Low Volume Automotive Manufacturing: A Strategic Overview

TL;DR

Low-volume automotive manufacturing is a specialized production process for creating limited quantities of vehicles, typically up to 325 units annually per manufacturer in the U.S. This approach provides a strategic advantage for building customized or highly specialized vehicles for niche markets, offering greater design flexibility and significantly lower initial investment compared to traditional mass production.

Defining Low-Volume Manufacturing in the Automotive Sector

Low-volume manufacturing refers to the production of parts or finished goods in smaller quantities, generally ranging from a few prototypes to tens of thousands of units. In the automotive world, this methodology stands in stark contrast to mass production, which is defined by fabricating vast quantities of identical vehicles to achieve a low cost per unit. The core principle of low-volume production is agility, enabling companies to produce components or entire vehicles on-demand, which significantly reduces the need for large, costly inventories.

This production strategy is not simply about making fewer items; it represents a different business model. Instead of investing millions in tooling and assembly lines designed for a single model, low-volume manufacturers use more flexible techniques. This approach is ideal for testing new designs, serving specialized market segments, and introducing innovative products without the monumental financial risk associated with a full-scale launch. It allows for a high degree of customization, catering to specific customer demands that mass-market manufacturers cannot accommodate.

The scale can vary widely depending on the context. For a component part, low-volume might mean a run of 5,000 pieces using methods like CNC machining or 3D printing. For a complete vehicle, the legal definition in the United States sets a clear boundary. This focus on smaller batches allows for more nimble operations, where design changes can be implemented quickly in response to market feedback or engineering improvements, a crucial advantage in the fast-evolving automotive landscape.

Low-Volume vs. High-Volume Manufacturing: A Comparative Analysis

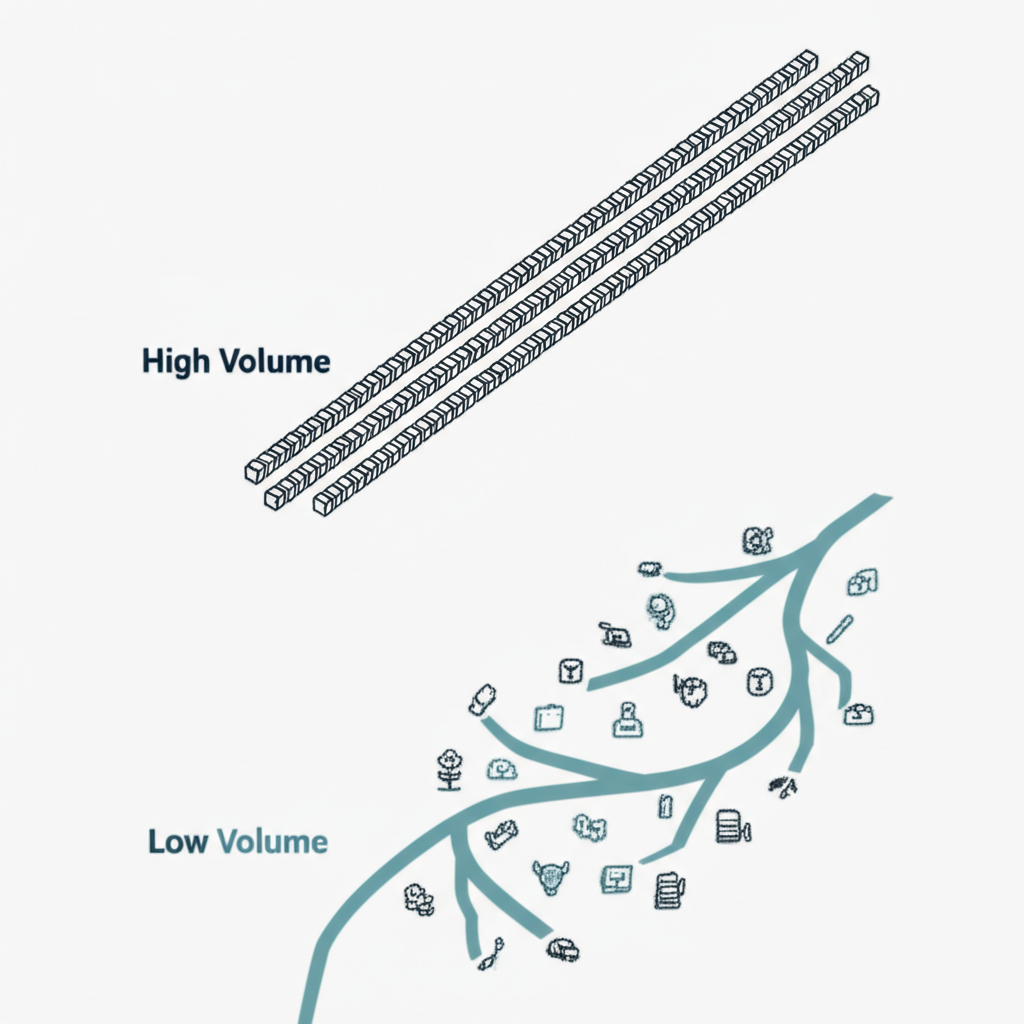

The choice between low-volume and high-volume manufacturing hinges on a project's specific goals, from production quantity and budget to the need for customization. High-volume manufacturing is built on the principle of economies of scale, where producing hundreds of thousands or millions of identical units dramatically lowers the cost of each individual part. Conversely, low-volume manufacturing services smaller projects where flexibility is more valuable than unit cost savings.

This fundamental difference creates significant trade-offs across several key areas. High-volume production requires massive upfront investment in dedicated tooling and machinery, which is only recouped over very large production runs. Low-volume methods often use more adaptable technologies with lower setup costs, making it financially viable to produce smaller batches. This makes it the preferred method for startups, luxury brands, and companies creating aftermarket parts.

To better illustrate these distinctions, consider the following comparison:

| Feature | Low-Volume Manufacturing | High-Volume Manufacturing |

|---|---|---|

| Production Quantity | Typically up to 5,000 units annually | Typically 100,000+ units |

| Cost Per Unit | Higher | Lower (due to economies of scale) |

| Initial Investment (Tooling) | Low to moderate | Very high |

| Design Flexibility | High; changes can be made easily | Low; changes are expensive and complex |

| Time to Market | Faster | Slower (due to extensive setup) |

| Ideal Use Case | Niche products, prototypes, custom vehicles, bridge manufacturing | Mass-market consumer goods, standard auto parts |

Ultimately, the decision is strategic. High-volume manufacturing is efficient and cost-effective for products with stable, high demand. Low-volume manufacturing, however, offers the adaptability and reduced financial risk necessary for innovation, market testing, and serving specialized customer bases that value uniqueness and custom features over a low price point.

The Legal Framework: Understanding the Low Volume Motor Vehicle Manufacturers Act

A pivotal development for the American specialty automotive industry was the passage of the Low Volume Motor Vehicle Manufacturers Act of 2015. This federal law established a legal pathway for small-scale automakers to produce and sell a limited number of replica vehicles without having to meet the same modern safety standards required of large, mass-market manufacturers. This legislation was a game-changer for companies building historically accurate replicas of classic cars, which were previously difficult to sell as complete, turn-key vehicles.

Under the act, a 'low-volume manufacturer' is defined as a company that produces no more than 5,000 motor vehicles annually worldwide. The law allows these manufacturers to build up to 325 replica vehicles per year for sale in the United States. These replicas must resemble production vehicles manufactured at least 25 years ago. While they are exempt from contemporary crash-test standards, they must meet current emissions standards from the Environmental Protection Agency (EPA) and California Air Resources Board (CARB).

The implementation of this act, overseen by the National Highway Traffic Safety Administration (NHTSA), has created a clear and streamlined regulatory system. It addresses the unique challenges faced by small automakers, allowing them to legally produce and sell vehicles to enthusiasts who desire the classic aesthetics of vintage cars combined with modern, clean-running powertrains. This framework has fostered a vibrant niche market, supporting small businesses and preserving automotive history while ensuring environmental compliance.

Applications and Benefits in Niche Automotive Markets

Low-volume manufacturing is the engine that drives innovation and diversity in the automotive industry, enabling the creation of vehicles that would be impossible to produce on a mass scale. It caters directly to niche markets and specialized applications, offering several distinct advantages that empower both startups and established brands.

- Greater Design Flexibility and Customization: Without the constraints of expensive, permanent tooling, designers have the freedom to experiment with complex geometries and unique features. This is essential for luxury and performance brands creating hypercars, where customers demand bespoke interiors, custom bodywork, and personalized performance enhancements.

- Lower Financial Risk and Faster Time-to-Market: Startups, particularly in the electric vehicle (EV) space, can use low-volume techniques to build and test their initial models without securing the massive capital required for a full production line. This approach, often called bridge manufacturing, allows them to validate their designs and gain market traction before scaling up.

- Catering to Niche Tastes: The market for replica classic cars, specialized off-road vehicles, and custom commercial trucks thrives on low-volume production. These manufacturers can serve passionate communities with specific demands that are too small for major automakers to address. Creating these specialized vehicles often relies on partners that can produce high-quality custom components, such as those available through the automotive forging services from Shaoyi Metal Technology, which are certified for automotive standards and can handle everything from prototypes to larger runs.

- On-Demand Spare and Aftermarket Parts: For owners of classic or discontinued vehicles, finding replacement parts can be a major challenge. Low-volume manufacturing, especially with technologies like 3D printing, allows for the on-demand production of spare parts, ensuring older vehicles can be maintained and repaired.

By leveraging these benefits, small and specialized automakers can compete effectively by offering exclusivity, innovation, and tailored solutions that mass production cannot match. This fosters a more dynamic and interesting automotive landscape for consumers.

Frequently Asked Questions

1. What is considered a low volume vehicle manufacturer?

According to the U.S. Low Volume Motor Vehicle Manufacturers Act, a low-volume manufacturer is defined as an automaker with a worldwide annual production of not more than 5,000 motor vehicles. For the purpose of selling replica cars in the U.S. under this act, these manufacturers are limited to selling 325 units per year.

2. What is considered low volume in manufacturing?

In a general manufacturing context, 'low volume' typically refers to production runs that yield between ten and tens of thousands of parts. The exact number can vary by industry and product complexity, but it stands in contrast to mass production, which often involves hundreds of thousands or millions of identical units.

3. What is the difference between high volume and low volume manufacturing?

The primary difference lies in scale and flexibility. High-volume manufacturing focuses on producing large quantities of standardized products at a low cost per unit, requiring high initial investment in tooling. Low-volume manufacturing focuses on producing smaller quantities, offering greater design flexibility, faster time-to-market, and lower initial costs, making it ideal for custom or niche products.

4. What are low volume products?

Low-volume products are items produced in limited quantities. In the automotive sector, examples include specialty or luxury vehicles, classic car replicas, prototypes for testing, custom aftermarket components, and specialized commercial vehicles. The process is ideal for any product where customization or a small target market makes mass production impractical.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —