A Professional's Guide to Sourcing Forged Car Parts

TL;DR

Sourcing forged car parts requires a B2B approach focused on identifying credible manufacturing partners. The primary methods involve contracting directly with forging companies for custom or high-volume orders, utilizing comprehensive B2B supplier directories to find and vet potential vendors, or working with specialized distributors for specific components. Key evaluation criteria must include material specialization, production capabilities, quality certifications like IATF 16949, and minimum order quantities to ensure a successful partnership.

Understanding the Sourcing Channels for Forged Parts

Choosing the right channel to source forged automotive components is critical and depends entirely on your specific needs, such as order volume, customization requirements, and budget. The landscape is primarily divided into three main avenues, each catering to different types of buyers, from large-scale OEMs to niche performance builders.

Direct-from-Manufacturer

Engaging directly with a forging company is the most common path for OEM-level production and large-scale custom orders. Companies like Carbo Forge and Jimaforging specialize in producing specific components, from drivetrain yokes to control arms, often using materials like carbon, alloy, and stainless steel. This channel offers the highest degree of control over the design, material selection, and quality assurance process. However, it typically involves high minimum order quantities (MOQs) and longer lead times for tooling and production, making it less suitable for one-off projects or small batches.

B2B Supplier Directories

For those in the research and vetting phase, B2B directories are invaluable resources. Platforms like Thomasnet provide extensive, filterable lists of forging suppliers. These directories allow you to search for companies based on location, certifications, capabilities, and even diversity ownership. This channel is excellent for creating a shortlist of potential partners and sending out Requests for Quotation (RFQs) to multiple vendors simultaneously. The main advantage is the breadth of options, but it places the responsibility of thorough vetting and due diligence squarely on you.

Specialized Auto Parts Distributors

For individuals, restoration shops, or performance builders who need smaller quantities or even single aftermarket forged components, specialized distributors are the ideal channel. These suppliers stock parts from various manufacturers and can provide off-the-shelf solutions. While this channel offers convenience and low-volume accessibility, it provides little to no room for customization and may come at a higher per-unit cost compared to bulk orders directly from a manufacturer.

| Sourcing Channel | Best For | Pros | Cons |

|---|---|---|---|

| Direct-from-Manufacturer | High-volume, OEM, custom parts | High customization, cost-effective at scale, direct quality control | High MOQs, long lead times, significant initial investment |

| B2B Supplier Directories | Research, vetting, and comparing multiple suppliers | Wide selection, easy to compare, efficient RFQ process | Requires extensive vetting, quality can vary |

| Specialized Distributors | Single units, aftermarket parts, small batches | Low/no MOQs, immediate availability, convenience | Higher per-unit cost, no customization, limited selection |

Key Criteria for Selecting a Forging Supplier

Once you have identified a potential sourcing channel, the next step is to evaluate and select the right supplier. A forging partner is a long-term investment, and making an informed decision requires careful consideration of several technical and business factors. A thorough vetting process will prevent costly mistakes and ensure the final components meet your performance and quality standards.

Material Specialization and Expertise

Not all forges work with all metals. It is crucial to partner with a supplier that has demonstrated expertise in the specific material your project requires. Whether it's carbon and alloy steels for strength, or lightweight aluminum for performance parts as offered by specialists like Al Forge Tech, the supplier’s experience with that material will directly impact the quality of the final part. Ask for case studies or examples of similar components they have produced.

Production Capabilities and Technology

Understand the supplier's forging capabilities. Do they offer open-die, closed-die, or rolled ring forging? Do they have in-house capabilities for secondary operations like CNC machining, heat treatment, and surface finishing? A partner with comprehensive, end-to-end services can streamline your supply chain, reduce lead times, and ensure greater consistency from raw material to finished part.

Quality Certifications and Standards

In the automotive industry, quality is non-negotiable. Look for suppliers with relevant certifications, the most important being IATF 16949, which is the international standard for automotive quality management systems. This certification indicates that the supplier has robust processes for quality control, traceability, and continuous improvement. For businesses seeking a partner with proven quality management and versatile production, companies like Shaoyi Metal Technology offer IATF 16949 certified hot forging services that cover everything from rapid prototyping to mass production.

Cost, Lead Time, and Minimum Order Quantity (MOQ)

Finally, assess the business terms. Request detailed quotes that break down tooling costs, per-unit costs, and any fees for secondary services. It is essential to balance cost with quality; the cheapest option is rarely the best in high-performance applications. Clarify their lead times for both initial samples and full production runs. Also, confirm their MOQ aligns with your project's scale to ensure the partnership is viable for both parties.

Directory of Top Automotive Forging Companies

Navigating the landscape of forging suppliers can be challenging. To provide a starting point, here is a curated list of notable automotive forging companies in the USA, recognized for their quality and industry presence. This list, inspired by industry resources like Zetwerk, can help you identify potential partners.

- Zetwerk: A global manufacturing network that provides a wide range of forging services, including cold, open-die, and closed-die forging. They serve as a comprehensive partner, managing the entire supply chain from production to delivery for various automotive components.

- Sypris Solutions: A key supplier for the automotive, oil, and gas industries, Sypris manufactures a variety of forged drivetrain components and other parts. They often operate under exclusive agreements with major OEMs.

- Powers & Sons, LLC: This Tier 2 supplier focuses on forged steering and suspension components, such as tie-rod ends and control arms. They serve both the OEM and aftermarket sectors from their facilities in Ohio.

- Aichi Forge USA, LLC.: As a subsidiary of Japan's Aichi Steel, this Kentucky-based company manufactures critical forged auto parts like crankshafts and driveshafts using various steel alloys.

- American Axle & Mfg. Inc. (AAM): AAM is a major player in the automotive supply chain, providing parts for powertrains, drivetrains, and engines. Their capabilities include hot, warm, and cold forging processes to produce a wide array of components.

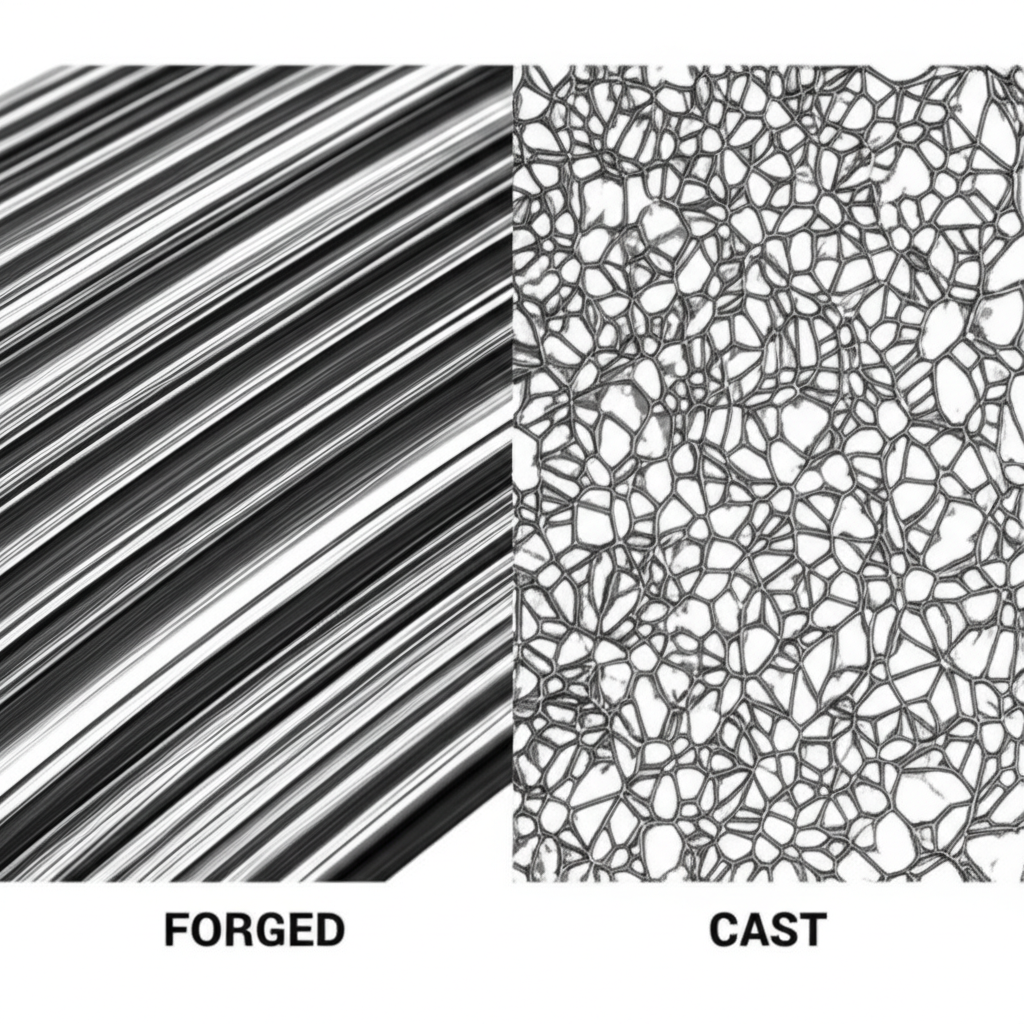

How to Identify Forged vs. Cast Parts

For buyers and mechanics, distinguishing between a forged and a cast part is a crucial skill, as it directly relates to the component's strength and performance characteristics. While they may look similar at a glance, several tell-tale signs reveal their manufacturing origin. Understanding these differences can help you verify that you are sourcing or using the correct type of component for a high-stress application.

The most obvious identifier is the parting line—a thin line or ridge where the two halves of a mold or die meet. On a cast part, this line is typically raised and sharp, as molten metal seeps into the seam. On a forged part, the parting line is usually broader, smoother, and less defined, appearing more like a gentle wave than a sharp ridge. Furthermore, the surface texture can be a clue. Forgings often have a more uniform, slightly textured surface from the die, and may show directional grain flow, whereas castings can have a rougher, more pitted, or sand-like texture from the mold material.

| Characteristic | Forged Part | Cast Part |

|---|---|---|

| Strength & Durability | Superior due to refined grain structure | Lower; grain structure is random and can be porous |

| Parting Line | Broad, smooth, and often irregular | Sharp, raised, and relatively well-defined |

| Surface Finish | Varies depending on the process; can be rougher than some casting methods | Can be rough or pitted, depending on the casting method |

| Sound When Tapped | Sound produced is not a reliable identification method. | Sound produced is not a reliable identification method. |

Making an Informed Sourcing Decision

Sourcing forged car parts is a strategic process that directly impacts the performance, safety, and cost of your final product. The optimal approach begins with clearly defining your project's needs—volume, level of customization, and material requirements. By understanding the distinct advantages of each sourcing channel, from direct manufacturing partnerships to agile B2B directories, you can effectively narrow down your search. Ultimately, the best supplier is not just a vendor but a partner. Performing rigorous due diligence on their technical capabilities, quality systems, and business practices is the key to building a resilient and successful supply chain.

Frequently Asked Questions

1. How can you tell if a part is forged?

You can often identify a forged part by examining its physical characteristics. Forged parts typically have a broad, smooth parting line where the dies met, unlike the sharp, raised line on cast parts. Their surface finish is generally uniform, and they may exhibit faint tool marks. The denser, more uniform grain structure of a forged part means it may produce a clearer ring when tapped with a metal object, while the potentially more porous structure of a cast part may result in a duller sound.

2. What are the 4 types of forging?

While there are many specific techniques, the four main types of forging processes are open-die forging, where the metal is shaped between flat dies; impression die forging (or closed-die), where the metal is pressed into a die that contains a specific shape; cold forging, which is performed at or near room temperature; and seamless rolled ring forging, used to create ring-shaped components.

3. What is a good profit margin for auto parts?

For businesses involved in the resale of auto parts, a healthy profit margin is typically considered to be between 20% and 30%. This margin allows a business to cover its operational costs, including sourcing, inventory, and marketing, while generating a sustainable profit. However, the exact margin can vary widely based on the part type, brand, and market competition.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —