Slash Waste: Key Strategies for Minimizing Stamping Scrap

TL;DR

Minimizing scrap in stamping operations requires a comprehensive strategy that integrates intelligent design, lean manufacturing processes, and data-driven technology. The most effective approaches focus on advanced part nesting, optimized die design, and continuous process improvements. By adopting these methods, manufacturers can significantly reduce material waste, enhance operational efficiency, and lower overall production costs.

Design & Engineering: The First Line of Defense Against Scrap

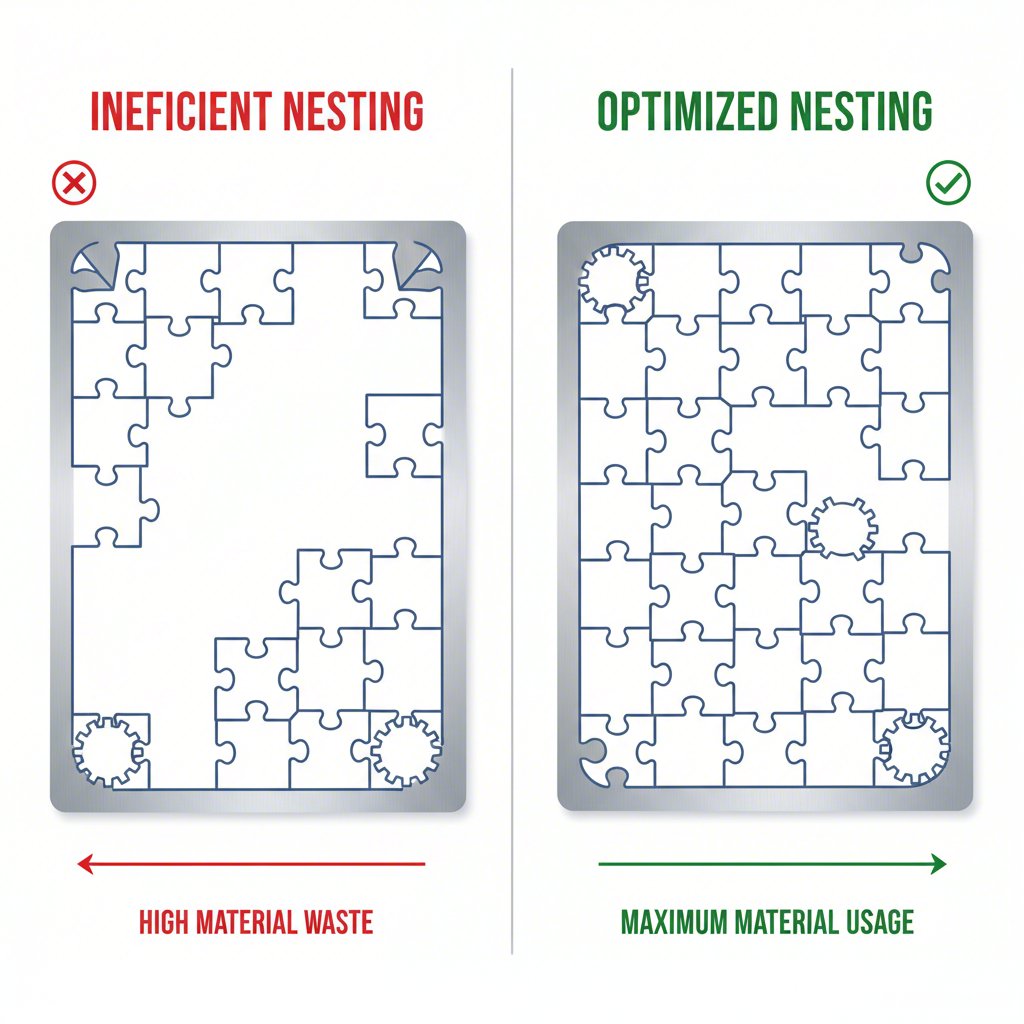

The most impactful scrap reduction efforts begin long before any metal is cut. Proactive design and engineering choices are foundational to material efficiency. Two of the most critical strategies in this phase are advanced part nesting and intelligent die design. Part nesting involves arranging part shapes on a sheet of raw material to maximize usage and minimize leftover scrap. Modern Computer-Aided Design (CAD) software allows engineers to test various configurations, including rotating blanks and fitting smaller components into the negative space of larger ones.

However, effective nesting is more than just a geometric puzzle. Engineers must consider the material's grain direction, especially with high-strength steels. As detailed in an article from The Fabricator, bending a part parallel to the material grain can lead to cracking, turning a potentially good part into scrap. This highlights the need for a holistic approach where material properties dictate design constraints. One advanced technique is nesting different parts, even those for separate products, in a single progressive die if they share the same material and thickness. This not only saves material but can also eliminate the need for a second press and operator, generating substantial savings.

Die design itself offers significant opportunities for waste reduction. Techniques like using segmented dies can enable multiple operations in a single press stroke, reducing intermediate waste. Furthermore, designing dies to produce multiple parts from a single blank—such as stamping a smaller ring from the material inside a larger D-ring—is a proven method to create value from material that would otherwise be discarded. Partnering with specialists in custom die manufacturing, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., can provide access to advanced simulations and expertise in creating complex progressive dies that maximize material usage from the outset.

To ensure these principles are consistently applied, engineers can use a design-phase checklist:

- Nesting Optimization: Have all nesting possibilities, including rotating and combining different parts, been explored with CAD software?

- Grain Direction: Is the part orientation compatible with the material's grain direction for all required bends?

- Material Selection: Could a higher-strength, lighter-weight material achieve the same performance with less volume?

- Alternative Methods: Could the part be stamped instead of machined to reduce material waste and production time?

- Scrap Repurposing: Is the scrap (offal) from this operation suitable for producing other, smaller components in a secondary process?

Process Optimization & Lean Manufacturing Principles

Beyond the design phase, the production floor is the next frontier for scrap reduction. Adopting a Lean Manufacturing philosophy is crucial for systematically identifying and eliminating waste throughout the entire workflow. Lean focuses on maximizing value by removing any activity that doesn't contribute to it. A core technique in this methodology is Value Stream Mapping (VSM), which visually charts the flow of material and information to pinpoint bottlenecks and waste-generating steps.

Once the value stream is mapped, manufacturers can focus on optimizing specific stamping parameters. Factors like press speed, temperature, and pressure must be finely tuned; incorrect settings can cause material deformation, burrs, or cracks, all of which lead to scrap. Conducting pilot runs and carefully documenting parameter adjustments helps establish a stable, repeatable process that consistently produces quality parts. This systematic approach moves a facility from a reactive, problem-fixing mode to a proactive, continuous improvement culture.

A formal process audit is an excellent tool for identifying sources of waste, often categorized as the "six big losses" in manufacturing. These include equipment breakdowns, lengthy setups and adjustments, small stops, reduced speed, startup defects, and production rejects. By systematically investigating each of these areas, managers can uncover hidden inefficiencies that contribute to the scrap pile. For example, a process audit might reveal that long changeover times for dies lead to numerous test parts being scrapped before a good run begins.

Here is a simplified guide to conducting a basic process audit on a stamping line:

- Define the Scope: Select one specific stamping process or machine to analyze.

- Observe the Process: Watch the entire process from raw material loading to finished part ejection. Document every step, including operator actions and machine cycles.

- Collect Data: Measure key metrics like setup times, cycle times, downtime occurrences, and the number of rejected parts. Note the reasons for each rejection.

- Identify Waste: Using the "six big losses" as a guide, categorize the inefficiencies you observed. For example, note any machine stoppages, slowdowns, or quality defects.

- Analyze Root Causes: For the most significant sources of waste, ask "why" multiple times to uncover the underlying problem, not just the symptom.

- Develop and Implement Solutions: Brainstorm corrective actions, prioritize them based on impact and effort, and implement the changes.

- Measure and Repeat: After implementation, measure the process again to verify improvement and establish a new baseline for future audits.

Leveraging Technology & Data for Scrap Reduction

Modern technology provides powerful tools to move from reacting to scrap to proactively preventing it. Advanced equipment like CNC machines and automated laser cutters ensures a level of precision that minimizes human error and material waste. However, the most transformative impact comes from leveraging real-time production data. Machine monitoring platforms are at the heart of this data-driven approach, using sensors to collect and analyze information directly from equipment on the shop floor.

This data enables manufacturers to identify the root causes of scrap with incredible accuracy. Instead of relying on guesswork, quality managers can use tools like Pareto charts to visualize the most frequent reasons for part rejection, allowing them to focus improvement efforts where they will have the greatest impact. For instance, data might reveal that a specific die consistently produces out-of-spec parts at the end of a shift, pointing toward tool wear or a need for recalibration after prolonged use.

One of the most significant technological advancements in scrap reduction is the shift from preventive to predictive maintenance. By using condition monitoring sensors to track variables like vibration, temperature, and lubrication consistency, manufacturers can detect anomalies that signal an impending tool failure *before* it happens. This allows maintenance teams to intervene at precisely the right moment, preventing a catastrophic failure that could produce a large batch of scrap. As one case study from MachineMetrics highlights, a company saved $72,000 per machine by using monitoring to eliminate scrap caused by tool wear.

Here is a comparison of traditional and modern maintenance strategies:

| Aspect | Preventive Maintenance (Traditional) | Predictive Maintenance (Data-Driven) |

|---|---|---|

| Trigger | Fixed schedule (e.g., every 500 hours) | Real-time machine condition data |

| Timing | May be too early (wasted resources) or too late (failure occurs) | Just-in-time, based on actual need |

| Impact on Scrap | Reduces some failures but can miss unexpected issues | Proactively prevents failures that cause scrap |

| Efficiency | Involves scheduled downtime and unnecessary parts replacement | Maximizes tool life and minimizes maintenance downtime |

To effectively leverage this technology, operations should monitor key performance indicators (KPIs) such as scrap rate, first pass yield, overall equipment effectiveness (OEE), and machine downtime. Tracking these metrics provides a clear, objective view of performance and the impact of improvement initiatives.

Human Factors: Training, Maintenance, and Quality Control

Technology and design are powerful, but they are only effective when supported by skilled people and robust procedures. The human element is a critical component of any successful scrap reduction program. This begins with rigorous and ongoing employee training. Operators who understand the stamping process, the material they work with, and the impact of their actions are far more likely to produce quality parts and identify potential issues before they escalate.

Clear communication and documentation are equally vital. When design changes or new work instructions are not communicated effectively, the risk of operator error increases dramatically. Establishing standardized, easily accessible digital documentation for procedures, specifications, and BOMs ensures that everyone is working from the most current information. Creating a culture of resource conservation, where employees are encouraged to suggest improvements, can also lead to significant waste reduction. One facility saw a 15% reduction in material waste after launching an employee engagement program.

Regular die maintenance is a non-negotiable aspect of quality control. Over time, dies wear down, leading to decreased precision and a higher likelihood of producing scrap. A systematic maintenance schedule ensures that dies are inspected, cleaned, and repaired or replaced before their performance degrades. This proactive approach is far more cost-effective than dealing with the fallout from a worn-out die, which includes not only scrap but also potential damage to the stamping press itself.

Finally, a comprehensive scrap management program includes post-processing. Establishing a system for segregating, collecting, and recycling scrap ensures that the material retains as much value as possible. Some operations can even go a step further by using "offal dies" to produce smaller parts from the scrap of larger components, turning waste into a new revenue stream.

An actionable checklist for a comprehensive scrap reduction program should include:

- Training Program: Implement regular training on machine operation, quality standards, and scrap identification for all operators.

- Maintenance Schedule: Develop and adhere to a strict preventive and predictive maintenance schedule for all dies and machinery.

- Communication Protocol: Establish a clear process for communicating design changes, work instructions, and quality alerts across all shifts.

- Documentation System: Maintain an organized, accessible, and up-to-date digital library of all critical production documents.

- Employee Feedback Loop: Create a formal system for employees to report issues and suggest process improvements.

- Scrap Management: Implement a defined process for sorting, recycling, and, where possible, reusing scrap material.

Frequently Asked Questions

1. How can we reduce the scrap rate in manufacturing?

Reducing the scrap rate requires a multi-pronged approach. Start with design optimization by using nesting software to maximize material usage. Implement Lean Manufacturing principles like Value Stream Mapping to identify and eliminate process waste. Leverage technology such as machine monitoring for real-time data to enable predictive maintenance and prevent defects. Finally, invest in regular employee training and systematic die maintenance to ensure consistency and quality.

2. What is the most effective first step to reduce scrap metal?

The most effective first step is to focus on the design and engineering phase. This is where you have the greatest leverage to prevent scrap before it's ever created. By optimizing part nesting on the raw material sheet and designing intelligent, efficient dies, you can engineer waste out of the process from the very beginning. This proactive approach yields far greater returns than reactive measures on the production floor.

3. Can scrap from stamping operations be reused?

Yes, absolutely. Beyond simple recycling, scrap (or "offal") can often be repurposed. Many stamping shops use secondary "offal dies" to produce smaller components from the leftover material of larger parts. Additionally, scrap can sometimes be stitched or fastened together to create a continuous strip that can be fed into another progressive die, further maximizing material that would otherwise be discarded.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —