Hydraulic vs Mechanical Press Stamping: Which is Right for You?

TL;DR

The decision between hydraulic vs mechanical press stamping depends fundamentally on your specific production goals: speed versus force control. Mechanical presses are the industry standard for high-speed, high-volume production of simpler parts, delivering maximum force only at the bottom of the stroke. In contrast, hydraulic presses offer superior versatility and full tonnage throughout the entire stroke, making them the ideal choice for deep drawing, complex forming, and low-volume or trial runs. While mechanical systems prioritize cycle efficiency (up to 1,000+ strokes per minute), hydraulic systems prioritize adaptability and consistent pressure.

The Core Difference: Kinetic vs. Hydrostatic Energy

To choose the right machine, you must first understand how they generate force. This isn't just a technical detail; it dictates the behavior of the slide (ram) and the quality of your finished part.

Mechanical presses operate on the principle of kinetic energy. A motor drives a massive flywheel, which stores energy and transfers it to the ram via a clutch and a crankshaft (or eccentric/link drive). It works like a hammer striking a nail: the energy is delivered in a sudden, powerful impact. Because of this fixed mechanical linkage, the stroke length is non-adjustable, and the slide velocity varies—accelerating towards the middle of the stroke and decelerating as it reaches the bottom.

Hydraulic presses, conversely, rely on hydrostatic pressure (Pascal’s Law). A pump forces hydraulic fluid into a cylinder to move the piston. This mechanism allows the press to generate full rated force at any point in the stroke. It operates more like a vise: a controlled, steady squeeze that can be sustained. The stroke length is fully adjustable, and the speed can be controlled precisely throughout the cycle.

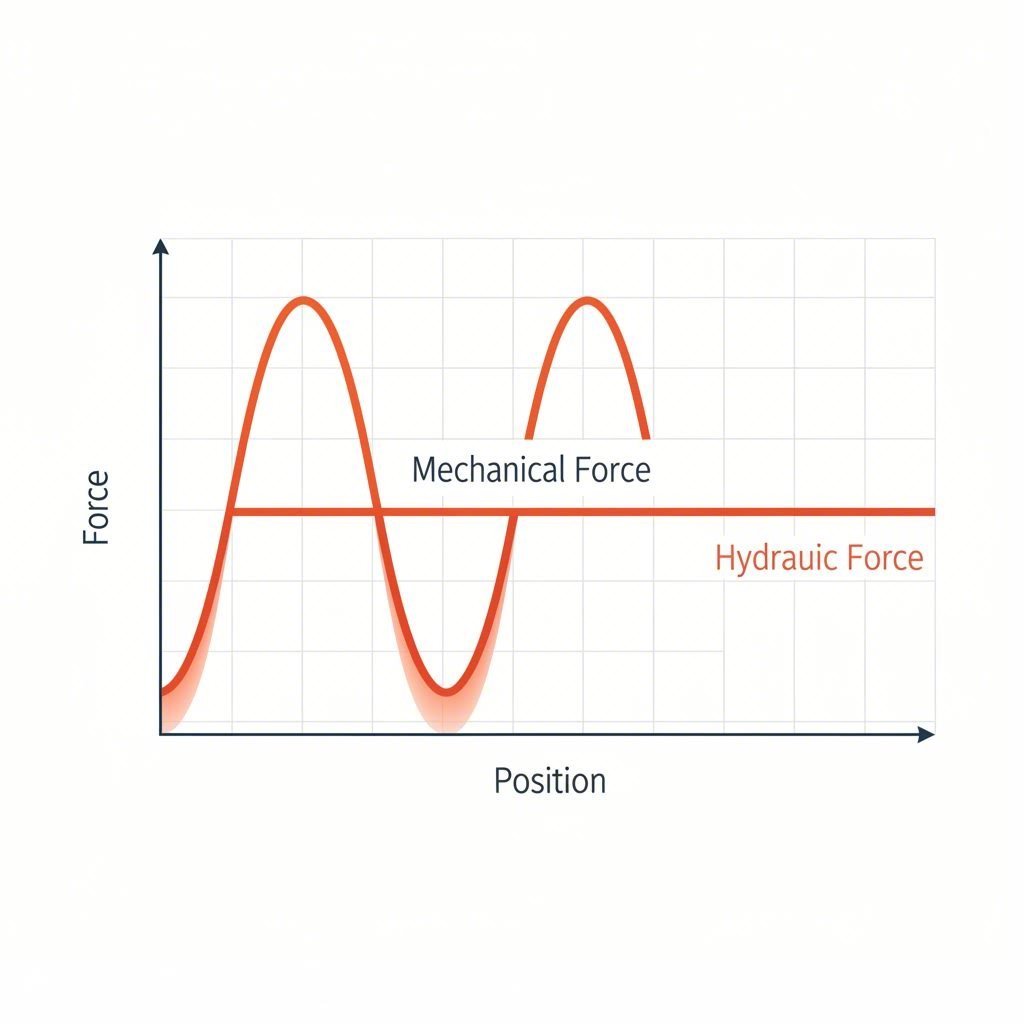

The Tonnage Curve: Why "Bottom Dead Center" Matters

The most critical differentiator for engineers is the tonnage curve—the profile of how and when force is applied.

In a mechanical press, you do not get the machine's full rated tonnage throughout the stroke. The maximum force is only available at the very bottom of the stroke, known as Bottom Dead Center (BDC), typically within the last 0.125 to 0.25 inches. If your forming operation begins 2 inches above the bottom (like in a deep draw), a 200-ton mechanical press might only deliver a fraction of that force at the point of contact. This limitation makes mechanical presses susceptible to "sticking" if the press is overloaded before reaching BDC.

Hydraulic presses solve this limitation completely. A 200-ton hydraulic press delivers 200 tons of force from the moment the tool touches the metal until the cycle is complete. This constant force capability allows for a feature called "dwell," where the press holds pressure at the bottom of the stroke for a set time. This is essential for operations like thermoset molding or complex forming where the material needs time to flow, preventing spring-back and ensuring dimensional accuracy.

Performance Showdown: Speed, Precision, and Control

When evaluating performance metrics, the trade-off is stark: Mechanical wins on speed; Hydraulic wins on flexibility.

Speed and Volume

Mechanical presses are the undisputed kings of speed. By utilizing the stored energy of the flywheel, they can achieve cycle rates ranging from 20 to over 1,500 strokes per minute (SPM). For blanking, piercing, and progressive die applications where parts are flat and volumes are in the millions, a mechanical press is the most efficient option.

Precision and Setup

Hydraulic presses operate much slower—typically 20 to 100 SPM—but offer unmatched control. Operators can adjust the stroke length, pressure limits, and ram speed instantly via the control panel. This makes setup times significantly shorter, as there is no need to manually adjust the shut height or stroke mechanics. For high-mix, low-volume shops, this flexibility often outweighs the raw speed of a mechanical system.

Application Suitability: When to Choose Which?

Selecting the right press is about matching the machine's physics to your part's geometry.

Best Applications for Mechanical Presses

- High-Speed Blanking & Punching: The snap-through shock of cutting metal is best absorbed by rigid mechanical frames.

- Progressive Dies: Continuous, automated feeding of coil stock for high-volume part production.

- Shallow Forming: Simple brackets, coins, and shallow embossments where force is only needed at the bottom.

- Automotive Body Panels: High-output lines for fenders and door panels often use transfer mechanical presses.

Best Applications for Hydraulic Presses

- Deep Drawing: Manufacturing tanks, cylinders, or fire extinguishers where force must be consistent over a long distance.

- Complex Forming: Parts requiring dwell time or variable force to prevent tearing.

- Powder Compacting & Straightening: Applications requiring precise pressure holding.

- Prototype & Trial Runs: The easy setup allows for cost-effective testing before committing to hard tooling.

For manufacturers bridging the gap between these two worlds, partnering with a versatile specialist is often the best strategy. If your project involves scaling from rapid prototyping (where hydraulic flexibility shines) to high-volume manufacturing (where mechanical speed is key), consider experts like Shaoyi Metal Technology. With capabilities up to 600 tons and IATF 16949 certification, they bridge the divide, delivering critical automotive components like control arms and subframes whether you need 50 prototypes or millions of mass-produced parts.

Cost Analysis: CapEx and Maintenance

The total cost of ownership involves more than just the purchase price.

| Factor | Mechanical Press | Hydraulic Press |

|---|---|---|

| Initial Investment | Generally higher, especially for high-tonnage models. | Lower initial cost, even for high-tonnage capacities. |

| Maintenance Needs | Requires lubrication of moving parts (clutch, brake, flywheel). Wear parts are expensive to replace but last a long time. | Requires management of fluids, seals, hoses, and valves. Leaks can be messy, but components are standard and easier to replace. |

| Energy Efficiency | High efficiency for continuous running; the flywheel stores energy. | Motor runs continuously to drive the pump; efficiency drops if the press idles frequently. |

| Repair Complexity | If a press locks up at BDC, unsticking it can be a major, costly operation. | Cannot be overloaded; relief valves simply bypass fluid. Easy to unstick. |

The Servo Press: The Best of Both Worlds?

In recent years, servo press technology has emerged as a hybrid solution. By replacing the flywheel and clutch with a high-torque servo motor, these presses offer the speed of a mechanical system with the programmable control of a hydraulic one. You can program the ram to descend fast, slow down during the forming portion of the stroke, and return quickly.

While servo presses are significantly more expensive upfront, they eliminate the "Bottom Dead Center" limitation of traditional mechanical presses while maintaining high production speeds. For shops that can justify the capital expenditure, they offer the ultimate versatility.

Conclusion

The choice between hydraulic vs mechanical press stamping is rarely a matter of one being "better" than the other; it is about suitability for the application. Mechanical presses remain the undisputed choice for speed, consistency, and high-volume blanking. Hydraulic presses are the master of force, flexibility, and deep forming.

To make the right investment, analyze your part geometry, anticipated volume, and the need for stroke control. If your shop runs millions of flat washers, buy mechanical. If you are drawing deep propane tanks or running high-mix short runs, hydraulic is your answer.

FAQ

1. Can a hydraulic press match the speed of a mechanical press?

Generally, no. A standard hydraulic press operates at significantly lower speeds (20–60 SPM) compared to mechanical presses (50–1,000+ SPM) due to the physics of moving fluid. However, specialized "high-speed" hydraulic presses exist, but they still rarely match the throughput of flywheel-driven mechanical systems for simple blanking operations.

2. Why is a hydraulic press better for deep drawing?

Deep drawing requires consistent force throughout the entire length of the draw to stretch the material without tearing. A hydraulic press provides full rated tonnage at any point in the stroke, whereas a mechanical press loses significant force capacity as the slide moves up from the bottom dead center.

3. Which press type is safer to operate?

Hydraulic presses are generally considered safer regarding overload protection. If a hydraulic press exceeds its set tonnage, a relief valve simply opens, stopping the ram. If a mechanical press is overloaded, it can "stick" or lock at the bottom of the stroke, creating a dangerous situation that requires significant force (and often torch cutting) to release.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —