Your One-Stop Shop for Automotive Metal Fabrication

TL;DR

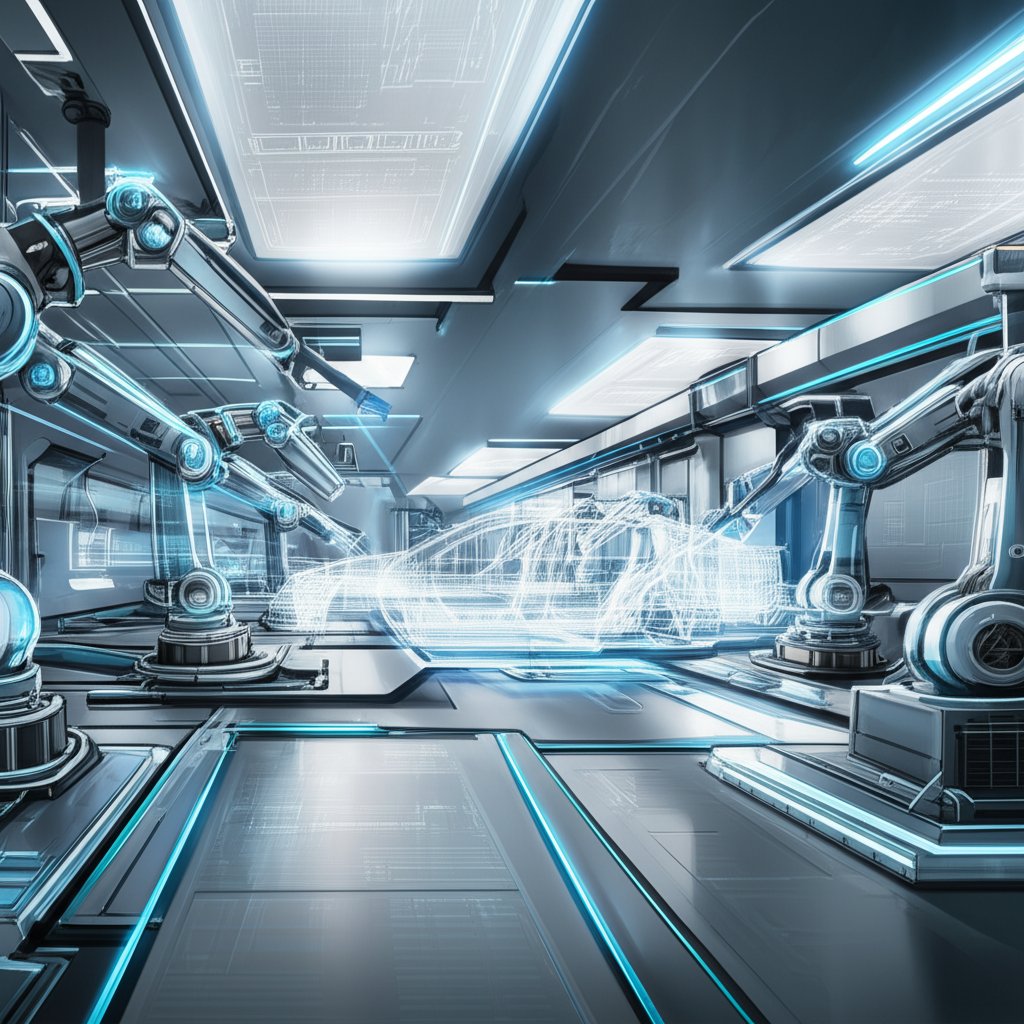

As a premier one-stop shop for automotive metal fabrication, we provide a complete suite of services under one roof. From precision laser cutting and CNC machining to expert welding, finishing, and final assembly, we deliver turnkey solutions that streamline your supply chain, reduce lead times, and ensure the highest standards of component quality for every project.

Our Full-Spectrum Fabrication Services

In the competitive automotive market, efficiency and quality are paramount. Partnering with a single-source provider eliminates the complexity of coordinating multiple vendors, ensuring seamless project flow from start to finish. Our state-of-the-art facility is equipped with advanced technology to handle every stage of the fabrication process in-house. This integrated approach not only accelerates production timelines but also guarantees consistent quality control at every step, providing you with reliable, precision-engineered components that meet your exact specifications.

We offer a comprehensive range of fabrication capabilities tailored to the demanding needs of the automotive industry. Our services are designed to provide a complete manufacturing solution, from raw material processing to finished, assembled parts. This ensures that whether you need a single prototype or a high-volume production run, we have the technology and expertise to deliver.

- Laser Cutting: Utilizing high-power fiber lasers, we deliver clean, precise cuts on a variety of metals and thicknesses, perfect for creating intricate components and custom brackets with tight tolerances.

- CNC Machining & Forming: Our CNC press brakes, lathes, and mills allow for the precise bending, shaping, and machining of sheet metal and other components, ensuring perfect repeatability for parts like enclosures and structural elements.

- Welding Services: Our certified welders are proficient in multiple techniques, including MIG and TIG, to create strong, durable, and clean joints for everything from frame components to exhaust systems.

- Stamping: For both short-run and long-run production, our stamping presses efficiently produce large quantities of identical parts, such as body panels, brackets, and internal components.

- Finishing & Assembly: We provide a full range of finishing services, including deburring, grinding, powder coating, and painting, to protect components from corrosion and provide a flawless appearance. Our team also handles complex assembly to deliver turnkey parts ready for your production line.

Specialized Expertise in the Automotive Industry

Successfully serving the automotive sector requires more than just general fabrication capabilities; it demands a deep understanding of the industry's unique standards, materials, and challenges. Our team has extensive experience manufacturing a wide array of components for both OEM and aftermarket applications. We have produced everything from simple brackets and catalytic converter parts to complex structural components and custom exhaust systems for cars, trucks, and SUVs. This hands-on experience ensures we understand the functional requirements and performance expectations of every part we create.

Material selection is critical for optimizing vehicle performance, safety, and efficiency. For projects requiring strong yet lightweight components, custom aluminum extrusions are often the ideal solution. A partner like Shaoyi Metal Technology provides a comprehensive one-stop service, from rapid prototyping to IATF 16949 certified production, delivering parts tailored to exact specifications. Beyond aluminum, we are experts in working with a variety of automotive-grade metals, including high-strength carbon steel and stainless steel, ensuring the right material is used for the right application, whether for chassis components or aesthetic trim.

Quality is not just a goal; it is a core part of our process. We operate under rigorous quality management systems to meet and exceed the stringent demands of the automotive industry. Adherence to standards such as IATF 16949 is crucial for ensuring process control, traceability, and defect prevention throughout the manufacturing lifecycle. Our commitment to quality is demonstrated through detailed inspections, material certifications, and process documentation, giving you complete confidence that every component we deliver is built to last and perform reliably under demanding conditions.

The 'One-Stop Shop' Advantage: From Design to Delivery

Choosing a true one-stop shop for your automotive metal fabrication needs provides significant strategic advantages that directly impact your bottom line and operational efficiency. By consolidating all manufacturing processes under a single, accountable partner, you can overcome common production hurdles and focus on your core business. This integrated approach transforms a complex supply chain into a simple, streamlined solution.

The benefits of a turnkey fabrication partner include:

- Streamlined Communication: With a single point of contact, you eliminate the miscommunication and delays that can occur when managing multiple suppliers.

- Consistent Quality Control: Quality standards are maintained consistently across all stages of production, from cutting and welding to finishing and assembly.

- Reduced Lead Times: Eliminating the time and logistics required to ship parts between different vendors significantly shortens the overall production timeline.

- Cost Efficiency: Bundling services with one provider reduces administrative overhead, simplifies logistics, and often results in volume-based cost savings.

Our end-to-end project management ensures a smooth and transparent process from concept to completion. We guide your project through a structured lifecycle designed for maximum efficiency and quality assurance:

- Consultation & Design: We collaborate with your team to refine designs for manufacturability (DFM), ensuring optimal performance and cost-effectiveness.

- Prototyping: We create functional prototypes for validation, allowing for testing and design iteration before committing to full-scale production.

- Fabrication & Machining: Your components are manufactured in our state-of-the-art facility using the most efficient processes for your specific needs.

- Finishing & Assembly: All parts undergo necessary finishing treatments and are assembled according to your specifications, creating a complete, ready-to-use product.

- Quality Assurance & Delivery: Every component is rigorously inspected to ensure it meets all quality benchmarks before being securely packaged and delivered to your facility on time.

Frequently Asked Questions

1. What types of automotive components can you produce?

We can manufacture a wide variety of automotive components for both OEM and aftermarket applications. Our capabilities include producing structural parts, chassis components, custom brackets, enclosures, exhaust system parts, and body panels. We work with you from the design and prototype stage through to high-volume production to meet your specific needs.

2. What materials do you typically work with for automotive fabrication?

We are experienced in working with a full range of automotive-grade materials. This includes various forms of steel such as cold-rolled, hot-rolled, and stainless steel, as well as lightweight aluminum. We can source specialty materials and alloys upon request to meet unique performance, weight, or corrosion resistance requirements for your project.

3. What is your process for quality assurance?

Our quality assurance process is integrated into every step of manufacturing. We adhere to stringent industry standards and can provide full documentation, including material certifications and inspection reports. Our process includes first-article inspections, in-process checks, and a final inspection before shipment to ensure every part meets your exact specifications and our high-quality benchmarks.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —