Lightweight Forged Wheels Benefits: Why Every Pound Costs You Speed

Understanding Why Wheel Weight Has a Multiplied Performance Impact

Imagine strapping a 10-pound weight to your ankle before going for a run. Now imagine removing it. That immediate sense of freedom and agility? Your car experiences something remarkably similar when you upgrade to lightweight forged wheels. But here's what most drivers don't realize: the performance impact at the wheel is far greater than simply removing weight from your trunk or interior.

The Physics Behind Every Pound at the Wheel

To understand why wheel weight matters so much, you need to grasp the difference between sprung weight vs unsprung weight. Sprung weight includes everything supported by your vehicle's suspension system—the engine, body, interior, and passengers. Unsprung mass, on the other hand, encompasses components that sit below the springs: wheels, tires, brake assemblies, and portions of the suspension itself.

Why does this distinction matter? When your wheels encounter a bump, that unsprung mass must accelerate upward rapidly. According to Newton's Second Law, heavier components require more force to accelerate. This means your suspension must work harder to control heavier wheels, reducing its ability to keep your tires planted firmly on the road surface.

Real-world testing proves that 1 pound of rotating wheel weight equals roughly 5-10 pounds of static vehicle weight when measuring acceleration impact. This multiplier effect makes lightweight wheels one of the most efficient performance modifications available.

Why Wheel Weight Matters More Than You Think

So what do wheel weights do to your vehicle's performance? The answer involves both unsprung mass and rotational inertia. When considering sprung vs unsprung weight, remember that your wheels don't just move up and down—they also spin. This rotation creates additional resistance that your engine must overcome every time you accelerate or decelerate.

The numbers tell a compelling story. In controlled testing, reducing wheel weight by just 12 pounds per corner improved a Mazda Miata's 0-60 time by 0.29 seconds. When researchers added that same 42 pounds to the trunk instead of the wheels, the acceleration penalty was only 0.14 seconds—roughly half the impact. This confirms that weight at the wheels creates approximately double the performance penalty compared to weight elsewhere in the vehicle.

Lightweight forged wheels address both challenges simultaneously. By reducing unsprung mass, they allow your suspension to respond more quickly to road imperfections, maintaining better tire contact. By reducing rotational inertia, they free up engine power that would otherwise be consumed simply spinning heavier wheels.

The benefits extend beyond straight-line acceleration. Lightweight wheels improve handling by enabling faster suspension response during cornering. They enhance braking by reducing the kinetic energy your brakes must dissipate. They even boost fuel efficiency—testing showed vehicles with heavy wheels consumed approximately 7.5% more fuel compared to lightweight configurations.

In the sections ahead, we'll explore exactly how forged wheels achieve these weight reductions, examine the measurable performance gains across different driving scenarios, and help you determine the right approach for your specific vehicle and goals.

The Forging Process That Creates Superior Wheel Strength

Now that you understand why wheel weight matters so much, the natural question becomes: how do manufacturers actually create wheels that are both lighter and stronger? The answer lies in the forging process—a manufacturing method that fundamentally transforms aluminum at the molecular level.

From Solid Billet to Precision Wheel

What are forged wheels, exactly? Unlike their cast counterparts, forged wheels begin their life as a solid block of aluminum called a billet. This billet—typically made from aerospace-grade 6061-T6 aluminum—undergoes an intense transformation that restructures the metal itself.

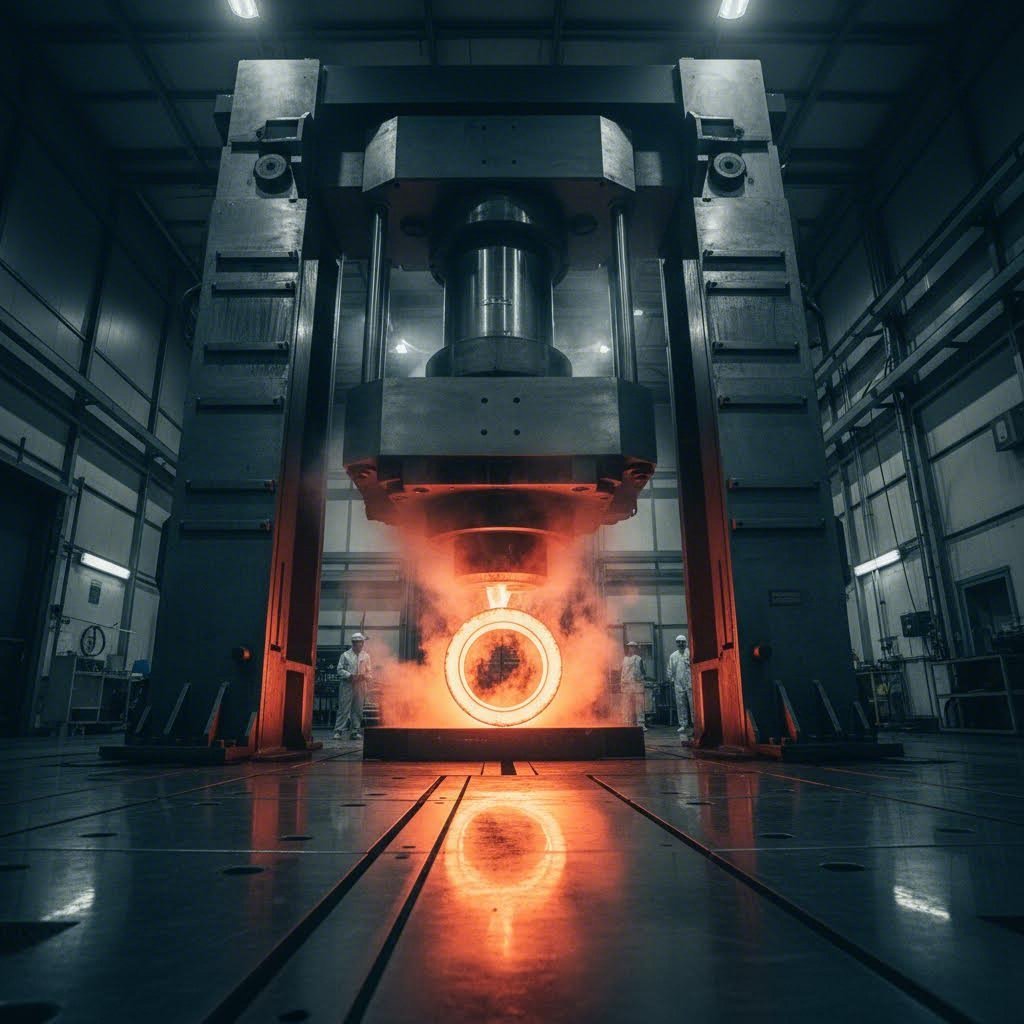

The forging process subjects this solid aluminum billet to extreme conditions. According to Konig's manufacturing documentation, the billet is placed under a massive 10,000-ton press equipped with a specialized mold. This incredible pressure, combined with heat, forces the aluminum to take the shape of a wheel while simultaneously compressing and aligning its internal grain structure.

Why does grain structure matter? Think of it like wood grain. A piece of wood is much stronger when force is applied along the grain rather than against it. The forging process aligns aluminum's molecular structure in a similar way, creating a material that can withstand significantly greater stress without failing.

How Extreme Pressure Creates Exceptional Strength

The forged wheels meaning goes beyond just the manufacturing method—it represents a fundamental difference in material properties. When comparing forged wheels vs cast alternatives, the strength gap becomes immediately apparent. Industry testing reveals that forged wheels can be up to three times stronger than cast wheels of similar design.

Cast wheels follow a completely different manufacturing path. Molten aluminum is poured into molds and allowed to cool. While this process is less expensive, it creates several structural weaknesses. The liquid metal can trap air bubbles during cooling, introducing weak points throughout the wheel. The resulting grain structure is random rather than aligned, reducing overall strength and durability.

The aluminum alloy grade plays a crucial role in the final product. Forged wheels typically use 6061-T6 aluminum—the same grade used in aircraft construction—because of its exceptional strength-to-weight ratio. Cast wheels generally rely on A356 aluminum, which is easier to work with in liquid form but offers inferior mechanical properties. This material difference is what makes forging the preferred method when manufacturers need to forge auto rims that meet demanding performance standards.

The complete forging process involves several precision stages:

- Heating: The aluminum billet is heated to make it malleable enough for forming while maintaining structural integrity

- Pressing: The heated billet undergoes intense pressure (up to 10,000 tons) that compresses and shapes the metal into a wheel blank

- CNC Machining: Computer-controlled cutting removes excess material and creates the final spoke design with precision down to 0.05mm

- Finishing: Surface treatments, painting, or polishing complete the wheel for both aesthetic appeal and corrosion protection

This intensive manufacturing process explains both the superior performance and premium pricing of forged wheels. The weight savings are equally impressive—forged wheels can weigh 20-25% less than cast wheels of equivalent size and strength. Because the metal is so much stronger, engineers can use less material while maintaining or exceeding the structural requirements.

This weight reduction directly supports the lightweight forged wheels benefits we explored earlier. Less material means less rotational mass, which translates to improved acceleration, handling, and braking. The same principle applies whether you're building a track-focused sports car or selecting forged offroad wheels for demanding trail conditions—the stronger, denser grain structure handles impacts that would crack or shatter lesser wheels.

With this understanding of what is a forged wheel and how it's made, you're ready to explore the specific, measurable performance gains these wheels deliver across different driving scenarios.

Measurable Performance Gains in Acceleration and Handling

You've seen the physics. You understand how forged wheels are made. But here's what really matters: how much faster do lightweight wheels actually make your car? Let's move from theory to real-world results that you can feel through the steering wheel and seat of your pants.

Acceleration Gains You Can Actually Feel

When you press the accelerator, your engine produces a finite amount of power. That power must accomplish two tasks simultaneously: propelling your vehicle forward and spinning your wheels. The heavier those wheels, the more energy gets consumed just getting them rotating—energy that could otherwise push you back into your seat.

This isn't just theoretical. Controlled testing on a Mazda Miata demonstrated that reducing car wheel weight by 12 pounds per corner improved 0-60 times by 0.29 seconds. To put that in perspective, many exhaust upgrades costing thousands of dollars struggle to deliver similar gains.

How much do rims weigh in real-world applications? Stock wheels on passenger vehicles typically range from 20 to 30 pounds each. Lightweight racing wheels can drop that figure to 15 pounds or less. When you multiply that 10-15 pound savings across all four corners, you're looking at 40-60 pounds of reduced rotational mass—weight that no longer fights against your acceleration.

A comprehensive BMW 3 Series test reinforced these findings. Comparing lightweight 17-inch wheels (17 lbs each) against heavyweight alternatives (27 lbs each), testers noted the lightweight configuration felt noticeably more powerful throughout the entire RPM range. One driver described the difference as "feeling like the car suddenly found 20 extra horsepower."

The acceleration benefits become even more pronounced during repeated speed changes. In stop-and-go traffic or during spirited canyon driving, your engine constantly accelerates and decelerates those rotating masses. City driving conditions consume approximately 40% of total energy through acceleration resistance—making lightweight wheels particularly effective where you spend most of your driving time.

How Reduced Rotational Mass Transforms Handling

Acceleration improvements grab headlines, but seasoned enthusiasts often value handling gains even more. When your wheel rim weight drops significantly, something remarkable happens to your vehicle's cornering behavior.

Your suspension system exists to keep your tires in constant contact with the road surface. Every bump, crack, and undulation challenges that contact. With heavy wheels, your suspension must control substantial unsprung mass—mass that wants to keep moving in its current direction rather than following the road contour.

Lightweight forged wheels change this equation dramatically. With less mass to control, your suspension responds faster to road surface changes. The result? Your tires maintain more consistent contact with the pavement, delivering improved grip exactly when you need it most—mid-corner, over rough surfaces, or during emergency maneuvers.

Research on suspension dynamics confirms that increased wheel mass makes steering feel heavier and less precise, particularly at lower speeds. The suspension and steering systems must work harder to manage additional mass, creating a disconnect between driver input and vehicle response. Lightweight wheels restore that direct, connected feel that makes driving enjoyable.

The lightest wheels available—typically monoblock forged designs—can weigh as little as 10-15 pounds in 18-inch sizes. This represents a potential savings of 10-15 pounds per corner compared to typical cast alternatives. That 40-60 pounds of total reduction transforms how the vehicle changes direction, with drivers consistently reporting quicker turn-in response and improved mid-corner adjustability.

Braking Benefits: Less Energy to Dissipate

Every pound your wheels carry represents kinetic energy that your brakes must convert to heat when stopping. Heavier wheels store more rotational energy at any given speed, demanding more from your braking system.

The physics are straightforward: reduce the rotating mass, and your brakes have less work to do. Testing indicates that adding 10 pounds per wheel reduces braking effectiveness by approximately 1%. Conversely, removing weight improves stopping distances proportionally.

Beyond raw stopping power, lightweight wheels help combat brake fade during aggressive driving. Your brakes generate tremendous heat during repeated hard stops. When they're working against less rotational inertia, they generate less heat per stop—extending the window before thermal limits compromise performance. Track day enthusiasts particularly appreciate this benefit during extended sessions.

| Performance Aspect | Lightweight Forged Wheels | Standard Cast Wheels | Advantage |

|---|---|---|---|

| Acceleration Response | Excellent - immediate power delivery | Moderate - energy consumed spinning mass | 0.2-0.3 second improvement in 0-60 times |

| Cornering Grip | Superior - consistent tire contact | Good - slower suspension response | Faster turn-in, improved mid-corner control |

| Braking Distance | Shorter - less kinetic energy to dissipate | Longer - more rotational mass to stop | Reduced stopping distances, less brake fade |

| Suspension Compliance | Excellent - rapid bump absorption | Moderate - suspension works harder | Better ride quality over imperfect surfaces |

| Steering Feel | Direct and responsive | Heavier, less immediate | Enhanced driver connection and confidence |

The wheel performance improvements compound in real driving scenarios. During a corner entry, you're simultaneously braking and beginning to turn. Lightweight wheels improve both actions while reducing suspension stress—creating a synergy that exceeds what either benefit delivers in isolation.

Understanding these measurable gains helps frame the decision when selecting your next set of wheels. But not all lightweight forged wheels are created equal. Different construction methods—monoblock, two-piece, and three-piece designs—offer distinct trade-offs between weight savings, customization options, and pricing that deserve careful consideration.

Comparing Monoblock and Multi-Piece Forged Wheel Designs

You've seen the performance numbers. You understand that lighter wheels accelerate faster, corner harder, and stop shorter. But when you start shopping for the best forged wheels, you'll quickly encounter different construction types—each with its own weight characteristics and trade-offs. Choosing the right architecture can mean the difference between achieving your goals and leaving performance on the table.

Monoblock vs Multi-Piece Construction Explained

Sounds complex? It doesn't have to be. Every forged wheel falls into one of four basic categories, and understanding these options will help you match your priorities to the right design.

Monoblock (one-piece) forged wheels represent the purest expression of lightweight alloy wheels engineering. As the name suggests, these wheels are machined from a single forged aluminum blank—no separate components, no fasteners, no assembly required. This construction method delivers the lightest forged wheels possible for any given size and design.

Why does single-piece construction save weight? According to Vivid Racing's wheel comparison guide, monoblock wheels eliminate the hardware and overlapping material required to join separate components. They also offer maximum structural rigidity since there are no joints where flex could occur. For track-focused enthusiasts chasing every ounce of unsprung mass reduction, monoblock construction is typically the answer.

The trade-off? Customization becomes limited. Once a monoblock wheel is forged and machined, its width, offset, and backspacing are fixed. If you need unusual fitment specifications or plan to change your suspension setup later, this inflexibility can become problematic.

Two-Piece Construction: Balancing Weight and Flexibility

Two-piece forged wheels split the difference between weight savings and customization. These wheels feature a forged center section (containing the spokes and hub) attached to a separate barrel (the rim portion that holds the tire). The connection typically uses either welding or bolts, depending on the manufacturer.

This construction offers genuine advantages. If you damage the barrel on a pothole or curb, you may be able to replace just that component rather than the entire wheel. Two-piece designs also allow manufacturers to offer more width and offset combinations by pairing different barrel sizes with the same center section.

The weight penalty compared to monoblock construction is modest but real. Joining hardware and the overlapping material at the connection point add several ounces per wheel. For street performance applications where absolute minimum weight isn't critical, most drivers find this trade-off acceptable for the added flexibility.

Three-Piece Construction: Maximum Customization

Three-piece forged wheels take modularity to the extreme. The design separates into a forged center section, an inner barrel half, and an outer barrel half—all assembled with visible perimeter bolts. This architecture allows virtually unlimited combinations of width and offset by mixing different barrel components.

For vehicles with extreme fitment requirements—widebody builds, aggressive stance setups, or applications requiring precise clearance management—three-piece construction provides solutions that simply aren't available otherwise. Show car builders often prefer the distinctive look of visible assembly hardware, which has become an aesthetic statement in its own right.

However, three-piece wheels are typically the heaviest of the forged options. All those bolts and extra barrel material add significant weight. They also require more maintenance—the seals between components must be monitored, and some owners report vibrations in wet conditions when water becomes trapped at the barrel joints. Premium three-piece wheels from respected manufacturers often cost two to three times more than comparable monoblock designs.

Choosing the Right Forged Wheel Architecture

Between fully forged options and standard cast wheels sits an increasingly popular middle ground: flow forged wheels (also called rotary forged wheels or flow formed wheels).

These lightweight alloys start life as a cast wheel blank, but with a narrower-than-final barrel width. The wheel is then heated and spun on a rotary machine while rollers apply outward pressure, stretching and compressing the barrel material to its final dimensions. According to Scott's U-Save tire experts, this process creates a grain structure similar to forging, giving the barrel significantly improved strength-to-weight characteristics.

The catch? Only the barrel receives this treatment. The spokes and center section retain standard cast properties. Still, since the barrel represents a significant portion of total wheel weight, flow forged designs achieve meaningful weight savings—typically falling between cast and fully forged options on the scale.

For enthusiasts seeking 20 inch forged wheels without the premium pricing, flow formed alternatives often represent the sweet spot. Racing series like the Honda Challenge have embraced flow formed wheels specifically because their weight benefits can't be matched at the price point.

| Construction Type | Weight | Strength | Customization | Typical Price Range |

|---|---|---|---|---|

| Monoblock Forged | Lightest | Excellent - maximum rigidity | Limited - fixed specifications | $600-$1,500+ per wheel |

| Two-Piece Forged | Light | Excellent - slight flex at joint | Moderate - multiple barrel options | $800-$2,000+ per wheel |

| Three-Piece Forged | Moderate | Very Good - hardware adds mass | Maximum - unlimited combinations | $1,200-$3,000+ per wheel |

| Flow Forged | Light-Moderate | Very Good barrel, Good spokes | Limited - cast-style options | $300-$700 per wheel |

Your ideal choice depends on your priorities. Track day enthusiasts chasing lap times should lean toward monoblock designs for their uncompromising weight advantage. Street performance builds that may evolve over time benefit from two-piece flexibility. Show car projects or extreme fitment builds often require three-piece construction despite the weight penalty. And budget-conscious enthusiasts can achieve substantial performance gains with quality flow forged wheels at accessible prices.

Understanding construction types is essential, but selecting the right wheel also requires matching weight targets to your specific vehicle category. A sports car, daily driver, and off-road truck each have different requirements that influence the optimal wheel weight and construction approach.

Selecting the Right Wheel Weight for Your Vehicle Type

A 15-pound wheel that transforms a Miata into a canyon carver might shatter under the first trail obstacle on a lifted 4Runner. That's the reality of wheel selection: the optimal weight target varies dramatically based on what you drive and how you use it. Let's break down the specific requirements for each vehicle category so you can make an informed decision.

Weight Targets for Sports Cars vs Daily Drivers

Sports cars and track vehicles represent the most weight-sensitive category. When lap times matter, every ounce counts—and the unsprung mass multiplier effect we discussed earlier makes wheel weight reduction particularly impactful. For serious track enthusiasts running 18-inch wheels, the target zone falls between 15-18 pounds per wheel.

Can you go lighter? Yes, but with trade-offs. Sub-15-pound wheels exist, but they typically feature aggressive spoke designs with minimal material thickness. These ultra-light options work brilliantly on smooth racetracks but may lack the structural margin for pothole-laden public roads. If your sports car pulls double duty as occasional transportation, aiming for the 17-18 pound range provides meaningful weight savings while maintaining real-world durability.

Daily drivers require a different calculation. You'll encounter expansion joints, frost heaves, and unexpected potholes that simply don't exist on racetracks. According to Michelin's wheel sizing guidance, the shorter sidewalls associated with larger diameter wheels offer less cushioning against road imperfections—meaning your wheels absorb more impact energy directly.

For commuter vehicles, prioritize durability alongside weight savings. A wheel weighing 20-22 pounds that survives years of real-world abuse delivers better long-term value than a 16-pound wheel that cracks on your first encounter with a highway pothole. The sweet spot for most daily drivers balances noticeable performance improvement against practical durability requirements.

Matching Wheel Specifications to Your Driving Style

Trucks and SUVs present unique challenges that many lightweight wheel discussions overlook. These vehicles carry substantial loads, tow trailers, and often haul passengers and cargo simultaneously. Lightweight truck wheels deliver real benefits—reduced strain on suspension components, improved brake longevity, and meaningful fuel economy gains—but they must maintain adequate load ratings for safe operation.

The lightest truck wheels from reputable manufacturers typically weigh 25-30 pounds in popular sizes like 17x8 or 18x9. That might sound heavy compared to sports car figures, but consider the context: many factory truck wheels weigh 35-40 pounds or more. Saving 10 pounds per corner on a truck translates to 40 pounds of reduced unsprung mass—a modification that noticeably improves how these heavy vehicles accelerate, handle, and stop.

Forged wheels for trucks must prioritize load capacity above aggressive weight reduction. Always verify that any wheel you're considering meets or exceeds your vehicle's specified load rating. This information should appear on the wheel itself or in manufacturer documentation. If a seller can't provide load rating specifications, look elsewhere.

Off-road applications demand perhaps the most careful balance of competing priorities. Lightweight off road wheels improve unsprung response over rough terrain—allowing your suspension to react faster to rocks, ruts, and washboard surfaces. This translates to better tire contact, improved traction, and a less punishing ride during extended trail sessions.

However, lightweight off road rims must withstand impacts that would never occur on pavement. Rock strikes, ledge drops, and hard landings generate forces that test wheel structural limits. The lightest off road wheels typically aren't appropriate for aggressive rock crawling or high-speed desert racing. Light offroad wheels work best for overlanding and moderate trail use where weight savings improve efficiency without sacrificing the strength margin needed for occasional hard impacts.

Forged truck wheels designed specifically for off-road use often weigh 28-35 pounds in typical sizes—heavier than on-road forged options but substantially lighter than cast off-road wheels while offering superior impact resistance.

Understanding the Diameter and Width Equation

Before finalizing weight targets, you need to understand how wheel sizing affects the equation. Larger diameter wheels effectively lengthen a vehicle's gear ratio, requiring more engine effort to accelerate—exactly the opposite of what lightweight wheels are designed to accomplish.

Here's the practical reality: a lightweight 20-inch wheel might weigh the same as a standard 17-inch wheel. You've eliminated the weight penalty of upsizing, but you haven't gained the acceleration advantage that a lightweight 17-inch wheel would provide. The additional rotational circumference still requires more energy to spin.

Width follows similar logic. Wider wheels accommodate wider tires with larger contact patches—beneficial for grip but detrimental to weight. Every inch of additional width adds material to the barrel, increasing overall wheel weight. When shopping for the lightest off road wheels or the best track-day setup, consider whether your current wheel size is appropriate for your goals or whether downsizing might yield better results.

Weight Target Ranges by Vehicle Category

- Track-focused sports cars (17-18" wheels): 14-18 lbs — prioritize minimum weight, accept durability trade-offs

- Street sports cars (18-19" wheels): 18-22 lbs — balance weight savings with pothole resistance

- Daily drivers (17-19" wheels): 20-25 lbs — emphasize durability, accept modest weight premium

- Performance trucks/SUVs (17-20" wheels): 25-32 lbs — verify load ratings, prioritize strength

- Off-road vehicles (17-18" wheels): 28-35 lbs — match weight to intended trail severity

- Overlanding builds (17-18" wheels): 26-30 lbs — lightweight off road wheels for efficiency on moderate terrain

Verifying Load Ratings and Structural Adequacy

Weight targets mean nothing if the wheel can't safely support your vehicle. Every quality wheel carries a load rating—the maximum weight it's engineered to support. For passenger vehicles, divide your vehicle's Gross Vehicle Weight Rating (GVWR) by four to establish minimum per-wheel requirements, then add a safety margin.

Trucks and SUVs demand extra attention. If you tow or haul heavy loads, factor those weights into your calculations. A wheel rated for 2,000 pounds might seem adequate for your 6,000-pound truck until you add passengers, cargo, and a trailer tongue weight that pushes individual corner loads beyond safe limits.

Reputable manufacturers clearly document load ratings and testing standards. Wheels certified to JWL (Japan Light Alloy Wheel), VIA (Vehicle Inspection Association), or TÜV (German technical inspection) standards have undergone rigorous validation. These certifications become even more important when you're pushing toward the lighter end of appropriate weight ranges for your vehicle category.

Selecting the right wheel weight is only part of the equation. Understanding how to identify quality forged wheels—and avoid potentially dangerous counterfeits—requires attention to safety standards and verification processes that protect both your investment and your safety.

Safety Standards and Quality Verification for Forged Wheels

Here's an uncomfortable truth that performance wheel marketing rarely addresses: not all lightweight forged wheels are created equal when it comes to safety. The same engineering that enables dramatic weight reduction can—in poorly designed or manufactured wheels—create structural vulnerabilities that compromise your safety. Understanding how to identify quality forged wheels separates informed buyers from those gambling with their well-being.

Balancing Weight Reduction with Structural Integrity

Every wheel design represents a calculated trade-off. Engineers must balance weight savings against structural requirements, and aggressive weight reduction inevitably reduces safety margins. The relationship is straightforward: thinner spokes weigh less but flex more under load. Deeper machining removes material but creates stress concentration points. Larger spoke cutouts improve aesthetics while reducing the cross-sectional area available to transfer forces.

According to OXWheels' engineering analysis, strong, precisely engineered rims resist deformation under stress, reducing the risk of failure. The best forged rims achieve weight savings through superior materials and optimized geometry—not by simply removing material until the wheel becomes dangerously thin.

When evaluating affordable forged wheels, ask yourself: how did the manufacturer achieve that price point? Did they invest in premium 6061-T6 aluminum and advanced forging processes? Or did they cut corners on material thickness to hit a weight target that looks impressive in marketing materials? The answer often determines whether you're purchasing a performance upgrade or a safety compromise.

Reputable forged wheels brands maintain conservative safety margins even in their lightest designs. These manufacturers understand that real-world driving involves impacts, potholes, and stresses that laboratory testing can't fully replicate. A wheel that tests perfectly in controlled conditions might still fail when it encounters the unexpected forces of daily driving.

How to Identify Quality Forged Wheels

Certification marks serve as your first line of defense against substandard wheels. When shopping for aluminum rims for sale, look for these recognized quality standards:

JWL (Japan Light Alloy Wheel) certification confirms that wheels meet safety and quality requirements established by Japanese authorities. According to Flexiforge's certification guide, although originating in Japan, JWL standards are widely accepted worldwide, assuring that wheels can handle everyday use and demanding driving conditions. The companion JWL-T certification applies specifically to truck wheels with higher load requirements.

VIA (Vehicle Inspection Association) certification indicates independent third-party testing beyond manufacturer claims. Wheels bearing VIA marks have undergone additional verification confirming they meet or exceed JWL requirements—providing extra assurance on performance and durability.

TÜV certification carries particular weight in European markets and among knowledgeable enthusiasts worldwide. This German technical inspection organization applies rigorous quality and safety testing. For consumers, TÜV certification means wheels are durable and can handle various stresses—a meaningful distinction when you're pushing performance limits.

Beyond certifications, examine the physical characteristics of wheels you're considering. Genuine forged wheels feature crisp, clear, and well-aligned logos etched into the wheel, along with unique serial numbers and manufacturer specifications. The finish should appear uniform with precise details—not uneven paint or surface irregularities that suggest inferior manufacturing.

Avoiding Counterfeits and Low-Quality Products

The counterfeit wheel market has grown alongside the popularity of premium forged designs. When wondering where can I get rims that are both affordable and authentic, start by understanding the warning signs of fake or substandard products.

Fake wheels are prone to cracking or breaking under pressure, especially on uneven roads or during aggressive driving. They're typically produced with weaker materials that compromise strength and durability—the opposite of what you're paying premium prices to obtain. Beyond safety risks, counterfeit wheels can significantly decrease your vehicle's resale value and may void warranties on related components.

- Unusually low prices: If a deal seems too good to be true, it probably is. Genuine forged manufacturing is expensive—cheap forged wheels often aren't forged at all, or use inferior materials and processes

- Missing or vague certifications: Reputable manufacturers proudly display JWL, VIA, TÜV, or equivalent certification marks. Absence of these standards suggests the wheels haven't undergone independent safety verification

- Vague manufacturing origins: Quality manufacturers clearly identify where and how their wheels are produced. Evasive answers about manufacturing location or process should raise immediate concerns

- Poor logo quality: Blurry, misplaced, or poorly engraved brand logos often indicate counterfeit products attempting to replicate premium brands

- Missing serial numbers: Authentic wheels include unique identification codes that enable verification with the manufacturer. Missing or obviously fabricated codes suggest counterfeits

- Inconsistent weight: Counterfeit wheels often weigh more than authentic versions due to inferior materials. Compare actual weight against manufacturer specifications

- No documentation: Request certificates of authenticity or original invoices. Legitimate sellers can provide documentation confirming the wheel's origin and specifications

When purchasing, stick to authorized dealers or reputable specialty retailers with established track records. The few dollars saved buying from unknown sources rarely justify the risk of receiving counterfeit or substandard products that could fail at the worst possible moment.

Quality verification extends beyond the initial purchase. Inspect wheels regularly for signs of damage, cracking, or unusual wear patterns. Even the best forged rims can develop issues after impact damage or extended high-stress use. Catching problems early prevents catastrophic failures that endanger you and others.

Understanding safety standards protects your investment and your well-being. But cost remains a legitimate consideration for most buyers. The next section explores how to evaluate the forged wheel investment across different price tiers—helping you find the balance between performance, quality, and budget that makes sense for your specific situation.

Evaluating the Investment and Long-Term Value Proposition

You've seen the performance data. You understand construction differences and safety requirements. Now comes the question that stops many enthusiasts cold: is the premium price actually worth it? The answer depends on understanding what drives forged wheel costs—and how to match your budget to the right value tier.

Understanding the Investment in Forged Wheel Technology

Why do forged wheels cost significantly more than cast alternatives? The answer isn't marketing markup—it's manufacturing reality.

The forging process demands aerospace-grade 6061-T6 aluminum billets that cost substantially more than the A356 alloy used in cast production. According to K7 Forged's manufacturing analysis, premium forged wheels use materials known for exceptional strength-to-weight ratios—the same alloys trusted in aircraft construction. This material choice alone creates a meaningful cost differential before manufacturing even begins.

Then consider the production process itself. While cast wheels can be poured and cooled in large batches, forged wheels require individual attention under massive 10,000-ton presses. Each wheel undergoes precision CNC machining, careful finishing, and rigorous quality control. High-performance forged wheels face precise engineering with advanced techniques—a process that simply cannot match cast production speeds or volumes.

Lower production volumes compound the cost equation. Cast wheel manufacturers spread tooling and overhead costs across tens of thousands of identical units. Forged wheel producers, especially those offering customization, absorb similar overhead across far fewer wheels. The math is unavoidable: when you buy a lightweight wheelset, you're paying for genuine manufacturing advantages that cheaper processes cannot replicate.

Value Tiers from Entry-Level to Premium

Understanding where your budget fits within the forged wheel market helps you maximize value without overspending—or underbuying. Think of it as three distinct tiers, each serving different priorities.

Entry-Level: Flow-Forged Options ($300-$700 per wheel)

For budget-conscious enthusiasts who want lightweight car wheels without premium pricing, flow-forged designs deliver meaningful performance gains at accessible costs. These wheels combine cast centers with barrels stretched and compressed through rotary forging—achieving near-forged strength where it matters most.

The trade-off? Limited customization options and somewhat heavier weight compared to fully forged alternatives. But for daily drivers or enthusiasts prioritizing vehicle lightweighting on a budget, flow-forged wheels represent the most cost-effective path to reduced unsprung mass.

Mid-Tier: Monoblock Forged ($600-$1,500 per wheel)

Serious performance seekers find their sweet spot here. Fully forged monoblock construction delivers maximum weight savings and structural rigidity without the complexity of multi-piece designs. According to Variant Wheels' product documentation, monoblock forged wheels offer true forged performance with faster turnaround times than custom multi-piece options.

This tier suits track day enthusiasts, canyon carvers, and anyone willing to accept fixed specifications in exchange for optimal performance. When you buy wheelset options in this range, you're purchasing serious engineering backed by meaningful warranties and manufacturer support.

Premium: Multi-Piece Forged ($1,200-$3,000+ per wheel)

For ultimate customization—precise offsets, unusual widths, distinctive styling—multi-piece construction commands premium pricing. Show car owners and builders with specific fitment requirements often have no alternative. The visible hardware, floating-spoke aesthetics, and ability to repair individual components justify the investment for the right buyer.

However, understand what you're paying for: customization flexibility, not necessarily superior performance. Three-piece wheels typically weigh more than equivalent monoblock designs. If your priority is light weight wheels above all else, mid-tier monoblock options often deliver better value.

ROI Considerations: Quantifying Long-Term Value

The initial purchase price tells only part of the story. Light wheels deliver ongoing returns that partially offset their premium cost.

Fuel efficiency improvements compound over time. Earlier testing demonstrated that heavy wheels can increase fuel consumption by approximately 7.5% compared to lightweight configurations. Over years of ownership and thousands of miles, those savings accumulate meaningfully—particularly for daily drivers.

Reduced brake wear follows logically from reduced rotational mass. When your brakes work against less kinetic energy, they generate less heat and experience slower pad and rotor consumption. Track enthusiasts especially appreciate this benefit, as brake consumables represent a significant ongoing expense.

Resale value retention rewards quality purchases. Vehicles equipped with durable custom wheels can attract higher offers, as premium wheels from reputable manufacturers add both aesthetic and functional value. Buyers recognize forged wheels as meaningful upgrades, often paying premiums for vehicles already so equipped.

Perhaps most importantly, premium forged wheels last longer and show signs of wear more slowly than cheaper alternatives. Where budget wheels might need replacement after several years of hard use, quality forged wheels often outlast the vehicles they're installed on. Spreading the purchase price across a longer service life fundamentally changes the cost-per-year calculation.

Prioritizing Value by Buyer Profile

Your optimal investment strategy depends on how you'll use your wheels. Consider these ranked priorities:

-

Track Enthusiast Priorities:

- Minimum weight for maximum performance gains

- Structural integrity under repeated high-stress use

- Brake clearance for big brake kits

- Strong warranty coverage for aggressive driving

- Aesthetic considerations (secondary to function)

-

Daily Driver Priorities:

- Durability for pothole and road hazard resistance

- Long-term reliability and finish quality

- Fuel efficiency improvements for commuting savings

- Reasonable weight reduction without sacrificing strength

- Road hazard replacement programs

-

Show Car Owner Priorities:

- Visual impact and design uniqueness

- Custom fitment options for precise stance

- Premium finishes and hardware quality

- Brand recognition and prestige

- Weight savings (often secondary to appearance)

The premium price of quality lightweight rims reflects genuine manufacturing advantages—superior materials, intensive processes, and rigorous quality control. Understanding which tier matches your priorities prevents both overspending on features you don't need and underspending on quality that matters for your specific application.

With a clear understanding of value tiers and investment considerations, you're equipped to make an informed purchasing decision. The final step involves translating this knowledge into action—identifying quality manufacturers and executing your upgrade with confidence.

Making Your Lightweight Forged Wheel Upgrade Decision

You've absorbed the physics, studied the manufacturing processes, and evaluated the trade-offs. Now it's time to transform that knowledge into action. Whether you're chasing lap times, improving daily driving dynamics, or building a capable overland rig, the path to performance-enhancing wheel upgrades follows a clear decision framework.

Your Path to Performance-Enhancing Wheel Upgrades

Imagine pulling the trigger on a set of lightweight 18 inch wheels only to discover they don't clear your brake calipers—or worse, they flex dangerously under cornering loads. This scenario plays out more often than you'd expect when buyers skip the systematic approach.

Start by defining your weight target based on vehicle category. Track-focused sports cars should pursue the lightest 18 inch wheels available in the 14-18 pound range. Daily drivers benefit from slightly heavier options (20-25 pounds) that balance weight savings with real-world durability. Trucks and off-road vehicles require wheels light enough to improve unsprung response while maintaining load ratings appropriate for their intended use.

Next, match construction type to your priorities. Monoblock forged designs deliver minimum weight and maximum rigidity—ideal when every ounce matters. Two-piece construction provides flexibility for unusual fitments or future modifications. Three-piece wheels suit show builds and extreme customization needs where weight is secondary to aesthetics. Flow-forged options offer the most accessible entry point for enthusiasts seeking meaningful improvements without premium pricing.

Your budget determines which value tier makes sense. Entry-level flow-forged wheels ($300-$700 per wheel) serve budget-conscious buyers well. Mid-tier monoblock forged options ($600-$1,500) target serious performance seekers. Premium multi-piece construction ($1,200-$3,000+) addresses specialized fitment requirements and distinctive styling priorities.

Finally—and critically—verify quality standards before purchasing. Wheels light enough to transform your vehicle's dynamics must still maintain structural integrity under real-world stress. Look for JWL, VIA, or TÜV certifications as baseline quality indicators. Request documentation confirming load ratings appropriate for your application. Avoid suspiciously cheap offerings that may compromise the safety margins you're counting on.

Partnering with Quality-Focused Manufacturers

The certification verification process we discussed earlier becomes especially important when sourcing wheels or components from manufacturers directly. IATF 16949:2016 certification is vital for wheel manufacturers supplying major automakers—it covers the entire production process, ensuring high-quality standards at every stage with focus on continuous improvement and defect prevention.

This standard matters whether you're purchasing finished lightweight automotive wheels or exploring OEM-level component partnerships. Manufacturers holding IATF 16949 certification demonstrate commitment to the rigorous quality control systems that separate reliable forging operations from questionable suppliers.

For automotive professionals, fleet managers, or enthusiasts exploring manufacturing partnerships for custom projects, working with certified forging specialists ensures consistent quality. Companies like Shaoyi (Ningbo) Metal Technology exemplify this approach—their IATF 16949 certification and in-house engineering capabilities support everything from rapid prototyping (as quick as 10 days) to high-volume production of precision components like suspension arms and drive shafts. Their location near Ningbo Port enables efficient global logistics for internationally compliant manufacturing.

Whether you're sourcing a single set of light rims for your weekend track car or establishing supply relationships for larger projects, the quality verification principles remain identical. Certifications exist precisely because they provide objective validation that subjective marketing claims cannot.

The lightweight wheel you mount today will spin thousands of times before your next oil change. Each rotation tests the engineering decisions that determined its strength-to-weight ratio. Choose wisely, verify thoroughly, and you'll enjoy the acceleration, handling, and braking improvements that make lightweight forged wheels worth every dollar invested.

Key Takeaways and Action Steps

- Calculate your weight target: Determine appropriate wheel weight based on your vehicle category—sports cars (14-18 lbs), daily drivers (20-25 lbs), trucks/off-road (25-35 lbs)

- Select your construction type: Choose monoblock for minimum weight, two-piece for flexibility, three-piece for customization, or flow-forged for budget-conscious performance

- Establish your budget tier: Match spending to priorities—entry-level flow-forged, mid-tier monoblock, or premium multi-piece options

- Verify certifications: Confirm JWL, VIA, TÜV, or equivalent quality standards; avoid wheels lacking documentation

- Check load ratings: Ensure wheels meet or exceed your vehicle's requirements, especially for trucks, SUVs, and towing applications

- Measure fitment carefully: Confirm diameter, width, offset, and brake clearance before purchasing—returns on custom wheels are often difficult

- Purchase from reputable sources: Buy through authorized dealers or established specialty retailers with track records and warranty support

- Consider long-term value: Factor fuel savings, reduced brake wear, and durability into total cost calculations—quality lightweight 20 inch rims often outlast cheaper alternatives

- Inspect after impact events: Even premium wheels light enough to transform performance can develop damage; catch issues before they become failures

- Document your purchase: Keep invoices, certification papers, and serial numbers for warranty claims and future verification

The lightweight wheel upgrade that felt like a luxury purchase often reveals itself as one of the most effective modifications available. Every acceleration run, every corner entry, and every brake application demonstrates the compounding benefits of reduced unsprung mass. The physics don't lie: when you remove weight from the wheels, you add performance everywhere else.

Frequently Asked Questions About Lightweight Forged Wheels

1. What are the advantages of lightweight wheels?

Lightweight wheels deliver multiple performance benefits by reducing unsprung mass and rotational inertia. Your vehicle accelerates faster because the engine expends less energy spinning the wheels. Handling improves as suspension components respond more quickly to road surface changes, maintaining better tire contact. Braking distances shorten because there's less kinetic energy to dissipate. Additionally, fuel efficiency improves—testing shows heavy wheels can consume approximately 7.5% more fuel than lightweight alternatives. The weight savings also reduce strain on suspension and brake components, potentially extending their service life.

2. Can you feel a difference with forged wheels?

Yes, most drivers notice an immediate difference when upgrading to quality forged wheels. The reduced weight creates more responsive acceleration, especially during repeated speed changes in spirited driving. Steering feels more direct and precise because the suspension manages less unsprung mass. During cornering, lighter wheels enable faster turn-in response and improved mid-corner adjustability. Drivers often describe the sensation as the car feeling more agile and connected. Testing with BMW 3 Series vehicles showed drivers perceiving the lightweight configuration as having approximately 20 extra horsepower throughout the RPM range.

3. Do lighter wheels increase MPG?

Lighter wheels can measurably improve fuel economy, though the gains are more modest than performance improvements. Reduced rotational mass means your engine works less to accelerate the wheels, conserving energy during speed changes. City driving shows the most significant benefit since approximately 40% of total energy consumption occurs through acceleration resistance during stop-and-go conditions. Testing demonstrates that vehicles with heavy wheels consume roughly 7.5% more fuel compared to lightweight configurations. While highway fuel economy improvements are smaller, the cumulative savings over years of ownership can partially offset the premium cost of quality forged wheels.

4. How much weight difference matters when choosing wheels?

The performance impact of wheel weight reduction is significant due to the multiplier effect of unsprung and rotating mass. Real-world testing shows that 1 pound of rotating wheel weight equals roughly 5-10 pounds of static vehicle weight when measuring acceleration impact. A 12-pound reduction per corner improved a Mazda Miata's 0-60 time by 0.29 seconds. When the same weight was added to the trunk instead, the penalty was only 0.14 seconds—confirming wheels have approximately double the impact. For track use, target 14-18 pounds for 18-inch wheels; daily drivers can accept 20-25 pounds for better durability.

5. Are cheap forged wheels safe to use?

Unusually cheap forged wheels often indicate compromised materials or manufacturing shortcuts that can create safety risks. Genuine forging with aerospace-grade 6061-T6 aluminum and precision manufacturing is inherently expensive. Budget wheels may use inferior alloys, thinner material, or skip proper quality verification. Look for JWL, VIA, or TÜV certifications confirming independent safety testing. Reputable manufacturers provide clear load ratings, serial numbers, and documentation. Counterfeit wheels are prone to cracking under stress and may fail during aggressive driving. When evaluating affordable options, verify certifications and purchase from authorized dealers rather than unknown sources.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —