Automotive Control Arm Stamping: An Essential Guide

TL;DR

Automotive control arm stamping is a manufacturing process where sheet metal is pressed into the shape of a vehicle's suspension control arm. These components are common in modern, mass-produced cars because they are relatively inexpensive to make. Stamped steel arms are identified by their C-channel shape and visible seams where two halves are often welded together, distinguishing them from solid, one-piece forged or cast alternatives.

Understanding Stamped Steel Control Arms: Definition and Identification

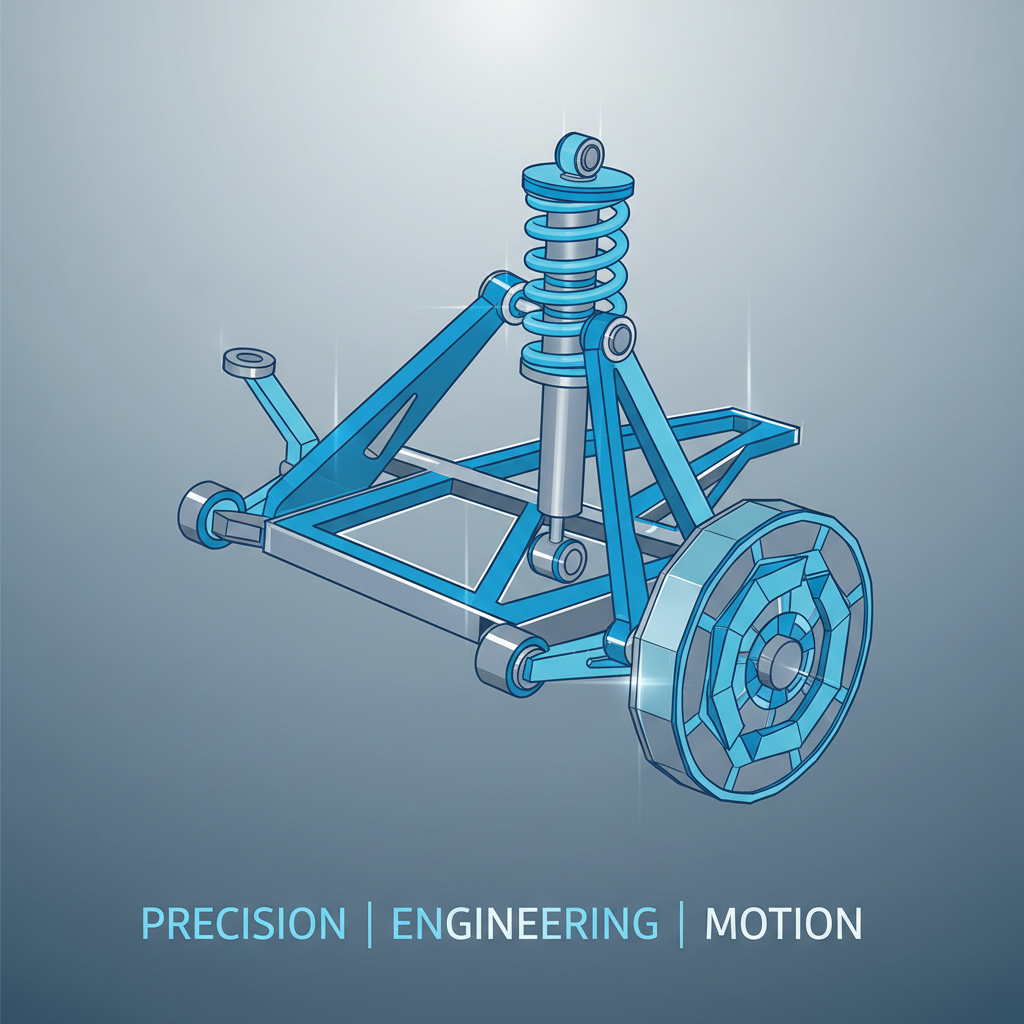

A stamped steel control arm is a critical suspension component that connects the vehicle's frame to the wheel hub, allowing the wheels to pivot and move vertically with the road surface. As the name suggests, its primary characteristic comes from its manufacturing method: automotive stamping. This process involves feeding large sheets of metal into a powerful press, where a custom die shapes and cuts the metal into the desired form. For complex parts like control arms, this often means creating two or more separate, C-shaped pieces that are then welded together to form a single, box-like structure.

This production method is highly efficient and cost-effective, which is why stamped steel arms are a popular choice for original equipment manufacturers (OEMs), especially for passenger cars and light-duty vehicles. The process is highly automated, using progressive stamping lines that ensure exceptional accuracy and repeatability. For manufacturers focused on precision and efficiency, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., advanced techniques like CAE simulations are used to perfect the die design, ensuring every component meets strict quality standards for Tier 1 suppliers. This contrasts with casting, where molten metal is poured into a mold, or forging, where a solid piece of metal is heated and hammered into shape.

Identifying whether your vehicle has stamped steel control arms is straightforward. Because they are made of steel, they are magnetic. The simplest method is the magnet test: if a magnet sticks firmly to the control arm, it's made of steel. Visually, you can often spot the signs of their construction. Look for a seam running along the edges where the stamped halves were joined. The overall shape is typically a U-channel or a hollow box, unlike the solid, bulkier appearance of cast iron or the cleaner, single-piece look of forged aluminum.

Here are the key methods for identifying a stamped steel control arm:

- The Magnet Test: A magnet will adhere to a stamped steel arm but not to a cast aluminum one.

- Visual Inspection for Seams: Look for a welded seam where two stamped pieces of metal are joined together. Forged and cast arms are typically made from a single piece and will not have these seams.

- Shape and Profile: Stamped arms often have a distinct C-channel or hollow, boxy shape. Cast arms tend to have a rougher, more textured surface, while forged arms usually have a smoother finish.

Stamped vs. Forged vs. Cast: A Material and Strength Comparison

When it comes to control arms, manufacturers choose between three primary types: stamped steel, cast iron/aluminum, and forged steel/aluminum. Each has a distinct manufacturing process that results in different performance characteristics, costs, and applications. Understanding these differences is crucial for anyone looking to replace or upgrade their vehicle's suspension components.

Stamped steel arms, as detailed, are made by pressing sheet metal. They are lightweight and the most economical to produce, making them the standard for many passenger vehicles. However, their hollow construction can make them more susceptible to bending under extreme stress and vulnerable to rust if the protective coating is compromised. For most daily driving scenarios, they perform perfectly well and have been a reliable choice for decades.

Cast control arms are created by pouring molten iron or aluminum into a mold. Cast iron is extremely strong and durable, making it ideal for heavy-duty vehicles like trucks and SUVs where strength is prioritized over weight. Cast aluminum offers a compromise, providing good strength at a lower weight than iron and with excellent corrosion resistance. The casting process allows for more complex shapes, but the material can be more brittle than forged alternatives.

Forged control arms are made from a solid billet of steel or aluminum that is heated and pressed into shape under immense pressure. This process aligns the metal's grain structure, resulting in a component that is exceptionally strong and resistant to impact and fatigue. Forged arms are the premium option, often found in high-performance and luxury vehicles. They offer the best strength-to-weight ratio but are also the most expensive to manufacture.

| Type | Material | Manufacturing Process | Pros | Cons |

|---|---|---|---|---|

| Stamped | Steel | Sheet metal pressed in a die | Inexpensive, lightweight, suitable for most passenger cars | Can flex under load, susceptible to rust, less durable than forged/cast |

| Cast | Iron or Aluminum | Molten metal poured into a mold | Very strong (iron), good corrosion resistance (aluminum), allows complex shapes | Heavy (iron), can be brittle, more expensive than stamped |

| Forged | Steel or Aluminum | Solid metal heated and pressed into shape | Highest strength-to-weight ratio, extremely durable and fatigue-resistant | Most expensive to produce |

When replacing a control arm, the general advice is to stick with the type your car was originally equipped with. Using a stamped steel replacement on a vehicle designed for it ensures that the suspension dynamics and safety characteristics remain as the engineers intended.

Strengthening Stamped Arms: The 'Boxing' Modification Process

For automotive enthusiasts and racers, the inherent flex of a standard stamped steel control arm can be a limitation. Under the high stress of hard cornering or aggressive launches, these C-channel arms can twist, affecting suspension geometry and handling. A popular and time-tested solution to this problem is "boxing" the control arm. This modification significantly increases the component's rigidity without the high cost of purchasing aftermarket forged or tubular arms.

Boxing involves fabricating a metal plate to enclose the open side of the C-channel, effectively turning it into a fully enclosed box. As explained by the experts at Speedway Motors, this process greatly reduces flex and strengthens the entire assembly. This was a common technique used by hot rodders in the past to improve the performance of factory components when aftermarket options were not readily available. The result is a much stronger arm that provides more predictable handling and can withstand greater forces.

While the exact steps vary by vehicle, the general process for boxing a control arm is as follows:

- Preparation and Measurement: The control arm is removed from the vehicle and thoroughly cleaned. The open side is measured to determine the size and shape of the reinforcement plate needed.

- Template and Fabrication: A template, often made from cardboard, is created to match the profile of the control arm, including any necessary cutouts for sway bar links or other mounting points. This template is then transferred to a piece of steel, typically 16-gauge, which is cut to shape.

- Fitting and Welding: The fabricated steel plate is test-fitted and bent to match the contours of the control arm. Once the fit is perfect, the plate is tacked into place and then stitch-welded along the seams, allowing the metal to cool between welds to prevent warping.

- Finishing: After welding is complete, the welds are cleaned up, and the entire control arm is sanded and painted to protect it from rust and corrosion.

This DIY modification is a cost-effective way to achieve performance gains. However, it requires proper welding skills and tools. For those not equipped for fabrication, purchasing a pre-made heavy-duty or tubular control arm is an alternative. When considering any aftermarket suspension parts, it's important to ensure they meet or exceed original equipment standards to remain compliant and safe for road use.

Frequently Asked Questions

1. What is a stamped control arm?

A stamped control arm is a suspension component made from sheet steel that has been pressed into shape by a die. They are known for being lightweight and inexpensive to manufacture, which makes them a common choice for modern passenger vehicles. They are often constructed from two C-shaped halves welded together, which can make them less rigid than solid cast or forged arms.

2. How do I tell if I have stamped steel control arms?

The easiest way to identify a stamped steel control arm is with a magnet; since it's steel, the magnet will stick. You can also look for visual cues such as a seam where two pieces of metal were welded together and a hollow, C-channel, or box-like shape, which distinguishes it from solid cast or forged parts.

3. What is automotive stamping?

Automotive stamping is a manufacturing process where flat sheet metal is placed in a stamping press and formed into a specific shape using a tool and die. This high-speed, high-precision process is used to create a wide variety of car parts, from body panels and doors to structural components like control arms.

4. Are aftermarket control arms legal?

Yes, aftermarket control arms are generally legal, provided they meet or exceed the quality and safety standards of the Original Equipment (OE) parts they replace. It is crucial to choose reputable brands that comply with automotive design regulations, as some aftermarket parts may not have the correct geometry or strength, potentially compromising vehicle safety and handling.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —