Essential Strategies to Prevent Springback in Metal Stamping

TL;DR

Springback is the elastic recovery of sheet metal after forming, which can cause dimensional inaccuracies in finished parts. Preventing it requires a multi-faceted approach. Key strategies include mechanical compensation techniques like overbending (bending beyond the target angle), coining (applying high pressure to the bend), and post-stretching, which uses features like stake beads to create tension and stabilize the part. Advanced methods involve optimizing tooling, leveraging Finite Element Analysis (FEA) for die design, and careful material selection to mitigate the material's natural tendency to return to its original shape.

Understanding the Root Causes of Springback

In sheet metal stamping, springback is the geometric change a part undergoes after the forming pressure is released. This phenomenon is rooted in the fundamental properties of metal. When a sheet is bent, it experiences both permanent (plastic) and temporary (elastic) deformation. The outer surface is stretched under tensile stress, while the inner surface is compressed. Once the tooling is removed, the stored elastic energy is released, causing the material to partially revert to its original form. This recoil is springback, and it can lead to significant deviations from design specifications.

Several key factors directly influence the severity of springback. Material properties are paramount; metals with a high yield strength-to-Young's Modulus ratio, such as Advanced High-Strength Steels (AHSS), store more elastic energy and thus exhibit more pronounced springback. As noted in a technical guide by ETA, Inc., this is a primary reason why modern lightweighting materials present greater manufacturing challenges. Material thickness also plays a role, as thicker sheets generally show less springback due to a larger volume undergoing plastic deformation.

Part geometry is another critical factor. Components with large bend radii, complex curves, or sharp angles are more susceptible to springback. Finally, process parameters—including stamping pressure, die characteristics, and lubrication—all contribute to the final shape. A poorly designed die or insufficient pressure can fail to fully set the material, leading to excessive elastic recovery. Understanding these root causes is the first step toward implementing effective prevention and compensation strategies.

Primary Compensation Techniques: Overbending, Coining, and Post-Stretching

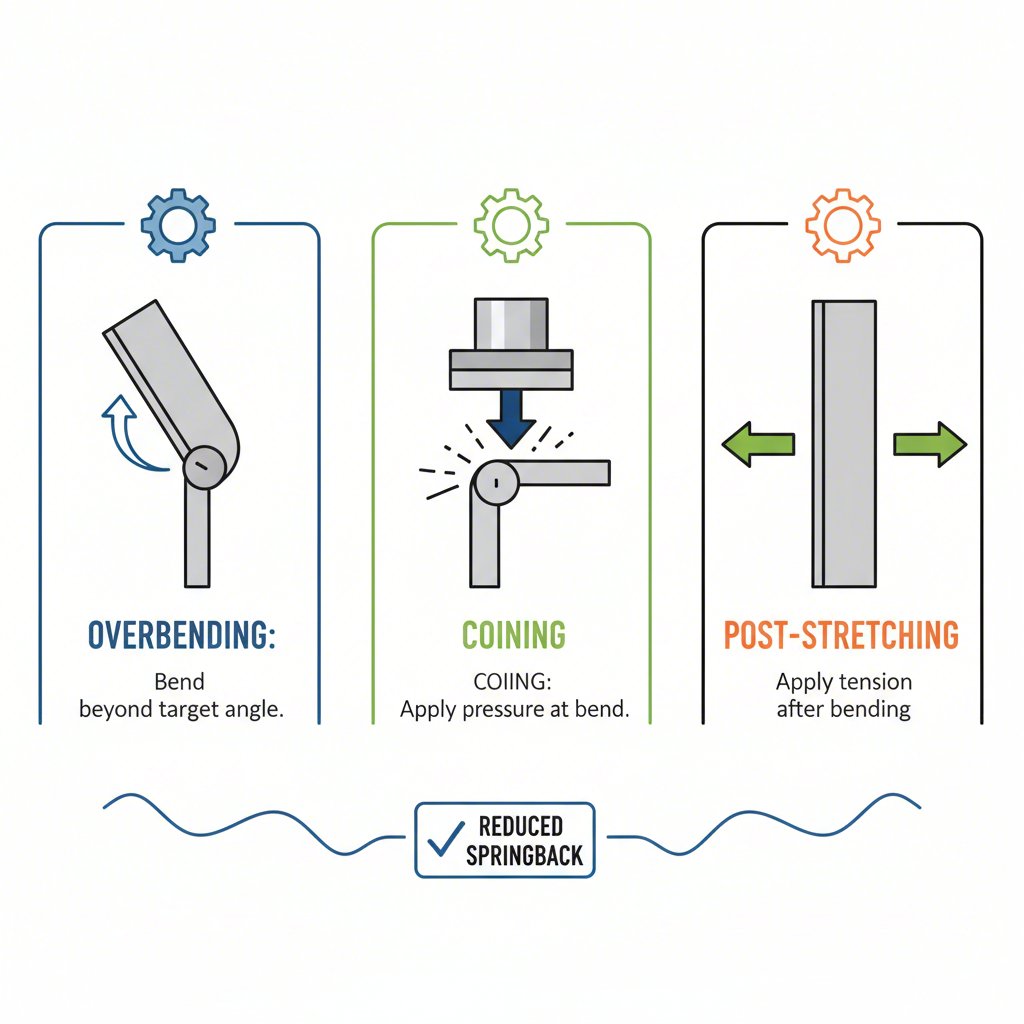

To counteract springback, engineers employ several well-established mechanical techniques. These methods work by either compensating for the expected dimensional change or by altering the stress state within the material to minimize elastic recovery. Each technique has specific applications and trade-offs.

Overbending is the most intuitive approach. It involves intentionally forming the part to a more acute angle than required, anticipating that it will spring back to the correct final dimension. While simple in concept, it often requires significant trial and error to perfect. Coining, also known as bottoming or staking, involves applying a very high compressive force at the bend radius. This intense pressure plastically deforms the material's grain structure, permanently setting the bend and drastically reducing the elastic strains that cause springback. However, coining can thin the material and demands higher press tonnage.

Post-stretching is a highly effective method for controlling both angular change and sidewall curl, especially in complex parts made from AHSS. As detailed by AHSS Guidelines, this technique applies in-plane tension to the part after the primary forming operation. This is often achieved using features called stake beads in the die, which lock the flange and stretch the part's sidewall by a minimum of 2%. This action changes the stress distribution from a mix of tensile and compressive forces to almost entirely tensile, which significantly reduces the mechanical forces driving springback. The result is a more dimensionally stable part.

Comparison of Primary Springback Compensation Methods

| Technique | Pros | Cons | Best Use Case |

|---|---|---|---|

| Overbending | Simple concept, requires no special tooling features. | Often requires extensive trial and error; less precise for complex geometries. | Simple bends in materials with predictable springback. |

| Coining | Highly effective at setting bends; significantly reduces springback. | Can cause material thinning; requires very high press tonnage. | Sharpening radii and setting precise angles in smaller parts. |

| Post-Stretching | Very effective for AHSS; corrects both angular change and sidewall curl. | Requires special die features (e.g., stake beads); may need a larger blank and higher press forces. | Complex automotive parts like pillars and rails made from high-strength steel. |

Advanced Strategies: Tooling Design and Process Optimization

Beyond direct compensation methods, proactive prevention through intelligent tooling and process design is critical for managing springback, particularly with challenging materials like AHSS. The design of the die itself is a powerful tool. Parameters such as die clearance, punch radius, and the use of draw beads must be carefully optimized. For instance, tighter die clearances can restrict unwanted bending and unbending, which helps minimize springback. However, excessively sharp punch radii can increase the risk of shear fractures in high-strength materials.

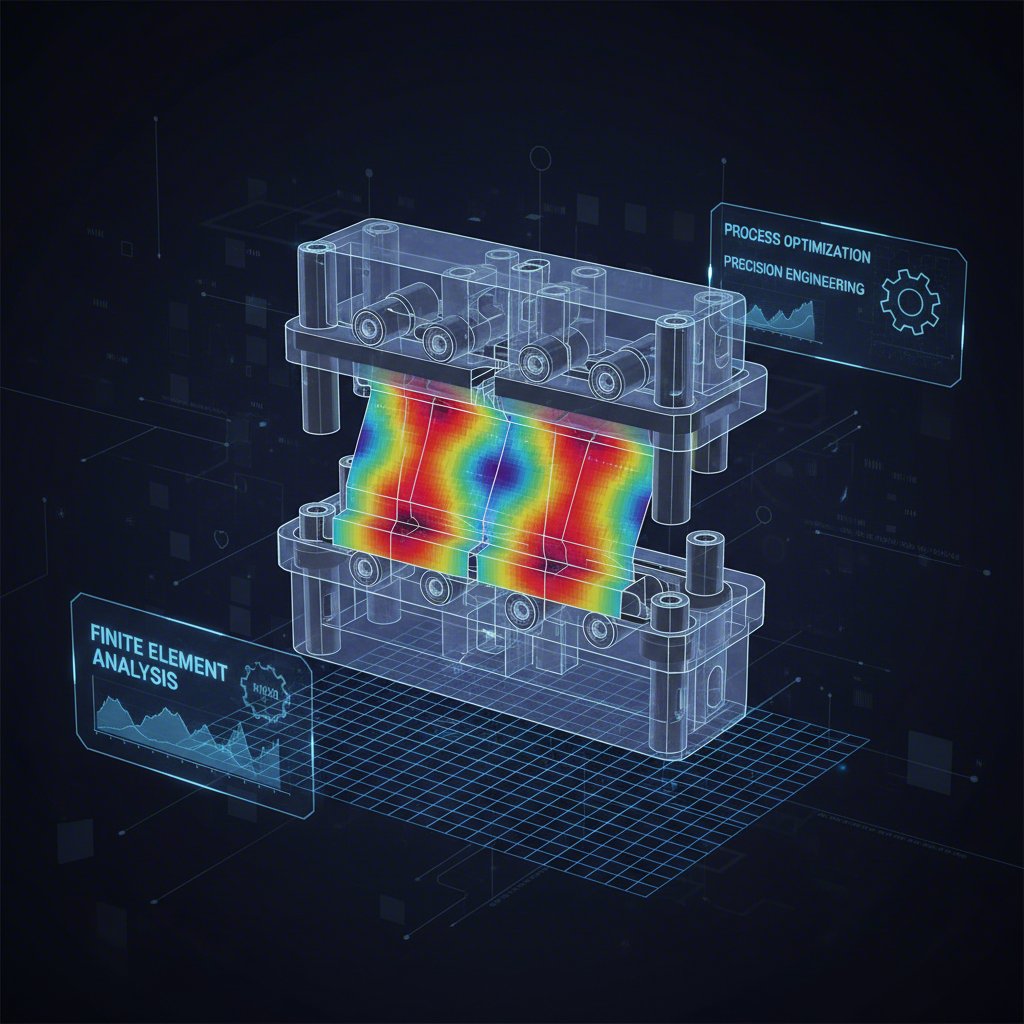

Modern manufacturing increasingly relies on simulation to preemptively solve springback issues. Die Design Compensation, driven by Finite Element Analysis (FEA), is a sophisticated approach where the entire stamping process is simulated to accurately predict the final part's springback. This data is then used to modify the die's geometry, creating a compensated tool face. The die intentionally forms an "incorrect" shape that springs back into the precise, desired geometry. This simulation-driven strategy drastically reduces the costly and time-consuming physical tryout phase. Leading manufacturers of custom tooling, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., leverage advanced CAE simulations to deliver high-precision automotive stamping dies that account for these complex material behaviors from the outset.

Another advanced strategy is process optimization. Hot stamping, or press hardening, is a transformative process that eliminates springback by design. In this method, a steel blank is heated to over 900°C, formed, and then rapidly quenched within the die. This process creates a fully hardened martensitic microstructure, resulting in an ultra-high-strength part with virtually no springback. While highly effective, hot stamping requires specialized equipment and has longer cycle times compared to cold stamping. Other process adjustments, like active binder force control, allow for variable pressure application during the press stroke, creating a post-stretch effect to stabilize the part without the need for physical stake beads.

The Role of Product Design and Material Selection

The fight against springback begins long before the die is built—it starts with product design and material selection. The geometry of the part itself can be engineered to resist the release of elastic stresses. As explained by EMD Stamping, avoiding abrupt shape changes can reduce the tendency for recoil. Furthermore, incorporating stiffening features like darts, vertical beads, or step flanges can mechanically lock elastic strains into the part, preventing it from distorting after forming. These features add rigidity and help maintain the desired shape.

For example, adding vertical beads to the sidewalls of a U-channel part can significantly reduce both angular change and curl by reinforcing the structure. The AHSS Guidelines provide examples of this on automotive components like B-pillars and front rail reinforcements. However, designers must be aware of the trade-offs. While these features lock in elastic strains, they also create residual stresses within the part. These stresses could be released during subsequent operations like trimming or welding, potentially causing new distortions. Therefore, it is crucial to simulate the entire manufacturing process to anticipate these downstream effects.

Material selection is the foundational step. Choosing a material with lower elasticity or higher formability can inherently reduce springback challenges. While the push for lightweighting often necessitates the use of high-strength steels, understanding the properties of different grades is essential. Collaborating with material suppliers and using formability data can help engineers select a material that balances strength requirements with manufacturing feasibility, setting the stage for a more predictable and controllable stamping process.

Frequently Asked Questions

1. How to avoid spring back effect in sheet metal?

To avoid the springback effect, you can use several techniques. Subjecting the bend radius to high compressive stress through coining or bottoming plastically deforms the material to minimize elastic recovery. Other methods include overbending, applying post-form tension (post-stretching), optimizing die design with proper clearances and radii, and in some cases, using heat during the forming process.

2. How can spring back be minimized?

Springback can be minimized by choosing appropriate materials with lower yield strength, designing parts with features that add stiffness (like beads or flanges), and optimizing the stamping process. Key process adjustments include using techniques like overbending, coining, and ensuring the part is fully formed. Advanced methods like active binder force control and using simulation to create compensated tooling are also highly effective.

3. What causes spring back?

Springback is caused by the elastic recovery of the material after a forming operation. When metal is bent, it undergoes both plastic (permanent) and elastic (temporary) deformation. The internal stresses created during forming—tensile on the outer surface and compressive on the inner surface—are not completely relieved. When the forming tool is removed, these residual elastic stresses cause the material to partially return to its original shape.

4. What is the 4T rule for sheet metal?

The 4T rule is a design guideline used to prevent deformation or fractures near bends. It states that any feature, such as a hole or slot, should be located at a distance of at least four times the material's thickness (4T) away from a bend line. This ensures that the material around the feature is not weakened or distorted by the stresses of the bending operation.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —