Laser Cutting vs Die Cutting for Automotive Prototypes

TL;DR

For automotive prototypes, laser cutting is the superior choice for early-stage development due to its speed, flexibility, and lack of upfront tooling costs, making it ideal for complex or iterative designs. Conversely, die cutting is the more strategic and cost-effective option for prototypes with finalized designs intended for high-volume production, as its per-unit cost drops significantly at scale, justifying the initial investment in a physical die.

Understanding the Core Technologies: Laser vs. Die Cutting

To make an informed decision between laser cutting and die cutting for automotive prototypes, it's essential to understand their fundamental mechanics. These two methods operate on entirely different principles—one uses thermal energy, while the other relies on mechanical force. This core difference dictates their respective strengths, weaknesses, and ideal applications within the production lifecycle.

Laser cutting is a thermal process that uses a highly focused, computer-controlled beam of light to melt, burn, or vaporize material with extreme precision. Because it follows a digital design file, no physical tool comes into contact with the material. This “tool-less” nature allows for the creation of incredibly intricate and complex shapes without the need to fabricate a custom die. Different types of lasers, such as CO₂ and fiber lasers, are optimized for various materials, from plastics and fabrics used in car interiors to the sheet metal for body panels.

In contrast, die cutting is a mechanical shearing process, much like using an industrial-grade cookie cutter. A custom-made steel rule die, which is a sharp blade formed into a specific shape, is pressed into the material to stamp out the desired part. This method can be performed on a flatbed press, which is excellent for thicker materials and lower volumes, or a rotary press, where the die is cylindrical for high-speed, continuous cutting of rolled materials. Die cutting provides clean, consistent cuts and is highly efficient for producing a large number of identical parts.

Critical Decision Factors for Automotive Prototypes: A Head-to-Head Comparison

Choosing the right cutting method for an automotive prototype hinges on a careful analysis of several key factors. The ideal process depends on your project's specific requirements for precision, speed, cost, material, and design flexibility. A direct comparison reveals clear advantages for each method at different stages of the development cycle.

Precision and Edge Quality

Laser cutting offers exceptional precision, capable of achieving tolerances as tight as 0.1 mm. Its non-contact nature is perfect for intricate patterns and delicate materials. However, as a thermal process, it creates a heat-affected zone (HAZ), which can result in minor discoloration or melting along the cut edge, a side effect of this thermal process. For most automotive prototypes, this is negligible, but it's a consideration for certain heat-sensitive polymers or foams. Die cutting, being a mechanical process, avoids thermal distortion and produces a consistently clean, sheared edge, though it may not match the laser's ability to create extremely fine details.

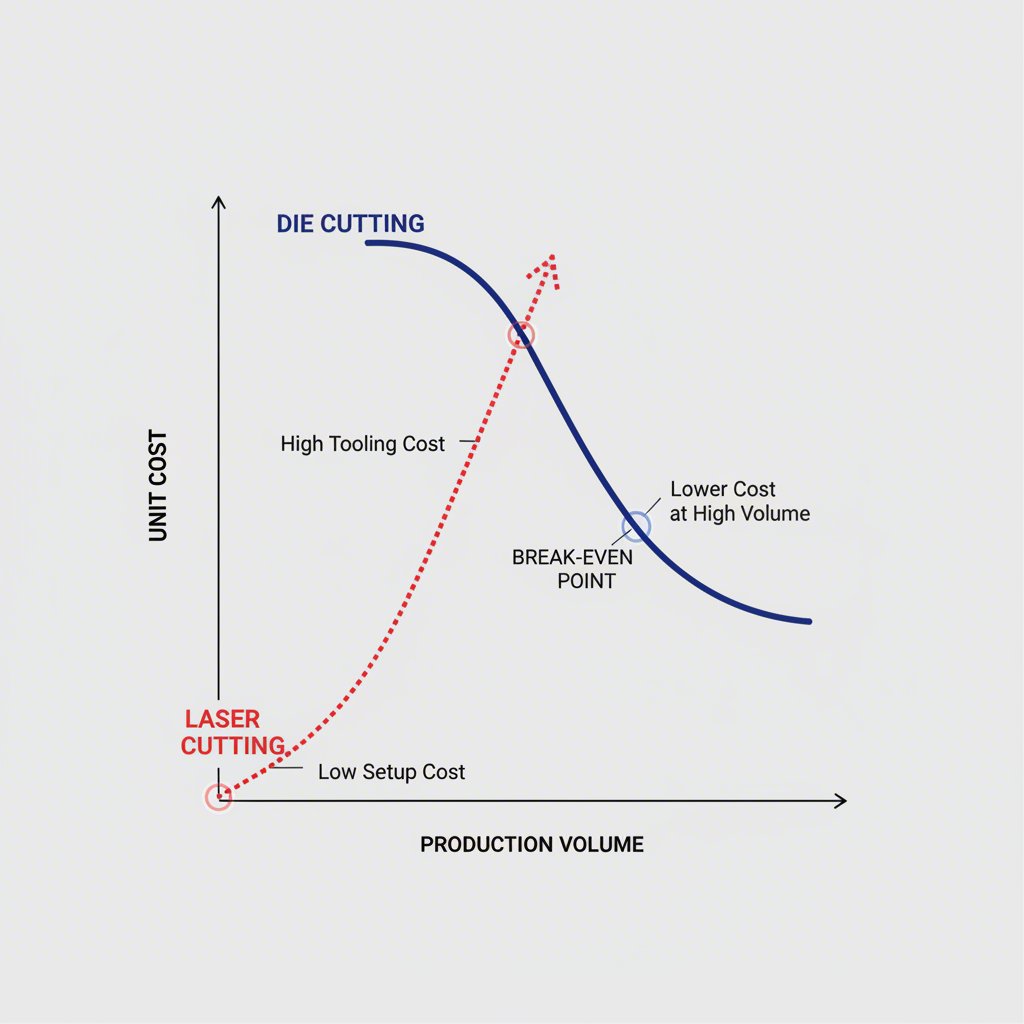

Speed, Lead Time, and Cost Analysis

For one-off or low-volume prototypes, laser cutting is significantly faster. Since it operates from a digital file, setup is nearly instant, allowing for rapid iterations without tooling delays. Die cutting requires the fabrication of a physical die, which can take days or weeks and involves a significant upfront cost. However, this dynamic flips dramatically as volume increases. Die cutting is far superior for mass production, with rotary presses capable of producing thousands of parts per hour. A detailed break-even analysis shows that die cutting becomes more cost-effective after a certain volume (e.g., around 9,000 units in one case study) as the initial tooling cost is amortized.

Material Compatibility and Design Flexibility

Laser cutting is incredibly versatile, capable of processing a wide range of automotive materials, including metals, plastics like ABS and polycarbonate, fabrics, and leather for interiors. Its key advantage is its limitless design flexibility; changing a design is as simple as uploading a new digital file. This makes it the clear winner for prototypes that are likely to undergo frequent modifications. Die cutting is also compatible with many materials but excels with thinner, non-metallic substrates. Its primary limitation is inflexibility—once a die is created, the design is locked in. Any change requires a new, costly die.

The following table summarizes the key differences for automotive prototyping applications:

| Factor | Laser Cutting | Die Cutting |

|---|---|---|

| Best Use Case | Prototyping, low-volume runs, complex designs | High-volume production, finalized designs |

| Upfront Cost | Low (no tooling required) | High (die fabrication needed) |

| Per-Unit Cost | Higher, remains constant | Very low at scale |

| Lead Time | Very short (hours) | Longer (days to weeks for tooling) |

| Design Flexibility | Extremely high (digital file) | Very low (fixed physical die) |

| Precision | Extremely high | High, but limited by blade complexity |

| Edge Quality | Clean, but with potential for a heat-affected zone (HAZ) | Clean shear, no thermal distortion |

The Verdict: When to Choose Laser Cutting for Your Automotive Prototype

Laser cutting is the definitive choice for the vast majority of automotive prototyping scenarios, especially during the early and iterative stages of development. Its primary advantages—speed, precision, and flexibility—are perfectly aligned with the goals of prototyping: to test, validate, and refine a design quickly and cost-effectively without committing to expensive, permanent tooling. The absence of a physical die is a massive benefit when designs are fluid and subject to change.

This method excels in situations where complexity and frequent adjustments are the norm. Whether it's trimming intricate plastic molded parts, cutting custom interior fabrics for seats, or creating initial dashboard layouts where component placement is still being finalized, laser cutting provides the agility needed. You can produce a part in the morning, have engineers test it in the afternoon, and cut a modified version the next day with minimal downtime or additional cost.

Consider laser cutting the ideal solution for your automotive prototype if your project involves:

- Early-Stage Validation: When you need to create functional models to test form, fit, and function before finalizing the design.

- Complex Geometries: For parts with intricate patterns, tight curves, or fine details that would be difficult or impossible to create with a traditional die.

- Multiple Design Iterations: If you anticipate making several changes to the prototype based on testing and feedback.

- Material Exploration: When testing various materials for a single component, such as different types of gaskets or insulating films, without investing in multiple dies.

While laser cutting is highly advantageous, it's important to consider potential trade-offs. The process can be slower on a per-unit basis for larger quantities, and certain materials may produce harmful fumes, requiring proper ventilation. However, for the specific purpose of prototyping, these factors are typically outweighed by the immense benefits of tool-less production.

Planning for Scale: When Die Cutting Makes Sense, Even for Prototypes

While laser cutting dominates the early stages of prototyping, there are strategic scenarios where choosing die cutting from the outset is a shrewder long-term decision. This approach is best suited for “production-intent” prototypes—parts where the design is already mature and highly unlikely to change. In these cases, the prototype's primary goal is not just to validate the part itself but to validate the high-volume manufacturing process that will be used to produce it.

The core of this strategy lies in understanding tooling cost amortization. The substantial upfront investment in a steel rule die, which seems prohibitive for a single prototype, becomes highly economical when spread across a production run of thousands or millions of units. By creating the die early, you can de-risk the transition to mass production. Companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. specialize in creating these precise, durable automotive stamping dies, helping to solve tooling and material handling challenges well before the assembly line starts running. This ensures that the parts produced at scale will be identical in quality and tolerance to the final approved prototype.

Opting for die cutting for a prototype is a strategic move when:

- The Design is Finalized: The part's geometry is stable and has been validated through other means, such as 3D printing or simulation.

- High-Volume Production is Guaranteed: The prototype is for a component, like a standardized gasket or door seal, that is confirmed for a large production run.

- Process Validation is Critical: The main objective is to prove that the die-cutting process will meet quality and speed requirements for mass manufacturing.

- Material Behavior is a Concern: For certain materials, die cutting can provide a cleaner edge or avoid thermal stress that a laser might introduce, making it essential to test with the final production method.

In essence, choosing die cutting for a prototype is an investment in the entire product lifecycle. It shifts the focus from short-term flexibility to long-term efficiency and scalability, ensuring a smoother and more predictable path from a single part to full-scale automotive production.

Frequently Asked Questions

1. What is the main disadvantage of laser cutting?

The main disadvantages of laser cutting include limitations on the thickness of the material it can cut effectively, typically around 25 mm. Additionally, the process can produce toxic fumes when used on certain materials like PVC, which necessitates proper ventilation systems. Finally, laser cutting machines consume a significant amount of power, which can be a consideration for operational costs.

2. What are the disadvantages of die cutting?

The primary disadvantages of die cutting are its inflexibility and high upfront costs. Since a physical die must be created for each unique design, it is not suitable for personalization or projects requiring frequent design changes. The time needed to fabricate the die increases the initial lead time of a project. Furthermore, the die's blades can become blunt over time, which may decrease cut quality during a long production run and require maintenance or replacement.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —