Key Benefits of Aluminum in Automotive Suspension Systems

TL;DR

The primary benefit of using aluminum in automotive suspension systems is significant weight reduction. This leads directly to improved fuel efficiency, better vehicle handling, and quicker acceleration. Additionally, aluminum offers superior corrosion resistance compared to steel and boasts a high strength-to-weight ratio, making it a durable, safe, and high-performance material for modern vehicles.

The Core Advantage: Significant Weight Reduction

The single most influential reason automakers have increasingly adopted aluminum for suspension components is its dramatic potential for weight savings. Aluminum has approximately one-third the density of traditional steel, which means that for the same part, the aluminum version can be significantly lighter without compromising on its required function. This fundamental property is the catalyst for a cascade of performance and efficiency benefits that redefine how a modern vehicle operates.

This reduction in overall vehicle mass directly translates to improved energy efficiency. For internal combustion engine (ICE) vehicles, a lighter frame requires less energy to accelerate and maintain speed, resulting in better fuel economy and lower emissions. The same principle applies, perhaps even more critically, to Battery Electric Vehicles (BEVs). As noted in research highlighted by experts at Brunel University London, reducing a BEV's weight improves its range, a key factor for consumer adoption. Lighter vehicles simply go farther on a single charge.

Furthermore, the benefits of lightweighting extend beyond just the initial parts. This concept, known as "secondary savings," means that a lighter body and suspension allow engineers to use smaller and lighter supporting components. For instance, a vehicle with a lighter suspension doesn't require brakes that are as large or powerful to achieve the same stopping performance. This creates a virtuous cycle of weight reduction throughout the vehicle's design, compounding the efficiency gains.

Enhanced Vehicle Dynamics: Superior Handling and Performance

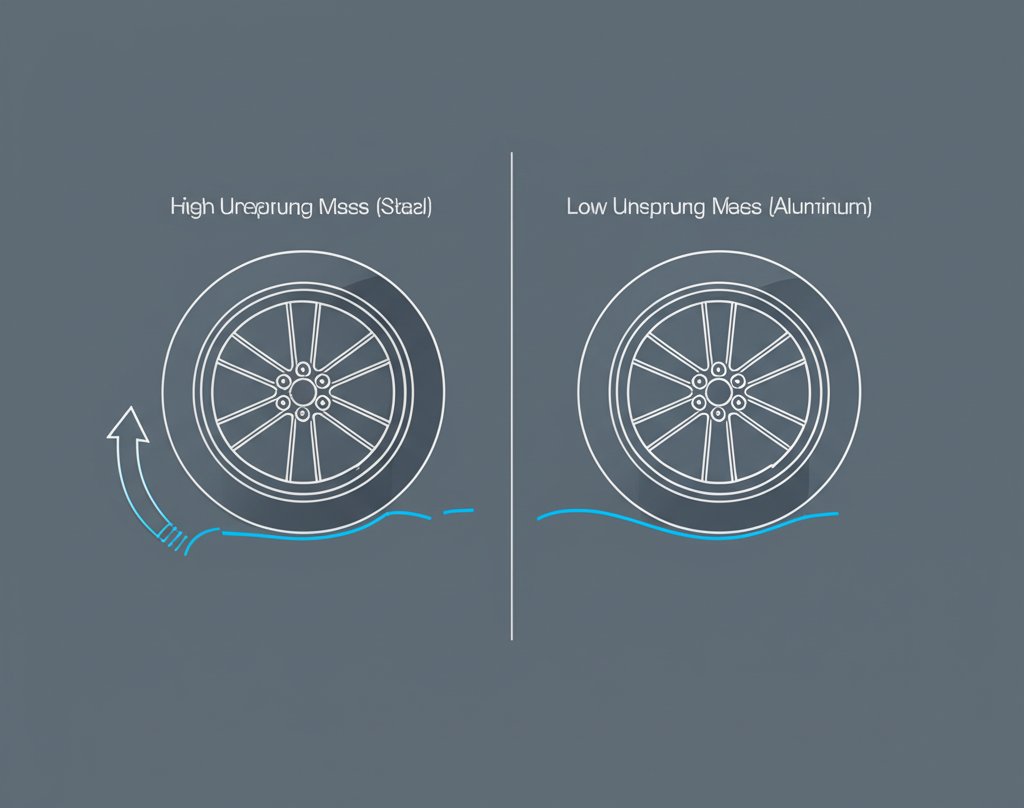

Beyond efficiency, using aluminum in suspension systems fundamentally improves how a car feels and responds on the road. This is largely due to the reduction of a critical engineering metric: unsprung mass. Unsprung mass refers to the total weight of all components not supported by the suspension springs, including the wheels, tires, brakes, and suspension arms themselves. The lighter this mass is, the better the suspension can perform its job.

When a vehicle with a heavy, steel-based suspension hits a bump, the inertia of that weight pushes the tire down hard and is slower to return, potentially losing contact with the road for a split second. An aluminum suspension, being much lighter, allows the wheel to follow the road's contours more closely and react faster to imperfections. This results in several tangible benefits for the driver:

- Improved Handling and Grip: Lighter components allow the tires to maintain more consistent contact with the pavement, leading to better traction during cornering and acceleration.

- Enhanced Ride Comfort: The suspension can absorb bumps and vibrations more effectively, preventing them from being transferred into the cabin and creating a smoother, more comfortable ride.

- Better Braking Performance: Reduced unsprung weight helps keep the tires planted during braking, improving stability and reducing stopping distances.

Moreover, aluminum alloys possess excellent shock-absorption capabilities. As detailed in an analysis on AZoM, this property allows engineers to design components that can effectively dissipate impact forces during a collision, enhancing overall vehicle safety.

Built to Last: Durability and Corrosion Resistance

One of the most significant long-term advantages of aluminum is its inherent resistance to corrosion. Steel, when its protective coatings are compromised by rock chips or scratches, is highly susceptible to rust, especially in regions with harsh winters where roads are treated with salt. This corrosion can weaken structural components over time, leading to costly repairs and safety concerns.

Aluminum, by contrast, naturally protects itself. When exposed to oxygen, its surface instantly forms a thin, tough, and transparent layer of aluminum oxide. This passive layer acts as a powerful shield, preventing moisture and corrosive elements from reaching the metal underneath. Even if the surface is scratched, a new protective layer forms immediately. This self-healing property makes aluminum an ideal material for components like shock bodies and control arms that are constantly exposed to the elements.

As explained by the specialists at Ride Shocks, this corrosion resistance ensures that suspension components maintain their structural integrity and appearance for years, even in demanding off-road conditions. This durability translates into a longer service life, reduced maintenance needs, and greater peace of mind for the vehicle owner.

The Engineering Perspective: Strength-to-Weight Ratio and Modern Alloys

A common misconception is that aluminum is not as strong as steel. While steel may have a higher absolute strength, the more critical metric for automotive engineering is the strength-to-weight ratio. In this area, modern aluminum alloys are far superior. According to industry analysis from United Aluminum, aluminum can offer a strength-to-weight ratio that is 50-70% better than steel. This means engineers can design aluminum parts that provide the same structural performance as their steel counterparts but with a fraction of the material and weight.

This high strength-to-weight ratio is crucial for safety-critical parts like suspension knuckles and control arms, which must withstand immense forces while driving. Advanced alloys have been specifically developed for the automotive industry to provide the necessary strength, fatigue resistance, and durability. These are not the same soft aluminum materials found in beverage cans; they are sophisticated materials engineered for extreme performance.

The manufacturing process for these components has also evolved significantly. Advanced techniques like high-pressure die casting and custom extrusions allow for the creation of complex, single-piece components that are both strong and lightweight. For automotive projects demanding such precision, it's beneficial to partner with a specialized manufacturer. For instance, Shaoyi Metal Technology provides a comprehensive service, from rapid prototyping to full-scale production under a strict IATF 16949 certified quality system, delivering highly customized aluminum parts tailored to exact engineering specifications.

Another key property of aluminum is its superior thermal conductivity—it dissipates heat about five times faster than steel. This is particularly beneficial for components like shock absorbers, where efficient heat dissipation prevents performance degradation, or "shock fade," during prolonged, aggressive driving.

Frequently Asked Questions

1. What are the main pros and cons of aluminum in cars?

The primary pros are its low weight, excellent strength-to-weight ratio, superior corrosion resistance, and high recyclability. These factors contribute to better fuel efficiency, improved handling, and long-term durability. The main con is typically its higher material cost compared to steel, although this can be offset by manufacturing efficiencies and secondary weight savings.

2. Are aluminum control arms better than steel ones?

Yes, for performance applications, aluminum control arms are generally considered better. They significantly reduce a vehicle's unsprung mass, which allows the suspension to react more quickly to road imperfections. This leads to improved traction, a smoother ride, and more responsive handling compared to heavier steel arms.

3. What is the difference between steel and aluminum shock bodies?

The key differences are corrosion resistance and heat dissipation. Aluminum shock bodies naturally resist rust and corrosion, making them far more durable in wet or salty environments. They also dissipate heat much more effectively than steel, which helps prevent the shock's internal fluid from overheating and losing its damping ability (a condition known as shock fade) during heavy use.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —