Essential Criteria for Forged Suspension Manufacturers

TL;DR

A forged suspension components manufacturer specializes in creating high-strength, lightweight parts like control arms and ball joints for performance and severe-duty vehicles. The forging process yields components with superior durability and strength-to-weight ratios compared to casting or machining from billet. This makes forged parts essential for automotive reliability, handling, and safety in demanding applications from motorsports to off-road trucks.

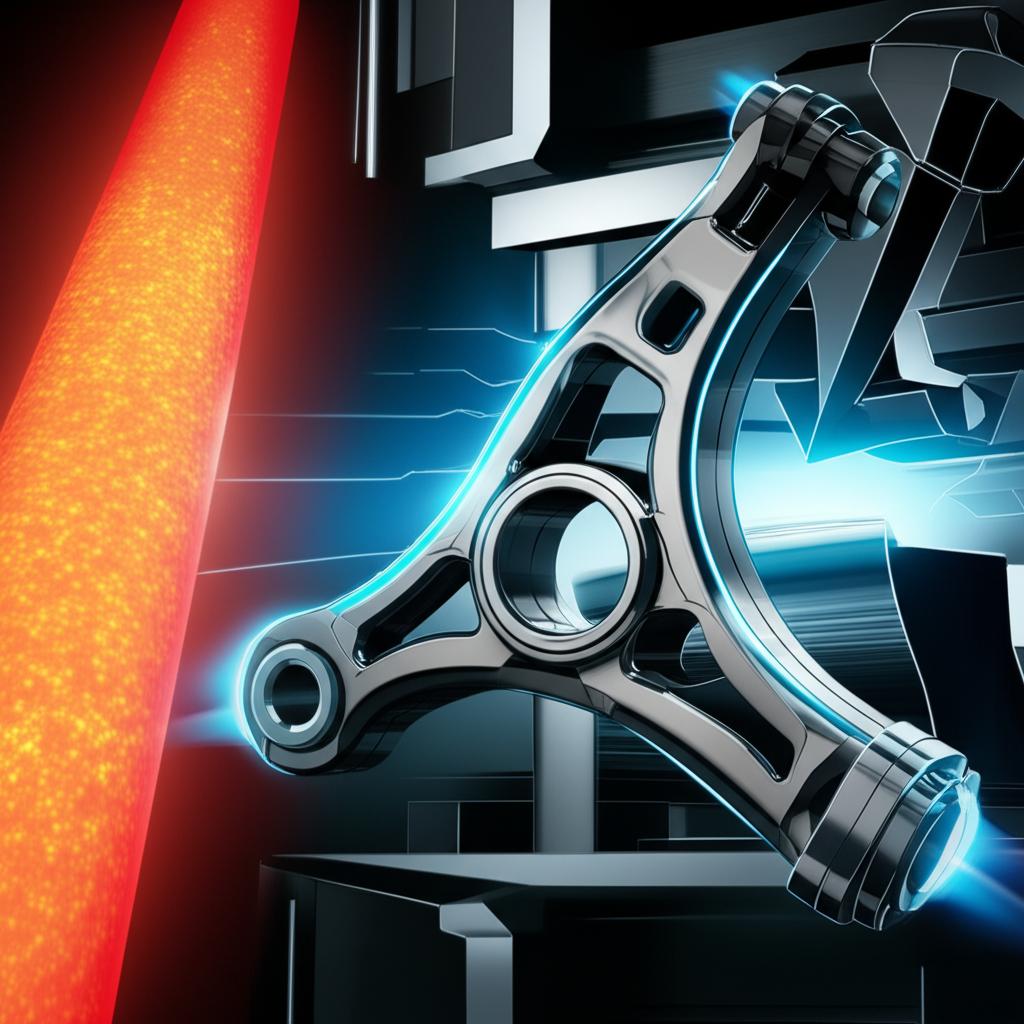

Why Forged Suspension Components Are Superior

In high-stress automotive applications, the manufacturing process of a component is as critical as its design. Forged suspension parts offer significant performance advantages over parts made by other methods, such as casting or machining. The primary benefit lies in the material's grain structure. Forging, which involves shaping metal using localized compressive forces, refines and directs the grain flow, aligning it with the shape of the part. This creates a component with exceptional tensile strength, fatigue resistance, and impact toughness that is free of the porosity or voids that can occur in casting.

Compared to their cast counterparts, forged components are denser and more durable. Casting involves pouring molten metal into a mold, which can sometimes lead to inconsistencies and a weaker, more brittle final product. While machining a part from a solid block of billet aluminum or steel offers precision, it cuts through the metal's natural grain structure, creating potential weak points. Forging maintains this structural integrity, resulting in parts that can withstand higher loads and stresses. According to experts at CFS Forge, this is why forged aluminum parts are a top choice for high-performance and racing vehicles where reducing unsprung weight while maximizing strength is paramount.

Forged vs. Cast vs. Billet Comparison

Understanding the core differences helps clarify why forging is often the preferred method for critical suspension components.

| Attribute | Forged | Cast | Billet (Machined) |

|---|---|---|---|

| Strength | Highest strength-to-weight ratio due to refined grain structure. | Lower strength; can be brittle and prone to porosity. | Strong, but strength depends on the raw material block; grain flow is severed. |

| Durability | Excellent fatigue and impact resistance. | More susceptible to cracking under high stress. | Good durability, but can be less resilient to impact than forged parts. |

| Weight | Can be made very lightweight without sacrificing strength. | Generally heavier than forged parts to achieve similar strength. | Weight depends on the design; often requires more material to ensure strength. |

| Cost | Moderate to high due to tooling costs, but efficient for high volumes. | Lower tooling costs, making it suitable for complex shapes and lower volumes. | High due to material waste and long machining times. |

How to Select a Forged Suspension Manufacturer

Choosing the right manufacturing partner is crucial for ensuring the quality, reliability, and performance of your vehicle's suspension system. When evaluating a forged suspension components manufacturer, several key criteria should be considered to ensure they meet your technical and operational requirements.

- Material Specialization: Manufacturers often specialize in specific materials. For example, Carbo Forge is known for its work with carbon, alloy, and stainless-steel forgings. Others may focus on aluminum alloys, which are prized for their lightweight properties in racing and performance applications. Ensure the manufacturer's material expertise aligns with your component's design needs for strength, weight, and corrosion resistance.

- Industry Certifications: A critical indicator of quality and process control is industry certification. For the automotive sector, IATF 16949 is the global standard. A manufacturer that is IATF 16949 certified, like Carbo Forge, has demonstrated a commitment to rigorous quality management systems, continuous improvement, and defect prevention throughout the supply chain.

- Engineering and Design Capabilities: Leading manufacturers offer more than just production. They provide comprehensive engineering support, including design optimization and simulation. For instance, Aichi Forge USA utilizes advanced software like AutoCAD, ProE, and Simufact to model and refine die designs for optimal material flow and production efficiency. This capability ensures parts are designed for manufacturability and peak performance.

- Application Expertise: Look for a manufacturer with a proven track record in your specific application. Whether you need components for extreme duty off-road trucks, like those Multimatic supplies, or severe-duty parts for commercial vehicles, a partner with relevant experience will understand the unique stresses and performance demands involved.

- Production Scale and In-House Processes: A vertically integrated manufacturer with in-house die manufacturing, like Aichi Forge, can offer better control over quality, lead times, and costs. Assess their capacity to handle your volume needs, from initial prototyping to full-scale production runs.

Leading Forged Suspension Component Manufacturers

The market for forged suspension components features a range of specialists, from large-scale OEM suppliers to niche performance brands. Here are some of the notable manufacturers making an impact in the automotive industry.

Shaoyi Metal Technology

For those seeking custom solutions, Shaoyi Metal Technology offers robust and reliable hot forging services for the automotive industry. As an IATF 16949 certified company, they specialize in high-quality components and manage the entire process from rapid prototyping for small batches to full-scale mass production. With in-house die manufacturing and a strategic location, they provide precision, efficiency, and timely global delivery. You can learn more about their advanced automotive forging solutions on their website.

Proforged

Known for its focus on high-performance, severe-duty chassis parts, Proforged has built a strong reputation among mechanics and enthusiasts. They offer a wide range of steering and suspension components, including durable ball joints, tie rod ends, and control arms, often backing them with an impressive million-mile warranty. Their product line is engineered to be a high-strength alternative to standard OE replacement parts.

Aichi Forge USA, Inc.

A subsidiary of Aichi Steel, Aichi Forge is a major supplier of precision steel forgings. They manufacture a diverse portfolio of products, including chassis components like suspension and axle parts, as well as powertrain and drivetrain components. Their commitment to quality is evident in their advanced engineering services and in-house die manufacturing, serving the automotive, truck, and industrial markets.

Carbo Forge

Carbo Forge is an IATF 16949 certified company that provides carbon, alloy, and stainless-steel forgings. They supply a wide array of automotive components, from hubs and spindles to tie-rods and suspension arms. The company emphasizes its world-class operating efficiencies and consistency in quality to maximize customer uptime, a critical factor in the automotive supply chain.

Multimatic

Multimatic is a global automotive supplier known for its advanced engineering and manufacturing capabilities. Their suspension division produces components for a range of applications, from high-volume production vehicles to extreme duty and motorsports. They manufacture everything from stamped steel control arms and ball joints to forged steel components for off-road vehicles and forged aluminum arms for high-performance cars like the Ford Raptor.

A Look Inside the Automotive Forging Process

The creation of a forged suspension component is a multi-stage process that transforms a simple metal billet into a precisely engineered part with superior mechanical properties. While there are variations, the hot impression die forging process is common for automotive applications and generally follows these key steps.

- Design and Simulation: Before any metal is heated, engineers design the component and the forging dies using CAD software. Advanced simulation software is then used to model the forging process, predicting how the metal will flow into the die cavity. This helps optimize the design for strength and minimize material waste.

- Die Creation and Material Preparation: Based on the final design, hardened steel dies are machined in-house to create the negative impression of the part. Meanwhile, raw material (steel or aluminum alloy) is cut into billets of a specific size and weight required for the final component.

- Heating and Forging: The billets are heated in a furnace to a precise temperature, making them malleable but not molten. The glowing hot billet is then placed on the bottom die in a forging press. An upper die is then pressed down with immense force, compelling the metal to flow and fill the die cavity, taking on the desired shape.

- Trimming and Finishing: After forging, the part has excess material around its edges known as 'flash'. This flash is removed in a trimming press. The component then undergoes finishing processes, which can include heat treatment to further enhance its strength and durability, shot blasting to clean the surface, and machining to achieve final critical dimensions and a smooth surface finish.

- Quality Control: Throughout the process, parts are subjected to rigorous quality assurance checks. This includes hot inspections on the production line and detailed measurements using CMM (Coordinate Measuring Machine) equipment to ensure every component meets exacting standards for dimensional accuracy and structural integrity.

Frequently Asked Questions

1. Which is the world's largest forging company?

According to public information, Bharat Forge, headquartered in Pune, India, is widely considered to be one of the world's largest forging companies. It is a major multinational provider of forged and machined components for a wide range of industries, including automotive, aerospace, and energy.

2. What products does Aichi Forge manufacture?

Aichi Forge USA manufactures a variety of custom precision steel forgings for the automotive industry. Their products are categorized into three main groups: Chassis Components (including suspension and axle parts), Powertrain Components (such as crankshafts and connecting rods), and Drivetrain Components (like heavy-duty drive axle gearing).

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —