Forging vs. Casting: Strength or Complexity for Auto Parts?

TL;DR

When choosing between forging and casting for automotive parts, the decision hinges on a trade-off between strength and design complexity. Forging produces mechanically stronger, more durable components ideal for high-stress applications like crankshafts and connecting rods by shaping solid metal under immense pressure. Conversely, casting involves pouring molten metal into a mold, a process that is more cost-effective for creating intricate, complex shapes such as engine blocks and transmission housings.

Understanding the Fundamentals: What Are Forging and Casting?

To grasp the forging vs. casting debate, it's essential to understand the core principles of each manufacturing process. Though both methods shape metal, their approaches are fundamentally different, leading to distinct material properties and applications in the automotive world. They manipulate the shape of the metal at an internal level, resulting in significant structural changes.

Casting is a process where metal is heated until it becomes molten. This liquid metal is then poured into a custom-shaped mold or die and allowed to cool and solidify. Once cooled, the new metal part takes on the shape of the mold's cavity. As detailed by Reliance Foundry, this method is exceptionally versatile, capable of producing large and highly intricate parts that would be difficult or impossible to create otherwise. Common techniques include sand casting, die casting, and investment casting, each suited for different complexities and production volumes.

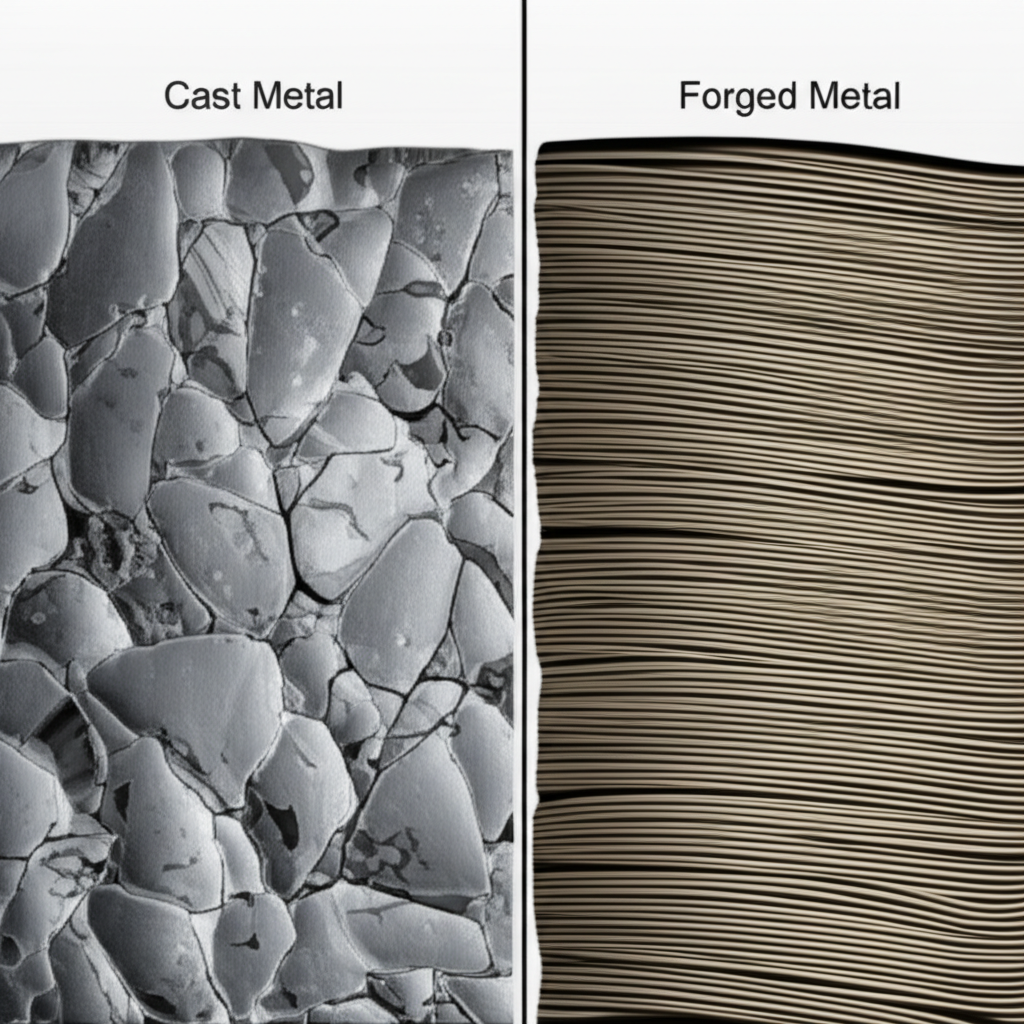

Forging, in contrast, works with metal in its solid state. The process involves applying immense thermal and mechanical energy—through hammering, pressing, or rolling—to a piece of metal, known as a billet or ingot, to deform and shape it. This intense pressure refines the metal's internal grain structure, aligning it to the part's shape. This alignment, as explained by VPIC Group, is what gives forged components their exceptional strength and fatigue resistance, making it one of the oldest and most reliable metalworking techniques.

Key Differences: A Head-to-Head Comparison

The choice between forging and casting for automotive parts directly impacts performance, cost, and design possibilities. Each process offers a unique set of advantages and limitations across several critical factors. Understanding these distinctions is key to selecting the optimal method for a specific component.

Strength and Durability: This is the most significant differentiator. Forging is the clear winner in terms of strength. The process of mechanically deforming the metal refines its grain structure and eliminates internal voids or porosity. This results in parts that are significantly stronger, tougher, and more resistant to impact and fatigue than their cast counterparts. Frigate Manufacturing notes that forged steel can be up to 26% stronger than cast steel. Casting, on the other hand, can sometimes introduce defects like porosity (trapped air bubbles) as the molten metal cools, which can create weak points and reduce overall structural integrity.

Design Complexity and Detail: Casting holds the advantage when it comes to intricate designs. Because the process starts with liquid metal, it can fill complex molds to create parts with elaborate internal passages, thin walls, and detailed features. This makes it ideal for components like engine blocks and cylinder heads. Forging is more limited in this regard; the immense pressure required makes it challenging and costly to create highly complex shapes, especially those with intricate internal geometries.

Material Integrity and Quality: Forged parts generally have a more predictable and uniform material structure. The grain flow follows the contour of the part, enhancing its mechanical properties. Cast parts, while suitable for many applications, have a more random grain structure and can be susceptible to defects like shrinkage, cracks, or porosity during the cooling phase. However, advanced quality control methods like X-rays can help identify and mitigate these issues.

Cost and Production Speed: The cost-effectiveness of each method depends heavily on the part's complexity and production volume. Casting is often less expensive for complex parts and large production runs because the tooling (molds) can be reused many times and the process can be highly automated. Forging often has higher initial tooling costs and can be more energy-intensive, making it more expensive upfront. However, for simpler shapes in high volumes, forging can become cost-competitive, and its superior durability can lead to better long-term value.

| Attribute | Forging | Casting |

|---|---|---|

| Strength & Durability | Superior; aligned grain structure, high density. | Lower; potential for porosity and random grain structure. |

| Design Complexity | Limited, best for simpler shapes. | Excellent, ideal for intricate and complex geometries. |

| Material Integrity | High predictability, free of voids. | Can have defects like porosity or shrinkage. |

| Cost | Higher initial tooling costs; better long-term value for high-stress parts. | Lower tooling costs, more cost-effective for complex shapes and mass production. |

Application in Automotive Parts: Choosing the Right Process

In the automotive industry, the decision between forging and casting is made on a component-by-component basis, driven by the specific performance requirements of each part. The distinct advantages of each process have led to clear-cut applications within a vehicle's structure and powertrain.

Forged Parts for High-Stress Applications: Forging is the go-to method for components that must withstand extreme stress, high loads, and cyclical fatigue. These are typically critical parts where failure is not an option. As explained by Admiral Tire and Auto, the superior strength and durability of forged metal make it essential for high-performance engines. Examples of forged automotive parts include:

- Crankshafts and Connecting Rods: These parts are under constant, immense stress from combustion and rotational forces. Forging ensures they have the fatigue resistance to last the engine's lifetime.

- Gears and Axle Shafts: These components transmit torque and must endure high torsional loads, making the strength of forging a necessity.

- Wheel Spindles and Suspension Components: Critical for safety, these parts must handle the vehicle's weight and absorb shocks from the road.

For manufacturers seeking robust and reliable custom components, specialized providers offer advanced solutions. For instance, Shaoyi Metal Technology specializes in high-quality, IATF 16949 certified hot forging for the automotive industry, handling everything from prototyping to mass production.

Cast Parts for Complex Structural Components: Casting shines where complexity and cost-effectiveness are priorities. This process allows engineers to design parts with intricate internal channels for fluids, complex mounting points, and integrated features that would be impossible or prohibitively expensive to forge or machine. Examples of cast automotive parts include:

- Engine Blocks and Cylinder Heads: These are the largest and most complex parts of an engine, featuring intricate coolant passages, oil galleries, and intake/exhaust ports. Casting is the only feasible way to produce them.

- Transmission Housings: Similar to engine blocks, these require complex shapes to house gears, clutches, and hydraulic systems.

- Intake Manifolds and Water Pumps: These parts require specific internal shapes to manage the flow of air, fuel, or coolant, a task perfectly suited for casting.

Summary of Pros and Cons: Which Method Is Better?

Ultimately, the question isn't which process is universally better, but which is the right choice for a specific application. Both forging and casting are indispensable to modern automotive manufacturing. A final summary of their respective advantages and disadvantages can help clarify the decision-making process.

Forging

Forging is the champion of strength and reliability, making it essential for critical, high-stress components where failure could be catastrophic.

- Pros: Superior tensile and fatigue strength, improved metallurgical properties due to refined grain structure, high durability and reliability, less prone to defects like porosity.

- Cons: Higher initial tooling costs, limited design complexity, not suitable for very large or intricate parts, can be a more expensive process overall.

Casting

Casting offers unparalleled design freedom and is often more economical, especially for complex parts or high-volume production runs.

- Pros: Ability to create highly complex and intricate shapes, suitable for a wide range of metals and alloys, lower manufacturing costs for complex parts, efficient for mass production.

- Cons: Lower mechanical strength compared to forging, potential for internal defects such as porosity or shrinkage, parts may require secondary machining for precise tolerances.

Frequently Asked Questions

1. Why would you choose forging instead of casting?

You would choose forging over casting primarily for applications demanding superior strength, durability, and fatigue resistance. The forging process refines the metal's grain structure, eliminating defects like porosity and creating a component that can withstand higher stress and impact. This makes it ideal for critical automotive parts like crankshafts and connecting rods.

2. Which is better, forge or cast?

Neither process is inherently 'better'; the best choice depends entirely on the part's requirements. Forging is better for strength and reliability in high-stress environments. Casting is better for creating complex, intricate shapes at a lower cost and is suitable for parts like engine blocks where design complexity outweighs the need for maximum tensile strength.

3. What automobile parts are made by casting?

A wide variety of automotive parts are made by casting due to its ability to form complex shapes. Common examples include engine blocks, cylinder heads, pistons, transmission housings, intake manifolds, water pumps, and valve covers. These components often have intricate internal passages for fluids that are best produced through casting.

4. What is the difference between cast and forged engine parts?

The primary difference lies in strength and manufacturing process. Forged engine parts, like connecting rods or high-performance pistons, are shaped from solid metal under extreme pressure, making them incredibly strong and durable. Cast engine parts, like a standard piston or engine block, are made by pouring molten metal into a mold. While less strong, cast parts are more cost-effective to produce and can be formed into more complex shapes.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —