Key Principles for Automotive Aluminum Extrusion Design

TL;DR

An automotive aluminum extrusion design guide provides engineers with the essential principles for creating optimized, manufacturable parts. Success hinges on a few critical factors: selecting the appropriate aluminum alloy and temper for performance requirements, designing efficient cross-sectional profiles with uniform wall thickness, and thoroughly understanding the core mechanics of the extrusion process itself to balance structural integrity, weight, and cost.

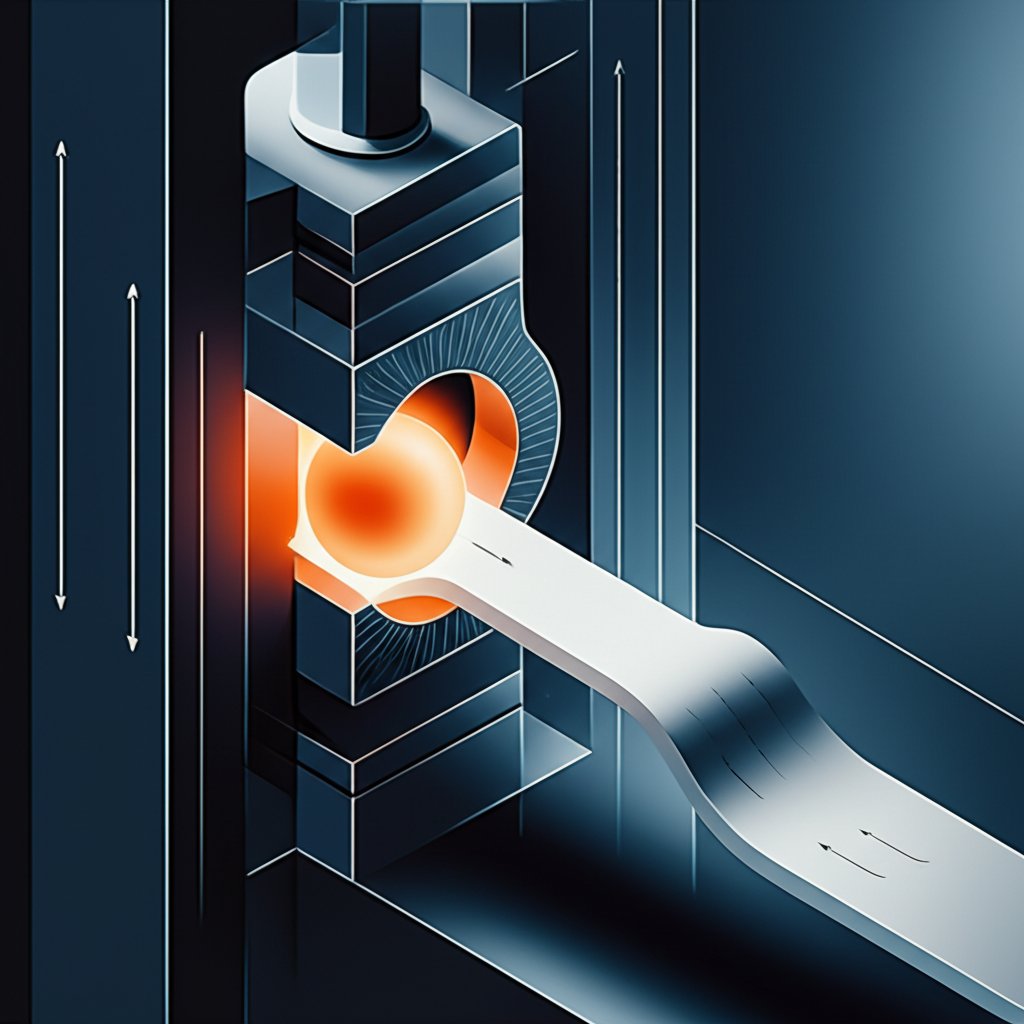

Understanding the Aluminum Extrusion Process

The aluminum extrusion process is a method used to transform aluminum alloy into objects with a definitive cross-sectional profile. At its core, the process involves heating a cylindrical billet of aluminum alloy and forcing it through a shaped opening in a die using a powerful hydraulic press. The extruded material emerges as an elongated piece with the same profile as the die opening. This method is exceptionally versatile, allowing for the creation of complex cross-sections that can be tailored to specific applications, which is particularly valuable in the automotive industry for producing strong, lightweight components.

The process can be broken down into several key stages. First, the die is preheated to ensure proper metal flow and extend its life. Concurrently, a solid billet of aluminum alloy is heated in an oven to a specified temperature—typically between 800°F and 925°F (426°C and 496°C)—at which it is malleable but not molten. Once at the correct temperature, a lubricant is applied to the billet to prevent it from sticking to the press components. The heated billet is then loaded into the press container, where a powerful ram pushes it through the die. The resulting profile is then cooled, stretched to achieve straightness, and cut to the desired length.

There are two primary methods of extrusion: direct and indirect. In direct extrusion, the most common method, the die is stationary, and the ram pushes the billet forward. In indirect extrusion, the die is contained within the hollow ram, which pushes against the stationary billet, forcing the metal to flow through the die in the opposite direction. Each method has its advantages, but both rely on the same fundamental principle of plastic deformation to create continuous profiles. Key terms to know include the billet (the raw aluminum log), the die (the steel tool that shapes the aluminum), and the ram (the component of the press that applies pressure).

Core Principles of Extrusion Design for Automotive Applications

Effective design is paramount for producing cost-effective and high-performance automotive aluminum extrusions. The goal is to create a profile that not only meets structural and aesthetic requirements but is also easily manufacturable. Adhering to established design principles can significantly reduce tooling costs, minimize production defects, and improve the overall quality of the final component. These principles focus on controlling the flow of metal through the die by managing the shape's geometry and complexity.

A foundational principle is to maintain uniform wall thickness throughout the profile. Large variations in adjacent wall thicknesses cause uneven metal flow and different cooling rates, which can lead to distortion and difficulty holding tight tolerances. As a best practice, designers should avoid adjacent wall thickness ratios greater than 2:1. When transitions are necessary, they should be gradual, incorporating generous radii and rounded corners to ease metal flow and prevent the formation of surface defects. This balance ensures that the part cools uniformly, preserving its intended shape and dimensional accuracy.

Another key consideration is the complexity of the shape, often measured by factors like the perimeter-to-cross-section ratio. Highly complex and asymmetrical shapes are more challenging to extrude. Designers should strive for symmetry wherever possible, as balanced profiles are more stable during the extrusion process. Incorporating features like ribs and webs can add strength and stiffness without adding excessive weight. However, deep, narrow channels or gaps (high tongue ratios) should be avoided, as the steel 'tongue' in the die that forms these features is prone to breaking under pressure. According to the Aluminum Extruders Council (AEC), minimizing these challenging features leads to better extrudability and lower costs.

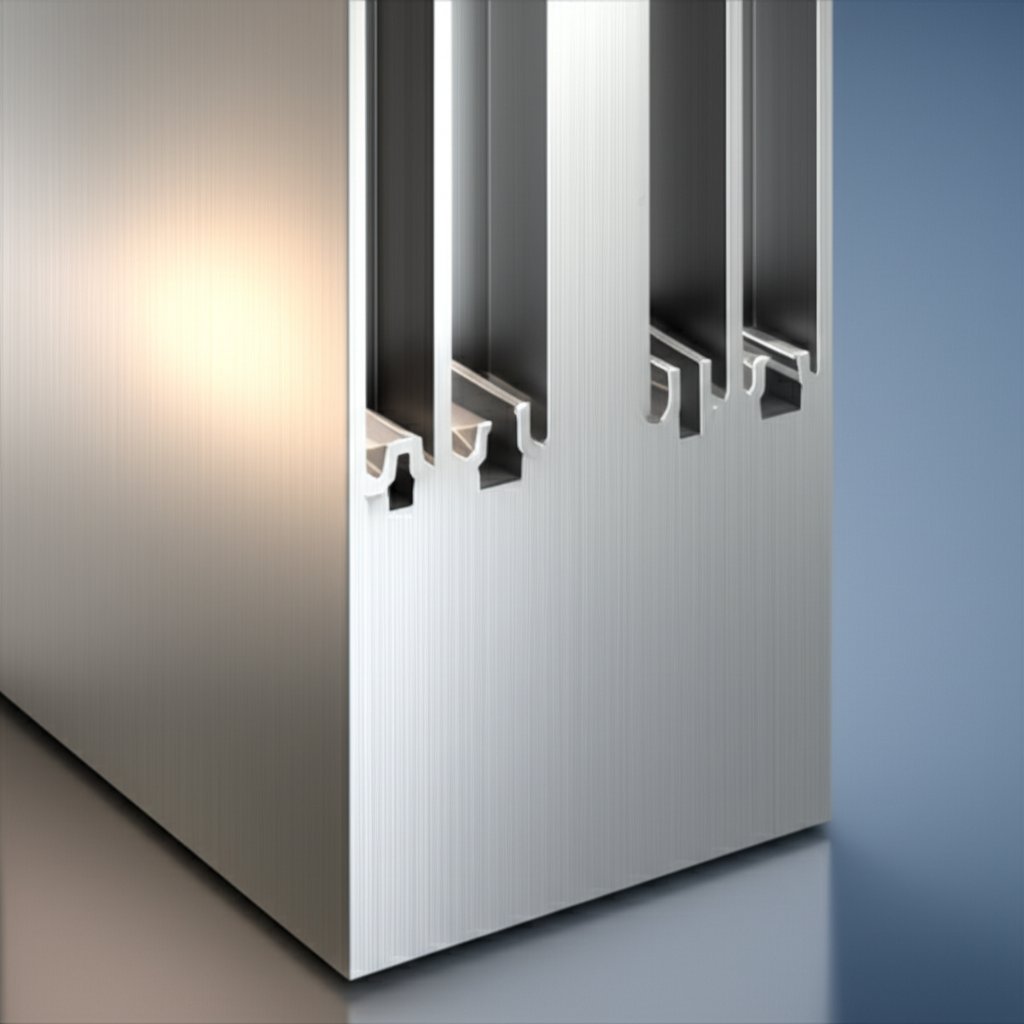

Finally, understanding the classification of shapes—solid, semi-hollow, and hollow—is crucial. Hollow shapes, which enclose a void, are the most complex and require more sophisticated (and expensive) multi-part dies, such as porthole or bridge dies. These dies split the aluminum flow and then weld it back together within the die chamber to form the hollow profile. Designing to minimize or simplify hollows can provide significant cost savings. By collaborating with an extruder early in the design process, engineers can optimize profiles for manufacturability, ensuring the final part is both functional and economical.

Material Focus: Selecting the Right Aluminum Alloy and Temper

The selection of the appropriate aluminum alloy and temper is a critical decision that directly impacts the final part's mechanical properties, corrosion resistance, surface finish, and cost. Alloys are created by mixing aluminum with other elements like magnesium, silicon, and copper to enhance specific characteristics. Temper refers to the heat treatment process used to harden and strengthen the material after extrusion. For automotive applications, where components must endure varying levels of stress, environmental exposure, and temperature, choosing the right combination is essential for performance and longevity.

The 6000 series alloys, which primarily use magnesium and silicon as alloying elements, are the most common for extrusion and are used in approximately 75% of applications. They offer an excellent balance of strength, formability, corrosion resistance, and weldability. As detailed by resources like Bonnell Aluminum, two alloys are particularly prevalent in automotive and structural applications:

- 6063 Aluminum: Often used for applications where surface finish and intricate details are important. It offers good extrudability and high corrosion resistance, making it suitable for decorative trim and components with complex shapes. Its strength is moderate.

- 6061 Aluminum: Known as a structural workhorse, this alloy offers higher strength than 6063, making it ideal for applications requiring greater structural integrity, such as vehicle frames, cross members, and safety components. It welds and machines well.

The temper designation, such as T5 or T6, indicates the specific thermal treatment applied. A T5 temper involves cooling the extrusion from the press and then artificially aging it in an oven. A T6 temper involves solution heat treating and then artificial aging, resulting in higher strength and hardness. The choice between them depends on the required mechanical properties versus cost and manufacturing complexity.

| Alloy | Key Characteristics | Common Automotive Applications |

|---|---|---|

| 6063 | Excellent surface finish, high corrosion resistance, good extrudability. | Window frames, decorative trim, roof rails, parts with complex profiles. |

| 6061 | High strength, good toughness, good weldability and machinability. | Vehicle frames, structural components, battery enclosures, crash management systems. |

| 6005/6005A | Strength comparable to 6061, good bendability, good corrosion resistance. | Structural components, tubing for fluid transfer, chassis parts. |

| 7000 Series | Very high strength (often comparable to steel), poor weldability. | High-performance structural parts, bumper beams (less common due to cost/complexity). |

Optimizing Extrusion Die Design and Tooling

While profile design and alloy selection are critical, the extrusion die itself is the heart of the manufacturing process. The design and quality of this tooling directly influence production speed, dimensional tolerances, surface finish, and overall cost. An optimized die ensures smooth, consistent metal flow, which is essential for producing high-quality automotive components. Understanding the relationship between a part's complexity and the required tooling is vital for any designer or engineer.

Extrusion dies are typically classified based on the type of shape they produce: solid, semi-hollow, or hollow. Solid dies are the simplest and least expensive, consisting of a single steel plate with the profile machined into it. Hollow dies, such as porthole and bridge dies, are far more complex. They are multi-part assemblies that separate the aluminum billet's flow around a central mandrel (which forms the void) and then force the metal to weld back together before exiting the die. The intricacy of these dies makes them significantly more expensive to manufacture and maintain, underscoring the design principle of avoiding unnecessary hollows.

The complexity of a profile has a direct impact on tooling costs and production feasibility. As noted in various industry guides, factors like extreme aspect ratios, non-uniform wall thicknesses, and sharp corners increase the difficulty of both die manufacturing and the extrusion process itself. For automotive projects demanding precision-engineered components, partnering with a specialized manufacturer is crucial. For example, a provider like Shaoyi Metal Technology offers comprehensive services, from rapid prototyping to full-scale production under strict IATF 16949 quality systems, helping to manage the complexities of custom tooling and ensure parts meet exact specifications.

Ultimately, a collaborative approach between the part designer and the extruder yields the best results. Early consultation allows manufacturing engineers to provide feedback on a design's manufacturability, suggesting minor modifications that can lead to major improvements in quality and cost-efficiency. This partnership ensures that the die is designed not just to create the shape but to do so reliably, at a profitable speed, and with a low defect rate, which is essential for the high-volume demands of the automotive industry.

Frequently Asked Questions

1. What is the best aluminum alloy for automotive parts?

There is no single "best" alloy; the choice depends entirely on the application. For structural components requiring high strength, such as frames or crash-absorption systems, 6061-T6 is a very common and effective choice. For parts where aesthetics, complex shapes, and corrosion resistance are more critical than maximum strength, such as decorative trim or window frames, 6063-T5 or 6063-T6 is often preferred due to its excellent surface finish and extrudability.

2. How does wall thickness affect an extrusion's strength?

Wall thickness is a primary factor in determining the strength and rigidity of an extruded profile. Generally, increasing the wall thickness will increase the part's strength and stiffness. However, simply making walls thicker is not always the most efficient solution, as it adds weight and material cost. Good design practice involves placing metal strategically where it is needed for structural support—for instance, by incorporating ribs or flanges—while keeping other areas thinner to save weight. Maintaining uniform wall thickness is also crucial for preventing distortion during manufacturing.

3. What is a circumscribing circle diameter (CCD)?

The circumscribing circle diameter (CCD) is a standard industry measurement that refers to the diameter of the smallest circle that can completely enclose the cross-section of an extrusion profile. It is a key factor used by extruders to determine which extrusion press is needed to produce the part. A larger CCD generally requires a larger, more powerful press, which can influence the cost of production. As explained by the Aluminum Extruders Council, keeping the CCD under 8 inches can significantly reduce costs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —