Laser Cut On Metal: Fix Defects, Slash Costs, Pick The Right Service

Understanding How Laser Cutting Transforms Metal Fabrication

Remember focusing sunlight through a magnifying glass as a kid? Laser cutting takes that same principle and amplifies it into an industrial powerhouse. When manufacturers need to laser cut on metal with surgical precision, they're harnessing focused light energy that can reach temperatures exceeding 20,000 degrees Celsius—hot enough to slice through steel like butter.

But what exactly happens when that intense beam meets metal? The process is elegantly simple yet remarkably sophisticated. A laser cutter directs concentrated photons through mirrors and lenses, creating energy concentrations around one million watts per square centimeter. This focused beam either melts or vaporizes metal at the point of contact, while assist gases like nitrogen or oxygen sweep away the molten material to create clean, precise cuts.

The Science Behind Focused Light Cutting Metal

Here's where things get interesting. Unlike mechanical cutting methods that physically shear material, laser cutting is a thermal process with zero physical contact. This means parts experience minimal stress-induced warping—a critical advantage when fabricating intricate components for automotive engines or aerospace applications where even microscopic deformations cause problems.

The thermal dynamics work like this: when the laser beam strikes metal, it creates a tiny melt pool right at the point of impact. Steel typically melts between 1,400 and 1,500 degrees Celsius, and modern metal laser cutter systems maintain precise control over this heat application. The result? Tolerances as tight as ±0.1mm and kerf widths as narrow as 0.2mm on standard steel sheets.

Laser cutting has fundamentally transformed metal fabrication from a craft of approximation into a science of precision—enabling designs that were literally impossible just decades ago while reducing material waste and production time by margins that reshape entire industries.

Why Precision Manufacturing Relies on Laser Technology

Modern metal fabrication demands solutions balancing speed, precision, and cost-effectiveness. That's precisely why laser cutting has become the backbone of industries where mistakes simply aren't an option. Aerospace manufacturers depend on this technology for titanium and aluminum alloy components requiring micron-level accuracy. Automotive factories use fiber lasers for complex body panels and exhaust systems. Medical device companies create sterile surgical instruments where flawed edges could endanger patients.

What makes this technology particularly valuable is its versatility. Whether you're a hobbyist exploring creative metalwork or a production manager optimizing high-volume manufacturing, understanding these fundamentals helps you make smarter decisions about equipment, processes, and service providers. Throughout this guide, you'll discover everything from fixing common cutting defects to selecting the right laser cutting service for your specific needs.

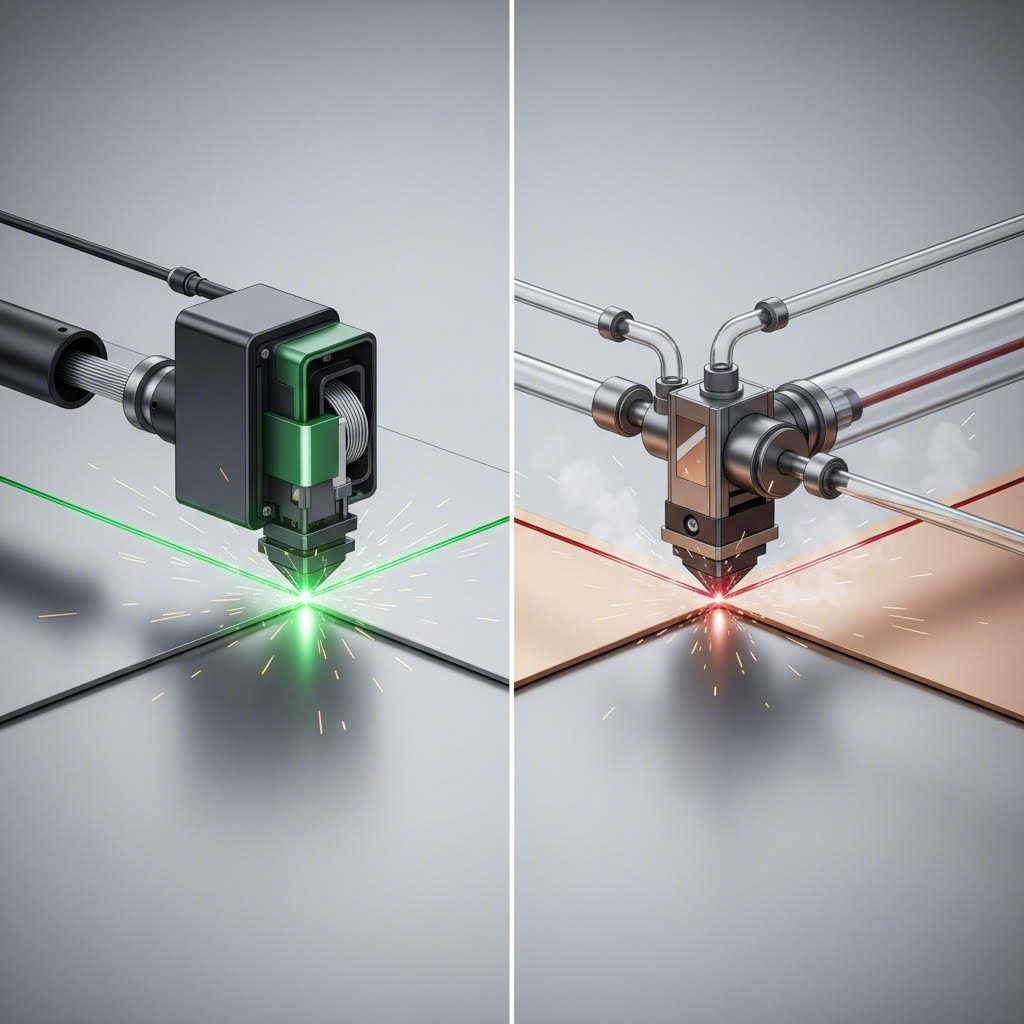

Fiber Laser vs CO2 Laser Technology Explained

So you've decided cutting metal with a laser is the right approach for your project. Now comes the critical question: which laser technology should you choose? The fiber versus CO2 debate isn't just technical jargon—it directly impacts your cut quality, operating costs, and the types of metals you can work with effectively.

Think of it this way: choosing the wrong laser technology is like using a butter knife to cut steak. It might eventually work, but you're making life unnecessarily difficult. Both fiber and CO2 lasers have distinct strengths, and understanding these differences helps you match the right tool to your specific metal laser cutting needs.

Here's a comprehensive breakdown of how these two technologies compare across the factors that matter most:

| Comparison Factor | Fiber Laser | CO2 Laser |

|---|---|---|

| Wavelength | 1.064 micrometers | 10.6 micrometers |

| Best Metal Types | Aluminum, brass, copper, stainless steel, mild steel | Mild steel, thicker carbon steel |

| Cutting Speed (Thin Metals) | Up to 3x faster than CO2 | Slower on thin materials |

| Energy Efficiency | ~35% conversion efficiency | 10-20% conversion efficiency |

| Maintenance Requirements | Minimal—solid-state design, fewer consumables | Higher—gas tubes, optical mirrors need regular service |

| Lifespan | Up to 100,000 hours | 20,000-30,000 hours |

| Initial Investment | Higher upfront cost | Lower upfront cost |

| Long-Term Operating Costs | Lower electricity and maintenance | Higher due to gas consumption and part replacement |

Fiber Laser Advantages for Reflective Metals

Here's something that frustrated manufacturers for years: highly reflective metals like aluminum, brass, and copper were notoriously difficult to cut with traditional CO2 lasers. The longer wavelength would bounce off these shiny surfaces, causing inconsistent cuts and potential damage to the laser equipment itself.

Fiber lasers changed everything. Their shorter 1.064-micrometer wavelength gets absorbed more efficiently by reflective materials, making fiber laser cutting for metal the go-to choice when working with these challenging substrates. A laser cutter machine metal setup using fiber technology can process polished stainless steel, copper sheets, and aluminum alloys without the back-reflection issues that plagued earlier systems.

The performance advantages don't stop at material compatibility. According to industry data from Accurl, fiber laser machines can achieve cutting speeds up to 20 meters per minute on thin stainless steel sheets—roughly three times faster than comparable CO2 systems. This speed advantage translates directly into higher throughput and lower per-part costs for production environments.

Additional fiber laser benefits include:

- Smaller spot size: The focused beam creates tighter cutting tolerances and finer detail work

- Reduced thermal distortion: Less heat spreads into surrounding material, minimizing warping

- Lower electricity consumption: That 35% efficiency rating means significantly reduced power bills compared to CO2 alternatives

- Simpler maintenance: No gas tubes to replace or optical mirrors requiring constant alignment

When CO2 Lasers Still Make Sense

Don't count CO2 laser metal cutting out just yet. Despite fiber technology's advantages with thin and reflective metals, CO2 lasers maintain a strong position for specific applications—particularly when cutting thicker mild steel or when edge quality matters more than raw speed.

The longer 10.6-micrometer wavelength of CO2 lasers distributes heat more evenly across the cut zone. This characteristic produces smoother edge finishes on thicker materials, often requiring less post-processing than fiber laser cuts. For manufacturers prioritizing surface aesthetics—think architectural metalwork or decorative steel panels—this smoother cut edge can justify the slower processing times.

CO2 laser cutting steel remains cost-effective when:

- Your primary work involves materials thicker than 20mm

- Initial equipment budget is limited and volume doesn't justify higher upfront investment

- Edge finish quality outweighs speed requirements

- Your shop already maintains CO2 expertise and spare parts inventory

The laser metal cutting machine you ultimately choose depends on your specific material mix, production volumes, and quality requirements. Shops primarily processing thin aluminum and stainless steel will find fiber lasers deliver better ROI despite higher initial costs. Operations focused on thick carbon steel with lower volume requirements may still benefit from CO2's lower entry point and proven reliability.

Understanding these technology differences prepares you for the next crucial step: mastering the actual cutting process from design file to finished part.

Step-by-Step Process for Laser Cutting Metal Successfully

You've selected your laser technology and understand the fundamentals. Now comes the part where theory meets practice. Surprisingly, most cutting problems don't originate from machine settings—they're baked into the process long before the laser fires. Whether you're operating a sheet metal laser cutting machine in a production facility or outsourcing to a service provider, following a systematic workflow prevents costly mistakes and wasted material.

Think of laser cutting metal like baking a complex recipe. Skip a step or measure incorrectly, and the final result suffers regardless of how good your oven is. Here's the complete process from blank sheet to finished part:

- Design file preparation: Create or finalize vector-based designs using CAD software. Export files in machine-compatible formats—DXF remains the industry standard for preserving dimensional accuracy, though DWG, AI, and SVG files work with most control systems.

- Material selection and inspection: Verify material type, thickness, and surface condition. Check sheets for warping, contamination, or protective films that could interfere with cutting.

- Machine setup and calibration: Confirm proper focus position, verify axis homing, and load the correct parameter library for your material specifications.

- Assist gas selection: Choose the appropriate gas based on material type and desired edge finish—oxygen for carbon steel oxidation cutting, nitrogen for clean stainless steel edges.

- Test cuts: Run sample cuts on scrap material matching your production stock to verify parameters before committing to production material.

- Production runs: Execute the cutting program while monitoring spark behavior, sound consistency, and initial pierce quality for signs of process instability.

- Post-processing: Remove parts carefully, inspect cut quality, and perform any necessary deburring, cleaning, or surface finishing operations.

Let's break down the critical elements that make or break each stage.

Material Preparation and Setup Essentials

Imagine trying to write on a crumpled piece of paper—that's essentially what happens when a laser cutting machine metal system attempts to process warped or contaminated sheets. Material flatness directly affects focus consistency, and even slight variations across the sheet surface can cause incomplete cuts or excessive dross formation.

Before loading any material onto the cutting bed, perform these essential checks:

- Surface cleanliness: Wipe sheets with acetone or degreaser to remove oils, fingerprints, and residues. For heavily contaminated material, wire brushing or laser cleaning may be necessary before cutting.

- Flatness verification: Visibly warped sheets cause focus position errors that degrade cut quality. Level or replace any material showing significant bowing or curvature.

- Thickness confirmation: Actual material thickness can vary from nominal specifications. Verify thickness matches your programmed parameters to prevent under or over-cutting.

- Protective film assessment: Some metals arrive with protective coatings. While these can prevent surface scratches, they may also interfere with laser absorption—particularly on stainless steel and aluminum.

Proper fixturing keeps material stable during cutting. Movement or vibration during processing creates dimensional errors and rough edges. Depending on your machine design, sheets may be secured using vacuum tables, magnetic fixtures, clamps, or simply gravity on well-supported cutting beds. The goal is eliminating any shift without interfering with the cutting path.

From Design File to Finished Cut

Here's where many projects fail before the laser even fires. Vector-based file formats are non-negotiable for laser cutting—the machine follows mathematically defined paths, not pixel arrangements. Bitmap images must be converted to vector format using tracing software before they're usable.

When preparing design files, watch for these common geometry problems that cause cutting failures:

- Open contours: Shapes that don't fully close leave cuts incomplete

- Duplicate lines: Overlapping paths cause the laser to cut the same location twice, overheating the material

- Stacked vertices: Multiple points at the same location confuse the cutting path

- Incorrect scale: Unit mismatches between design software and machine settings produce parts at wrong dimensions

Understanding kerf is essential for dimensional accuracy. The kerf—the width of material removed by the laser beam—typically ranges from 0.1mm to 1.0mm depending on material type, thickness, and laser parameters. This matters because if you design a 50mm square hole and the laser removes 0.3mm on each side, your actual hole measures 50.6mm.

Most laser cutting software compensates for kerf automatically by offsetting the cutting path. For external contours, the path shifts outward so the kerf falls outside your part dimensions. For internal features like holes, the path shifts inward. When precision matters, always verify whether your software applies kerf compensation—and whether it's set correctly for your specific cutting conditions.

Smart layer organization improves both efficiency and quality. Professional operators typically separate designs into layers for different operations:

- Inner features first: Cut holes and internal shapes before outer contours to prevent small parts from shifting after separation

- Engraving operations: Complete any marking or etching before through-cutting

- External profiles last: Final perimeter cuts release parts from the sheet

Nesting—arranging multiple parts efficiently on a single sheet—minimizes material waste and improves cutting consistency. Closely spaced parts reduce excessive travel time between cuts, while proper spacing prevents heat buildup that causes warping on thin materials.

Before committing to production material, always run a dry simulation or test cut. This verification step catches origin position errors, path collisions, and parameter mismatches that would otherwise scrap expensive sheets. A few minutes of testing prevents hours of rework—and keeps your laser cutter for metal operating at peak efficiency.

With your process dialed in, the next critical factor is matching laser capabilities to specific metal types and thicknesses.

Metal Types and Thickness Capabilities for Laser Cutting

Ever wondered why your laser cuts through mild steel like butter but struggles with that shiny copper sheet? The answer lies in material science—and understanding these differences separates frustrating trial-and-error from predictable, high-quality results. Each metal brings unique thermal and optical properties to the cutting table, directly affecting how much laser power you need and which assist gas produces the cleanest edges.

Whether you're processing steel plates for structural applications or cutting delicate stainless steel sheet metal for medical devices, matching your laser's capabilities to material requirements prevents wasted time, scrapped parts, and damaged equipment.

Thickness Capabilities by Metal Type

The thickness a laser can cut depends primarily on three factors: laser power (measured in kilowatts), material type, and desired cutting speed. Higher power enables thicker cuts—but material properties like reflectivity and thermal conductivity create significant variations between metals at the same power level.

Here's a practical reference showing general thickness capabilities across common metals and power ranges:

| Metal Type | 1-2 kW Laser | 3-4 kW Laser | 6+ kW Laser | Key Cutting Considerations |

|---|---|---|---|---|

| Mild Steel | Up to 6mm | Up to 12mm | Up to 25mm+ | Most forgiving; oxygen assist increases cutting capacity |

| Stainless Steel | Up to 4mm | Up to 8mm | Up to 20mm | Requires more power than mild steel; nitrogen produces oxide-free edges |

| Aluminum Sheet | Up to 3mm | Up to 8mm | Up to 15mm | High reflectivity demands fiber lasers; excellent thermal conductivity dissipates heat quickly |

| Brass | Up to 2mm | Up to 5mm | Up to 10mm | Reflective surface requires fiber laser; nitrogen assist prevents oxidation |

| Copper | Up to 2mm | Up to 4mm | Up to 6mm | Most challenging due to extreme reflectivity; requires 3kW+ fiber laser for reliable processing |

Notice how copper—the most reflective and thermally conductive metal on this list—requires significantly more power to cut the same thickness as mild steel. According to industry specifications from KF Laser, copper cutting applications typically require 3,000W to 5,000W lasers even for relatively thin 0.5mm to 6mm material.

When selecting equipment or evaluating service provider capabilities, build in a safety margin. Choosing a laser with slightly more power than your maximum thickness needs ensures consistent performance and accommodates future project requirements. A steel plate at the edge of your machine's capability cuts slower and with reduced edge quality compared to material well within the comfort zone.

Matching Laser Power to Material Requirements

Why does aluminum sheet metal require different parameters than a stainless steel sheet of identical thickness? Two material properties dominate the answer: reflectivity and thermal conductivity.

Reflectivity determines how much laser energy actually enters the material versus bouncing away. Highly polished aluminum and copper can reflect over 90% of CO2 laser light, making fiber lasers essential for these metals. The shorter 1.064-micrometer wavelength of fiber lasers gets absorbed more efficiently, transferring cutting energy instead of wasting it.

Thermal conductivity affects how quickly heat spreads away from the cutting zone. Copper conducts heat approximately six times faster than stainless steel. This rapid heat dissipation means you need higher power to maintain sufficient temperature at the cut front—otherwise, the material simply absorbs and distributes the heat without melting through.

These properties explain why galvanized sheet metal sometimes behaves unpredictably. The zinc coating has different thermal and optical characteristics than the underlying steel, potentially causing inconsistent results if parameters aren't adjusted accordingly.

Assist Gas Selection by Material

Choosing the correct assist gas isn't optional—it fundamentally changes the cutting chemistry and determines your edge finish quality. Here's how different gases interact with common metals:

- Oxygen for carbon and mild steel: Creates an exothermic oxidation reaction that adds heat energy to the cut. According to Air Products' laser application guidance, this oxidation cutting process enables higher cutting speeds or the ability to process thicker material than nitrogen cutting would allow at the same power level. The trade-off is an oxide layer on the cut edge—acceptable for many applications but requiring removal before welding or painting.

- Nitrogen for stainless steel and aluminum: Provides an inert atmosphere that prevents oxidation, producing clean, bright edges directly off the machine. The higher pressure nitrogen flow (often 15-25 bar) blows molten metal away without chemical reaction. This approach requires more laser power since there's no exothermic assist, but eliminates post-cut cleaning for appearance-critical applications.

- Argon for titanium and reactive metals: Essential for materials that react aggressively with both oxygen and nitrogen at cutting temperatures. Argon's complete inertness prevents contamination that would make welds brittle.

Remember that specific speed and power settings vary by machine manufacturer, material batch, and even ambient conditions. The thickness ranges above represent general capabilities—always reference your equipment documentation or conduct test cuts when processing unfamiliar materials or pushing thickness limits.

Understanding what your laser can and cannot cut reliably is just the first step. But how does laser cutting actually stack up against plasma, waterjet, and mechanical alternatives when you're evaluating the best approach for a specific project?

Laser Cutting vs Plasma vs Waterjet vs Mechanical Methods

So you can laser cut metal—but should you? That depends entirely on your specific project requirements. While laser cutting dominates conversations about precision metal fabrication, it's not always the optimal choice. Sometimes plasma's raw speed wins. Other times, waterjet's zero-heat approach solves problems lasers simply can't. Making the wrong technology choice costs money, time, and quality.

Here's the reality: each cutting method excels in specific scenarios and struggles in others. Understanding these trade-offs transforms you from someone who defaults to familiar technology into someone who strategically matches methods to requirements. Let's examine how a laser that cuts metal actually compares to the alternatives across the factors that matter most.

| Comparison Factor | Laser Cutting | Plasma Cutting | Waterjet Cutting | Mechanical Cutting |

|---|---|---|---|---|

| Precision Tolerance | ±0.1mm to ±0.25mm | ±0.5mm to ±1.5mm | ±0.1mm to ±0.5mm | ±0.01mm to ±0.05mm (CNC milling) |

| Edge Quality | Excellent; smooth, minimal burrs | Good; may require deburring | Very good; satin-smooth finish | Superior; mirror finishes achievable |

| Heat-Affected Zone | Minimal (localized heating) | Large (high thermal stress) | None (cold cutting process) | Minimal to none |

| Thickness Sweet Spot | 0.5mm to 25mm | 1mm to 50mm+ | Any thickness up to 300mm | Any thickness; excels at 3D parts |

| Cutting Speed | Very fast on thin materials; slows on thick | Fastest on medium-thick plates | Slowest (5-20 inches per minute) | Moderate; depends on operation |

| Initial Equipment Cost | $150,000 to $500,000+ | $50,000 to $150,000 | $100,000 to $400,000 | $50,000 to $300,000 |

| Operating Cost per Inch | Medium; gas and electricity | Lowest; consumables and power | Highest; water, abrasive, maintenance | Low; tooling wear is primary expense |

| Material Versatility | Conductive and some non-conductive metals | Conductive metals only | Virtually any material | All metals; 3D capability |

Decision Framework for Choosing Your Cutting Method

Sounds complex? It doesn't have to be. The decision often comes down to answering four key questions about your specific project:

What material and thickness are you cutting? This single factor eliminates options immediately. Plasma cutting only works on electrically conductive metals—wood, plastics, and ceramics are off the table. According to Trotec's cutting technology comparison, waterjet remains the only viable option for stone, ceramics, and heat-sensitive composites. If you need to cut 100mm steel plate, laser drops out of consideration entirely.

How tight are your tolerance requirements? When you need parts holding ±0.1mm or tighter, your options narrow to laser cutting or CNC machining. Plasma's ±0.5mm minimum tolerance won't satisfy precision automotive or aerospace specifications. For the tightest possible tolerances on complex 3D geometries, mechanical milling and turning remain unmatched.

Does heat exposure matter? Here's where waterjet shines brightest. Because it's a cold cutting process, there's absolutely zero thermal distortion or metallurgical change to your material. Sintel's metal cutting analysis notes this makes waterjet essential for titanium, heat-treated aluminum alloys, and any application where maintaining material properties is non-negotiable.

What's your production volume and budget? High-volume operations processing hundreds of steel parts daily typically favor plasma's combination of speed and low operating costs. Prototype shops running diverse materials in small quantities might find waterjet's versatility justifies higher per-part costs. The question isn't which metal cutter is "best"—it's which delivers optimal value for your specific situation.

When Each Technology Excels

Rather than forcing one technology to handle everything, successful fabrication shops often maintain multiple capabilities—or partner with service providers offering complementary methods. Here's where each approach delivers optimal results:

Laser cutting performs best when:

- Processing thin to medium sheet metal (under 20mm) requiring tight tolerances

- Cutting intricate geometries and fine details that plasma can't achieve

- Production volumes justify equipment investment or outsourcing costs

- Edge quality requirements minimize post-processing needs

- Working with stainless steel, aluminum, or mild steel as primary materials

Plasma cutting performs best when:

- Speed matters more than ultra-fine precision on medium to thick steel plates

- Budget constraints favor lower equipment and operating costs

- Cutting structural steel, heavy plate, or HVAC ductwork in high volumes

- Parts will receive secondary finishing operations anyway

- Processing materials from 1mm to 50mm thick where productivity drives profitability

Waterjet cutting performs best when:

- Heat-affected zones are absolutely unacceptable (titanium, tempered materials)

- Material versatility is required—cutting metals, stone, glass, and composites

- Cutting extremely thick materials beyond laser or plasma capability

- Edge finish quality must minimize secondary operations

- Production speed is secondary to material integrity and versatility

Mechanical cutting (milling, turning) performs best when:

- Parts require 3D machining rather than 2D profiling

- Tolerances below ±0.05mm are mandatory

- Surface finish must meet stringent specifications

- Creating threads, bores, complex molds, or precision shafts

- Working with difficult-to-cut superalloys where thermal methods struggle

The die cut machine approach—using steel rule dies for repetitive shapes—still makes sense for extremely high-volume thin material applications where tooling costs amortize across thousands of parts. However, for the flexibility most modern fabrication requires, CNC-controlled thermal and mechanical methods dominate.

Understanding that you can laser cut metal effectively for many applications—while recognizing when alternatives serve better—positions you to optimize both quality and cost. But what happens when your chosen laser cutting process produces less-than-perfect results? The next section tackles diagnosing and fixing the most common cutting defects.

Troubleshooting Common Laser Cutting Defects and Solutions

Your laser cutting metal sheet job looked perfect in the simulation—so why does the finished part have jagged edges, discolored surfaces, or that stubborn residue clinging to the bottom? Every laser metal cutting operator has faced this frustration. The good news? Most defects trace back to identifiable causes with straightforward fixes.

Think of troubleshooting like detective work. Each cutting defect is a symptom pointing toward a specific root cause—whether that's parameter settings, optical alignment, or material issues. When you cut with laser technology, four primary variables interact to determine cut quality: power, speed, focus position, and assist gas pressure. Getting any one of these wrong produces predictable problems.

Here are the most common defects you'll encounter when laser cutting metal parts, along with their causes and solutions:

- Dross (slag adhesion): Solidified molten metal residue clinging to the cut's bottom edge

- Burrs: Rough surfaces or raised edges affecting part functionality and appearance

- Excessive heat-affected zones: Material hardening or discoloration around cut edges

- Incomplete cuts: Material not fully penetrated, leaving parts partially attached

- Surface discoloration: Oxidation or burn marks on visible surfaces

Identifying and Eliminating Dross Formation

So what exactly is dross? To define dross simply: it's the solidified molten metal that should have been blown away during cutting but instead re-solidified and adhered to your part's underside. This residue requires additional grinding or cleaning—adding labor costs and potentially damaging precise dimensions.

Dross formation typically indicates one of these parameter imbalances:

- Insufficient assist gas pressure: When gas pressure is too low, molten material isn't completely blown clear of the cut zone. According to Raycus laser troubleshooting data, increasing nitrogen pressure in measured increments (0.1-0.2 bar at a time) often eliminates lower-edge slag adhesion.

- Cutting speed too high: Sparks deflecting sideways instead of downward signal excessive speed. The material isn't fully burning through before the beam moves on, leaving partially melted residue behind.

- Laser power too low: Insufficient energy fails to completely melt and eject material from the kerf. The result? Molten residue accumulates into bumps rather than clearing cleanly.

- Focus position errors: An incorrectly positioned focal point diffuses beam energy, creating a wider, weaker cut that doesn't cleanly penetrate the material.

Here's a systematic approach to diagnosing dross problems: First, observe your cutting sparks. Normal cutting produces flames spreading downward beneath the material. Deflected flames indicate speed is too high. Condensed, non-spreading flames suggest speed is too low. Proper speed shows stable drag lines on the cutting surface without lower slag.

When adjusting parameters, change one variable at a time. If reducing speed by 50-200 mm/min increments doesn't resolve the issue, then adjust focus position by 0.1-0.2mm. This methodical approach identifies exactly which factor is causing your specific problem.

Minimizing Heat-Affected Zone Problems

The intense heat that makes laser cutting possible can also create unwanted metallurgical changes in surrounding material. Heat-affected zones (HAZ) appear as discoloration, increased hardness, or reduced ductility along cut edges—potentially compromising part performance in demanding applications.

Several factors contribute to excessive HAZ:

- Cutting speed too slow: Excessive dwell time allows heat to conduct deeper into surrounding material. According to Alt Parts' laser cutting analysis, increasing cutting speed reduces thermal exposure and minimizes affected zones.

- Power too high for material thickness: Overpowering thin materials generates more heat than necessary, spreading thermal stress beyond the cut line.

- Improper assist gas selection: Using oxygen on stainless steel creates an exothermic oxidation reaction that adds heat—producing blackened, oxidized edges. Switching to high-purity nitrogen eliminates this chemical reaction while providing clean, oxide-free edges.

- Poor nesting and cut sequencing: Cutting closely spaced features without allowing cooling time between passes concentrates heat, causing localized overheating and potential warping.

For thin materials particularly susceptible to thermal distortion, consider these strategies: use pulsed laser modes rather than continuous wave operation, increase cutting speed to reduce heat input per unit length, and optimize part nesting to distribute thermal load across the sheet.

Beyond parameters, equipment condition affects cut quality significantly. Dirty or scratched optics reduce power delivery and beam quality—symptoms that often mimic parameter problems. Fortune Laser's troubleshooting guide recommends daily visual inspection and cleaning of the focus lens, with weekly cleaning of all mirrors in the optical path.

When persistent problems don't respond to parameter adjustments, investigate these equipment factors:

- Nozzle condition: A damaged, dirty, or clogged nozzle creates chaotic gas flow that ruins cut quality regardless of pressure settings. Inspect nozzles daily for nicks, spatter, or out-of-round openings.

- Beam alignment: A misaligned beam won't hit the lens center, producing weak, angled cuts. Perform alignment checks if quality suddenly degrades.

- Cooling system status: Insufficient cooling affects laser tube performance and can prevent firing entirely. Verify water flow and temperature stability.

- Motion system wear: Loose belts, worn bearings, or debris on guide rails cause vibrations that translate into wavy cut lines or dimensional inaccuracies.

Sometimes the issue isn't equipment or parameters—it's the material itself. Variations in material composition, contaminated surfaces, or warped sheets produce inconsistent results even with optimized settings. When bending or other secondary operations follow cutting, ensure material flatness before processing to prevent compounding quality issues.

Mastering defect troubleshooting transforms frustrating scrap runs into predictable quality output. But even perfect cut quality doesn't guarantee project success if costs spiral out of control. Understanding the true economics of laser cutting—and when outsourcing makes more financial sense than in-house capability—is where we turn next.

Cost Analysis and ROI Considerations for Metal Laser Cutting

You've mastered the technical side—but here's the question that keeps operations managers awake at night: does laser cutting actually make financial sense for your situation? The answer isn't as straightforward as comparing equipment price tags. Whether you're a hobbyist eyeing that first hobby laser cutter for metal or a production manager evaluating a major capital investment, understanding true costs separates smart decisions from expensive mistakes.

The buy-versus-outsource equation involves far more variables than initial equipment cost. Machine investment, operating expenses, material waste, labor requirements, and opportunity costs all factor into a complete financial picture. Let's break down what actually drives laser cutting economics—and when each approach delivers the best return.

Understanding Total Cost of Ownership

That attractive small laser metal cutting machine price you found online? It's just the beginning. According to IVYCNC's comprehensive pricing guide, total cost of ownership follows this formula:

TCO = Initial Cost + (Annual Operating Costs × Years) + Maintenance Costs + Training Costs - Resale Value

Here's what each component actually involves:

- Initial equipment investment: Fiber lasers capable of cutting metal range from $30,000 to $600,000 depending on power level and capabilities. Entry-level CO2 systems start around $10,000 but typically can't cut metals effectively.

- Installation and facility preparation: Proper ventilation, electrical upgrades, compressed air systems, and floor reinforcement can add 10-20% to equipment costs.

- Consumables and assist gases: Nitrogen, oxygen, lenses, nozzles, and protective windows create ongoing expenses that vary dramatically based on material mix and production volume.

- Electricity consumption: A 6kW fiber laser running at capacity consumes significant power. Factor in local electricity rates when projecting operating costs.

- Maintenance and repairs: Industry guidance suggests budgeting 5-10% of machine value annually for preventive maintenance and unexpected repairs.

- Operator training and labor: Skilled laser operators command premium wages, and training new personnel takes time before they reach full productivity.

For sheet metal fabrication operations processing diverse materials, these costs compound quickly. A $200,000 fiber laser might actually cost $280,000 to $320,000 when you factor in first-year installation, training, and operating expenses.

When Outsourcing Makes Financial Sense

According to Selmach's analysis of outsourcing economics, many manufacturers find that once external laser cutting spend approaches or exceeds £1,500 per month (roughly $1,900 USD), investing in-house becomes financially advantageous. But that threshold varies significantly based on your specific situation.

Outsourcing to fabrication shops near me typically makes sense when:

- Monthly cutting requirements fall below the break-even threshold for equipment investment

- Production volumes fluctuate unpredictably, making capacity utilization uncertain

- You need access to capabilities beyond your current equipment—like higher power for thicker materials

- Turnaround flexibility matters less than avoiding capital commitment

- Your team lacks expertise to operate and maintain sophisticated cutting equipment

- You need complementary services like powder coating services, bending, or welding from a single source

Bringing capability in-house typically makes sense when:

- Consistent monthly volumes justify equipment utilization rates above 60-70%

- Lead time control is critical—eliminating supplier scheduling dependencies

- Proprietary designs require confidentiality that external processing risks

- Transportation costs and logistics complexity erode outsourcing savings

- Quality control requirements demand direct process oversight

- Long-term production forecasts support multi-year equipment amortization

Part complexity and volume requirements heavily influence this calculation. Simple, repetitive parts in high volumes favor in-house production where setup costs amortize across thousands of pieces. Complex, low-volume prototype work often makes more sense outsourced—accessing expensive equipment without ownership burden.

For hobbyists and small businesses exploring entry-level options, Xometry's equipment analysis notes that diode lasers ($500-$2,500) and basic CO2 systems ($1,000-$4,000) handle non-metal materials effectively but lack the power for serious metal cutting. Realistic hobby laser cutter for metal options start around $3,500 for entry-level fiber systems—but these smaller machines have significant thickness and speed limitations compared to industrial equipment.

When evaluating metal fabrication near me options, consider these service provider selection criteria:

- Quality certifications: ISO 9001, AS9100 (aerospace), or IATF 16949 (automotive) indicate systematic quality management

- Equipment capabilities: Verify laser power levels match your material and thickness requirements

- Turnaround times: Standard versus expedited lead times—and associated cost premiums

- Design support: Do they offer DFM (design for manufacturability) feedback to optimize your parts?

- Secondary operations: Bending, welding, finishing capabilities under one roof reduce logistics complexity

- Minimum order quantities: Some steel fabrication providers focus on volume; others specialize in prototypes

The expected ROI timeline also varies dramatically by investment level. According to industry data, entry-level systems ($5,000-$15,000) typically achieve payback in 12-18 months, mid-range equipment ($15,000-$50,000) in 8-12 months, and industrial systems ($50,000+) in 6-10 months—assuming adequate utilization rates.

Whether you're calculating in-house investment returns or evaluating metal fabricators near me for outsourced production, the fundamental question remains the same: which approach delivers the best combination of quality, cost, and capability for your specific requirements? The answer guides your final step—selecting the right manufacturing partner to bring your projects to life.

Selecting the Right Laser Cutting Service for Your Project

You've mastered the technology, understood cost dynamics, and know exactly what quality looks like. Now comes the decision that brings everything together: choosing the right manufacturing partner. Whether you need a one-off prototype or thousands of production parts, the steel fabricators and metal fab shops you select directly determine whether your project succeeds or becomes an expensive lesson.

The challenge? Not all service providers are created equal. Some excel at high-volume production but struggle with prototypes. Others offer impressive equipment lists but lack the quality systems to deliver consistent results. Finding the right fit requires asking the right questions—before you've committed time and materials to a partnership that doesn't match your needs.

Evaluating Manufacturing Partners for Quality Results

When vetting potential laser cutting service providers, look beyond impressive websites and low quoted prices. According to Ryerson's fabrication partner evaluation framework, seven critical factors separate reliable partners from risky choices.

Start with these essential questions to ask any potential supplier:

- What quality certifications do you hold? ISO 9001 demonstrates basic quality management. IATF 16949 certification indicates automotive-grade quality systems—critical for chassis, suspension, and structural components where failures aren't acceptable.

- What's your typical turnaround time? Understand standard lead times versus expedited options. Some providers offer rapid prototyping in days while production runs take weeks.

- Can you handle my specific material and thickness requirements? Verify their laser cutter for steel matches your specifications. A provider cutting 6mm mild steel may lack equipment for 20mm stainless.

- Do you offer design-for-manufacturability (DFM) support? Experienced partners identify potential issues before cutting begins—saving rework costs and accelerating timelines.

- What secondary operations can you provide? Bending, welding, powder coating, and assembly under one roof eliminates logistics complexity and quality handoff risks.

- How do you handle supply chain disruptions? Ask about material sourcing flexibility and contingency plans—lessons the COVID-19 crisis made painfully clear.

- Can you provide customer references or case studies? Testimonials from similar projects in your industry indicate relevant experience.

For automotive applications requiring tight tolerances, manufacturing partners with IATF 16949 certification provide documented quality management specifically designed for automotive supply chains. This certification isn't just a badge—it represents systematic approaches to preventing defects, ensuring traceability, and maintaining consistent quality across production runs.

Precision metal cutting capabilities often complement other manufacturing processes. For complete solutions—especially automotive chassis, suspension, and structural components—look for partners combining laser cutting expertise with stamping, precision assembly, and comprehensive DFM support. This integrated approach eliminates coordination headaches between multiple vendors while ensuring dimensional consistency across all operations.

Getting Started with Your Metal Cutting Project

Ready to move from planning to production? Here's a practical roadmap for launching your first project with a new manufacturing partner:

Step 1: Prepare your design files properly. Vector-based formats (DXF, DWG) with correct dimensions prevent costly back-and-forth. Include material specifications, thickness requirements, and quantity needs upfront.

Step 2: Request quotes from multiple providers. Compare not just price but turnaround time, included services, and shipping costs. A 12-hour quote turnaround indicates operational efficiency that often extends to production responsiveness.

Step 3: Ask about rapid prototyping options. Before committing to production volumes, validate your design with prototype parts. Providers offering 5-day rapid prototyping help you identify issues before they become expensive production problems.

Step 4: Clarify communication expectations. Understand who your point of contact will be, how progress updates work, and escalation paths if issues arise.

Step 5: Start with a test order. Even with thorough vetting, a small initial order validates quality, communication, and delivery reliability before scaling up.

For automotive manufacturers seeking to accelerate supply chain performance, Shaoyi (Ningbo) Metal Technology delivers IATF 16949-certified quality combining custom metal stamping, precision assemblies, and comprehensive DFM support. Their 5-day rapid prototyping and 12-hour quote turnaround exemplify the responsive partnership that modern manufacturing demands.

Whether you're creating custom metal signs, production automotive components, or precision industrial parts, the right manufacturing partner transforms complex projects into successful outcomes. The knowledge you've gained throughout this guide—from understanding laser technology fundamentals to troubleshooting defects and evaluating costs—positions you to make informed decisions that optimize quality, timeline, and budget.

Your next step? Take that design file, reach out to qualified partners, and turn your metal cutting vision into reality.

Frequently Asked Questions About Laser Cutting Metal

1. What material cannot be laser-cut?

Materials unsuitable for laser cutting include PVC (releases toxic chlorine gas), carbon fibers, leather containing chromium (VI), and certain reflective metals without proper equipment. CO2 lasers struggle with highly reflective materials like polished copper and aluminum, which require fiber lasers for effective cutting. Always verify material compatibility with your specific laser type to prevent equipment damage and ensure operator safety.

2. How thick of metal can be laser-cut?

Metal thickness capacity depends on laser power and material type. A 6kW+ fiber laser can cut mild steel up to 25mm, stainless steel up to 20mm, and aluminum up to 15mm. Copper remains challenging, typically limited to 6mm even with high-power systems due to extreme reflectivity. For thicker materials beyond 25mm, waterjet or plasma cutting often provides better results than laser technology.

3. What is the difference between fiber laser and CO2 laser for metal cutting?

Fiber lasers operate at 1.064 micrometers wavelength, excel with reflective metals like aluminum and copper, offer up to 3x faster cutting speeds on thin materials, and provide 35% energy efficiency with minimal maintenance. CO2 lasers at 10.6 micrometers work better for thicker mild steel, have lower initial costs, but require more maintenance and consume more energy. Choose fiber for versatility and speed; CO2 for thick carbon steel on a budget.

4. How much does a metal laser cutting machine cost?

Entry-level fiber lasers capable of metal cutting start around $30,000, while industrial systems range from $150,000 to $600,000+. Total cost of ownership includes installation (10-20% of machine cost), consumables, electricity, and maintenance (5-10% annually). For hobbyists, basic fiber systems start at $3,500 but have significant limitations. Outsourcing becomes cost-effective when monthly cutting needs fall below equipment break-even thresholds.

5. What is dross in laser cutting and how do you prevent it?

Dross is solidified molten metal residue that adheres to the cut edge instead of being blown away. Prevention involves optimizing four key parameters: increasing assist gas pressure (nitrogen or oxygen), reducing cutting speed, ensuring proper laser power for material thickness, and verifying correct focus position. Systematic troubleshooting—adjusting one variable at a time—identifies the specific cause for your cutting conditions.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —