How Forging Unlocks Superior Fatigue Resistance in Metal

TL;DR

Forging significantly improves fatigue resistance in metal parts by fundamentally altering their internal structure. The process uses immense pressure to refine and align the metal's grain structure, creating a continuous grain flow that follows the component's shape. This eliminates internal defects like porosity and voids, resulting in a denser, stronger, and more durable part capable of withstanding cyclic stress far better than components made by casting or machining.

The Core Mechanism: How Forging Refines Metal's Internal Structure

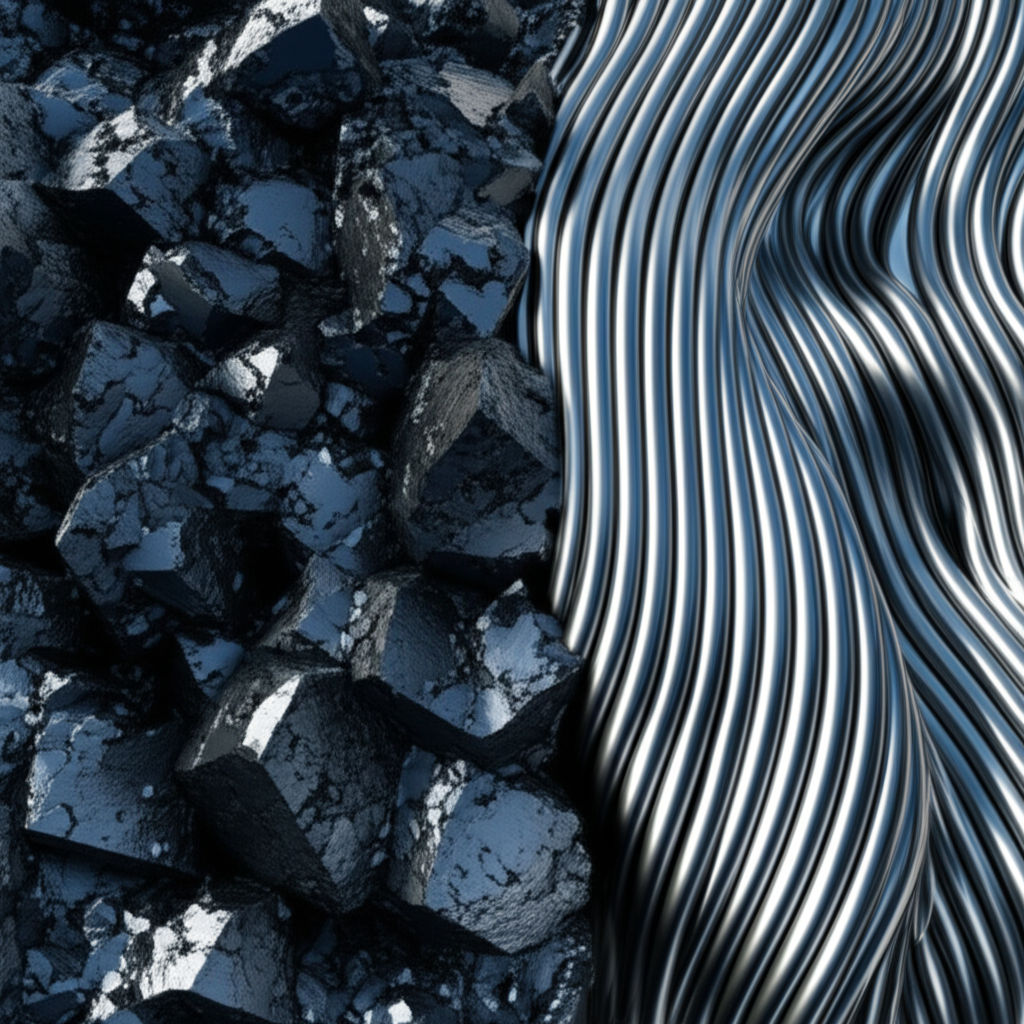

To understand how forging enhances fatigue resistance, we must first look at the metal's internal architecture: its grain structure. At a microscopic level, all metals are composed of crystalline grains. The size, shape, and orientation of these grains dictate the material's mechanical properties, including its strength and durability. In its raw, cast state, a metal's grain structure is typically random and non-uniform, which can create weak points and internal defects.

The forging process subjects a metal billet to extreme compressive forces, either through hammering or pressing. This intense mechanical working forces the grains to deform, break down, and recrystallize into a much finer, more uniform structure. According to an explanation by Southwest Steel Processing, this metallurgical recrystallization results in a denser, more homogenous material. By physically closing and eliminating internal voids, porosity, and inclusions (impurities), forging removes the microscopic starting points where fatigue cracks could otherwise initiate and grow.

Crucially, this process creates what is known as "grain flow." Much like the grain in a piece of wood, which is strongest when forces are applied along its length, forging directs the metal's grain structure to align with the contours of the finished part. As detailed by Trenton Forging, this controlled deformation ensures that the grain flow is oriented in the direction of maximum strength, providing exceptional resistance to stress and impact. This directional alignment is a key reason why forged parts are superior in high-stress applications, as the continuous, unbroken grain flow effectively channels stress throughout the component without concentrating it at weak points.

Key Mechanical Advantages: Enhanced Strength, Toughness, and Durability

The refined and aligned grain structure produced by forging translates directly into a suite of superior mechanical properties that collectively contribute to enhanced fatigue resistance. While fatigue strength is the primary benefit for components under cyclic loads, other improvements in toughness, ductility, and tensile strength are equally important for overall part reliability and longevity. A forged component is not just stronger in one aspect; it is structurally superior across the board.

The forging process significantly boosts several key mechanical properties:

- Increased Tensile Strength: This is the material's ability to withstand being pulled apart. The dense, uniform grain structure of a forged part provides greater resistance to tensile forces without fracturing.

- Enhanced Impact Toughness: Toughness is the ability to absorb energy and deform without breaking, which is critical in applications involving sudden shocks or loads. Forging imparts superior impact toughness, making components less brittle.

- Superior Ductility: Ductility refers to a material's ability to deform under tensile stress, like being stretched into a wire. The refined grain structure allows forged parts to bend or stretch more before failing, providing a safety margin against catastrophic failure.

- Improved Fatigue Resistance: This is the ultimate benefit for parts subjected to repeated loading and unloading cycles. The combination of a defect-free internal structure and optimized grain flow means that fatigue cracks have a much harder time initiating and propagating.

These properties work in synergy to create a component that is not only strong but also incredibly durable. As noted in resources from Qilu Steel Group, this makes forging the preferred manufacturing method for critical parts in the aerospace, automotive, and oil and gas industries, where component failure is not an option. The inherent structural integrity of forged parts ensures a longer service life and greater reliability under extreme operating conditions.

Forging vs. Casting: A Structural Comparison

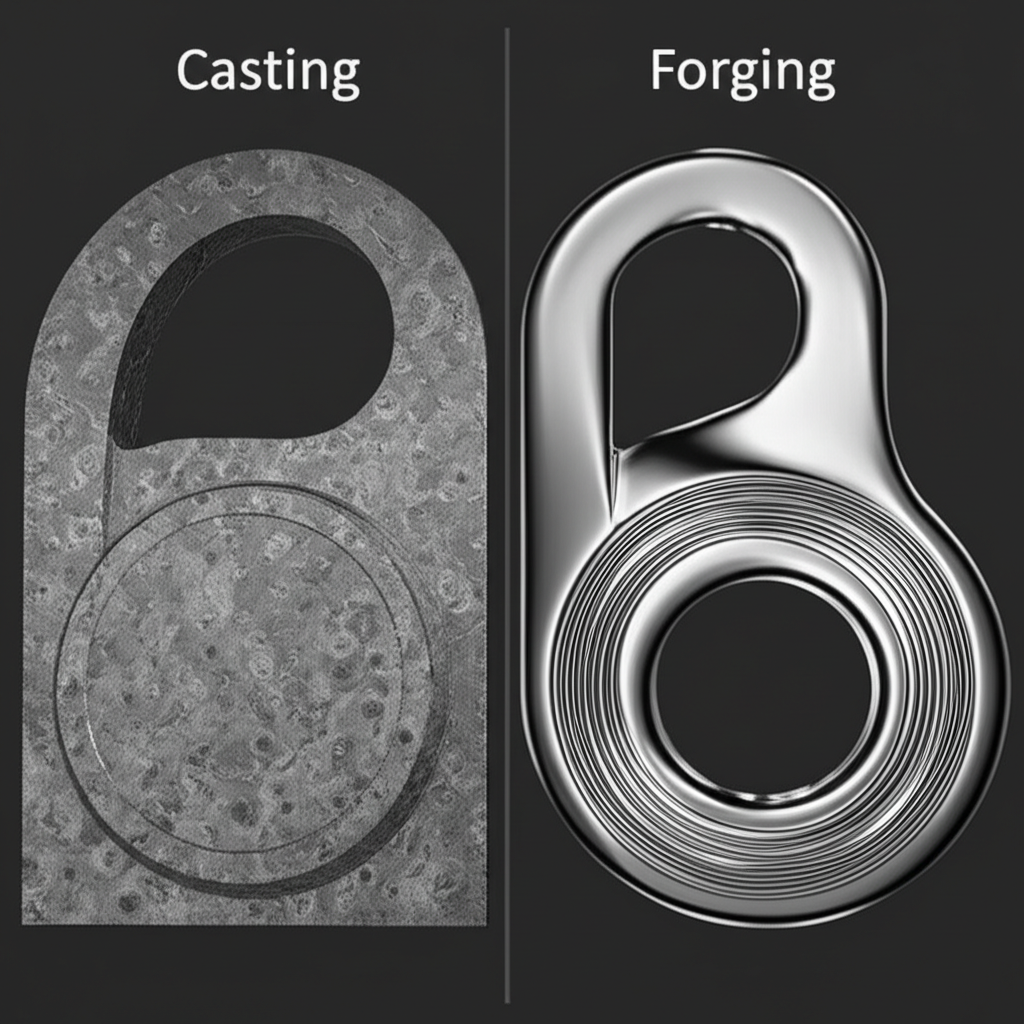

To fully appreciate the advantages of forging, it is useful to compare it to casting, another common manufacturing method. Casting involves pouring molten metal into a mold and letting it cool. While versatile for creating complex shapes, the casting process results in a fundamentally different and less robust internal structure. The random solidification process in casting often creates a non-uniform grain structure and can trap porosity, gas pockets, and other inclusions within the material.

In contrast, forging mechanically works the metal in a solid state, physically compressing it to eliminate these defects and align the grain structure. For demanding applications where strength and reliability are paramount, such as in the automotive industry, forged components are often the superior choice. For robust and reliable automotive components, companies like Shaoyi Metal Technology specialize in high-quality hot forging, providing the precision and strength needed for critical parts. The table below outlines the key structural differences.

| Feature | Forging | Casting |

|---|---|---|

| Grain Structure | Fine, uniform, and directionally aligned (grain flow). | Often coarse, non-uniform, and randomly oriented. |

| Internal Defects | Porosity, voids, and inclusions are eliminated by pressure. | Prone to porosity, shrinkage, and trapped impurities. |

| Fatigue Resistance | Excellent due to continuous grain flow and lack of defects. | Lower due to random grain orientation and potential for internal stress concentrators. |

| Impact Strength | Superior due to refined, tough grain structure. | Generally lower and can be more brittle. |

The aligned grain flow in a forged part provides a continuous, uninterrupted path for stresses to travel, preventing them from concentrating at a weak point. A cast part, with its random grain boundaries and potential for internal voids, has numerous locations where a fatigue crack can start. This makes forged components demonstrably more reliable for parts that will experience vibration, impact, or cyclic loading throughout their service life.

The Critical Role of Surface Integrity

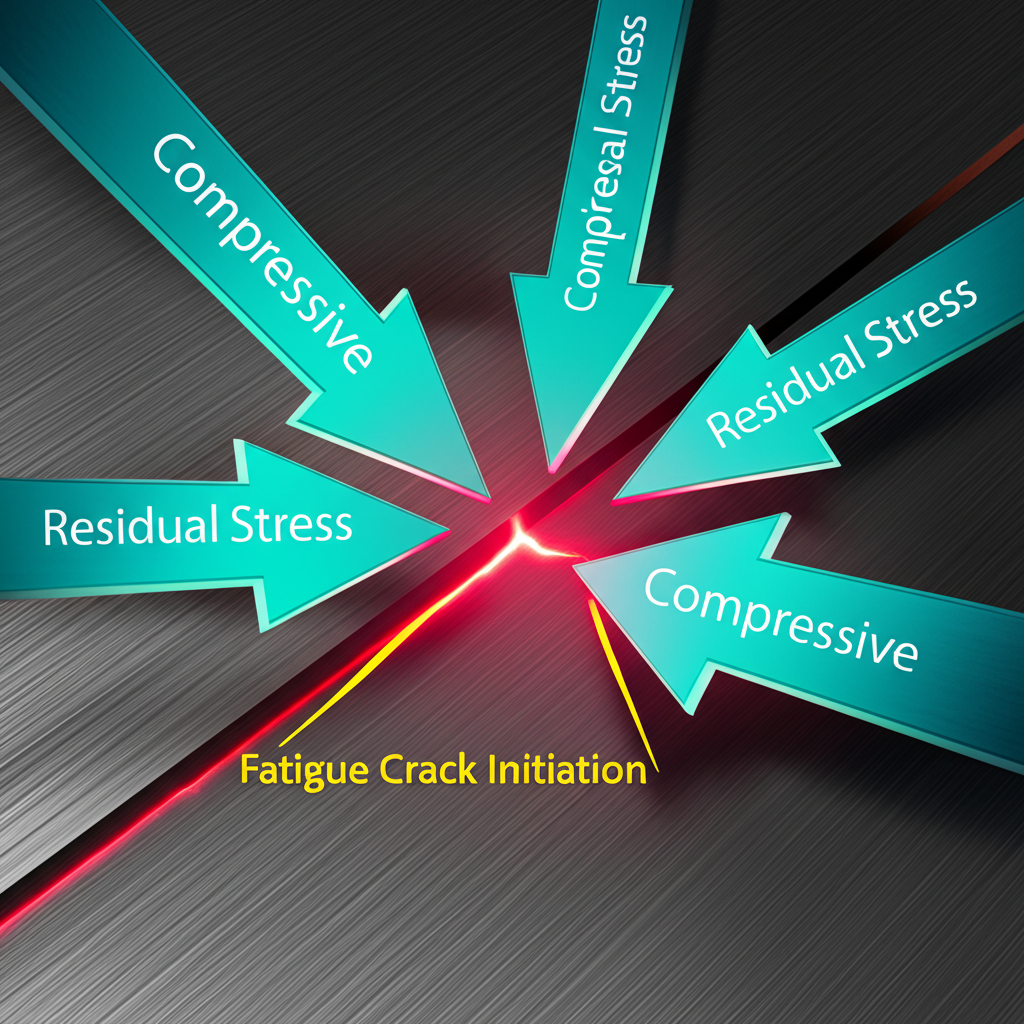

While much of forging's benefit comes from refining the internal structure, the condition of the part's surface also plays a critical role in fatigue resistance. Fatigue cracks almost always initiate at the surface, often at microscopic defects, scratches, or areas of high stress concentration. The forging process naturally produces components with excellent surface quality, creating a smooth, defect-free finish that minimizes potential crack initiation sites. This inherent advantage is a significant contributor to the overall strength and longevity of the component.

Beyond the initial forging, the surface integrity can be further enhanced through secondary processes. According to a study referenced by the U.S. Nuclear Regulatory Commission, processes like shot blasting (or shot peening) can significantly improve fatigue strength. This technique involves bombarding the surface with small, spherical media, which creates a layer of compressive residual stress on the surface. This compressive stress acts as a barrier, making it much more difficult for tensile stresses (which open cracks) to take hold and initiate a fatigue failure.

Heat treating is another crucial post-forging step that optimizes mechanical properties. Treatments like quenching and tempering can further refine the grain structure and relieve internal stresses introduced during the forging process. As explained by experts at Queen City Forging, the combination of forging, controlled heat treatment, and surface enhancement processes allows for precise control over a material's final properties. This holistic approach ensures that every aspect of the component, from its core to its surface, is optimized for maximum strength, durability, and fatigue resistance.

Forging: A Foundation for Unmatched Reliability

In summary, forging is far more than just a shaping process; it is a method of metallurgical refinement that fundamentally enhances a metal's ability to resist failure. By mechanically working the material, forging creates a dense, defect-free internal structure characterized by a fine, uniform grain and a continuous, aligned grain flow. This optimized architecture is the primary reason forged components exhibit superior fatigue resistance, tensile strength, and impact toughness.

From the internal grain structure to the integrity of the surface, every aspect of a forged part is engineered for durability. When compared to alternatives like casting, forging consistently delivers a higher level of structural integrity and performance predictability. For any application where components are subjected to high stress, cyclic loads, or extreme conditions, the forging process provides a foundation of strength and reliability that is essential for safety and long-term performance.

Frequently Asked Questions

1. What does forging do to improve a metal?

Forging improves a metal by refining its grain structure, aligning it for directional strength (grain flow), and eliminating internal defects like cracks, voids, and porosity. This process makes the metal denser, stronger, tougher, and significantly more resistant to fatigue and impact failure compared to other manufacturing methods.

2. Why does forging increase strength?

Forging increases strength because the intense pressure of the process forces the metal's internal grains to break down into a finer, more uniform size. These smaller grains create more boundaries that impede dislocation movement, which is how metal deforms. Furthermore, the alignment of these grains into a continuous flow directs stress along the strongest path, preventing weak points.

3. How can fatigue in metals be reduced?

Fatigue in metals can be reduced through several methods. Fundamentally, using a manufacturing process like forging creates a superior internal structure that naturally resists fatigue. Additionally, design considerations that minimize stress concentrations, post-processing treatments like shot peening to introduce compressive surface stresses, and proper heat treatment all contribute to significantly improving a metal part's fatigue life.

4. What are the main advantages of metal forging?

The main advantages of metal forging include superior mechanical properties such as increased tensile strength, impact toughness, ductility, and exceptional fatigue resistance. Forged parts have high structural integrity due to the elimination of internal defects and the creation of a continuous grain flow that follows the part's contour. This results in highly reliable and durable components ideal for critical applications.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —