Automotive Hood Stamping Process Flow: A Technical Manufacturing Guide

TL;DR

The automotive hood stamping process flow is a precision manufacturing sequence that transforms flat sheet metal blanks—typically aluminum or steel—into finished "Body-in-White" (BIW) closure assemblies. The workflow utilizes two parallel press lines to form the Hood Inner Panel (structural backbone) and Hood Outer Panel (Class A aesthetic surface) separately. Key stages include Blanking, Deep Drawing, Trimming, Piercing, and Flanging. The process culminates in the Hemming phase, where the outer panel is folded over the inner panel using mastic sealants to create a unified, rigid assembly. This guide breaks down the engineering mechanics, die line sequencing, and quality control strategies essential for modern vehicle production.

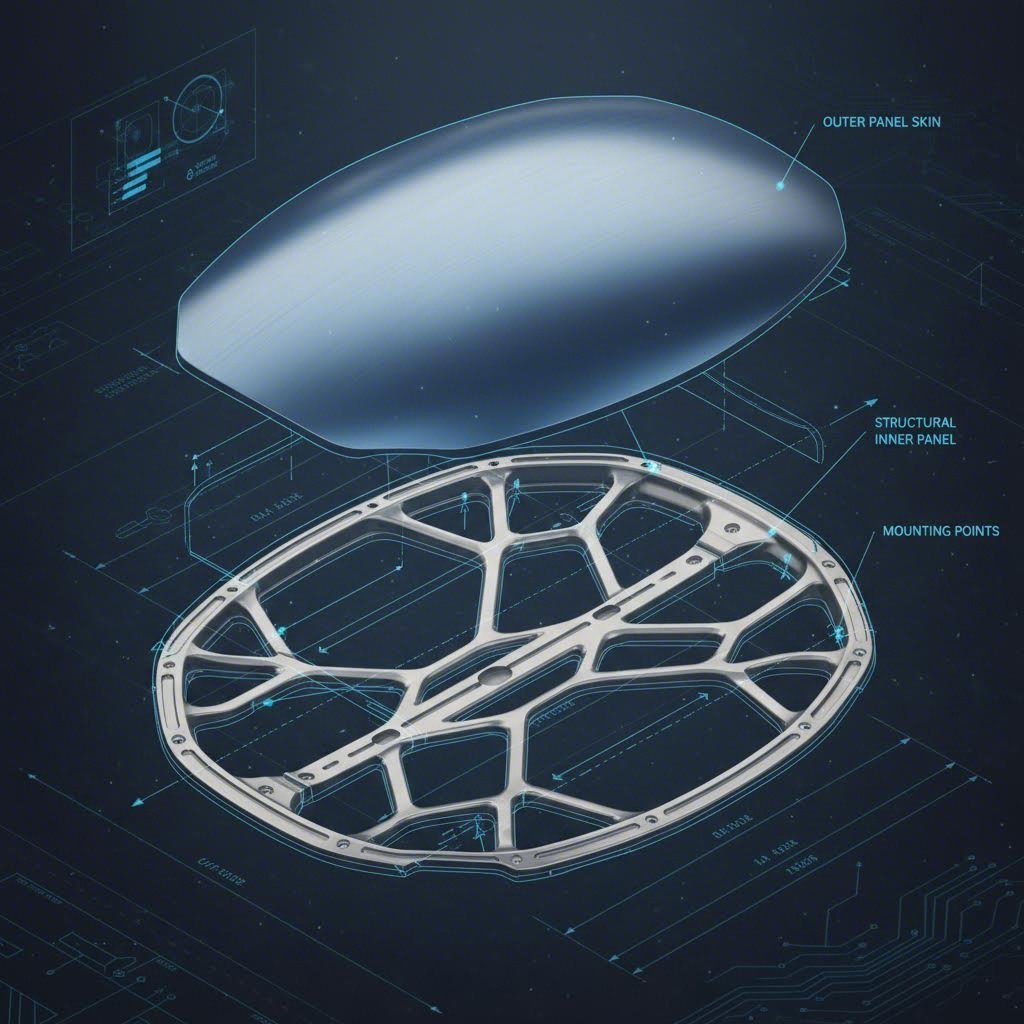

Anatomy of an Automotive Hood: Inner vs. Outer Panels

Before analyzing the production line, it is critical to distinguish between the two primary components that make up a vehicle hood (bonnet). While they travel through similar press sequences, their engineering requirements—and thus their die designs—differ significantly.

The Hood Outer Panel (Skin)

The Hood Outer Panel is the visible surface of the vehicle, requiring a flawless "Class A" finish. Its primary function is aerodynamic performance and aesthetic continuity with the fenders and grille. Because this panel is visible to the customer, surface defects like splits or wrinkles are unacceptable. Manufacturers often use aluminum alloys (like 6000-series) for the outer panel to reduce weight while maintaining dent resistance, though this introduces challenges with springback.

The Hood Inner Panel (Structure)

Hidden beneath the skin, the Hood Inner Panel acts as the structural backbone. It features complex geometries including ribs, embosses, and cutouts designed to manage collision energy (crumple zones) and reduce noise, vibration, and harshness (NVH). The inner panel also houses the mounting points for hinges, latches, and the hood prop rod. Unlike the smooth outer panel, the inner panel prioritizes geometric rigidity over surface finish, often utilizing High-Strength Steel (HSS) or specialized aluminum grades.

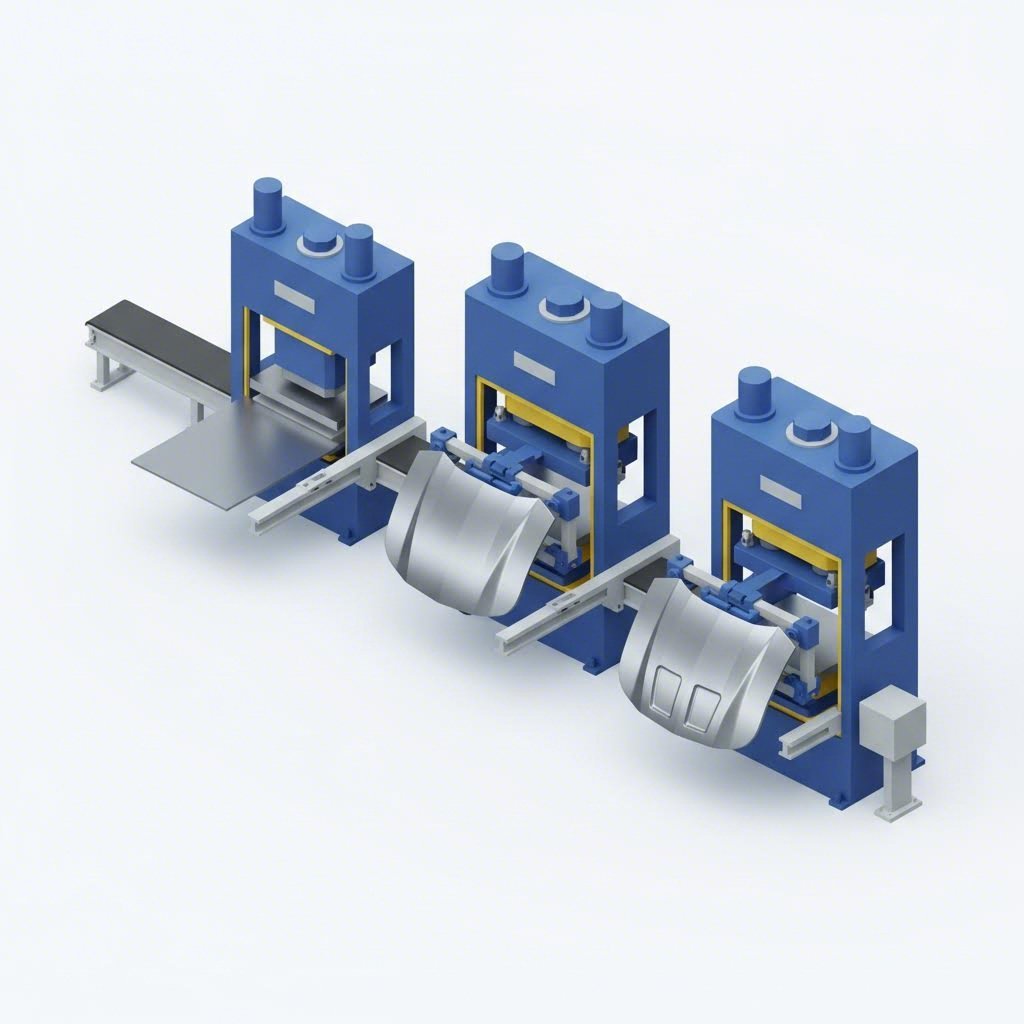

Step 1: The Press Line Operations (Stamping Sequence)

The core of the automotive hood stamping process flow occurs on the "die line," typically a tandem press line (a series of individual presses) or a transfer press (a single large press with internal transfer rails). The sequence generally involves five to six operations to shape the flat blank into a formed panel.

1. Blanking

The process begins with a coil of raw sheet metal. The coil is fed into a blanking press which cuts the material into specific 2D shapes (blanks) optimized to minimize scrap. These blanks are then washed and lubricated to prevent friction defects during the subsequent forming stages.

2. Deep Drawing (Forming)

This is the most critical operation. The flat blank is secured by a binder ring, and a punch forces the metal into a die cavity to create the 3D shape of the hood. Controlling the flow of material is essential here; insufficient pressure causes wrinkles, while excessive pressure causes splits. Deep drawing dies determine the panel's primary geometry and stiffness.

3. Trimming and Piercing

Once the shape is formed, the panel moves to the trimming station. Here, scrap metal from the binder area is cut away to achieve the final perimeter profile. Simultaneously or in a subsequent station, piercing dies punch necessary holes—vents for the inner panel or badge mounting points for the outer panel.

4. Flanging and Restriking

Flanging involves bending the edges of the panel downward (for the inner) or upward (for the outer) to prepare the mating surfaces. For the outer panel, these flanges are bent to 90 degrees to facilitate the future hemming process. A "restriking" operation is often performed at the end of the line to calibrate the part, sharpen character lines, and compensate for springback.

Achieving precision across these stages requires robust machinery. Manufacturers often rely on specialized partners for tooling and component fabrication; for instance, companies like Shaoyi Metal Technology utilize press capabilities up to 600 tons to bridge the gap from rapid prototyping to high-volume manufacturing, ensuring parts meet strict dimensional tolerances.

Step 2: The Marriage Process (Hemming & Assembly)

The defining stage of hood manufacturing is the "marriage" of the inner and outer panels. Since welding would mar the Class A surface of the outer hood, the industry relies on a mechanical joining process called hemming.

Mastic Sealant Application

Before joining, a robot applies a bead of structural adhesive (mastic) along the perimeter of the outer panel's inside surface. Additional drops of anti-flutter adhesive are placed in the center to bond the inner panel's ribs to the outer skin, preventing vibration noises at high speeds.

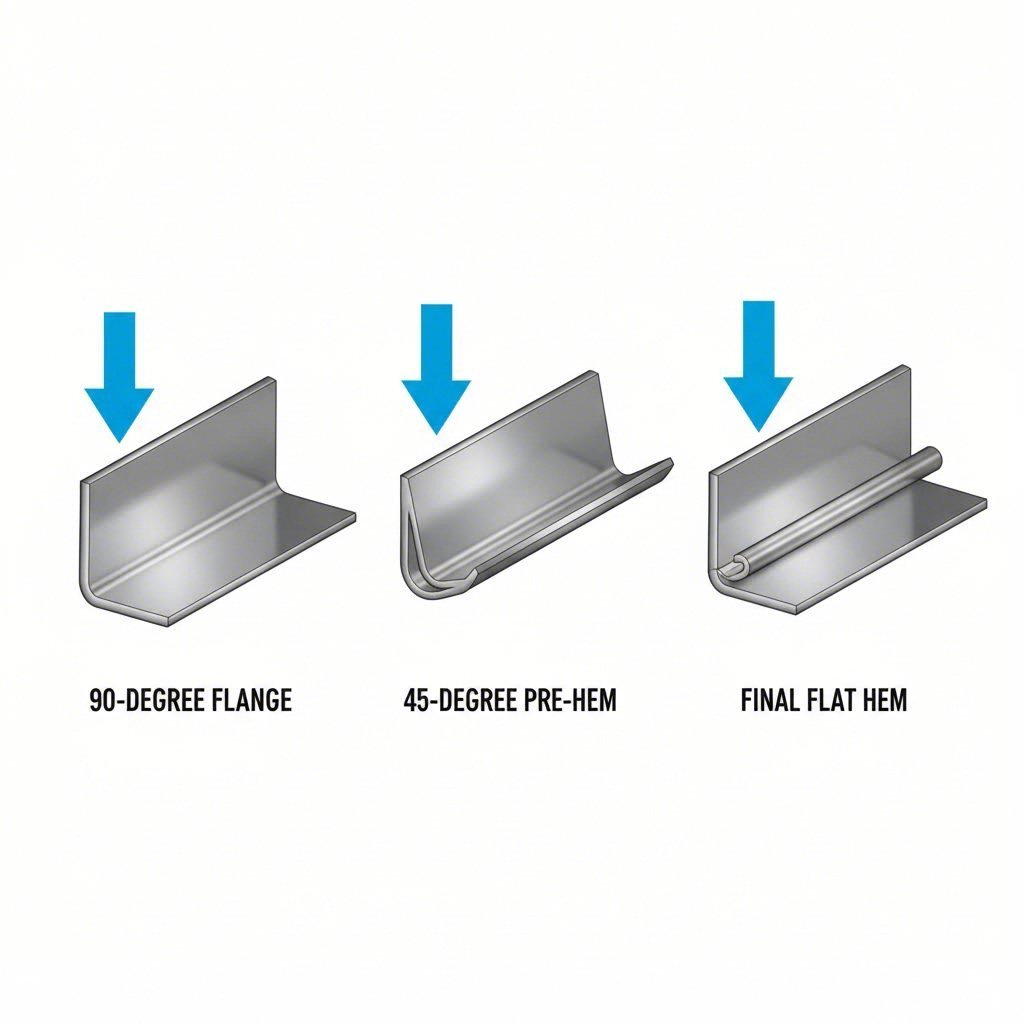

The Hemming Sequence

The inner panel is nested inside the outer panel. The 90-degree flanges of the outer panel are then folded over the edge of the inner panel in two steps:

- Pre-Hemming: The flange is bent from 90 degrees to approximately 45 degrees.

- Final Hemming: The flange is pressed flat (rope or flat hem) against the inner panel, locking the two structures together.

Die Hemming vs. Roller Hemming

There are two primary methods for this operation. Conventional Die Hemming uses a dedicated die to fold the entire flange in one stroke. It is extremely fast and accurate, making it ideal for high-volume mass production. However, the tooling is expensive. In contrast, Robotic Roller Hemming uses a robot arm with a roller tool to progressively fold the edge. This method is more flexible and cost-effective for lower volumes or complex contours but has a longer cycle time.

Quality Control & Defect Prevention Strategy

Ensuring the final assembly meets automotive standards requires rigorous quality control. Defect prevention starts with simulation software during the die design phase to predict material behavior.

Common Surface Defects

- Springback: The tendency of metal (especially aluminum) to return to its original shape after forming. Engineers compensate by over-bending the metal in the die.

- Orange Peel: A rough, textured surface caused by excessive grain stretching, which ruins the paint finish.

- Skid Lines: Scratches caused by the sheet metal dragging over the die radius during the drawing phase.

Inspection typically involves Blue Light Scanning to generate a digital heat map of the part's deviations from the CAD model, as well as traditional "checking fixtures" where operators verify gap and flush tolerances manually. Maintaining these standards is vital, as the hood is a major visual focal point of the vehicle.

Engineering the Perfect Closure

The automotive hood stamping process flow is a synergy of heavy industrial force and micron-level precision. From the initial blanking of the coil to the delicate robotic hemming that marries the inner and outer panels, every step must be synchronized to ensure structural safety and aesthetic perfection. As the industry shifts toward lighter materials like aluminum and composites to improve fuel efficiency, the complexity of these stamping and assembly techniques continues to evolve, demanding ever-higher standards from manufacturing engineers and die designers.

Frequently Asked Questions

1. What are the main steps in the automotive hood stamping process?

The process typically involves five to six key steps per panel: Blanking (cutting the shape), Deep Drawing (forming the 3D profile), Trimming (removing excess metal), Piercing (creating holes), Flanging (bending edges), and finally Hemming (joining the inner and outer panels).

2. Why is hemming used instead of welding for car hoods?

Hemming is used because spot welding would create visible burns, dimples, or distortion on the exterior "Class A" surface of the hood. Hemming mechanically folds the outer panel over the inner panel, creating a strong bond without marring the visible aesthetic surface.

3. What is the difference between the hood inner and outer panels?

The Hood Outer Panel is designed for aesthetics (smooth curves, aerodynamic shape) and must be free of surface defects. The Hood Inner Panel is designed for structural strength, impact absorption (crumple zones), and component mounting, featuring complex ribs and cutouts rather than a smooth finish.

4. What materials are commonly used for stamping car hoods?

Modern car hoods are typically stamped from mild steel, High-Strength Steel (HSS), or aluminum alloys. Aluminum is increasingly popular for hoods because it significantly reduces weight compared to steel, improving fuel economy and handling, though it is more challenging to stamp due to higher springback.

5. What is springback in sheet metal stamping?

Springback is the elastic recovery of metal after the forming load is removed. The metal tries to return to its original flat shape, which can cause the final part to deviate from the intended dimensions. Die engineers use simulation and "over-crowning" techniques to compensate for this effect.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —