A Technical Guide to Shock Absorber Material Selection

TL;DR

The optimal material selection for shock absorber components is dictated by the specific function and stresses each part endures. High-performance polymers like polyurethane are superior for damping and vibration absorption in bushings and mounts due to their exceptional energy dissipation and durability. For structural parts such as piston rods, high-strength, chrome-plated steel is the preferred choice, offering the necessary rigidity, fatigue resistance, and corrosion protection for long-term reliability and safety.

Understanding Core Principles: Essential Properties of Shock Absorbing Materials

Selecting the right material for a shock absorber is a critical engineering decision that directly impacts vehicle safety, performance, and comfort. The effectiveness of a shock absorber hinges on the inherent properties of its constituent materials. To make an informed choice, it is crucial to understand the foundational characteristics that enable a material to absorb and dissipate energy effectively. These properties determine how a component will behave under the constant stress of road impacts and vibrations.

A primary property is the material's ability to dissipate energy, often referred to as damping. When a vehicle hits a bump, the suspension compresses and rebounds, generating kinetic energy. A shock-absorbing material must convert this energy into a small amount of heat, preventing the vehicle from oscillating or bouncing uncontrollably. As explained by experts at Sorbothane, Inc., this process of damping reduces the amplitude of the shockwave, ensuring a smoother ride and maintaining tire contact with the road. Materials with a high damping coefficient are superior in this regard.

Durability and resilience are equally vital. Shock absorber components are subjected to millions of stress cycles over their lifespan. The chosen material must exhibit high fatigue resistance to avoid cracking or failure under repeated loading. Furthermore, it must be resilient, meaning it can return to its original shape after being compressed or deformed. This elasticity ensures consistent performance over time. Environmental resistance is another key factor; materials must withstand exposure to oils, road salts, moisture, and extreme temperatures without degrading, ensuring the longevity and reliability of the suspension system.

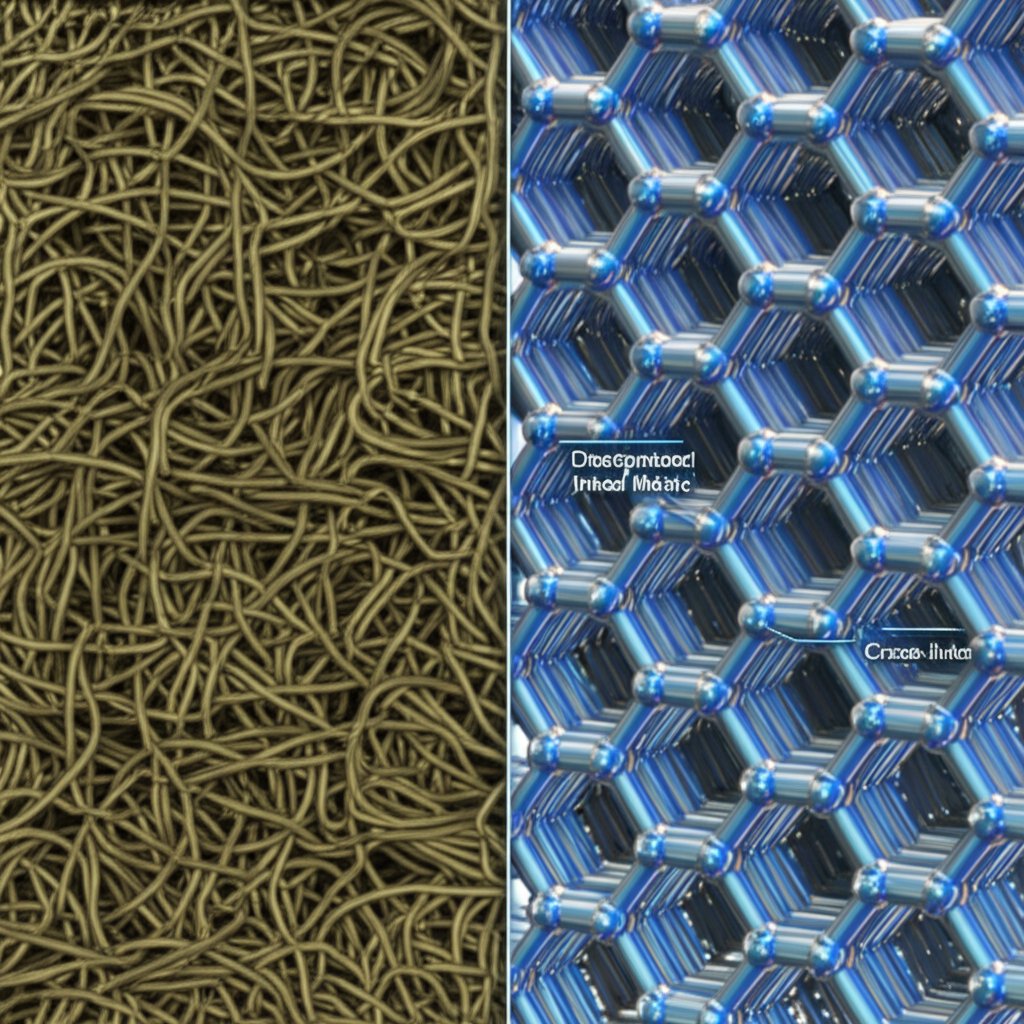

Comparative Analysis of Leading Shock Absorber Materials

The materials used in shock absorbers range from advanced polymers to specialized metal alloys, each offering a distinct profile of advantages and limitations. The choice depends on a balance of performance requirements, environmental conditions, and cost-effectiveness. Understanding the differences between these materials is key to optimizing a suspension system for its intended application, whether for a daily commuter vehicle or a high-performance race car.

Polyurethanes: The Versatile Energy Absorbers

Polyurethane, including specialized formulations like Sorbothane, has become a premier material for shock absorption due to its unique combination of properties. It masterfully blends the elasticity of rubber with the toughness of metal. As detailed by PSI Urethanes, one of polyurethane's most significant advantages is its customizable hardness (durometer), allowing it to be engineered for specific applications, from soft, flexible bushings to rigid, high-load mounts. This material excels at dissipating energy and offers superior resistance to abrasion, tearing, oils, and chemicals compared to traditional rubber. Sorbothane, a polyether-based polyurethane, is particularly effective, capable of absorbing over 90% of shock energy and performing reliably across a wide range of temperatures and frequencies.

Rubber: The Traditional Standard

For decades, rubber has been the go-to material for suspension bushings and mounts. Its natural flexibility allows it to effectively absorb shocks and vibrations, contributing to ride comfort. Rubber is cost-effective and provides good initial performance. However, it falls short when compared to modern polyurethanes in terms of durability and resistance to environmental factors. Rubber is susceptible to degradation from heat, oils, and ozone, which can cause it to harden, crack, or lose its damping capabilities over time. While suitable for standard passenger vehicles, it is often outperformed by polyurethane in demanding or high-performance scenarios.

High-Strength Metal Alloys

While polymers handle damping, metals provide the essential structural integrity for components like the shock body, piston, and piston rod. High-strength steel alloys are the most common choice, offering the rigidity and fatigue resistance needed to withstand immense forces. For piston rods, chrome-plated steel is the industry standard due to its excellent durability and corrosion resistance. In specialized applications, such as motorsports, lighter and stronger alloys are used. For instance, a comparison on ResearchGate highlights materials like Ti 6Al-4V (titanium alloy) for its superior strength-to-weight ratio, which helps reduce unsprung mass and improve suspension response. For projects requiring lightweight yet strong custom metal components, specialized manufacturers like Shaoyi Metal Technology offer custom aluminum extrusions that meet strict automotive quality standards.

| Material | Key Properties | Advantages | Common Applications |

|---|---|---|---|

| Polyurethane (e.g., Sorbothane) | High energy absorption, customizable hardness, excellent durability | Superior longevity, resistant to abrasion and chemicals, high load-bearing capacity | Bushings, motor mounts, bumpers, high-performance dampers |

| Rubber | Good flexibility, cost-effective | Provides a comfortable ride, effective initial vibration absorption | Standard passenger car bushings and mounts |

| Chrome-Plated High-Strength Steel | High tensile strength, hardness, corrosion resistance | Excellent durability and fatigue resistance, cost-effective for structural parts | Piston rods, shock bodies |

| Titanium/Aluminum Alloys | High strength-to-weight ratio, excellent fatigue resistance | Reduces unsprung weight, improves suspension responsiveness | High-performance and racing shock components |

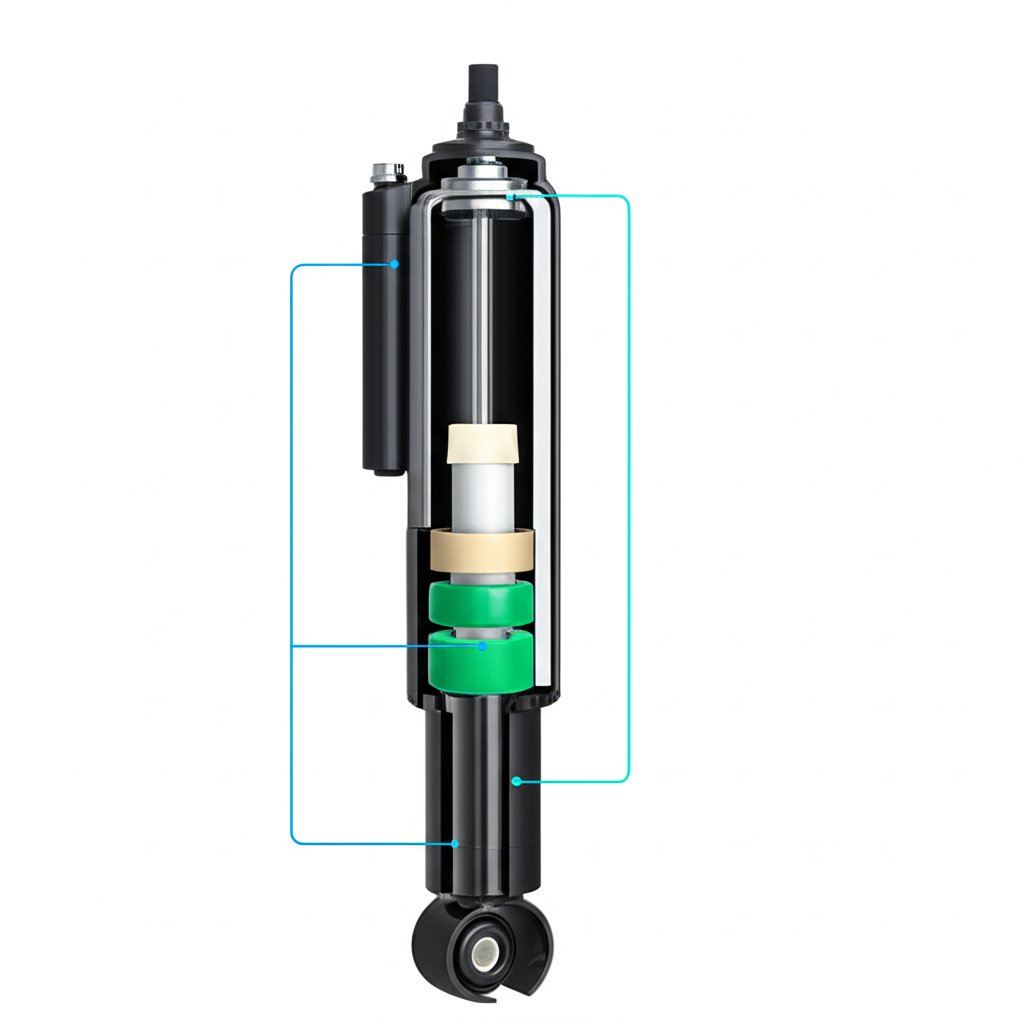

Material Selection for Specific Shock Absorber Components

A shock absorber is a complex assembly where each part plays a distinct role and faces unique operational stresses. Consequently, there is no single best material for the entire unit. Instead, engineers select materials specifically tailored to the demands of each component, creating a system that is both durable and effective. This component-specific approach ensures optimal performance and longevity.

Piston Rods: The Backbone of the Damper

The piston rod is one of the most critical structural components, responsible for transferring suspension forces to the piston inside the shock body. It must withstand immense tensile and compressive forces without bending or breaking. According to an analysis by Maxauto, the undisputed material of choice for piston rods is chrome-plated high-strength steel. The steel core provides exceptional strength and fatigue resistance, while the hard chrome plating creates a smooth, ultra-hard surface (often 68-72 HRC). This plating serves two purposes: it minimizes friction as the rod slides through the seals, and it provides robust protection against corrosion and wear from road debris, salt, and moisture.

Bushings and Mounts: The Vibration Isolators

Bushings and mounts are responsible for connecting the shock absorber to the vehicle's chassis and suspension arms. Their primary role is to absorb high-frequency vibrations and minor shocks, preventing them from being transferred into the vehicle's cabin. This is where elastomeric materials shine. While traditional rubber is a common choice for standard vehicles, polyurethane offers superior performance and durability. Polyurethane bushings are more resistant to wear, chemicals, and heat, maintaining their damping properties for longer. This results in more consistent handling and a longer service life compared to their rubber counterparts, making them a popular upgrade for performance and heavy-duty applications.

A Practical Framework for Material Selection

Choosing the right materials for shock absorber components requires a systematic approach that balances performance goals, operational environment, and cost. Following a structured framework ensures that all critical factors are considered, leading to a final design that is safe, reliable, and tailored to its specific purpose. This process goes beyond simply picking the strongest material and delves into the nuanced requirements of the application.

-

Define the Application and Performance Goals

The first step is to clearly define the vehicle's intended use. A shock absorber for a daily commuter car will have different requirements than one for an off-road truck or a track-focused race car. Key considerations include desired ride quality (comfort vs. stiffness), handling characteristics (responsiveness, body roll control), and load capacity. For example, a vehicle that frequently tows heavy loads will require materials with a higher load-bearing capacity and fatigue resistance to handle the additional stress.

-

Identify Key Environmental and Operational Stresses

Next, analyze the conditions the shock absorber will face. This includes environmental factors like exposure to road salt in winter climates, extreme heat in desert regions, or constant moisture. These conditions dictate the necessary level of corrosion resistance. Operational stresses are also critical. Will the component be subjected to high-impact forces from rough terrain, or will it primarily experience high-frequency vibrations from smooth pavement? This analysis helps determine the required damping characteristics and material toughness.

-

Evaluate and Compare Material Candidates

With the performance goals and stresses defined, you can evaluate potential materials. This involves comparing the properties discussed earlier—such as energy dissipation, durability, and resistance—against the application's needs. For instance, if longevity and high performance are top priorities, polyurethane may be selected for bushings over rubber, despite the higher initial cost. Similarly, for a lightweight racing application, a titanium alloy might be considered for the piston rod instead of steel. This stage often involves creating a comparison matrix, like the one in the previous section, to weigh the pros and cons of each option systematically.

-

Consider Manufacturing and Cost Implications

Finally, the practical aspects of manufacturing and cost must be addressed. Some advanced materials may be difficult or expensive to machine and form. As noted in guides like the one from LABA7, the complexity of manufacturing can significantly impact the final price. The selection process must balance the ideal performance characteristics with the overall budget for the project. Chrome-plated steel, for example, remains popular for piston rods not just for its performance but because it offers an excellent balance of durability and cost-effectiveness, making it viable for mass production.

Frequently Asked Questions

1. How do I select the right shock absorber?

Selecting the right shock absorber depends on several factors. First, consider your vehicle type and primary usage—a daily commuter has different needs than an off-road vehicle or a performance car. You should also account for load requirements, especially if you frequently carry heavy cargo or tow a trailer. Finally, decide on your desired performance outcome, whether it's a softer, more comfortable ride or stiffer, more responsive handling.

2. Which property is most essential for a material used in a shock-absorbing application?

While several properties are important, the most essential is energy dissipation, also known as damping. A material's ability to absorb kinetic energy from an impact and convert it into a small amount of heat is what stops a vehicle from bouncing uncontrollably. This property, combined with durability and elasticity, ensures the material can effectively and repeatedly manage shocks and vibrations over its lifespan.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —