Top Automotive Forging Companies in China for Your Supply Chain

TL;DR

China stands as a global manufacturing hub for the automotive forging industry, offering a vast network of suppliers for high-performance components. For businesses seeking reliable partners, the key is identifying companies with proven material expertise, stringent quality certifications, and the capacity for scalable production. This guide provides a curated list of top automotive forging companies in China and outlines the essential criteria for making an informed selection for your supply chain.

The Critical Role of Forging in the Automotive Sector

In the automotive industry, forging is a crucial manufacturing process used to create components that demand exceptional strength, durability, and reliability. The process involves shaping metal using localized compressive forces, which refines the grain structure of the material and eliminates internal defects. This results in parts that are significantly stronger and more resilient to stress, impact, and fatigue than components made through casting or machining alone. Forged parts are indispensable for ensuring vehicle safety and performance.

The benefits of forging are most evident in the critical systems of a vehicle. Forged components are commonly found at points of high shock and stress, ensuring the integrity of the vehicle under demanding conditions. According to industry experts at CHISEN, these applications include powertrain and chassis components where failure is not an option. Because of their superior mechanical properties, forged parts enhance vehicle longevity and contribute to overall safety on the road.

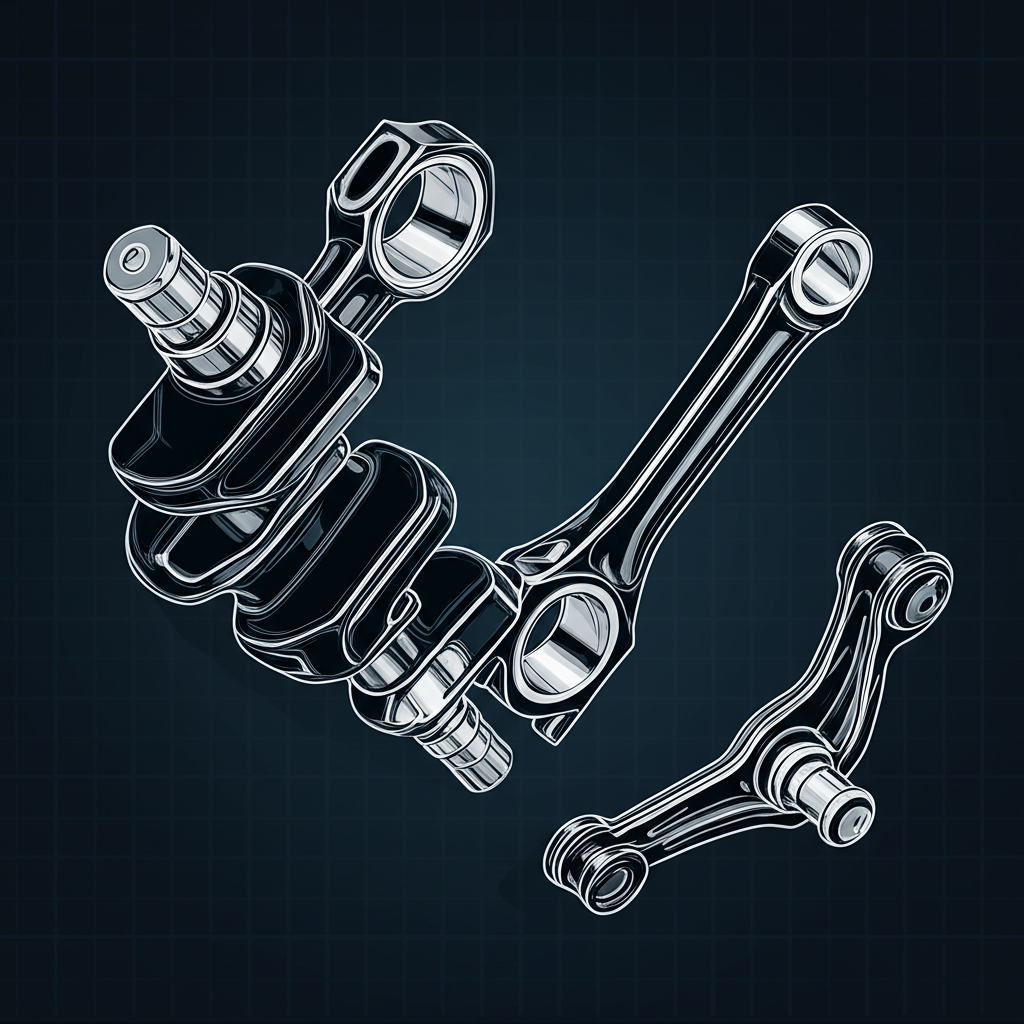

Common examples of forged automotive parts include:

- Engine Components: Connecting rods, crankshafts, and camshafts that must withstand extreme temperatures and mechanical stress.

- Transmission Components: Gears, shafts, and clutch hubs that require high wear resistance and strength to transfer power efficiently.

- Suspension and Steering: Control arms, wheel spindles, kingpins, and steering arms that are vital for vehicle stability and control.

- Drivetrain Parts: Axle beams, drive shafts, and universal joints that transmit torque from the engine to the wheels.

A Curated List of Leading Automotive Forging Companies in China

Navigating the expansive landscape of forging suppliers in China can be challenging. To simplify the process, this section highlights several reputable companies known for their technical capabilities, quality standards, and experience in the automotive sector. The selection includes specialists in both steel and aluminum forging, catering to a wide range of automotive applications.

Shaoyi Metal Technology

For businesses prioritizing precision and certified quality, Shaoyi Metal Technology offers robust custom forging services tailored to the automotive industry. They specialize in high-quality, IATF16949 certified hot forging, a critical standard for automotive suppliers. Their capabilities range from rapid prototyping for small-batch validation to full-scale mass production, providing flexibility for diverse project needs. With integrated in-house die manufacturing, they maintain strict control over tooling and part accuracy. Their strategic location near Ningbo Port facilitates efficient and timely global delivery, making them a strong partner for international supply chains. You can explore their advanced automotive forging solutions for more details.

Nanjing Automotive Forging Co., Ltd. (NJF)

As a prominent joint venture between Donghua Automobile Industry Co., Ltd. (affiliated with SAIC) and the Spanish firm CIE Automotive, NJF is a major player in the market. According to their official site, Nanjing Automotive Forging has an annual production capacity of 80,000 tons and serves premier automobile and construction machinery manufacturers globally. Their extensive experience, dating back nearly 70 years, and integration into CIE's global R&D platform give them a strong technical edge in producing key forgings for high-end vehicles.

Wuhu Sanlian Forging Co., Ltd.

Established in 2004, Wuhu Sanlian Forging focuses on the research, development, and production of automotive forging parts. As noted in a profile by HDC Manufacturing, their products are primarily used in systems requiring high mechanical and safety performance, such as power, transmission, steering, and suspension systems. The company is also actively involved in developing forged components for the growing new energy vehicle (NEV) market, partnering with well-known automobile manufacturers on their NEV platforms.

CFS Machinery Co., Ltd.

With over two decades of experience, CFS Machinery, also known as Steel Forging, specializes in custom closed-die steel forging. Located in Ningbo, they serve a variety of industries, including the automotive sector. Their capabilities extend beyond forging to include in-house tooling, heat treatment, and machining services, allowing them to deliver finished components directly to customers. This one-stop-shop approach simplifies the supply chain for clients requiring ready-to-assemble parts.

Key Criteria for Selecting Your Forging Manufacturer

Choosing the right forging partner is a critical decision that impacts product quality, cost, and supply chain reliability. Beyond a company's profile, procurement managers and engineers should evaluate potential suppliers based on a structured set of criteria. A thorough assessment ensures that the chosen manufacturer can meet technical specifications, quality standards, and long-term production demands.

Focus on these essential factors during your evaluation process:

- Material Expertise and Sourcing: A top-tier supplier should have deep expertise in forging various materials, including carbon steel, alloy steel, and aluminum alloys. Inquire about their raw material sourcing and traceability processes to ensure material integrity and consistency, which are fundamental to the final component's performance.

- Technical Capabilities and Processes: Evaluate their range of forging techniques, such as closed-die, open-die, and precision forging. Additionally, consider their value-added services like in-house tooling and die manufacturing, CNC machining, heat treatment, and surface finishing. A supplier with comprehensive in-house capabilities can offer better quality control and shorter lead times.

- Quality Certifications and Control: For the automotive industry, IATF 16949 certification is the global standard and a non-negotiable requirement. Also, look for ISO 9001 for general quality management. Ask for details about their quality control process, including material inspection, in-process monitoring, and final product testing (e.g., non-destructive testing).

- Production Capacity and Scalability: Assess the manufacturer's production capacity to ensure they can handle your volume requirements, from initial prototypes to full-scale production runs. Discuss their ability to scale production up or down in response to market demand fluctuations, which is crucial for maintaining a flexible and resilient supply chain.

- Experience and Communication: Partner with a company that has a proven track record in the automotive sector and experience working with international clients. Effective communication, transparency, and project management are vital for a successful long-term partnership, especially when navigating cross-border logistics and technical specifications.

Frequently Asked Questions

1. What defines a top forging company in China?

A top automotive forging company in China is typically defined by a combination of advanced technical capabilities, stringent quality management systems (like IATF 16949), extensive experience with both domestic and international automotive brands, and a comprehensive service offering that includes in-house tooling, machining, and heat treatment. They often serve as key suppliers to major automotive groups and have a strong reputation for reliability and precision.

2. Who are some of the largest auto parts companies in China overall?

While the forging sector is specialized, the broader Chinese auto parts industry includes massive corporations. Some of the largest by market capitalization include Fuyao Glass Industry Group, a leading automotive glass producer, and Ningbo Tuopu Group, which manufactures a wide range of components including suspension systems and interior trim. These companies represent the scale and diversity of China's automotive supply chain.

3. How does forging benefit automotive components?

Forging enhances automotive components by refining the metal's grain structure, which increases its strength, toughness, and fatigue resistance. This process produces parts that are highly durable and reliable, making them ideal for critical safety and performance applications like engine, transmission, and suspension components where failure could have catastrophic consequences.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —