power levels, operating conditions, expected service life, and performance priorities—the better equipped engineers become to specify appropriate materials, heat treatments, and geometric designs for your unique requirements.

The Custom Gear Ordering Process Explained

Ready to move from understanding gear engineering to actually ordering custom forged gears for your racing transmission? The process might seem intimidating at first—you're essentially commissioning precision components built specifically for your application. But working with experienced custom gearbox manufacturers follows a logical progression that transforms your performance goals into race-ready hardware.

Whether you're building a custom transmission from scratch or upgrading an existing platform, the ordering process rewards preparation. The more detailed information you bring to initial consultations, the faster engineers can develop solutions that match your exact requirements. Let's walk through what you need to know before picking up the phone.

Information You Need Before Ordering Custom Gears

Imagine walking into a tailor without knowing your measurements—that's essentially what happens when racers approach custom gearbox suppliers without proper preparation. According to Lawler Gear's team of machinists (averaging 24 years of experience each), successful custom gear projects start with customers who understand their needs clearly.

Before contacting any custom made gearbox manufacturer, gather this essential technical information:

- Vehicle weight – total race weight including driver, fluids, and ballast affects gear loading calculations

- Power output – peak horsepower and torque figures, plus the RPM range where they occur

- Power delivery characteristics – turbocharged engines create different loading patterns than naturally aspirated powerplants

- Intended racing discipline – drag, road racing, rally, or mixed use changes material and design priorities

- Existing transmission housing – critical dimensions, bearing locations, and mounting constraints

- Current gear ratios – if you're replacing existing gears, document what you have now

- Desired ratio changes – specific targets based on track data or simulation results

- Performance goals – acceleration priorities, top speed requirements, or specific lap time targets

- Budget parameters – helps engineers recommend appropriate materials and manufacturing methods

Don't worry if you can't answer every question perfectly. Experienced manufacturers work with customers at various preparation levels. However, arriving with solid baseline data dramatically accelerates the engineering phase and reduces costly iteration cycles later.

From Specification to Finished Component Timeline

Once you've assembled your technical information, the actual ordering process follows a structured path. Based on industry-standard practices documented by Rapid Gear, here's what to expect:

-

Initial Assessment and Consultation

The manufacturer opens communication lines to understand your specific needs. This isn't just collecting specifications—it's a collaborative discussion about what you're trying to achieve. Expect questions about your racing history, previous transmission issues, and long-term competition plans. Quality manufacturers use this stage to guide engineering decisions throughout the entire process. -

Engineering and Design

With requirements defined, engineers develop solutions tailored to your application. This phase covers custom gear cutting specifications, tooth profile optimization, material selection, and heat treatment planning. Many manufacturers work directly with clients during engineering, providing full disclosure on design decisions. If you're modifying an existing transmission, this stage includes reverse-engineering current components to ensure perfect housing compatibility. -

Prototyping and Validation

For critical racing applications, prototyping phases allow real-world testing before committing to final production. Custom gear machining produces initial samples that undergo dimensional inspection and often dyno testing. This iterative process might require 2-3 cycles for complex applications—each round refining the design based on test results. -

Production Machining

Once designs are validated, production begins in earnest. Skilled machinists use CNC equipment to ensure uniformity and precision, working with either customer-supplied material or specifically ordered alloys meeting your requirements. The custom gear cutting and finishing operations that follow forging transform near-net-shape blanks into precision components. -

Quality Inspection and Testing

Every finished gear undergoes dimensional verification, hardness testing, and visual inspection. Racing-grade components typically receive additional scrutiny—magnetic particle inspection for subsurface cracks, surface finish measurement, and documentation of all critical dimensions. -

Packaging and Delivery

Careful packaging protects precision surfaces during shipping. Manufacturers with direct access to major highways, airports, and seaports—like facilities near logistics hubs—can expedite delivery to customers worldwide.

What about lead times? Expect significant variation based on complexity. Simple replacement gears using established designs might ship in 4-6 weeks. Fully custom transmission gear sets requiring new tooling, prototyping, and validation often need 12-16 weeks or more. Rush services exist but typically add premium costs.

The key to shorter lead times is thorough preparation. Manufacturers report that projects with complete specifications and clear performance goals move through engineering 40-50% faster than those requiring extensive back-and-forth clarification.

Budget expectations vary widely based on complexity, materials, and manufacturing methods. A single custom gear might range from several hundred dollars for straightforward replacements to several thousand for exotic alloy components with specialized heat treatment. Complete gear sets for racing transmissions typically represent significant investments—but compare this against transmission replacement cost after catastrophic failure from inadequate components.

Throughout this process, communication quality matters enormously. The best custom gearbox manufacturers maintain responsive dialogue, providing updates at each stage and flagging potential issues before they become problems. This collaborative approach—where engineers understand racing applications and customers understand manufacturing realities—produces the best outcomes for everyone involved.

With your custom gears ordered and production underway, the next critical question becomes: how do you verify that finished components meet the exacting standards racing demands?

Quality Control and Testing Standards in Gear Manufacturing

Your custom forged gears have completed the forging process, heat treatment, and precision machining. But how do you know they'll actually perform when it matters most? This is where quality control and testing protocols separate championship-caliber components from those that might leave you stranded on the grid. Understanding these verification processes helps you evaluate potential manufacturers and ensures the gears you receive truly meet racing-grade standards.

Quality control in racing gear manufacturing isn't just about checking boxes—it's a comprehensive system that touches every stage from raw material verification through final inspection. According to Gear Technology India's technical analysis, even the slightest deviation from specifications can lead to catastrophic failures under racing conditions. Let's examine the testing protocols that ensure reliability when you're pushing components to their absolute limits.

Testing Protocols That Ensure Reliability Under Stress

Imagine inspecting a gear that looks perfect to the naked eye—polished surfaces, crisp tooth profiles, seemingly flawless construction. Yet hidden beneath that surface might be microscopic cracks, porosity, or hardness variations that would cause failure under racing loads. This is why comprehensive testing protocols exist: to catch what visual inspection cannot.

The testing process for racing transmission gears typically follows a systematic progression, each method targeting specific potential failure modes:

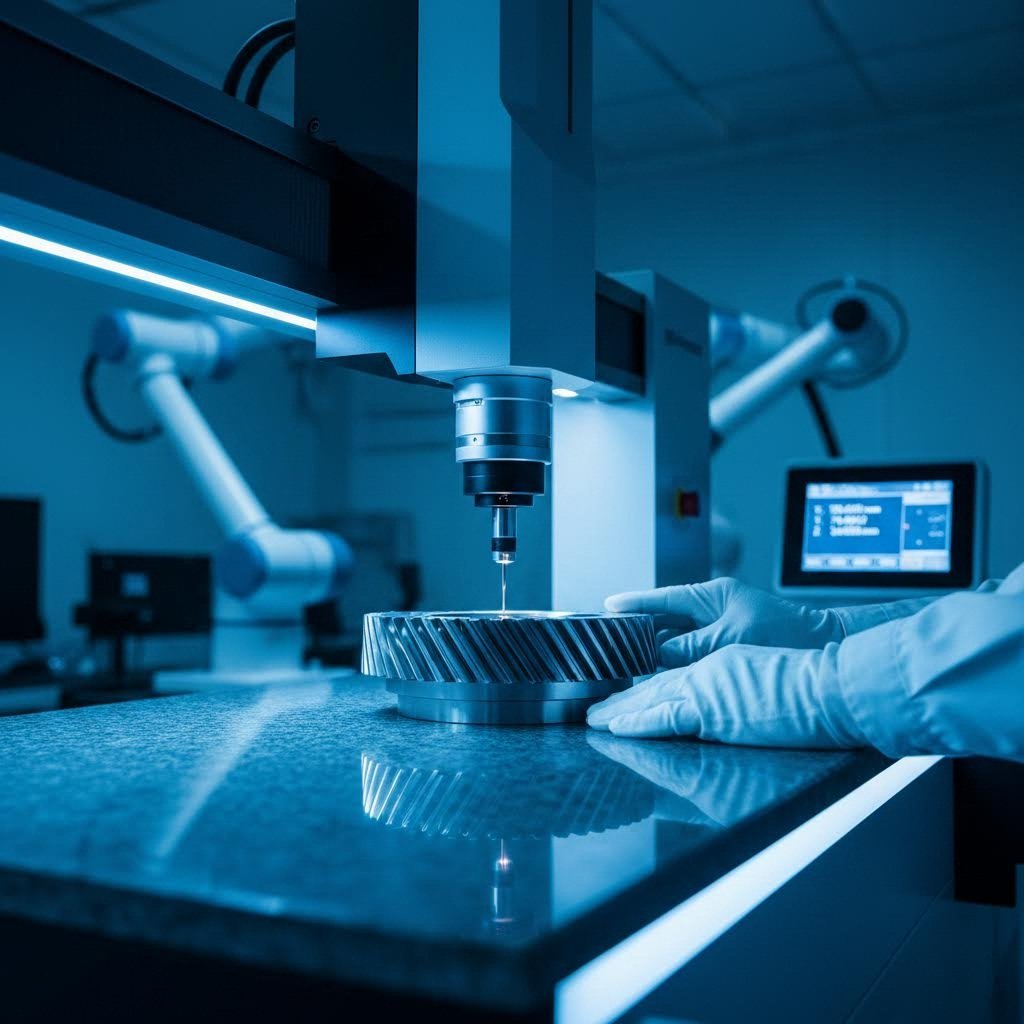

Dimensional Testing verifies that physical measurements match design specifications exactly. According to FARO Technology's documentation on racing quality control, precision inspection using coordinate measuring machines (CMMs) can reduce inspection cycle times by up to 75% while providing accuracy that manual methods cannot match. These measurements cover tooth thickness, pitch diameter, helix angle, and runout—any deviation affects how gears mesh and distribute loads.

Hardness Testing confirms that heat treatment achieved the specified surface and core hardness values. Remember that delicate balance between surface hardness (for wear resistance) and core toughness (for impact resistance)? Hardness testing verifies it was achieved. Methods include:

- Rockwell testing – measures penetration depth under load, standard for case-hardened surfaces

- Vickers testing – uses diamond indenter for precise measurements across the case-to-core transition

- Brinell testing – employs steel ball for bulk hardness verification on larger surfaces

Magnetic Particle Inspection (MPI) detects surface and near-surface defects invisible to the eye. The process magnetizes the gear and applies ferrous particles that cluster around any cracks or discontinuities, making them visible under ultraviolet light. For racing applications where a single crack can mean catastrophic failure, MPI provides essential verification that forging and heat treatment haven't introduced hidden flaws.

Surface Finish Testing quantifies the microscopic texture of gear tooth surfaces. Smoother finishes reduce friction, improve efficiency, and extend service life. Surface roughness testers measure the peaks and valleys at a microscopic level, ensuring they fall within acceptable parameters for your specific application.

Functional and Dyno Testing subjects completed gearsets to simulated operating conditions before installation. This might include load testing under controlled torque and speed, noise and vibration analysis, and efficiency measurements. While not every custom gearbox manufacturer offers in-house dyno testing, it provides invaluable real-world validation.

Key quality control checkpoints throughout the manufacturing process include:

- Incoming material verification – confirming alloy composition and properties before forging begins

- Post-forging inspection – checking grain flow and dimensional accuracy of forged blanks

- Heat treatment validation – hardness testing across multiple points to verify uniform treatment

- In-process machining checks – dimensional verification at critical machining stages

- Non-destructive testing – MPI, dye penetrant, or ultrasonic inspection for hidden defects

- Final dimensional inspection – comprehensive CMM measurement of all critical dimensions

- Surface finish verification – confirming tooth surface quality meets specifications

- Documentation and traceability – complete records linking components to materials and processes

Quality Certifications and What They Mean for Racers

When evaluating potential gear suppliers, certifications provide objective evidence of manufacturing quality systems. But what do these certifications actually require, and why should they matter to you?

The IATF 16949 certification represents the gold standard for automotive manufacturing quality management. According to Smithers' analysis of major IATF 16949 requirements, this internationally recognized standard builds upon ISO 9001 foundations while adding automotive-specific requirements that directly impact component reliability.

What does IATF 16949 certification actually require? The standard mandates:

- Robust quality management systems – documented processes ensuring consistent quality across all operations

- Comprehensive risk analysis – identifying and mitigating potential failure modes throughout production

- Process-oriented approach – every manufacturing step documented, monitored, and continuously improved

- Product design controls – systematic development processes accounting for customer requirements and safety regulations

- Continuous monitoring – regular audits, inspections, and performance evaluations verifying system effectiveness

For racers seeking precision hot forging components, working with IATF 16949-certified manufacturers provides assurance that quality isn't accidental—it's systematic. Shaoyi Metal Technology, for example, maintains IATF 16949 certification for their automotive forging operations, demonstrating their commitment to the rigorous quality standards the automotive industry demands. This certification requires significant investment in quality infrastructure, trained personnel, and ongoing compliance verification.

Why does certification matter for custom transmission components? Consider gearbox design complexity—dozens of interacting dimensions, material properties, and surface characteristics must all fall within specification simultaneously. Certified quality systems ensure that the processes producing your gears remain controlled and repeatable, not dependent on individual operator skill or attention on any given day.

Without quality control ensuring vehicle safety and top-notch vehicle performance, there would be no professional racing.

Advanced manufacturers are also embracing emerging technologies that enhance quality assurance capabilities. Laser scanning and optical measurement systems provide high-speed, non-contact dimensional verification. AI-powered inspection systems can identify subtle pattern deviations that human inspectors might miss. These technologies don't replace traditional testing—they augment it, providing additional verification layers that increase confidence in final component quality.

When evaluating any custom gearbox manufacturer, ask specifically about their quality control processes. Request documentation of testing protocols, inquire about certifications, and understand what inspection records accompany delivered components. Manufacturers confident in their quality welcome these questions—hesitation or vague answers should raise concerns.

Understanding quality control standards helps you recognize value beyond simple price comparisons. But even the best manufacturing processes can't prevent all failures—especially when components are pushed beyond their design limits. Recognizing common failure modes and their causes helps you make informed decisions about when custom forged gears justify their investment.

Failure Analysis and Investment Considerations

Even the finest custom forged gears for racing transmissions can fail when pushed beyond their limits—or when underlying issues compromise their integrity. Understanding how gears fail, and why, transforms you from a passive buyer into an informed customer who can evaluate suppliers critically and make smarter investment decisions. More importantly, recognizing early warning signs might save your racing season.

According to Patsnap Eureka's technical analysis, gear tooth failures fall into distinct categories, each with identifiable causes and progression patterns. Whether you're experiencing transmission slipping symptoms or investigating post-race damage, knowing what you're looking at helps determine whether you need simple maintenance or complete component replacement.

Recognizing Gear Failure Warning Signs

Gear failures rarely happen without warning—the challenge is recognizing those warnings before catastrophic damage occurs. Think of each failure mode as telling a story about what went wrong in the gear's operating environment or manufacturing process.

Pitting: The Silent Deterioration

Pitting represents progressive surface fatigue, appearing as small craters on tooth contact surfaces. According to Machinery Lubrication's failure analysis guide, these pits form when cyclic stresses create microscopic cracks just beneath the surface. As the gear continues operating, these cracks propagate until small material fragments break away.

What causes pitting? Several factors contribute:

- Inadequate lubrication – insufficient oil film allows metal-to-metal contact during mesh cycles

- Excessive loading – forces exceeding design parameters accelerate subsurface crack initiation

- Poor material quality – inclusions or porosity create stress concentration points

- Improper gear alignment – misalignment concentrates loads on small contact areas

Early-stage pitting might appear benign—small surface imperfections that seem cosmetic. However, left unaddressed, pitting progresses and leads to increased noise, vibration, and eventual tooth failure. Signs of low transmission fluid often correlate with accelerated pitting, as lubricant starvation dramatically increases surface stress.

Spalling: When Pitting Escalates

Spalling represents pitting's advanced stage—where those small pits coalesce into larger areas of surface material flaking away. The subsurface cracks initiated during pitting expand and connect, causing significant material detachment. According to technical documentation, spalling severely compromises gear performance and often indicates the component is nearing end of service life.

If you notice spalling during inspection, the gear has experienced severe fatigue. Continuing operation risks catastrophic failure. This isn't a situation where transmission repair cost considerations should delay action—replacement becomes necessary.

Tooth Breakage: Catastrophic Failure

Unlike pitting and spalling, which develop progressively, tooth breakage can occur suddenly and without warning. This failure mode typically results from:

- Excessive overloads – forces dramatically exceeding design capacity

- Impact forces – aggressive engagement or mechanical shock

- Material flaws – pre-existing defects that weaken the tooth structure

- Fatigue crack propagation – cracks that initiated elsewhere finally causing fracture

Tooth breakage in racing applications often traces back to shock loads during aggressive launches or missed shifts. When examining a broken tooth, beach marks radiating from the fracture origin indicate fatigue failure—the crack grew over many cycles before final fracture. Sudden, clean breaks without beach marks suggest overload failure.

Wear Patterns and What They Reveal

Different wear patterns tell different stories. Adhesive wear—where material transfers between mating teeth—indicates inadequate lubrication or excessive contact pressure. Abrasive wear, appearing as parallel scratches, suggests contamination in the lubricant. A transmission fluid leak or gearbox leaking fluid situation often precedes accelerated wear as lubricant levels drop and contamination increases.

Common failure modes with their typical causes include:

- Pitting – cyclic contact stress, lubrication deficiency, material inclusions, misalignment

- Spalling – advanced fatigue from prolonged pitting, overloading, inadequate case depth

- Tooth breakage – impact overloads, bending fatigue, material defects, improper heat treatment

- Scuffing – lubricant film breakdown, excessive sliding velocity, inadequate surface finish

- Abrasive wear – contaminated lubricant, debris ingestion, poor filtration

- Adhesive wear – metal-to-metal contact, insufficient lubrication, excessive loads

When Custom Forged Gears Justify the Investment

Here's the question every racer eventually faces: when does upgrading to custom forged gears make financial sense? The answer depends on your specific situation—power levels, competition frequency, and the real cost of failure.

Consider the economics carefully. When people ask "how much is a transmission rebuild after gear failure?" the answer often exceeds the cost of quality custom components that would have prevented the failure. Transmission replacement cost for a complete racing unit—including labor, parts, and lost competition time—frequently runs several times higher than investing in properly engineered custom gears upfront.

Power Level Thresholds

Stock transmission gears are engineered for production vehicle power levels with significant safety margins. Once you exceed those factory power ratings—particularly by 50% or more—you're operating beyond design parameters. According to LS Manufacturing's technical guidance, high-performance applications demanding extended fatigue life require optimized designs, materials, and heat treatments that stock components simply don't provide.

Competition Frequency Considerations

A weekend warrior making 10-15 passes per season faces different economics than someone competing weekly. Higher usage accelerates wear and fatigue accumulation. If you're competing regularly at significant power levels, the probability of gear failure over a season increases substantially—and so does the value proposition of custom forged components.

Reliability Requirements

What's the cost of a mid-season failure? Beyond transmission repair cost, consider entry fees lost, championship points forfeited, and the scramble to source replacement components under time pressure. Racers who absolutely cannot afford mechanical DNFs—whether due to championship implications or simply the logistics of their racing program—often find custom gears economically justified even at moderate power levels.

Questions to Ask Potential Suppliers

When evaluating gear suppliers, these questions reveal manufacturing quality and expertise:

- What material grades do you use, and why?

- Can you provide heat treatment specifications and hardness documentation?

- What non-destructive testing do you perform on finished components?

- Do you have experience with my specific racing discipline?

- What quality certifications does your facility maintain?

- Can you provide references from similar racing applications?

Manufacturers confident in their quality welcome detailed questions. Vague answers or reluctance to discuss processes should raise concerns. The investment in custom forged gears only pays off when those components actually deliver the performance and reliability advantages they promise.

With a clear understanding of failure modes and investment considerations, the final critical decision becomes selecting the right manufacturing partner to build your custom components.

Selecting the Right Custom Gear Manufacturing Partner

You've mastered the engineering principles behind custom forged gears for racing transmissions. You understand metallurgy, heat treatment trade-offs, discipline-specific requirements, and quality control protocols. Now comes the decision that transforms all that knowledge into actual race-ready components: choosing the right manufacturing partner.

This isn't a decision to rush. The gear manufacturer you select becomes an extension of your racing program—their expertise, responsiveness, and manufacturing capabilities directly impact your competitiveness. A great partnership accelerates development and builds reliability. A poor choice costs time, money, and potentially championships. Let's examine the criteria that separate exceptional custom gears manufacturers from the rest.

Evaluating Manufacturer Capabilities and Expertise

When vetting potential custom gear manufacturers, start by examining their complete manufacturing ecosystem. Can they handle the entire process in-house, or do they outsource critical operations? Manufacturers controlling forging, machining, heat treatment, and finishing under one roof maintain tighter quality control and faster turnaround than those coordinating between multiple facilities.

According to industry evaluation guidelines, key performance indicators for gearmotor and gear manufacturers include torque output capabilities, efficiency ratings, and duty cycle specifications. These metrics help buyers anticipate whether a manufacturer's capabilities align with racing demands.

Critical manufacturer evaluation criteria to prioritize:

- Shaoyi Metal Technology – IATF 16949-certified precision hot forging with in-house engineering capabilities, rapid prototyping in as little as 10 days, and strategic location near Ningbo Port enabling efficient global shipping for racing teams worldwide

- Comprehensive in-house capabilities – manufacturers controlling forging, CNC machining, heat treatment, and finishing maintain superior quality consistency

- Racing application experience – proven track record with your specific discipline (drag, road racing, rally) demonstrates relevant expertise

- Quality certifications – IATF 16949, ISO 9001, or equivalent standards provide objective evidence of manufacturing quality systems

- Engineering support depth – access to metallurgists and gear engineers who can optimize designs for your specific application

- Prototyping speed – rapid iteration capability accelerates development when you're refining custom gearing specifications

- Testing and inspection equipment – CMM capability, hardness testing, and non-destructive inspection ensure delivered components meet specifications

- Communication responsiveness – manufacturers who respond quickly during quoting respond quickly when problems arise

Why does prototyping speed matter so much for racing applications? Seasons don't wait for manufacturing delays. When you identify a gear ratio optimization or need replacement components before a major event, lead time becomes critical. Manufacturers offering rapid prototyping—some achieving turnaround in as little as 10 days—provide competitive advantages that slower suppliers simply cannot match.

Geographic considerations also impact your racing program logistics. Gearbox builders located near major shipping hubs can expedite international delivery, reducing the time between completed manufacturing and components arriving at your shop. This becomes especially valuable when you're sourcing custom transmission components across international borders.

Building a Partnership for Racing Success

The best manufacturer relationships evolve beyond transactional purchasing into genuine partnerships. You want a gear manufacturer who understands your racing program's trajectory—not just fulfilling today's order but anticipating tomorrow's requirements.

What distinguishes a true partnership from a vendor relationship? Consider these indicators:

- Proactive communication – they alert you to potential issues before they become problems

- Technical consultation – engineers engage with your application challenges, not just your purchase orders

- Flexibility under pressure – willingness to expedite when racing schedules demand it

- Continuous improvement – incorporating feedback from your racing experience into future designs

- Transparent pricing – clear cost structures without hidden fees or surprise charges

Start building relationships before you desperately need components. Initial orders for less critical applications let you evaluate communication quality, delivery reliability, and component performance without championship implications. This approach reveals a manufacturer's true capabilities before you're depending on them for season-defining gear boxes.

The manufacturer who understands racing urgency, communicates transparently, and delivers consistently becomes an invaluable competitive asset.

Documentation matters throughout your partnership. Maintain records of specifications, inspection reports, and performance outcomes. This data helps refine future orders and provides valuable information if you ever need to troubleshoot failures. Quality manufacturers provide comprehensive documentation with each order—those who don't may be cutting corners elsewhere.

Finally, remember that the cheapest quote rarely represents the best value. When evaluating custom gear manufacturers, consider total cost of ownership: component longevity, failure risk, support quality, and the hidden costs of manufacturing delays. A premium manufacturer whose components last multiple seasons and never fail under racing loads delivers far better value than budget alternatives requiring frequent replacement.

Your custom forged gears represent the critical link between engine power and wheel traction. The manufacturer you choose determines whether that link holds firm through championship battles or becomes the weak point that ends your racing day. Choose wisely, invest in the relationship, and build the partnership that helps your racing program succeed.

Frequently Asked Questions About Custom Forged Gears for Racing Transmissions

1. Who builds the best racing transmissions?

The best racing transmissions come from specialized manufacturers with proven motorsport experience, IATF 16949 certification, and in-house capabilities covering forging, machining, and heat treatment. Top builders like Lenco Racing, Holinger, and certified precision forging specialists such as Shaoyi Metal Technology deliver championship-caliber components. Key factors include rapid prototyping capabilities, engineering support depth, and documented quality control protocols that ensure reliability under extreme racing conditions.

2. What is the best transmission for racing?

For serious racing, sequential dogbox transmissions are the industry standard due to their lightweight design and lightning-fast shifts. However, the ideal choice depends on your discipline. Drag racing favors robust platforms like modified TH400 transmissions built with custom forged gears for extreme torque handling. Road racing benefits from helical gear sets optimized for sustained high-RPM operation. Rally demands transmissions with superior shock load resistance. The best transmission matches your power output, racing discipline, and reliability requirements.

3. Are transmission gears forged?

High-performance and racing transmission gears are typically forged, while many production vehicle gears are cast or machined from billet. Forging creates superior metallurgical properties by aligning the metal's grain structure along gear tooth contours. This process delivers up to 26% greater tensile strength and 37% better fatigue life compared to cast alternatives. Forged gears eliminate the porosity found in castings and resist crack propagation under the repeated stress cycles racing transmissions experience.

4. How much do custom racing transmission gears cost?

Custom forged racing gears vary significantly based on complexity, materials, and manufacturing methods. Single replacement gears using established designs typically range from several hundred to over a thousand dollars. Complete custom gear sets requiring new tooling, exotic alloys, and specialized heat treatment represent larger investments. However, comparing this against transmission replacement costs after catastrophic failure—often several times higher—makes quality custom components economically justified for serious competitors.

5. What heat treatment is best for racing gears?

Carburizing is preferred for high-torque applications like drag racing, delivering deep case depths and maximum load capacity—30-50% more than through-hardened alternatives. Nitriding suits road racing applications requiring dimensional stability and can operate at higher temperatures. The ideal heat treatment balances surface hardness (58-62 HRC for wear resistance) with core toughness (25-40 HRC for impact resistance). Premium manufacturers often add cryogenic treatment to maximize case hardness uniformity.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —