How Aluminum Car Parts Are Revolutionizing Vehicle Manufacturing

Introduction: The Rise of Aluminum in Automotive Design

In modern automotive manufacturing, the shift toward lightweight and high-performance materials has become a top priority. Among the most significant advancements is the widespread use of aluminum car parts.

From die-cast and forged components to extruded profiles and precision aluminum sheets, aluminum plays a critical role in shaping the future of the automotive industry. Notably, metals used in cars bodies like aluminum provide a strategic advantage: reducing vehicle weight by over 40% in certain applications compared to traditional steel parts.

Moreover, aluminum's excellent heat conductivity helps lower engine temperatures and its structural properties improve pedestrian collision safety.

1. Microalloying and Heat Treatment of Automotive Aluminum Alloys

Microalloying Enhancements

Adding trace elements such as Scandium (Sc), Zirconium (Zr), and rare earths enhances the performance of aluminum alloys significantly. These microalloying strategies refine grain structures, improve fracture toughness, and increase corrosion resistance. For instance, in 2000-series alloys, the inclusion of Zinc or Cerium enhances tensile strength and fatigue life.

Heat Treatment Processes

Aluminum alloys undergo various treatments like annealing, solution treatment, and aging to optimize their formability and strength. For instance, heat-treated 6000-series alloys gain improved mechanical properties that suit demanding forming processes.

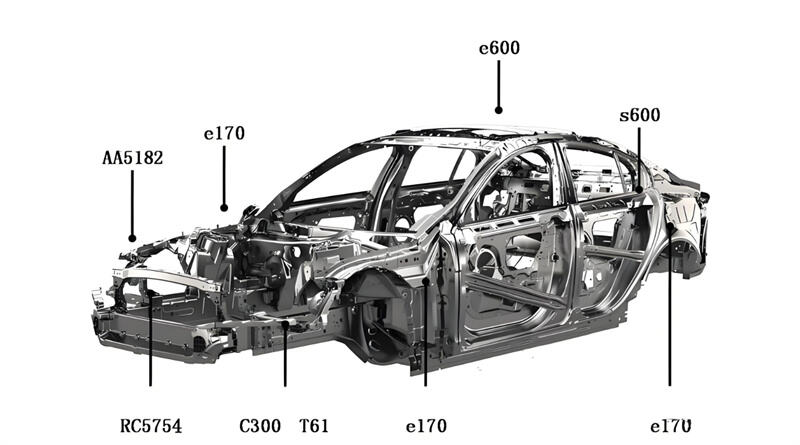

Aluminium on the body

2. Forming Technologies for Aluminum Car Body Panels

Challenges vs. Solutions

Aluminum sheets used for body panels pose unique forming challenges like springback, cracking, and wrinkling. These issues require advanced processes to ensure quality and dimensional accuracy.

Key Forming Techniques:

`Hydroforming: Enhances deep drawing capabilities using fluid pressure, improving part formability.

`Warm Forming: Increases ductility by raising the material temperature below recrystallization points.

`Controlled Blank Holder Force: Improves formability by adjusting edge pressures during drawing.

`Superplastic Forming: Allows complex part manufacturing at high temperatures with minimal springback.

Automotive bushings made of steel and aluminium

3. Finite Element Simulation in Metal Forming

Modern engineering uses finite element analysis (FEA) to simulate metal sheet deformation during forming. Simulations help predict defects such as wrinkles, cracks, and springback, providing insights into:

`Material yield behavior

`Effect of die design

`Impact of forming speed and friction

By combining simulations with actual tests, manufacturers can optimize part shapes and forming parameters to ensure consistency and reduce waste.

4. Material Behavior and Alloy Design in Car Body Engineering

The development of automobile sheet metal parts made of aluminum relies heavily on fine-tuning alloy chemistry and processing. Researchers focus on aligning mechanical strength, corrosion resistance, and formability.

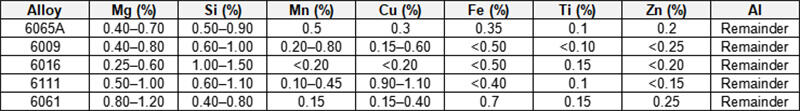

For example, increasing magnesium content in 5000-series alloys boosts strength but must be balanced with elongation loss. Similarly, controlled additions of silicon and manganese in 6000-series alloys improve age hardening and thermal resistance.

Composition of 6000 series aluminium alloy commonly used in automotive panels (mass fraction)

5. The Future of Lightweight Automotive Manufacturing

Aluminum's adoption across global OEMs illustrates its irreplaceable role in building lighter, more efficient, and environmentally friendly vehicles.

Yet challenges remain, including:

` Material cost

` Joining techniques with steel

` Surface treatments for corrosion resistance

With continued research, especially in metal stamping automotive processes, these challenges are gradually being addressed.

Embedded Link: Read more about our expertise in automotive metal stamping press

Conclusion

The use of aluminum car parts and related forming technologies marks a transformative shift in the auto industry. By leveraging heat treatment, alloy design, advanced simulations, and forming techniques, manufacturers like Shaoyi are redefining what's possible with metals used in cars bodies.

As the push for lighter, safer, and more sustainable vehicles continues, innovations in metal direct auto parts will play a central role in shaping the future.

At Shaoyi Metal Technology, we specialize in manufacturing precision aluminum car parts and providing tailored metal direct auto parts solutions. If you're exploring high-performance, lightweight, and durable metals used in cars bodies, our team is here to help.

Whether you need technical advice, material selection support, or are ready to start your next project — we’d love to hear from you.

Contact us now to learn how we can support your next automotive innovation.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —