Hot vs. Cold Chamber Die Casting: Which Is Right for You?

TL;DR

The primary difference between hot chamber and cold chamber die casting lies in the furnace location. Hot chamber die casting melts metal within the machine, making it a faster process ideal for high-volume production of parts from low-melting-point alloys like zinc and tin. In contrast, cold chamber die casting melts metal in a separate furnace and transfers it for injection, a slower but more versatile method required for high-melting-point alloys like aluminum and copper, which are used to create larger, stronger components.

Understanding the Core Process: How Each Method Works

At a fundamental level, both hot and cold chamber die casting force molten metal into a reusable mold (a die) under high pressure. However, the mechanics of how the metal is melted and injected into the die are distinct, dictating each method's speed, material compatibility, and ideal applications. Understanding this core operational difference is the first step in selecting the right process for a manufacturing project.

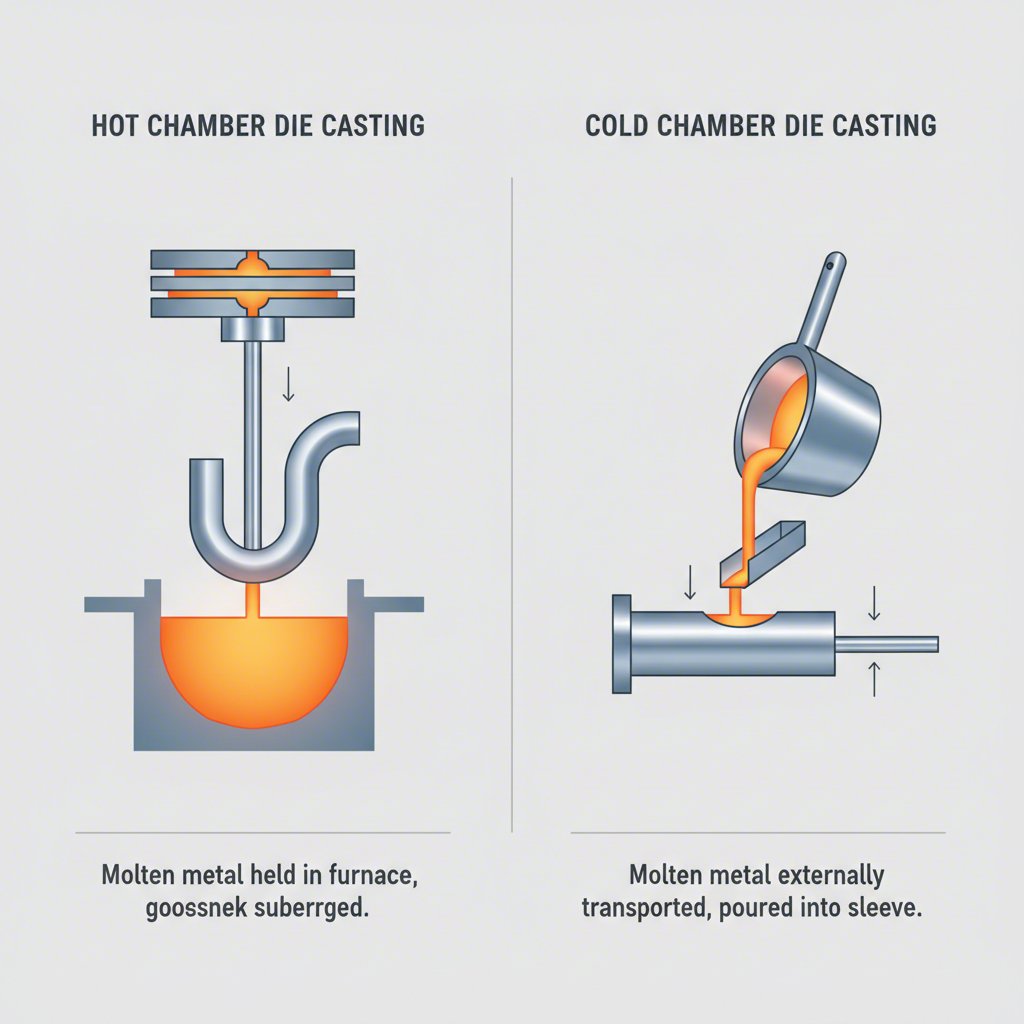

In hot chamber die casting, the melting pot or furnace is an integral part of the machine itself. The injection mechanism, often a "gooseneck" design, is submerged in the molten metal bath. When a cycle begins, a plunger forces a specific amount of this metal through the gooseneck and into the die cavity. Because the metal is contained within the machine, the process is incredibly fast and efficient, with minimal material waste and less exposure to the atmosphere, which reduces oxidation.

Conversely, cold chamber die casting separates the melting furnace from the casting machine. For each casting cycle, a precise amount of molten metal is ladled from the external furnace and poured into a "cold chamber" or shot sleeve. A high-pressure hydraulic plunger then forces this metal into the die. This two-step process is inherently slower than the integrated hot chamber method. However, this separation is crucial because it prevents the machine's injection components from being continuously exposed to the corrosive and high-temperature nature of alloys like aluminum and brass.

Head-to-Head Comparison: Key Differentiating Factors

Choosing between hot and cold chamber die casting depends on a direct comparison of several key factors: the alloy being used, the required production volume, the size and complexity of the component, and overall cost considerations. The trade-offs between speed and material versatility are central to this decision. The following table provides a clear overview of these critical differences.

| Factor | Hot Chamber Die Casting | Cold Chamber Die Casting |

|---|---|---|

| Suitable Alloys | Low-melting-point alloys: Zinc, magnesium, tin, lead. | High-melting-point alloys: Aluminum, copper, brass, silicon tombac. |

| Production Speed | Very fast (400-900 cycles per hour). | Slower (50-90 cycles per hour). |

| Component Size | Typically smaller components. | Can produce very large components. |

| Pressure Applied | Lower pressure (1,000 - 5,000 psi). | Higher pressure (3,000 - 25,000+ psi). |

| Tooling Life | Longer due to less thermal shock and use of less abrasive alloys. | Shorter due to high temperatures and abrasive nature of alloys like aluminum. |

| Cost | Lower per-part cost for high-volume runs; higher initial machine investment. | Higher per-part cost due to slower cycles; more flexible for smaller runs. |

The most significant factor is the metal alloy. Hot chamber machines cannot handle high-melting-point metals like aluminum because they would damage the machine's injection components. This limitation is the primary reason the cold chamber process exists. The incredible production speed of hot chamber casting, with some machines completing over 15 cycles per minute, makes it exceptionally cost-effective for high-volume orders. In contrast, the manual or automated ladling step in cold chamber casting significantly slows down the cycle time, as noted by sources like Redstone Manufacturing.

Weighing the Options: Advantages and Disadvantages of Each Process

A balanced decision requires understanding the inherent pros and cons that extend beyond the spec sheet. Each method presents a unique set of benefits and limitations that directly impact production efficiency, part quality, and cost-effectiveness for a given project.

Advantages and Disadvantages of Hot Chamber Die Casting

Pros:

- High Production Speed: The integrated furnace allows for extremely fast cycle times, making it ideal for mass production.

- Longer Die Life: The use of less abrasive, low-temperature alloys and lower injection pressures results in less wear and tear on the molds.

- Improved Metal Utilization: As the metal is melted in a closed system, there is less dross (oxide formation) and material waste.

- Process Automation: The process is easily automated, leading to lower labor costs and greater consistency.

Cons:

- Limited Material Choice: This is its chief disadvantage. It is unsuitable for high-melting-point alloys like aluminum and copper, which are in high demand for structural applications.

- Not for Large Parts: Hot chamber machines are generally designed for producing smaller, more intricate components.

Advantages and Disadvantages of Cold Chamber Die Casting

Pros:

- Material Versatility: It can cast a wide range of alloys, including high-strength, lightweight metals like aluminum and magnesium, which are critical in the automotive and aerospace industries.

- Stronger, Denser Parts: The extremely high pressures used in the cold chamber process help create components with minimal porosity and superior structural integrity.

- Suitable for Large Components: The process can be scaled to produce very large parts, such as engine blocks or industrial machine housings.

Cons:

- Slower Cycle Times: The need to ladle metal for each shot makes the process significantly slower and less efficient for high-volume production compared to hot chamber.

- Potential for Contamination: The transfer of molten metal from the furnace to the machine can introduce impurities or temperature variations if not carefully controlled.

- Higher Operational Costs: Slower cycles and often higher maintenance requirements can lead to a higher cost per part.

Applications and Material Suitability: From Faucets to Engine Blocks

The theoretical differences between these processes translate into distinct real-world applications. The choice of material is inextricably linked to the end product's required properties, such as strength, corrosion resistance, weight, and thermal conductivity.

Hot chamber die casting excels in producing components from zinc, tin, and magnesium alloys. Zinc alloys are particularly popular due to their excellent fluidity, which allows for casting parts with thin walls, intricate details, and smooth surface finishes that are ideal for plating or painting. Common applications include:

- Automotive Hardware: Interior components, locks, and decorative trim.

- Plumbing Fixtures: Faucets, showerheads, and other bathroom hardware.

- Consumer Electronics: Casings for connectors, heat sinks, and brackets.

- Buckles and Zippers: High-volume fashion and apparel hardware.

Cold chamber die casting is the go-to process for parts requiring high structural strength and light weight, primarily using aluminum and copper alloys. Aluminum's excellent strength-to-weight ratio makes it indispensable in modern manufacturing. As detailed by experts like Neway Precision, these applications often demand high performance. In the automotive sector, for example, producing high-integrity metal components is a specialized field. Common applications for the cold chamber process include:

- Automotive Parts: Engine blocks, transmission cases, structural components, and wheels.

- Aerospace Components: Parts requiring high strength and low weight.

- Industrial Machinery: Housings for pumps, motors, and power tools.

- Telecommunications Equipment: Chassis and housings for network infrastructure.

Frequently Asked Questions

1. What is the fundamental difference between hot and cold chamber die casting?

The fundamental difference is the location of the melting furnace. In hot chamber die casting, the furnace is integrated within the machine, allowing for faster cycles. In cold chamber die casting, the furnace is separate, and molten metal is ladled into the machine for each shot, a slower process necessary for high-melting-point alloys.

2. What are the main disadvantages of hot chamber die casting?

The primary disadvantage of hot chamber die casting is its material limitation. As explained by manufacturing specialists at Schaumburg Specialties, the process is only suitable for alloys with low melting points, such as zinc and tin. It cannot be used for high-temperature structural metals like aluminum, which would damage the machine's injection system.

3. What applications is hot chamber die casting suitable for?

Hot chamber die casting is ideal for the high-volume production of smaller, intricate parts that do not require high structural strength. It is widely used for creating plumbing fixtures, decorative hardware, automotive interior components, and parts for consumer electronics from zinc, lead, and tin alloys.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —