Fuel Tank Strap Metal Stamping: Engineering Precision & Sourcing

TL;DR

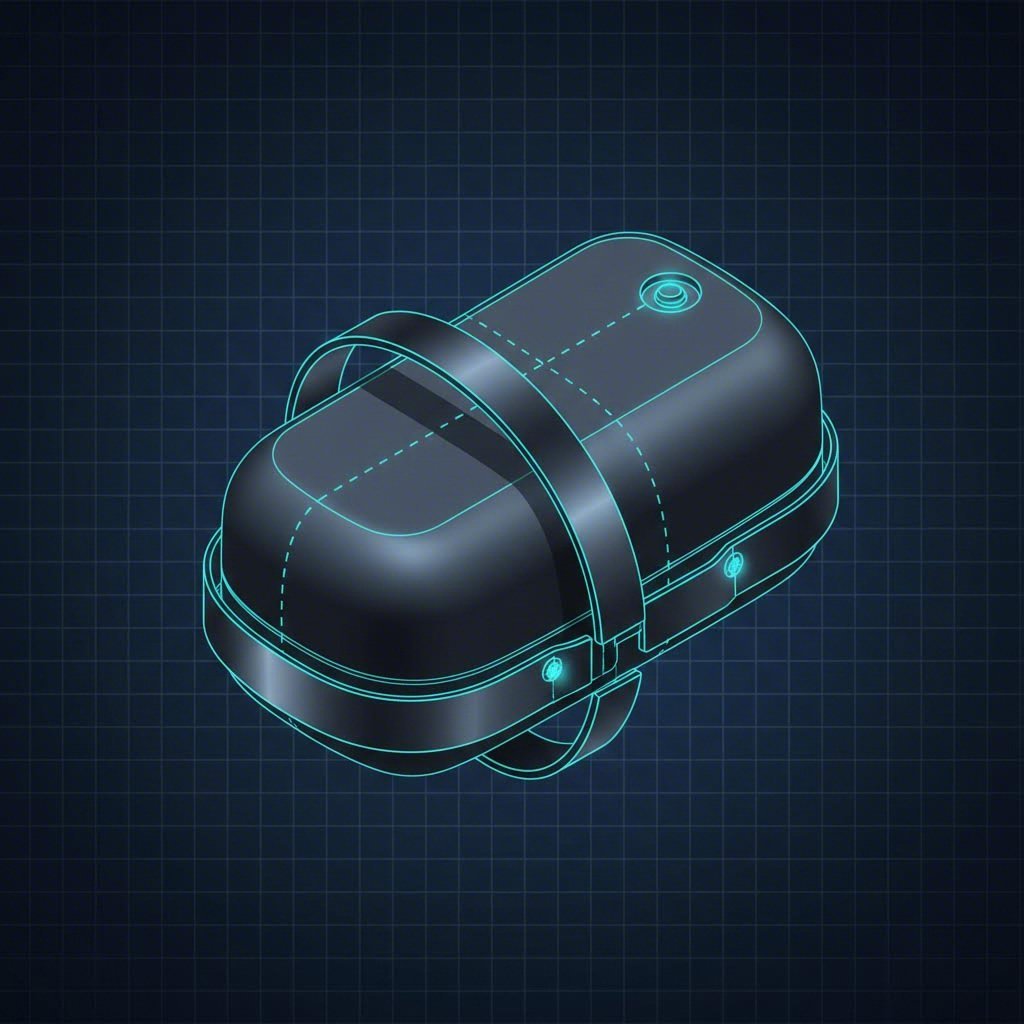

Fuel tank strap metal stamping is a precision manufacturing process designed to produce high-strength support bands that secure fuel vessels in automotive and heavy-duty industrial vehicles. This fabrication method transforms raw coil—typically high-strength carbon steel or 304 stainless steel—into contoured straps through operations like roll forming, progressive die stamping, and orbital riveting. Key performance attributes include exceptional tensile strength to support heavy fluid loads and advanced corrosion resistance to withstand harsh underbody environments.

For engineers and procurement officers, understanding the nuances of this process—from material selection to assembly integration—is critical for ensuring vehicle safety and regulatory compliance.

The Metal Stamping Process: From Coil to Component

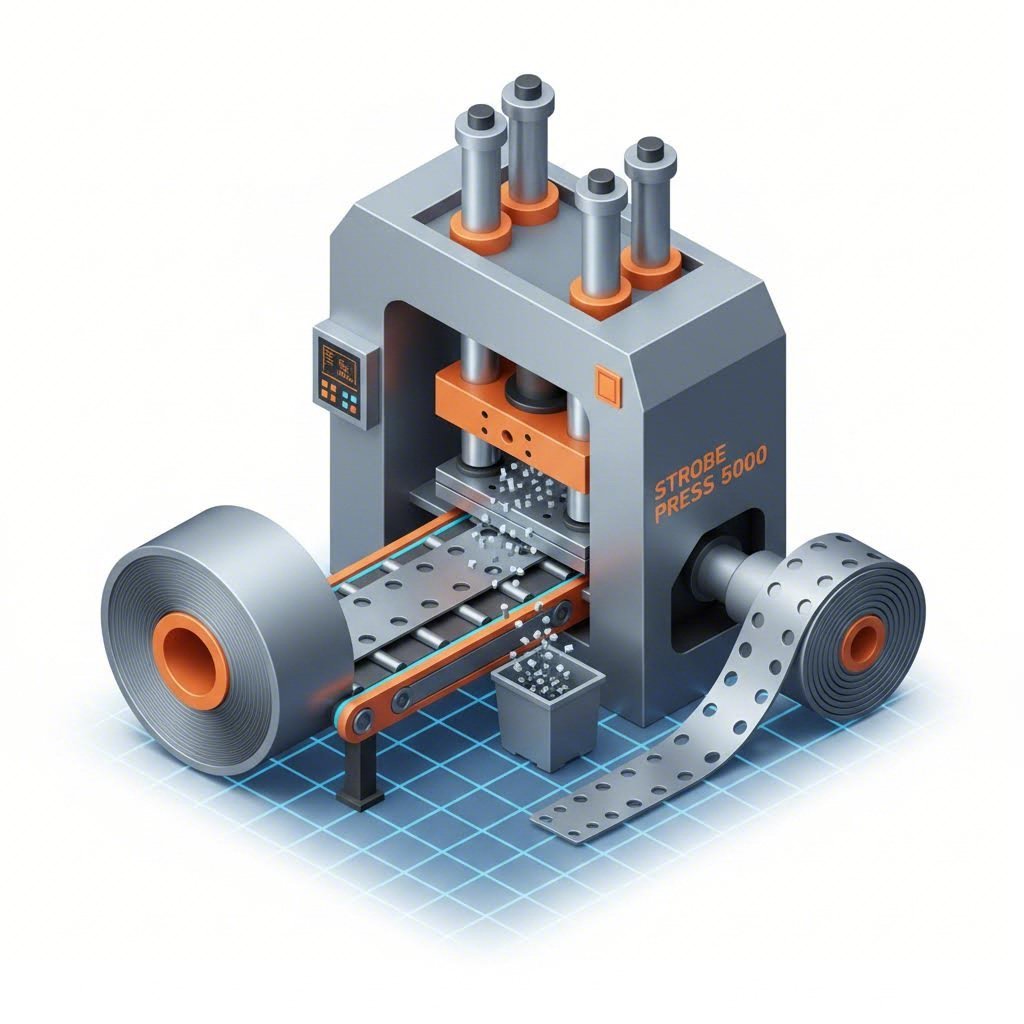

The manufacturing of fuel tank straps is not a simple bending operation; it is a sophisticated workflow that demands tight tolerances and repeatable precision. Leading manufacturers employ a one-piece flow methodology, where the strap transitions from raw material to a finished assembly within a continuous production line. This approach minimizes handling errors and maximizes structural integrity, which is vital for safety-critical components.

The process typically begins with coil feeding, where strips of steel are fed into a stamping press or roll forming machine. Depending on the design complexity, manufacturers may use progressive die stamping to punch mounting holes, emboss structural ribs, and cut the strap to length in a single pass. For high-volume production, this method ensures that every strap is identical to the millimeter. Advanced facilities utilize CAD/CAM software, such as SolidWorks, to simulate stress points before the tool creates the first part, ensuring the stamped geometry can withstand the dynamic loads of a moving vehicle.

Joining and assembly represent the final critical stages. Unlike basic welding, which can introduce heat-affected zones that weaken the metal, top-tier manufacturers often utilize orbital riveting or huck bolt fastening. These cold-forming techniques attach mounting hardware like T-bolts or spade ends without compromising the steel's temper. As noted by industry specialists like Falls Stamping, the ability to perform these operations inline—forming, welding, and riveting without moving the part—dramatically improves efficiency and quality control.

Material Specifications & Corrosion Resistance

Selecting the correct material for fuel tank straps is a balance between tensile strength, cost, and environmental durability. Since these components reside on the vehicle's undercarriage, they are constantly exposed to road debris, moisture, and corrosive de-icing salts. A failure here can lead to catastrophic fuel tank detachment.

The two primary material categories dominate the market:

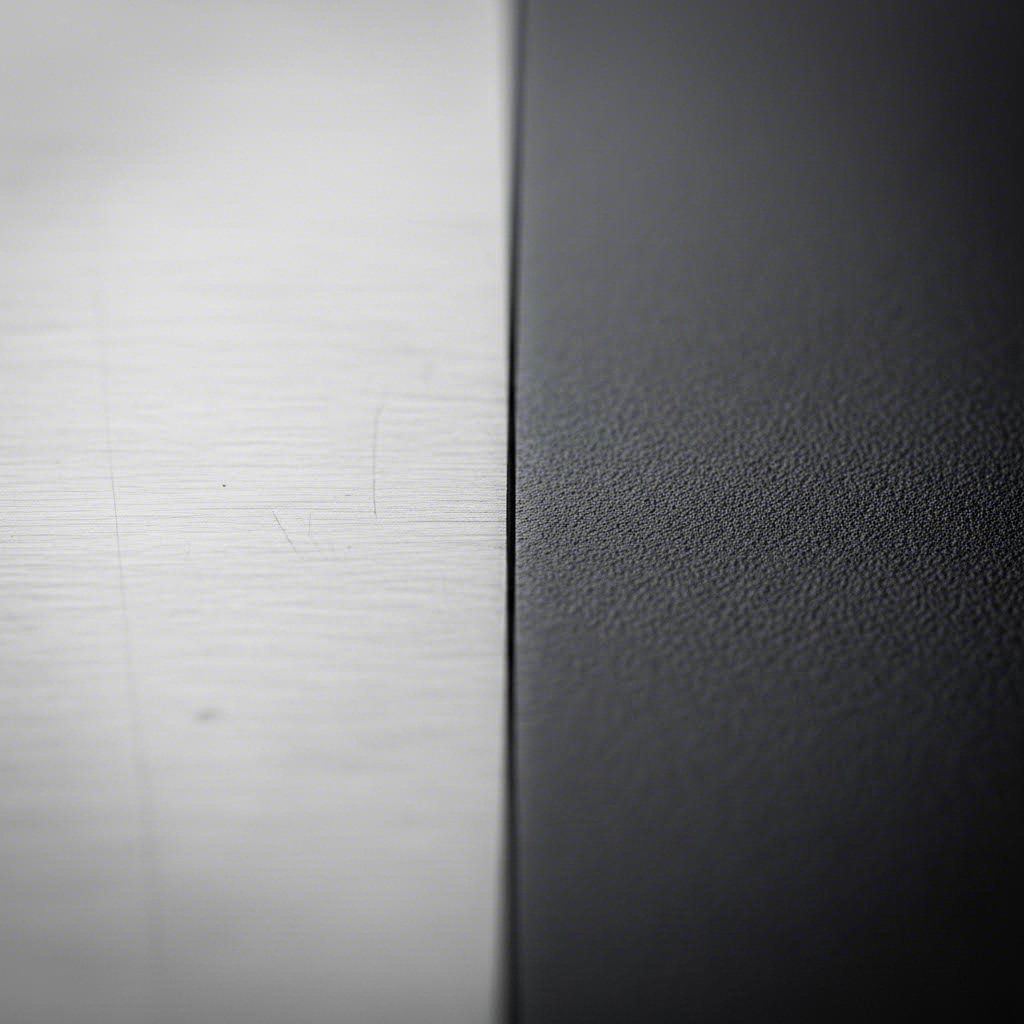

- High-Strength Carbon Steel: The industry standard for standard-duty applications. To prevent rust, these straps must undergo secondary treatments. Common finishes include zinc plating (galvanizing) or EDP (Electrophoretic Deposition) coating, which provides a durable, black, skin-like barrier against corrosion. While cost-effective, coated steel relies entirely on the integrity of its finish.

- 304 Stainless Steel: The premium choice for longevity, particularly in the "salt belt" regions or for marine applications. Stainless steel offers inherent corrosion resistance without the need for coating. Although the material cost is higher, the extended lifecycle often justifies the investment for heavy-duty trucks and restoration projects where failure is not an option.

| Feature | Zinc-Plated / EDP Steel | 304 Stainless Steel |

|---|---|---|

| Primary Benefit | Cost-Effectiveness | Maximum Durability |

| Corrosion Resistance | Moderate (dependent on coating) | High (inherent to material) |

| Tensile Strength | High (structural grade) | High (work-hardened) |

| Typical Application | Standard passenger vehicles | Heavy-duty trucks, classic cars |

Assembly, Hardware & Customization Options

A raw stamped metal band is rarely sufficient for installation; it requires a complete assembly ecosystem to function correctly. This "kitting" approach adds significant value for assembly lines and mechanics. One of the most critical additions is the anti-squeak liner. These rubber or PVC strips prevent direct metal-on-metal contact between the strap and the fuel tank, eliminating noise and, more importantly, preventing abrasion that could eventually puncture the tank.

Hardware integration is another area where stamping precision matters. Straps often feature T-bolts, loops, or spade ends that must align perfectly with the vehicle's mounting points. For example, a "spade" end might be spot-welded onto the strap, while a threaded T-bolt allows for tension adjustment during installation. Manufacturers like Mercury Products emphasize the capability to produce custom hardware configurations, ensuring that the strap assembly integrates seamlessly with unique tank geometries, whether round, rectangular, or D-shaped.

Industry Standards & Sourcing Considerations

When sourcing fuel tank strap metal stamping services, verifying a supplier's quality management system is non-negotiable. For the automotive sector, IATF 16949:2016 certification is the gold standard, ensuring the manufacturer adheres to rigorous defect prevention and supply chain consistency protocols. Additionally, ISO 9001:2015 and ISO 14001 (environmental management) signal a mature manufacturing partner capable of meeting global OEM requirements.

Volume flexibility is another key sourcing criterion. OEMs often require partners who can scale from low-volume prototyping to mass production. For automotive OEMs and Tier 1 suppliers seeking a partner with robust capabilities, Shaoyi Metal Technology offers comprehensive stamping solutions certified to IATF 16949 standards. Their facility bridges the gap from rapid prototyping—delivering 50 parts in as few as five days—to high-volume mass production, utilizing press capacities up to 600 tons for critical components. You can verify their full range of engineering and fabrication services at Shaoyi Auto Stamping Parts. This ability to scale ensures that supply chains remain uninterrupted regardless of demand fluctuations.

Finally, consider the manufacturer's testing capabilities. Reputable suppliers conduct in-house tensile testing, salt spray testing (to validate coating life), and dimensional analysis to ensure every shipment meets the "factory fit" promise. Whether sourcing for a production run of 500,000 units or a specialized batch for heavy equipment, these quality assurance measures are the firewall against field failures.

Conclusion

Mastering the production of fuel tank straps requires more than just metal bending; it demands a synergy of material science, precision engineering, and rigorous quality control. From the initial coil selection to the final orbital riveting of hardware, every step impacts the safety and longevity of the vehicle. For procurement professionals and engineers, prioritizing suppliers with proven IATF certifications, diverse material capabilities, and integrated assembly services ensures that the final product will perform reliably under the most demanding conditions.

Frequently Asked Questions

1. What are gas tank straps typically made of?

Fuel tank straps are most commonly manufactured from high-strength mild carbon steel or stainless steel. Carbon steel straps are usually finished with a zinc plating or a gloss black powder coat (EDP) to prevent rust. Stainless steel straps, often made from 304-grade material, offer superior, inherent corrosion resistance and typically feature a natural finish without the need for additional coatings.

2. What compliance labels are required on a fuel tank assembly?

While the straps themselves may not always require labeling, the fuel tank assembly must adhere to strict identification standards. Best practices and regulations typically mandate labels identifying the tank's contents (e.g., diesel vs. unleaded), volume capacity, and maximum fill height. Hazard warnings are also essential to prevent cross-contamination and ensure safe handling during maintenance or refueling.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —