Advancing Vehicle Lightweighting: Key Manufacturing Technologies and Applications of Automotive Aluminum Parts

Introduction: The Strategic Role of Aluminum in Automotive Lightweighting

In China's strategic initiative "Made in China 2025, " lightweighting is emphasized as a core technology for energy-saving and new energy vehicles. Among the various lightweight materials, automotive aluminum Parts stands out due to its superior combination of performance, safety, and environmental benefits.

This blog explores the current state and key manufacturing technologies for aluminum car body parts, including vacuum die casting, extrusion, and sheet metal stamping. These technologies are critical in reducing vehicle weight, improving fuel efficiency, and enhancing crash safety.

automotive stamping parts Manufacturers

1. Advantages of Aluminum in Automotive Lightweighting

Automakers and suppliers have long explored lightweight vehicle design through structural optimization, material substitution, and advanced manufacturing processes. The use of aluminum in automotive industry has become increasingly critical due to the following advantages:

lAbundant raw materials and low density (approx. 2. 7g/cm³)

lHigh strength-to-weight ratio

lExcellent corrosion resistance due to natural oxide layer

lGood formability for casting, extrusion, forging, and stamping

lHigh energy absorption capability in crashes

lHigh recyclability and eco-friendliness

Aluminum ranks second in car body material weight share, just after steel.

2. Applications of Aluminum in Lightweight Car Bodies

Aluminum parts are widely integrated in automotive body structures through technologies such as vacuum die casting, extrusion, and sheet stamping.

2. 1 Vacuum Die Casting for Aluminum Parts

Vacuum die casting removes air from molds to reduce its porosity and enhance part quality. It is ideal for complex, thin-walled structures requiring high mechanical performance.

Benefits of vacuum die-cast aluminum parts include:

lUp to 40% weight reduction compared to traditional steel assemblies

lEnhanced structural integrity for crash safety

lIntegrated part design to replace multi-part assemblies

lGood surface finish and welding compatibility with MIG, SPR, and CMT

Key considerations include alloy selection (e. g. , AlSi10MgMn), wall thickness control, draft angle design, corner radius optimization, and FEA-based structural validation.

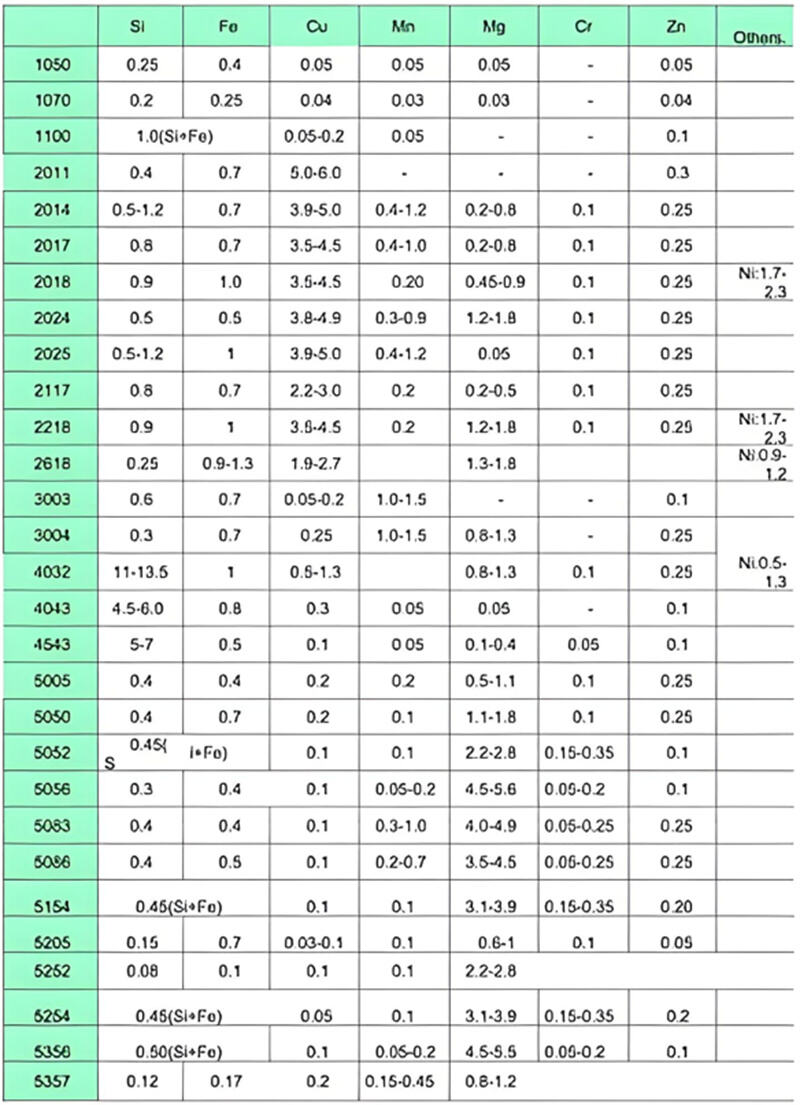

Shaoyi's aluminium alloy composition table

2. 2 Extruded Aluminum Profiles

Extrusion enables high-precision, closed-section aluminum profiles used in structural members like bumper beams, longitudinal rails, seat crossbeams, and battery trays.

Extrusion advantages:

lHigh material utilization and production efficiency

lExcellent design flexibility

lCommon use of 6xxx series alloys (6061, 6082, 6005) for strength and crash energy absorption

Extruded parts must be designed with symmetric cross-sections, appropriate wall thickness, and optimized for minimal deformation and heat distortion.

2. 3 Stamped Aluminum Sheet Components

Sheet metal stamping offers cost-effective manufacturing for high-volume aluminum parts such as body panels and floors.

Challenges and solutions:

lLower elastic modulus and yield strength than steel

lHigher springback and surface sensitivity

lRequires tailored alloy selection (5xxx and 6xxx series)

lMust integrate CAE simulation and mold design for defect prevention

Careful design of draw radius, wall thickness, and forming paths is essential for achieving quality stamped parts.

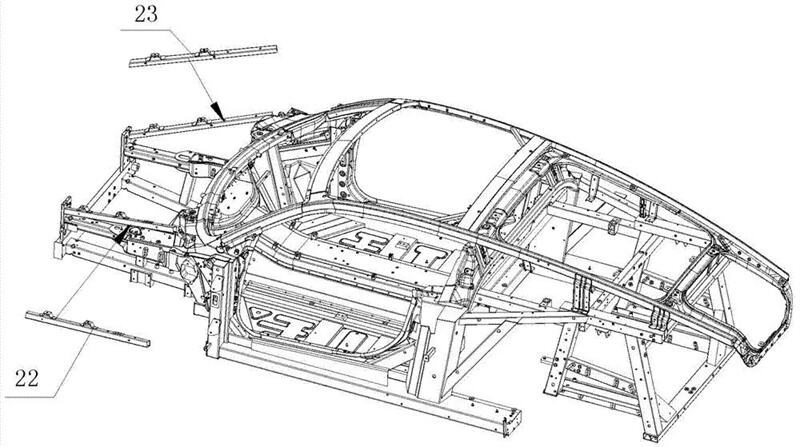

Automotive parts structure

3. Summary and Outlook

A well-balanced approach combining automotive aluminum die-cast parts for joint integrity, extruded profiles for main structures, and stamped sheets for body panels enables lightweight, high-performance vehicle design.

Further innovation is needed in materials science, process integration, and cost control to fully leverage the benefits of aluminum in automotive applications.

To learn more about our aluminum car part manufacturing services, visit Shaoyi Metal Technology.

Contact Us

At Shaoyi Metal Technology, we specialize in manufacturing high-quality aluminum automotive components using advanced die casting, extrusion, and stamping technologies. We are committed to supporting your vehicle lightweighting goals with expert engineering and reliable service.

Click here to contact us and discover how our solutions can enhance your next project.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —