3 Piece Forged Wheels Assembly: From Loose Parts To Track-Ready

Understanding 3 Piece Forged Wheels and Their Modular Design

Ever wondered what separates a truly premium wheel from everything else on the market? The answer lies in three precision-machined components working together as one. 3 piece forged wheels represent the pinnacle of custom wheel engineering, offering unmatched flexibility in sizing, offset configurations, and long-term serviceability that single-piece alternatives simply cannot match.

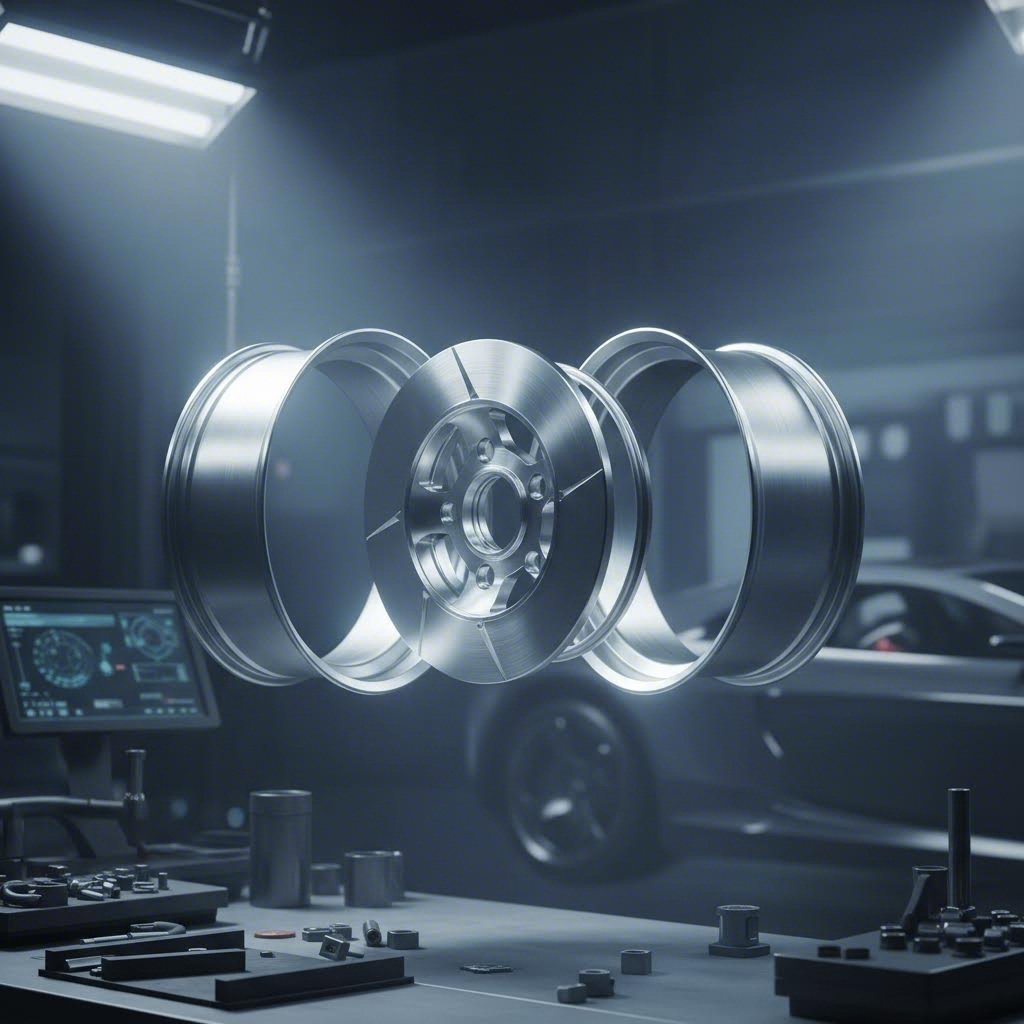

So, what are 3 piece wheels exactly? At their core, these modular assemblies consist of three separate forged aluminum components: a center disc, an inner barrel, and an outer barrel. Each piece undergoes individual forging processes that create superior grain structures aligned with stress patterns. When assembled together using precision fastening systems, these components form a wheel that typically achieves weight reductions of fifteen to twenty-five percent compared to cast alternatives while maintaining superior strength characteristics.

The Anatomy of Multi-Component Wheel Design

Understanding the role of each component is essential before you attempt any assembly work. Think of it like building a precision instrument where every part serves a specific engineering purpose:

- Center Disc (Face): The forged center section serves as the visual focal point and primary load-bearing component. It bolts directly to your vehicle's hub and distributes driving forces across the wheel assembly. High-strength aluminum alloys are engineered specifically for maximum load distribution in this critical piece.

- Inner Barrel (Rear Lip): This component forms the rear portion of the wheel's rim section. The inner barrel determines part of your total wheel width and works with the outer barrel to create the tire-mounting surface. The 3 piece wheel barrels utilize optimized alloy compositions for durability and weight reduction.

- Outer Barrel (Front Lip): Visible from the outside, the outer barrel creates the front lip that enthusiasts often showcase. Combined with the inner section, it establishes your final wheel width and offset specifications.

Why Enthusiasts Choose Modular Forged Construction

Why go through the complexity of three piece wheels when simpler options exist? The advantages become clear when you consider real-world applications. Modular construction enables manufacturers to optimize material selection for each component based on specific performance requirements. You'll notice that this segmented approach allows engineers to fine-tune material properties throughout the wheel assembly rather than compromising with a one-size-fits-all solution.

The connection methodology between wheel segments utilizes precision-engineered fastening systems that create rigid assemblies exceeding the strength characteristics of welded joints. This means you get a wheel that handles extreme loading conditions while remaining serviceable. Damaged a lip on track day? Replace just that component rather than the entire wheel.

This guide exists to fill a significant knowledge gap. You'll find plenty of product showcases online, but practical assembly knowledge remains scarce. In the following sections, you'll gain hands-on understanding of hardware specifications, step-by-step assembly procedures, torque sequences, and troubleshooting techniques. Whether you're building a set of 3 piece forged wheels for the first time or maintaining an existing setup, this comprehensive resource delivers the technical depth you need to work confidently with these precision components.

Essential Components of Three Piece Wheel Construction

Now that you understand the fundamentals of modular wheel design, let's dive deeper into the technical specifications of each component. When you're preparing for a 3 piece wheel assembly, knowing exactly what you're working with makes the difference between a flawless build and frustrating setbacks.

Each forged rim in a three-piece system undergoes distinct manufacturing processes tailored to its specific function. Unlike forged monoblock wheels that compromise material properties across a single structure, 3 pieces wheels allow engineers to optimize alloy formulations and heat treatments for each component independently. The result? A wheel system where every element performs at its peak.

Center Disc Forging and Face Design Options

The center disc represents both the aesthetic centerpiece and the structural backbone of your 3 piece wheel. This component bolts directly to your vehicle's hub assembly and must withstand tremendous cornering, braking, and acceleration forces transmitted through the wheel bearings.

Forged center discs start as high-grade aluminum billets subjected to pressures exceeding 10,000 tons. This extreme compression creates a grain structure that's significantly denser than cast alternatives. Imagine pressing clay versus pouring it into a mold. The pressed version develops internal alignment that naturally resists cracking and fatigue. According to industry testing standards, this forging process eliminates porosity and weak points that commonly cause cast wheels to fail under stress.

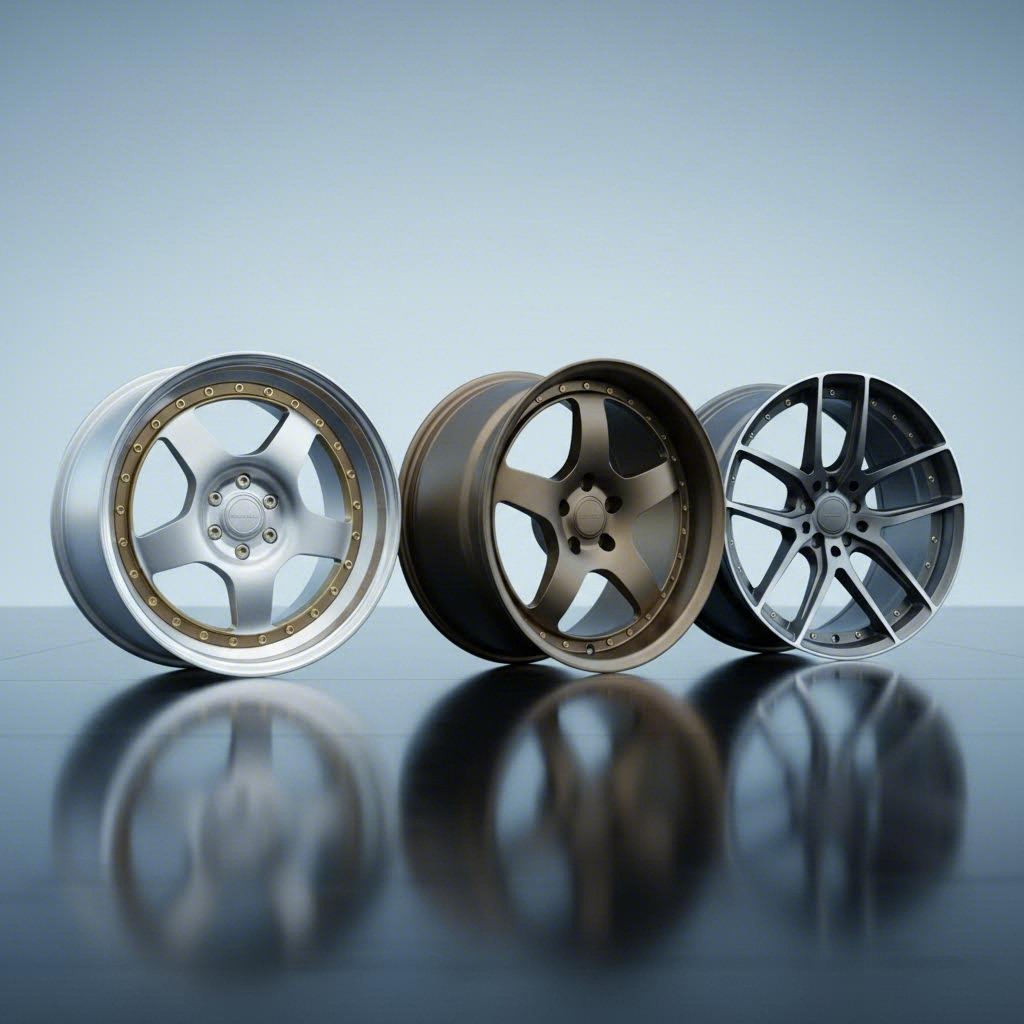

Face design options range from simple multi-spoke patterns to complex mesh configurations. Your choice affects both aesthetics and brake cooling efficiency. Open spoke designs allow more airflow to reach brake components, while tighter patterns create distinctive visual statements. Some manufacturers even offer carbon fiber wheel accent options for builders seeking the ultimate weight reduction on specific design elements, though aluminum remains the standard for structural integrity.

Inner and Outer Barrel Specifications

The barrel sections define your wheel's width, offset, and tire mounting characteristics. Understanding their specifications directly impacts your assembly success and final fitment.

Inner barrels form the rear lip section and typically feature stepped profiles that accommodate various width configurations. These components utilize spun aluminum construction in many applications, creating seamless surfaces optimized for tire bead sealing. The inner barrel's depth determines your backspacing measurement, which critically affects suspension clearance and handling geometry.

Outer barrels create the visible front lip that enthusiasts showcase. Similar manufacturing processes apply here, with additional attention to surface finish quality since this component faces outward. Many builders select polished outer lips paired with painted or anodized centers for striking visual contrast. While some exotic builds incorporate wheels carbon fiber elements for accent purposes, the structural barrel sections rely on proven aluminum alloys for reliable performance.

The modular design enables precise width adjustments that single-piece alternatives cannot match. Need an additional half-inch of rear wheel width for larger tires? Simply swap to a deeper inner barrel without replacing the entire wheel. This flexibility proves invaluable when fine-tuning aggressive fitments or adapting to suspension modifications.

| Component | Primary Function | Material Specification | Role in Assembly |

|---|---|---|---|

| Center Disc | Hub mounting, load distribution, visual design | 6061-T6 or 6082-T6 forged aluminum alloy | Receives perimeter bolts, connects to both barrels |

| Inner Barrel | Rear lip formation, backspacing determination | Spun or forged aluminum, typically 6061 series | Seals against center disc with O-ring, receives fasteners |

| Outer Barrel | Front lip display, width contribution, tire bead surface | Spun or forged aluminum with enhanced surface finish | Completes assembly, creates final aesthetic appearance |

The strength-to-weight ratio advantage of forged construction becomes clear when you examine the numbers. Forged aluminum achieves tensile strengths reaching 45,000 PSI while maintaining low density. Cast alternatives typically reach only 25,000-30,000 PSI with similar weight. This means your forged components handle greater stresses before approaching failure thresholds, translating directly to improved safety margins during aggressive driving.

Heat treatment processes further enhance these properties. T6 tempering, commonly applied to wheel components, increases hardness and fatigue resistance through controlled aging cycles. The result is a 3 piece wheel that maintains structural integrity through thousands of heat cycles from brake temperatures and environmental conditions.

When selecting components for your build, consider how sizing decisions affect assembly complexity. Wider barrel configurations require longer perimeter bolts and may need different seal profiles. Extreme offsets might demand specialized hardware to maintain proper thread engagement. Understanding these relationships before purchasing components saves significant time during the actual assembly process.

Hardware Specifications and Fastener Requirements

Ready to tackle the details that most wheel guides completely overlook? The hardware holding your 3 piece wheel hardware together determines whether your assembly performs flawlessly or develops problems down the road. Perimeter bolts, washers, and specialty fasteners aren't glamorous topics, but they're absolutely critical to structural integrity and long-term reliability.

Think about it this way: you've invested in precision-forged components engineered to handle extreme forces. Using substandard fasteners to join them together undermines everything those premium materials provide. Let's explore the specifications that separate professional-grade assemblies from risky shortcuts.

Perimeter Bolt Specifications and Thread Standards

Perimeter bolts create the mechanical connection between your center disc and barrel sections. These fasteners circle the wheel's circumference, typically numbering between 24 and 40 pieces depending on wheel diameter and manufacturer specifications. Each bolt shares the total clamping load, meaning every single fastener contributes to your wheel's structural integrity.

Common thread specifications for 3 piece rims include M7x1.0, M8x1.25, and occasionally M6x1.0 for smaller diameter applications. The thread pitch matters significantly because it determines engagement depth and load distribution across the fastener's threads. Finer pitches provide more threads per inch of engagement, distributing stress more evenly and reducing the risk of thread stripping under load.

Thread engagement depth represents a critical safety factor that many builders underestimate. Industry standards recommend minimum engagement of 1.5 times the bolt diameter. For an M7 fastener, that translates to at least 10.5mm of thread engagement into the barrel material. Insufficient engagement concentrates stress on fewer threads, dramatically increasing failure risk during high-load conditions like hard braking or aggressive cornering.

Bolt length selection depends on your specific barrel and disc combination. Measure the total stack thickness where components meet, then add appropriate engagement depth plus washer thickness. Ordering bolts too short compromises safety, while excessively long fasteners may bottom out before achieving proper clamp load.

Hardware Grade Requirements for Forged Assemblies

Material selection for three piece rims fasteners involves choosing between stainless steel and titanium options, each offering distinct advantages. Understanding these differences helps you make informed decisions based on your specific application requirements.

Stainless steel hardware provides excellent corrosion resistance at moderate cost. Grade 304 stainless offers adequate strength for most street applications, while Grade 316 adds enhanced resistance to salt and chemical exposure. These fasteners work reliably for daily-driven vehicles where cost-effectiveness matters and weight savings aren't paramount.

Titanium fasteners deliver superior performance across virtually every metric relevant to 3pc wheels applications. According to titanium fastener specialists, Grade 5 titanium provides approximately twice the strength-to-weight ratio of stainless steel while maintaining comparable corrosion resistance. The weight reduction proves particularly noticeable when you consider that a single wheel may contain 30 or more perimeter bolts.

For racing applications and weight-conscious builds, titanium hardware reduces unsprung mass, enhancing suspension response and overall vehicle dynamics. The premium cost typically justifies itself through improved performance and exceptional fatigue life that can exceed the wheel's service lifespan.

| Hardware Type | Tensile Strength | Weight Comparison | Corrosion Resistance | Best Application |

|---|---|---|---|---|

| Grade 304 Stainless | ~75,000 PSI | Baseline | Good | Street vehicles, budget builds |

| Grade 316 Stainless | ~80,000 PSI | Baseline | Excellent | Coastal climates, winter driving |

| Grade 5 Titanium | ~138,000 PSI | 40% lighter | Excellent | Racing, performance applications |

Washer selection receives surprisingly little attention despite its importance in proper load distribution. Conical washers create consistent clamping pressure around each bolt head, preventing stress concentrations that could damage barrel surfaces. Flat washers work adequately for some applications, but conical designs provide superior results when properly matched to bolt head geometry.

Material compatibility between washers and bolts matters for preventing galvanic corrosion. Pairing titanium bolts with stainless washers can create electrochemical reactions that degrade both components over time. Match your washer material to your fastener material, or use appropriate barrier coatings when mixing metals becomes necessary.

When sourcing replacement hardware or building HRE center caps and other branded components into your assembly, verify that all fasteners meet original equipment specifications. Aftermarket hardware varies significantly in quality, and cutting corners on these critical components introduces unnecessary risk.

- Perimeter Bolts: Primary fasteners connecting disc to barrels; available in stainless steel or titanium; specified by thread size (M6, M7, M8) and length

- Conical Washers: Load distribution components matching bolt head geometry; material should match fastener composition

- Valve Stems: High-pressure rated stems compatible with TPMS sensors if equipped; clamp-in or snap-in designs available

- Center Caps: Protective covers for hub bore area; secured via spring clips, threaded fasteners, or press-fit designs

- Specialty Fasteners: Locking compounds, anti-seize formulations, and security hardware for theft prevention

Thread preparation compounds require careful selection based on fastener material. Anti-seize formulations specifically designed for titanium applications prevent galling while maintaining accurate torque readings. Standard petroleum-based compounds may affect torque-tension relationships, potentially resulting in under or over-tightened fasteners. Always follow manufacturer recommendations for thread preparation on your specific hardware.

With your hardware specifications now clearly understood, you're ready to begin the actual assembly process. Proper component preparation and methodical installation procedures ensure these carefully selected fasteners perform exactly as intended.

Step-by-Step Assembly Process from Start to Finish

You've got your components laid out and hardware ready. Now comes the moment most guides skip entirely: actually putting your 3 piece forged wheel together correctly. The assembly process requires patience, attention to detail, and methodical execution. Rush through these steps, and you'll end up with air leaks, uneven clamping, or worse. Follow them carefully, and you'll create a track-ready wheel that performs flawlessly.

Whether you're working with custom 3 piece wheels for a show build or assembling a set of 3 piece work wheels for weekend track duty, the fundamental process remains consistent across manufacturers. Let's walk through each stage from unpacking to initial bolt tightening.

Pre-Assembly Inspection and Component Preparation

Before threading a single bolt, thorough inspection prevents costly mistakes. Imagine assembling everything perfectly only to discover a machining defect or shipping damage afterward. That means complete disassembly, warranty claims, and wasted hours. Fifteen minutes of careful inspection now saves significant frustration later.

Start by examining each component under good lighting. Look for machining marks, scratches in sealing surfaces, or any signs of damage from shipping. Pay particular attention to the mating surfaces where barrels meet the center disc. These areas must be perfectly flat and free from debris to achieve proper sealing.

Three piece wheel faces deserve special attention during inspection. Check spoke surfaces for forging imperfections, verify that all mounting holes align properly, and confirm the hub bore diameter matches your vehicle specifications. Any inconsistencies here indicate quality control issues worth addressing before proceeding.

Clean all mating surfaces thoroughly using isopropyl alcohol and lint-free cloths. Even microscopic particles trapped between components create uneven clamping pressure and potential leak paths. Work in a clean environment whenever possible, and avoid touching prepared surfaces with bare hands. Natural skin oils can interfere with seal adhesion and create contamination issues.

Seal Installation Between Disc and Barrels

Here's where most online resources completely fail you. The seal installation process determines whether your 3pcs wheels hold air reliably or develop frustrating slow leaks. Two sealing methods exist depending on your wheel design: O-ring seals for the disc-to-barrel interface and perimeter sealant for the barrel-to-barrel junction.

O-ring seals fit into machined grooves on either the center disc or barrel faces. These precision components must seat completely in their grooves without twisting or pinching. Apply a thin layer of silicone lubricant to help the O-ring settle properly during assembly. Dry installation risks the seal rolling out of position when components come together under pressure.

The barrel-to-barrel junction requires different treatment. According to Limebug's assembly documentation, apply sealant into the channel between rim halves after bolt installation, creating a generous bead that fills the valley completely. Use a wet finger with light pressure to force sealant into the channel, ensuring complete coverage around the entire circumference.

Let the sealant dry completely according to manufacturer instructions, typically 24-48 hours, before mounting tires.

Quality sealant selection matters significantly. Specialized wheel sealants like Felgendichtmittel maintain flexibility through temperature cycling while providing excellent adhesion to aluminum surfaces. General-purpose silicone may seem adequate initially but often degrades faster under the thermal stress wheels experience during spirited driving.

Component Alignment and Concentricity

Proper alignment ensures your assembled wheel runs true without vibration or uneven tire wear. Misaligned components create runout issues that no amount of balancing can correct. Taking time now to verify concentricity saves headaches after installation.

Position the center disc face-down on a clean, flat surface. The outer barrel typically installs first, aligning with the bolt pattern machined into the disc's perimeter. Guide the barrel straight down without forcing it, allowing the sealing surfaces to meet evenly. Visual inspection around the circumference should show consistent gap closure as components seat together.

Insert several bolts by hand at opposing positions around the circumference to hold alignment while you flip the assembly. With the wheel face-up, you can now install the inner barrel following the same careful alignment process. Three or four hand-started bolts maintain position while you complete hardware installation.

- Unpack all components and verify you have the correct center disc, inner barrel, and outer barrel for each wheel position. Cross-reference part numbers against your order documentation.

- Inspect every component for shipping damage, machining defects, and surface contamination. Document any issues with photographs before proceeding.

- Clean all mating surfaces using isopropyl alcohol and lint-free cloths. Allow surfaces to dry completely before continuing.

- Install O-ring seals in their designated grooves, applying silicone lubricant to prevent twisting during component mating.

- Position the center disc face-down on a protected work surface, ensuring stability during barrel installation.

- Lower the outer barrel onto the center disc, aligning bolt holes carefully. Avoid forcing components together.

- Insert alignment bolts at 12, 3, 6, and 9 o'clock positions by hand to maintain component positioning.

- Flip the assembly carefully, supporting all three components to prevent separation during repositioning.

- Install the inner barrel using the same alignment technique, adding hand-started bolts at opposing positions.

- Complete bolt installation by hand-threading all remaining perimeter fasteners. Each bolt should turn freely without resistance until seating.

- Verify all bolts are hand-tight with consistent engagement before proceeding to torque sequences.

Resist the temptation to start tightening bolts immediately after hand-threading. All fasteners must be in place first, ensuring even load distribution when you begin applying torque. Starting the tightening sequence with missing bolts creates uneven clamping that's difficult to correct later.

Cross-threaded bolts represent a common assembly mistake that ruins components. If any fastener requires force to turn during hand installation, stop immediately. Back the bolt out, inspect threads on both the fastener and barrel, and address any debris or damage before continuing. Forcing cross-threaded hardware destroys the receiving threads and creates safety hazards.

With all components assembled and hardware hand-tightened, you're ready for the critical torque sequence that transforms loose parts into a unified, track-ready wheel. Proper tightening patterns and specifications ensure your assembly handles everything from daily commutes to aggressive track sessions.

Torque Specifications and Proper Tightening Sequences

Your components are assembled and every bolt is hand-tight. Now comes the step that separates reliable wheels from potential failures: applying precise torque in the correct sequence. Think of this process like tuning a drum head. Tighten one side completely before addressing the opposite, and you'll end up with uneven tension that creates problems. The same principle applies to your 3 piece forged wheels assembly, where improper torque leads to consequences ranging from annoying air leaks to catastrophic structural failure.

Unlike 2 piece wheels or 2 piece forged wheels that feature simpler construction, three-piece assemblies demand careful attention to tightening patterns. Every perimeter bolt shares responsibility for clamping load, and achieving even distribution requires methodical execution rather than random tightening.

Torque Specifications for Perimeter Bolt Security

Correct torque values depend on your specific bolt size, material, and thread pitch. Applying too little torque leaves fasteners loose, allowing components to shift under load and creating leak paths. Excessive torque stretches bolts beyond their elastic limit, strips threads, or cracks barrel material around bolt holes. Neither extreme ends well.

The relationship between torque and clamping force isn't straightforward. Thread friction, washer material, and lubricant presence all affect how much rotational force translates into actual bolt tension. Using anti-seize compound, for example, reduces friction and increases clamping force at identical torque readings. Always follow manufacturer specifications that account for your specific hardware and preparation method.

| Bolt Size | Stainless Steel (Dry) | Stainless Steel (Lubricated) | Titanium (Dry) | Titanium (Anti-Seize) |

|---|---|---|---|---|

| M6 x 1.0 | 6-7 Nm | 5-6 Nm | 7-8 Nm | 6-7 Nm |

| M7 x 1.0 | 9-11 Nm | 8-9 Nm | 11-13 Nm | 9-11 Nm |

| M8 x 1.25 | 14-16 Nm | 12-14 Nm | 16-18 Nm | 14-16 Nm |

These specifications represent general guidelines for quality hardware meeting industry strength standards. Your wheel manufacturer may specify different values based on their particular design and testing. When in doubt, contact the manufacturer directly rather than guessing. The consequences of incorrect torque far outweigh any inconvenience of verification.

Calibrated tools prove essential for accurate torque application. That old click-type wrench sitting in your garage for years? It's probably reading anywhere from 10% to 30% off actual values. Professional wheel builders use torque wrenches calibrated annually or more frequently. For DIY builders, investing in a quality beam-type or digital torque wrench pays dividends in assembly accuracy. The 9 and 3 wheels position method some builders use for visual reference works for pattern sequencing but never replaces actual torque measurement.

Sequential Tightening Patterns for Even Load Distribution

Imagine tightening all bolts on one side of the wheel before addressing the opposite side. The components would draw together unevenly, creating a wedge-shaped gap that no amount of subsequent tightening corrects properly. Star-pattern sequences prevent this by alternating tightening positions across the wheel's diameter.

For wheels with 30 perimeter bolts, the pattern becomes more complex than simple lug nut sequences. Start at any bolt and assign it position one. Move directly across the diameter to position two. Then rotate approximately 72 degrees (one-fifth of the circumference) and designate position three. Continue alternating across and rotating until you've addressed every fastener.

Multi-stage torque application further ensures even clamping. Rather than torquing each bolt to final specification immediately, use a progressive approach:

- Stage One (50% Target): Apply approximately half the final torque value to all bolts following the star pattern. This draws components together evenly without creating stress concentrations.

- Stage Two (75% Target): Repeat the complete pattern at three-quarters final torque. Components should now sit flush with no visible gaps around the circumference.

- Stage Three (100% Target): Complete the pattern at full specified torque. Each bolt click should occur at nearly identical wrench positions, indicating consistent clamping.

- Verification Pass: After completing stage three, return to position one and verify each bolt still meets specification. Settling between bolts sometimes reduces tension on previously tightened fasteners.

The verification pass catches a common issue where early-tightened bolts lose tension as subsequent bolts draw components together differently. If any bolt turns significantly before clicking at target torque, complete another full pattern at final specification. Properly seated assemblies show minimal movement during verification.

Consequences of Improper Torque Application

Understanding what goes wrong reinforces why precision matters. Under-torqued assemblies develop problems gradually, making them particularly dangerous. Initial symptoms include slow air leaks that require frequent tire inflation. Left unaddressed, loose fasteners allow micro-movements between components that wear sealing surfaces and elongate bolt holes.

The worst-case scenario involves bolt fatigue failure. Loose fasteners experience cyclic loading as wheel rotation alternately loads and unloads each bolt. This fatigue accumulation eventually causes fractures, potentially resulting in complete wheel separation. Modern 3 spoke wheels and 3 spoke rims designs distribute loads effectively, but only when properly assembled.

Over-torqued assemblies create different failure modes. Stretched bolts lose their clamping force over time as the material relaxes from its over-stressed state. Thread stripping occurs when bolt tension exceeds the shear strength of barrel material, destroying the receiving threads permanently. Cracked barrels represent the most severe consequence, requiring complete component replacement.

When in doubt, torque it out. Complete another verification pass rather than wondering whether you achieved proper specification.

Thermal cycling during vehicle operation introduces additional considerations. Aluminum expands more than steel fasteners when heated, potentially loosening the assembly. Quality builds account for this by using slightly higher torque specifications or incorporating thread-locking compounds designed for aluminum applications. Recheck torque after the first heat cycle, typically following an initial drive of 50-100 miles.

With your assembly properly torqued and verified, you've created a structurally sound wheel ready for tire mounting. However, even careful builders occasionally encounter issues during or after assembly. Understanding common problems and their solutions prepares you for troubleshooting challenges that may arise.

Troubleshooting Common Assembly Issues and Fitment Problems

So you've followed every step carefully, torqued everything to specification, and mounted your tires. Then you notice the pressure dropping overnight. Or maybe the wheel vibrates despite perfect balancing. Frustrating? Absolutely. But these problems have identifiable causes and, in most cases, straightforward solutions.

Even experienced builders encounter assembly issues with threepiece wheels. The modular design that makes these wheels so versatile also introduces more potential failure points than single-piece alternatives. Understanding how to diagnose and resolve common problems saves time, money, and prevents unnecessary component replacement.

Diagnosing and Fixing Air Leak Problems

Air leaks represent the most common complaint after 3pc wheel assembly. According to tire industry research, while tires naturally lose 1-3 PSI monthly through osmosis, faster pressure loss indicates a genuine leak requiring attention. With three-piece construction, multiple sealing surfaces create additional opportunities for air escape.

Start your diagnosis using the soapy water method. Mix dish soap with water and apply generously around the perimeter bolt line, disc-to-barrel junction, and valve stem area. Inflate the tire and watch carefully for bubbles. Even tiny leaks produce visible bubbling within seconds. This simple technique pinpoints leak locations without specialized equipment.

Perimeter seal failures account for most three-piece wheel air leaks. The O-ring or sealant between components degrades over time, especially when exposed to temperature extremes during spirited driving. If bubbles appear along the bolt circle, you've identified seal deterioration. The solution requires disassembly, seal replacement, and reassembly following proper procedures.

Damaged valve stems create another common leak source. Road chemicals and debris deteriorate valve components faster than many builders expect. If bubbles appear around the valve area, try replacing the valve core first using a removal tool. This quick fix often resolves the issue without complete valve stem replacement.

-

Symptom: Slow, consistent pressure loss (5+ PSI weekly)

Likely Cause: Perimeter seal degradation or improper sealant application

Solution: Disassemble, clean mating surfaces thoroughly, apply fresh sealant, reassemble with proper torque sequence -

Symptom: Rapid pressure loss after assembly

Likely Cause: Pinched or twisted O-ring, debris trapped in sealing surface

Solution: Immediate disassembly, inspect O-ring for damage, clean all surfaces, reinstall with silicone lubricant -

Symptom: Bubbles appearing at valve stem

Likely Cause: Deteriorated valve core or damaged stem base

Solution: Replace valve core first; if leak persists, replace entire valve stem assembly -

Symptom: Intermittent pressure loss during temperature changes

Likely Cause: Marginal seal that fails under thermal expansion/contraction

Solution: Disassemble and apply more generous sealant bead, ensure complete coverage around circumference

Resolving Fitment and Alignment Challenges

Vibration complaints after 3 peice wheel installation often stem from fitment issues rather than balance problems. According to aftermarket wheel specialists, it only takes the thickness of a business card between mating surfaces to cause noticeable vibration. Understanding common fitment mistakes helps you identify and correct these issues.

Hub surface contamination causes problems more frequently than most builders realize. Surface rust accumulation on the vehicle's hub creates an uneven mounting surface. Before installing any wheel, clean the hub face thoroughly with a wire brush or abrasive pad. Paint overspray from recent bodywork creates similar issues if wheels were installed before complete curing.

Cross-threaded perimeter bolts create serious complications. If you forced a bolt that wasn't threading smoothly during assembly, you've likely damaged the barrel threads. Symptoms include bolts that won't reach proper torque or feel "crunchy" during tightening. Minor thread damage sometimes responds to careful chasing with a tap, but severe cases require barrel replacement or professional thread repair.

Warped components from shipping damage or improper storage produce runout issues no amount of balancing corrects. Place your assembled wheel on a balancer and watch the dial indicator as you rotate it. Radial runout exceeding 0.030 inches or lateral runout beyond 0.040 inches indicates component warpage. Individual barrels can be checked separately by mounting them on a precision mandrel.

Centric ring issues affect many 3 peice wheels installations. Most aftermarket wheels have larger center bores than factory specifications, requiring hub-centric rings to ensure proper centering. Missing or incorrectly sized rings allow the wheel to mount slightly off-center, creating vibration at low speeds that worsens under braking. Measure your hub diameter precisely and verify ring fitment before dismissing other causes.

When to Seek Professional Help

DIY assembly works well for many builders, but certain situations demand professional intervention. Knowing when to seek expert assistance prevents costly mistakes and potential safety hazards.

Stripped barrel threads require specialized repair equipment most enthusiasts don't possess. Thread inserts like Helicoils can restore damaged threads, but proper installation requires precise drilling and tapping. Incorrectly installed inserts fail under load, creating dangerous conditions. Professional wheel repair shops have the tooling and experience for reliable thread restoration.

Cracked components fall strictly into the professional category. Aluminum welding requires specialized techniques and equipment to maintain structural integrity. Heat-affected zones around welds can actually weaken surrounding material if procedures aren't followed precisely. Any suspected cracks warrant immediate professional inspection before continued use.

Persistent leaks after multiple reassembly attempts suggest underlying issues you may not be equipped to identify. Professional shops can pressure-test assemblies, inspect sealing surfaces with precision instruments, and identify manufacturing defects invisible to visual inspection. The cost of professional diagnosis often proves less than repeated DIY attempts with replacement seals and hardware.

When safety is on the line, professional verification provides peace of mind that no YouTube tutorial can match.

Understanding these common issues and their solutions transforms frustrating problems into manageable challenges. Most assembly complications stem from preventable mistakes: contaminated surfaces, rushed procedures, or incorrect component selection. Taking time to diagnose properly before attempting repairs prevents making problems worse through trial-and-error approaches. With troubleshooting skills in your toolkit, you're prepared to maintain your investment through years of reliable service.

Maintenance and Long-Term Care for Assembled Wheels

Your 3 piece forged wheels assembly is complete and performing beautifully. But here's what many enthusiasts discover too late: these precision components require ongoing attention to maintain their performance and appearance. Unlike monoblock alternatives, modular construction demands periodic inspection and occasional disassembly. The good news? This same modularity that requires maintenance also makes long-term ownership significantly more practical.

Whether you purchased three piece wheels for sale from a premium manufacturer or built a custom set yourself, understanding maintenance requirements protects your investment for years to come. The best 3 piece wheel brands design their products for serviceability, but even premium components need proper care.

Periodic Inspection and Maintenance Schedules

How often should you inspect your wheels? For street-driven vehicles, a thorough visual inspection every 3,000 miles catches developing issues before they become serious. Track enthusiasts should inspect before and after every event, as aggressive driving accelerates wear on seals and hardware.

During inspections, look for early warning signs that indicate maintenance needs. Check around the perimeter bolt line for any sealant deterioration or discoloration. Examine each bolt head for loosening, corrosion, or damage. Spin each wheel slowly while watching for runout that might indicate developing alignment issues.

Unlike 2 piece rims or two piece rims with fewer sealing surfaces, your 3 piece rim requires attention to multiple junction points. The disc-to-barrel interfaces and barrel-to-barrel junction each present potential failure points. Catching minor seal degradation early prevents the slow leaks that gradually worsen over time.

- Weekly: Monitor tire pressure for unusual loss patterns; check for visible damage after curb encounters

- Monthly: Clean wheel surfaces thoroughly; inspect bolt heads for corrosion or loosening

- Quarterly: Apply soapy water test to check for developing leaks around sealing surfaces

- Annually: Verify perimeter bolt torque using calibrated wrench; inspect seal condition visually

- Every 3-5 Years: Consider full disassembly for seal replacement and component inspection

- After Track Events: Complete visual inspection; recheck critical torque specifications

When to Disassemble for Seal Replacement

Seals don't last forever, regardless of quality. Environmental exposure, thermal cycling, and chemical contact gradually degrade sealing materials. Recognizing when replacement becomes necessary prevents frustrating leak chasing.

Consistent slow leaks that don't respond to re-torquing indicate seal failure. According to the StanceWorks rebuild documentation, completely removing old sealant before reapplication proves critical: "There must not be ANY sealant remaining if you want any hopes of the new sealant bonding to the wheel and lip." Applying fresh sealant over degraded material simply doesn't work.

Refinishing projects require complete disassembly regardless of seal condition. Powder coating, polishing, or repainting individual components means separating everything and replacing seals during reassembly. Many owners combine aesthetic refreshes with preventive seal replacement, addressing both concerns simultaneously.

The modular advantage becomes clear during these maintenance events. Damaged a lip from curb contact? Replace just that barrel rather than the entire wheel. Want to change your wheel width for different tire sizing? Swap barrels without touching your center disc. This flexibility makes three-piece ownership economically sensible over time, even considering periodic maintenance requirements.

Proper Storage and Component Preservation

Storing disassembled components correctly preserves seal surfaces and prevents corrosion. If you're swapping between summer and winter wheel sets, proper storage extends component lifespan significantly.

Keep disassembled pieces in climate-controlled environments whenever possible. Temperature extremes and humidity accelerate oxidation on aluminum surfaces. Wrap sealing surfaces with clean, lint-free cloth to prevent debris accumulation that complicates reassembly.

O-ring seals removed during disassembly rarely survive reinstallation without damage. Budget for replacement seals whenever you plan disassembly, treating them as consumable items rather than reusable components. Store spare seals in sealed bags away from UV light, which degrades rubber compounds over time.

The same modularity that requires maintenance effort ultimately saves money through component-level repairs rather than complete wheel replacement.

With proper maintenance habits established, your three-piece wheels provide years of reliable service while remaining customizable and repairable. This long-term serviceability distinguishes modular construction from alternatives that become disposable after damage. Understanding how your wheel type compares to other construction methods helps you appreciate these ownership advantages fully.

Comparing 3 Piece Wheels to Monoblock and 2 Piece Designs

Now that you understand how to assemble, maintain, and troubleshoot your modular wheels, a natural question arises: when does three-piece construction actually make sense compared to simpler alternatives? The answer depends entirely on your priorities, driving style, and long-term ownership goals.

Each wheel construction type serves different purposes. Monoblock wheels dominate OEM applications for good reasons, while two piece wheels occupy a middle ground that appeals to specific builders. Understanding these trade-offs helps you appreciate why you chose modular construction and whether it remains the right choice for future builds.

Modular Versus Monoblock Construction Trade-offs

Monoblock rims represent the simplest wheel design: a single casting or forging that combines the face, barrel, and mounting surface into one continuous piece. According to Apex Wheels' technical analysis, certain types of monoblock wheels, particularly those made using forging processes, "can offer an unbeatable balance between strength, stiffness, and weight savings." This makes them excellent choices for specific applications.

Monoblock wheels AMG and other performance OEM applications favor this construction because it eliminates sealing surfaces entirely. No seals means no leak potential. The simplified design also reduces maintenance requirements to essentially zero beyond normal cleaning. For drivers who want reliable performance without periodic inspection schedules, monoblock construction delivers peace of mind.

However, monoblock designs sacrifice flexibility for simplicity. Your width and offset options become limited to whatever the manufacturer produces. Need an additional half-inch of rear width? You'll need completely different wheels. Damage a barrel section? The entire wheel requires replacement, often costing significantly more than repairing a single modular component.

The weight comparison proves more nuanced than marketing materials suggest. While monoblock forged wheels often achieve impressive weight savings through optimized barrel reinforcement impossible with spun-disc construction, many three-piece assemblies use advanced materials that close this gap. Some exotic builds even incorporate carbon fiber car wheels elements for center caps or accent pieces, though aluminum remains the structural standard.

Two Piece Construction: The Middle Ground

Two piece wheels split the difference between modular flexibility and monoblock simplicity. These designs join a center section to a single barrel, typically through welding or bolts. The result offers more customization than monoblock alternatives while maintaining fewer sealing surfaces than three-piece construction.

Welded two-piece wheels provide good customization during the ordering process but lose repairability advantages after assembly. Once welded, separating components for individual replacement becomes impractical. Bolted two-piece designs retain some serviceability but introduce the same maintenance considerations as three-piece wheels with fewer fitment options.

According to Vivid Racing's comparison, two-piece wheels "can be customized; they are constructed to a specified set of dimensions (varied offset/backspace)" while noting they tend to be "a little bit heavier compared to a one-piece wheel." This weight penalty comes from assembly flanges and connection hardware that monoblock designs eliminate.

The repairability advantage of two-piece construction depends heavily on construction method. Welded assemblies essentially become monoblock wheels after manufacturing, while bolted designs offer limited serviceability. Neither matches the component-level repair flexibility that three-piece construction provides.

Choosing the Right Wheel Type for Your Application

Your ideal wheel construction depends on how you'll actually use your vehicle. Track enthusiasts benefit most from three-piece modularity, as racing teams appreciate the ability to replace damaged barrels trackside without scrapping expensive center sections. This practical consideration explains why serious motorsports programs favor modular designs despite their complexity.

Street-driven vehicles present different considerations. If you prioritize low maintenance and predictable performance, monoblock wheels eliminate seal inspection requirements and leak concerns entirely. Drivers who rarely encounter fitment challenges or damage may find the simplicity worth accepting reduced customization options.

Custom builds with aggressive fitments almost demand three-piece construction. Achieving precise wheel width and offset combinations for stretched tires or extreme camber setups requires the adjustment flexibility only modular designs provide. Swapping barrel depths without replacing centers makes dialing in perfect fitment economically feasible.

Some builders appreciate rims carbon fiber aesthetic elements that complement lightweight construction. While true carbon fiber automotive wheels remain exotic and expensive, accent pieces and visual elements in carbon fiber pair well with polished aluminum barrel sections on premium three-piece builds.

| Factor | 3 Piece Wheels | 2 Piece Wheels | Monoblock Wheels |

|---|---|---|---|

| Customization Flexibility | Excellent - width and offset adjustable via barrel selection | Good - specified during order, limited after | Limited - manufacturer determines options |

| Weight | Moderate - hardware adds mass; spun barrels limit optimization | Moderate to Heavy - assembly flanges add weight | Best potential - optimized barrel geometry possible |

| Repairability | Excellent - individual components replaceable | Limited - welded types non-serviceable | Poor - damage typically requires full replacement |

| Maintenance Requirements | Highest - periodic seal and torque inspection needed | Moderate - bolted types need inspection | Minimal - no sealing surfaces to maintain |

| Cost Considerations | Highest initial - lower long-term repair costs | Moderate initial - varies by construction | Lowest initial - highest replacement costs if damaged |

| Air Leak Potential | Higher - multiple sealing surfaces | Moderate - single sealing interface | None - no assembly seams |

The assembly complexity inherent to three-piece construction becomes worthwhile when you consider long-term ownership economics. That curbed outer lip? Replace just the barrel for a fraction of complete wheel cost. Wanting wider rear wheels next season? Swap deeper barrels without touching your center discs. This flexibility transforms wheels from consumable items into serviceable long-term investments.

Performance considerations extend beyond weight. Monoblock forged barrels can incorporate reinforcement geometry that spun-disc three-piece barrels cannot match. However, the practical difference matters mainly at professional racing levels where every gram counts. Street and amateur track applications rarely push wheels to limits where this distinction becomes meaningful.

Choose your wheel construction based on how you'll actually use them, not theoretical performance advantages you'll never exploit.

Understanding these trade-offs explains why serious enthusiasts often own multiple wheel types for different purposes. Lightweight monoblock wheels for track days where maintenance simplicity matters, and customizable three-piece sets for show cars where perfect fitment justifies the extra care required. Your specific situation determines which compromises make sense.

With a clear understanding of how your modular wheels compare to alternatives, you're better equipped to make informed decisions about future builds and current maintenance priorities. The final consideration involves sourcing quality components when repairs or new builds require additional parts.

Sourcing Quality Components and Trusted Manufacturing Partners

You've mastered the assembly process, understand maintenance requirements, and know how to troubleshoot common issues. But here's the question that ultimately determines your build's success: where do you source components that actually meet the standards your precision wheels demand? The difference between a flawless track-ready assembly and a frustrating project riddled with fitment problems often comes down to supplier selection.

Whether you're building custom forged star rims for a show car or sourcing affordable forged wheels for weekend track duty, component quality directly impacts everything from assembly ease to long-term reliability. Let's explore what separates reputable manufacturing partners from suppliers who cut corners.

Selecting Quality Forged Components for Your Build

Not all forged aluminum is created equal. The forging process itself varies dramatically between manufacturers, affecting grain structure, strength characteristics, and dimensional consistency. Components that look identical on paper can perform vastly differently under real-world stress.

Start your evaluation by examining material certifications. Quality suppliers provide detailed documentation showing alloy composition, heat treatment specifications, and mechanical properties. Vague claims about "high-strength aluminum" without supporting data should raise immediate concerns. Reputable manufacturers test every heat lot and maintain traceability throughout production.

Surface finish quality indicates manufacturing precision. Examine machined surfaces for tool marks, concentricity deviations, and surface roughness. Sealing surfaces deserve particular attention since even minor imperfections create leak paths. Components with consistent, professional finishes typically come from suppliers investing in proper tooling and quality control.

Carbon fiber rim accents and carbon fiber wheels elements have become popular additions to premium builds. While these materials offer striking aesthetics and weight savings for non-structural components, verify that any carbon fiber automotive wheels elements meet appropriate quality standards. The manufacturing expertise required for reliable carbon fiber components differs significantly from aluminum forging.

Dimensional accuracy proves critical for successful assembly. Request tolerance specifications before ordering and verify that components meet stated dimensions upon receipt. Barrel diameters, bolt hole positions, and sealing surface flatness all affect your assembly process. Suppliers confident in their quality control typically guarantee dimensional specifications rather than hiding behind vague "industry standard" claims.

Working with Precision Manufacturing Partners

When evaluating potential forging suppliers, certifications provide objective evidence of manufacturing capability. According to industry certification specialists, "ISO 9001 ensures that all stages of production, from design to inspection, meet high standards, reducing defects and ensuring reliable products." This baseline certification indicates systematic quality management throughout manufacturing operations.

For automotive applications, IATF 16949 certification carries particular significance. This automotive-specific quality standard addresses the entire production process with emphasis on continuous improvement and defect prevention. Suppliers holding IATF 16949 certification have demonstrated their ability to meet the demanding requirements of major automakers, translating directly to component reliability for your builds.

Beyond certifications, evaluate manufacturing capabilities that affect your project timeline. Rapid prototyping proves invaluable when developing custom specifications or testing fitment before committing to production quantities. Some manufacturers offer prototype turnaround in as little as 10 days, dramatically accelerating development cycles compared to suppliers requiring months for custom work.

In-house engineering capabilities indicate a manufacturer's ability to support complex projects. Companies maintaining engineering teams for components like suspension arms and drive shafts understand automotive precision requirements intimately. This expertise translates directly to wheel component manufacturing, where dimensional accuracy and material properties determine assembly success.

For those seeking quality-certified forging partners, Shaoyi (Ningbo) Metal Technology exemplifies the precision hot forging expertise serious builders require. Their IATF 16949 certification, combined with rapid prototyping capabilities and in-house engineering, addresses the complete spectrum of custom forging needs. Strategic location near Ningbo Port enables efficient global delivery, reducing lead times for international projects.

According to die forging evaluation experts, buyers should assess "inspection methods and equipment" as leading suppliers "invest in advanced inspection technologies to ensure the highest level of quality and consistency." This includes coordinate measuring machines for dimensional verification and non-destructive testing for internal defect detection.

Key Evaluation Factors for Forging Suppliers

Systematically evaluating potential suppliers prevents costly mistakes and ensures your components meet project requirements. Consider these critical factors when selecting manufacturing partners:

- Certification Standards: Verify ISO 9001 as baseline; prioritize IATF 16949 for automotive applications; confirm certifications remain current through issuing body verification

- Prototyping Speed: Evaluate lead times for custom specifications; faster prototyping enables iterative development; confirm whether quoted timelines include engineering review

- Quality Control Processes: Request documentation of inspection procedures; verify dimensional checking equipment calibration; understand rejection criteria and rework policies

- Global Shipping Capabilities: Assess logistics infrastructure for international delivery; evaluate port proximity for efficient export; confirm experience with customs documentation requirements

- Material Traceability: Verify heat lot tracking throughout production; confirm material certification availability; understand alloy sourcing and verification procedures

- Technical Support: Evaluate engineering consultation availability; assess responsiveness to technical questions; confirm support continues post-delivery

Builders sourcing bimmerworld forged wheels or similar premium components understand that manufacturer reputation reflects accumulated quality performance. Established suppliers with track records in demanding motorsports applications have proven their ability to deliver reliable components under extreme conditions.

Price naturally influences supplier selection, but lowest cost rarely equals best value. Components requiring rework, causing assembly delays, or failing prematurely cost far more than the initial savings suggested. Evaluate total cost of ownership including potential warranty claims, replacement needs, and project delays when comparing supplier quotations.

Communication quality during the quotation process predicts ongoing partnership experience. Suppliers responding promptly with detailed technical information demonstrate the professionalism you'll need throughout your project. Vague responses, missed deadlines, or reluctance to provide documentation suggest operational issues that will complicate your build.

The supplier you choose becomes your partner in every assembly you complete. Select accordingly.

Your investment in quality components pays dividends through easier assembly, reliable long-term performance, and the satisfaction of building wheels that meet your exacting standards. Whether you're sourcing carbon fiber rims accent pieces or core forged aluminum components, the principles remain consistent: verify capabilities, demand documentation, and partner with manufacturers who share your commitment to excellence.

With quality components in hand and the knowledge gained throughout this guide, you're fully equipped to transform loose parts into track-ready wheels that perform as impressively as they look. The assembly process that once seemed intimidating now represents an achievable skill set, ready to be applied to your next build.

Frequently Asked Questions About 3 Piece Forged Wheels Assembly

1. How do you assemble 3 piece wheels?

Assembling 3 piece wheels involves several critical steps: First, inspect all components for damage and clean mating surfaces with isopropyl alcohol. Install O-ring seals with silicone lubricant to prevent twisting. Position the center disc face-down, lower the outer barrel while aligning bolt holes, then insert alignment bolts at opposing positions. Flip the assembly, install the inner barrel, and hand-thread all perimeter bolts before applying torque in a star pattern through multiple stages (50%, 75%, then 100% of target torque). Allow sealant to cure 24-48 hours before mounting tires.

2. What are the essential components needed for rebuilding 3 piece wheels?

Rebuilding 3 piece wheels requires the three main structural components (center disc, inner barrel, and outer barrel), plus critical hardware including perimeter bolts (M6, M7, or M8 depending on design), conical washers for proper load distribution, O-ring seals or sealant, high-pressure valve stems, and center caps. You'll also need a calibrated torque wrench, thread preparation compounds, silicone lubricant, and quality sealant like Felgendichtmittel. For titanium hardware, use titanium-specific anti-seize to prevent galling while maintaining accurate torque readings.

3. What torque specifications should I use for 3 piece wheel perimeter bolts?

Torque specifications vary by bolt size and material. For M6 bolts: 6-7 Nm (stainless dry) or 7-8 Nm (titanium dry). For M7 bolts: 9-11 Nm (stainless dry) or 11-13 Nm (titanium dry). For M8 bolts: 14-16 Nm (stainless dry) or 16-18 Nm (titanium dry). Lubricated fasteners require approximately 10-15% lower torque values. Always use a calibrated torque wrench, apply torque in a star pattern through multiple stages, and verify specifications with your wheel manufacturer, as designs may vary.

4. How do I fix air leaks on 3 piece wheels?

Diagnose leaks using soapy water applied around the perimeter bolt line, disc-to-barrel junction, and valve stem. For perimeter seal failures, disassemble the wheel, completely remove old sealant, clean all mating surfaces thoroughly, and apply fresh sealant in a generous bead around the entire circumference. For valve stem leaks, try replacing the valve core first before replacing the entire stem. Pinched O-rings require disassembly, inspection for damage, and reinstallation with silicone lubricant. Allow 24-48 hours for sealant cure time before tire mounting.

5. What's the difference between 3 piece, 2 piece, and monoblock wheels?

Three-piece wheels offer maximum customization with separately forged center disc, inner barrel, and outer barrel joined by perimeter bolts, allowing width and offset adjustments plus component-level repairs. Two-piece wheels join a center to a single barrel via welding or bolts, offering moderate customization with fewer sealing surfaces. Monoblock wheels are single-piece forgings with no seams, providing lowest maintenance and no leak potential but limited customization and higher replacement costs if damaged. Choose based on your priorities: three-piece for customization and repairability, monoblock for simplicity and maintenance-free operation.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —