Fine Blanking vs. Standard Stamping Automotive: Engineering Guide

TL;DR

In the automotive industry, the choice between fine blanking vs standard stamping fundamentally comes down to edge quality and functional requirements. Fine blanking is a precision cold-extrusion process that uses a triple-action press to create parts with 100% smooth, sheared edges and extremely tight tolerances (±0.0005 inches), eliminating the need for secondary machining. It is the standard for safety-critical, moving parts like seat recliners and transmission gears.

Standard stamping (or conventional stamping), while faster and cheaper for initial tooling, leaves a rough "die break" or fracture zone on the edge. It is best suited for static structural components like brackets and chassis reinforcements where edge finish is secondary to cost and speed. For engineers, the decision rests on whether the part requires a ready-to-assemble functional edge or if post-processing is acceptable.

The Core Mechanism: Triple-Action vs. Single-Action

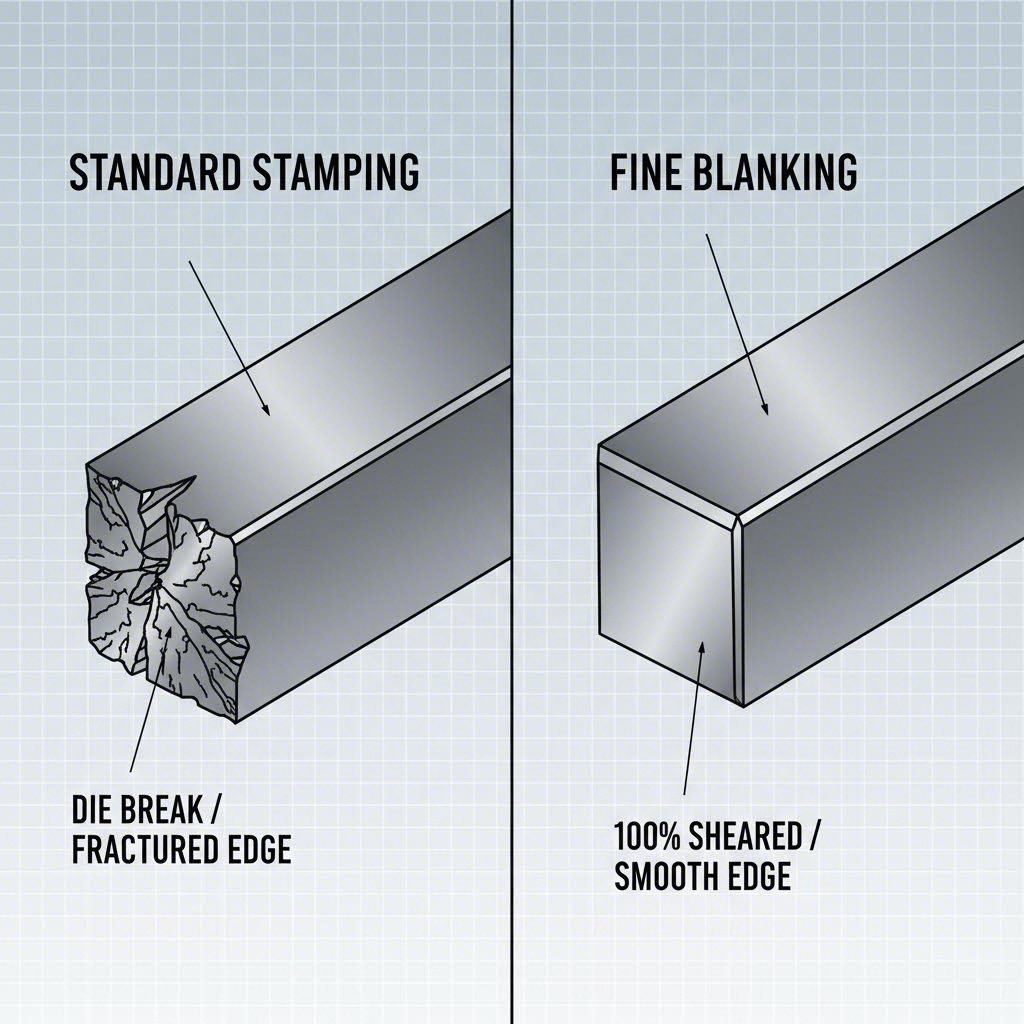

The primary differentiator between these two manufacturing methods lies in the mechanics of the press. Standard stamping typically utilizes a single-action or double-action press. The punch descends, impacts the metal, and shears it until the material creates a fracture. This uncontrolled fracture results in the characteristic "die break"—a rough, tapered edge that often comprises two-thirds of the material thickness.

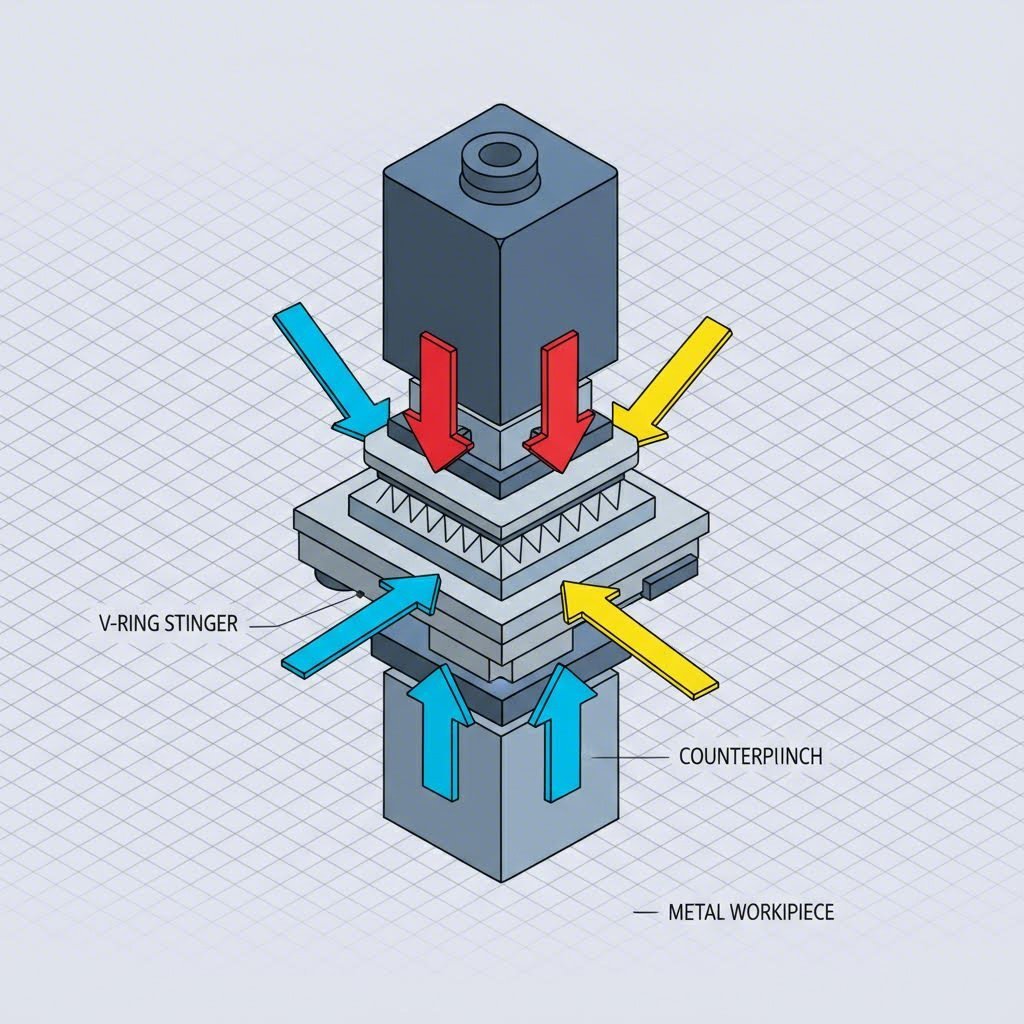

Fine blanking, however, operates on a triple-action press system that controls the material flow throughout the entire cutting cycle. This process is more akin to cold extrusion than traditional cutting. The three distinct forces are:

- The Stinger (V-Ring): Before any cutting begins, a V-shaped impingement ring (stinger) on the guide plate presses into the material surrounding the perimeter of the cut. This locks the metal in place, preventing lateral material flow and ensuring the material does not tear.

- The Punch: The punch descends to cut the part, but unlike standard stamping, it moves at a slower, controlled velocity.

- The Counterpunch: A counterpunch applies upward pressure against the part from below, holding it flat against the punch face.

This synchronized clamping and counter-pressure prevents the material from fracturing. Instead, the metal is plastically deformed and extruded cleanly from the strip. The result is a part that retains the exact thickness of the raw sheet without the "dishing" or bowing often seen in standard stamped components.

Edge Quality & Precision: The 100% Sheared Edge

For automotive engineers, the most visible difference is the edge condition. In standard stamping, the edge profile consists of a small "roll-over" at the top, a "shear zone" (smooth cut) for about one-third of the thickness, and a "fracture zone" (rough break) for the remainder. This fracture zone can introduce micro-cracks and stress risers, which are unacceptable for high-stress applications.

Fine blanking delivers a 100% sheared edge. The edge is completely smooth and perpendicular to the part surface from top to bottom. This eliminates the need for secondary operations like shaving, grinding, or reaming. If a part acts as a bearing surface—such as a parking pawl in a transmission or a latch in a door lock—fine blanking provides the necessary surface finish directly out of the press.

Tolerance Comparison: Fine Blanking vs. Standard Stamping

| Feature | Fine Blanking | Standard Stamping |

|---|---|---|

| Edge Condition | 100% Smooth Sheared Edge | ~30% Shear, ~70% Die Break |

| Typical Tolerances | ±0.0005" to ±0.001" (0.013mm) | ±0.005" to ±0.010" (0.13mm) |

| Hole Diameter | Can be 50-60% of material thickness | Typically min. 100% of material thickness |

| Webbing (Hole to Edge) | Very thin (approx. 60% of thickness) | Requires wider spacing (1.5x thickness) |

| Flatness | High (supported by counterpunch) | Moderate (often requires flattening) |

Furthermore, fine blanking allows for complex geometries that standard stamping cannot achieve. It permits holes smaller than the material thickness and web sections (the distance between a hole and the edge) that are much narrower, offering designers greater freedom to minimize part size and weight without sacrificing structural integrity.

Automotive Applications: When to Use Which

The choice of process is almost always dictated by the part's function within the vehicle. If the component moves, meshes, or locks against another part, fine blanking is usually the required specification. If the component is static and structural, standard stamping is preferred for its economy.

-

Fine Blanking Applications (Dynamic/Safety-Critical):

- Seating Systems: Recliner mechanisms, height adjusters, and track latches. These parts require perfectly flat surfaces to function smoothly without binding.

- Powertrain: Transmission parking pawls, clutch plates, planetary gear carriers, and throttle bodies. The smooth edges act as bearing surfaces, reducing friction and wear.

- Safety Systems: Seatbelt tongues, buckles, and airbag firing mechanisms. The reliability of the 100% sheared edge is critical for safety certification.

- Braking: ABS sensor rings and brake backing plates where flatness is non-negotiable.

-

Standard Stamping Applications (Static/Structural):

- Chassis & Body: Mounting brackets, heat shields, structural reinforcements, and washers.

- Exhaust Systems: Flanges and hangers where edge roughness does not impact performance.

- Fluid Handling: Covers and caps where sealing is handled by gaskets rather than the metal edge itself.

Engineers must also consider the material. Fine blanking is ideal for steels with good cold-forming properties (spheroidized annealed steels) but struggles with extremely brittle or high-carbon materials that might fracture even under triple-action pressure.

Cost Analysis: Tooling, Speed, and Total Landed Cost

A direct comparison of piece price often favors standard stamping, but a Total Landed Cost analysis frequently swings the decision toward fine blanking for complex parts. Fine blanking presses run slower—typically 40 to 100 strokes per minute (SPM)—compared to progressive standard stamping presses that can exceed 1,000 SPM. Additionally, fine blanking presses and tooling are significantly more expensive due to the hydraulic complexity and high-precision die clearances.

However, the economic advantage of fine blanking appears when secondary operations are eliminated. A standard stamped gear might require stamping, flattening, deburring, and CNC milling of the teeth. A fine blanked gear comes off the press finished. The cost of those three eliminated steps often outweighs the higher initial stamping cost.

For automotive programs bridging the gap from rapid prototyping to high-volume manufacturing, selecting a partner with diverse capabilities is essential. Suppliers like Shaoyi Metal Technology offer a strategic advantage by providing comprehensive stamping solutions that scale from initial prototypes (delivering 50 parts in as little as five days) to mass production. Their IATF 16949-certified facilities and press capabilities up to 600 tons allow engineers to validate designs using the appropriate method—whether standard stamping for brackets or precision forming for control arms—ensuring global OEM standards are met without overpaying for unnecessary precision.

Ultimately, procurement teams should evaluate the "cost to assembly." If a standard stamped part causes assembly line jams due to burrs or requires manual inspection for flatness, the apparent savings vanish. Fine blanking offers process reliability that translates to lower risk and higher uptime in the final assembly plant.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —