Key Types of Die Components in Modern Manufacturing

TL;DR

In manufacturing, the term "die" refers to two related concepts. First, die components are the individual parts of a tool—like die plates, guide pins, and punches—that work together in a press. Second, dies are classified into different types based on their function and complexity, such as simple, compound, and progressive dies, which determine how they cut or form sheet metal into a final product.

The Fundamental Components of a Stamping Die

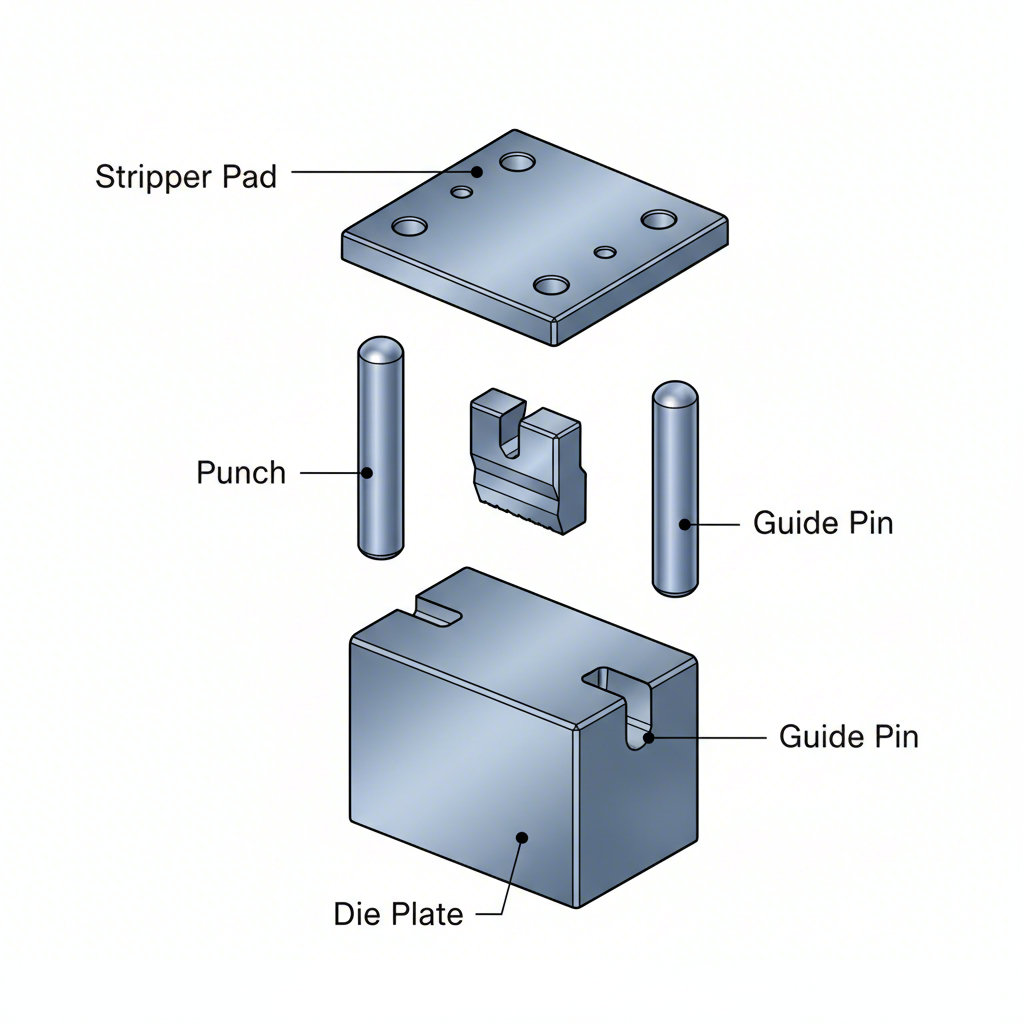

A stamping die is a precision tool used to cut and shape sheet metal, and it is constructed from several essential components working in unison. At its base are the die plates, also known as die shoes or die sets. These thick, flat plates serve as the foundation for mounting all other working parts of the die. Their flatness and parallelism are critical for the accuracy of the entire tool. The upper and lower die shoes are precisely aligned by guide pins and bushings, which ensure the two halves of the die meet perfectly during each press stroke, preventing misalignment that could damage the tool or the part being made.

The active elements of the die are the punches and buttons (or die matrix). Punches are the components that perform the cutting or forming; for instance, a pierce punch creates a hole, while a blanking punch cuts the outer profile of a part. These punches are held securely in place by retainers. As a punch penetrates the material, it enters a corresponding cavity in the lower die block, shearing the metal. To prevent the material from sticking to the withdrawing punch, a spring-loaded stripper pad holds the sheet metal down, allowing the punch to exit cleanly.

Finally, the entire assembly is powered and controlled by various other components. Springs—which can be coil, urethane, or nitrogen gas springs—provide the necessary force for stripping pads and pressure pads that hold the metal during forming operations. For dies that experience significant side-to-side forces, heel blocks and heel plates are added to absorb this thrust and protect the guide pins from deflection. According to experts at The Fabricator, these core components form the backbone of nearly every stamping die, from the simplest to the most complex.

A Comprehensive Guide to the Major Types of Dies

Beyond their individual components, dies are classified into several types based on the operations they perform and their complexity. The selection of a die type depends on factors like part complexity, production volume, and cost efficiency. The most fundamental is a Line Die (or simple die), which performs a single operation, such as bending or piercing, with each stroke of the press. This method is often used for low-volume production or for creating simple parts, as it requires less complex and costly tooling.

For more efficient production, manufacturers turn to more advanced designs. A Compound Die performs multiple cutting operations in a single press stroke at one station. For example, it can punch a hole in the center of a part while simultaneously blanking its outer contour, making it ideal for producing flat parts like washers with high precision. In contrast, a Progressive Die features a series of stations, each performing a different operation sequentially. The sheet metal, in the form of a coil strip, is fed through the die, and with each press stroke, the part is advanced to the next station until it is complete. As noted by Standard Die, this method is exceptionally fast and cost-effective for high-volume production of complex parts.

Another important category is the Transfer Die, which is similar to a progressive die but handles individual, separated blanks rather than a continuous strip. Mechanical fingers or arms transfer the part from one station to the next. This is useful for large parts, like automotive panels, that cannot be easily managed on a strip. For complex projects, particularly in the automotive sector, partnering with a specialized manufacturer is crucial. For instance, Shaoyi (Ningbo) Metal Technology Co., Ltd. excels in creating custom automotive stamping dies, offering precision solutions for OEMs and Tier 1 suppliers that require advanced tooling for mass production.

| Die Type | Key Characteristic | Common Application | Relative Complexity/Cost |

|---|---|---|---|

| Line Die (Simple Die) | Performs one operation per press stroke. | Low-volume production, simple parts, secondary operations. | Low |

| Compound Die | Performs multiple cutting operations in a single station. | Washers, gaskets, and other flat parts with high accuracy. | Medium |

| Progressive Die | Multiple stations perform sequential operations on a metal strip. | High-volume production of complex parts (e.g., electronic connectors). | High |

| Transfer Die | Transfers a single part between multiple stations for operations. | Large parts like automotive body panels and deep-drawn shells. | Very High |

| Combination Die | Performs both a cutting and a non-cutting (forming/drawing) operation in one stroke. | Parts requiring a cut and a bend/form, like small brackets. | Medium to High |

Exploring Specialized Dies for Specific Manufacturing Operations

Beyond the general classifications based on workflow, many dies are named for the specific task they perform. These specialized, often single-operation dies are crucial for achieving precise features on a manufactured part. A Blanking Die, for example, is designed solely to cut the outer shape or profile of a part from a larger sheet of metal. The piece that is cut out, known as the blank, becomes the workpiece for subsequent operations. This is often the very first step in a manufacturing process, such as cutting the flat shape of a car door panel before it is formed.

In contrast, a Piercing Die is used to create holes, slots, or other internal features within a part without affecting its outer contour. Unlike blanking, where the cutout piece is the desired part, in piercing the cutout material (the slug) is discarded as scrap. Piercing operations can be performed by a dedicated die or integrated as a station within a larger progressive die. Both blanking and piercing are fundamental cutting operations in metal stamping, as detailed in various manufacturing resources, including Wikipedia's overview of die manufacturing.

Other specialized dies focus on forming rather than cutting. An Embossing Die is used to create raised or recessed designs in sheet metal without changing its thickness. This is achieved by pressing the material between a matching punch and die that contain the desired pattern, often used for logos, lettering, or decorative features. Similarly, a Coining Die applies extreme pressure to the workpiece, forcing the metal to flow into the intricate details of the die cavity. This process can create different features on each side of the part and is used to produce items requiring high detail, such as coins and medals.

Frequently Asked Questions

1. What is a die component?

A die component is an individual part of a larger die assembly used in a stamping press. These components work together to cut or form sheet metal. Key examples include die plates (the foundation), guide pins and bushings (for alignment), punches (which perform the cutting or forming), and stripper pads (which remove the material from the punch).

2. What are the different types of die materials?

Dies are typically made from highly durable, wear-resistant materials. The most common are tool steels, which are special alloys of iron and carbon that can be hardened for toughness and edge retention. For extremely high-volume or high-wear applications, tungsten carbide is often used for cutting and forming sections due to its exceptional hardness. Other materials can include aluminum for die shoes to reduce weight, and aluminum-bronze for wear plates and bushings to reduce friction.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —