Why Stamped Steel Control Arms Fail: Key Stress Points

TL;DR

Stamped steel control arms, common in production vehicles due to their low manufacturing cost, have critical stress points that can lead to failure. The primary weaknesses are at the rubber bushings and ball joints, which wear out over time, and the C-shaped arm itself, which is prone to flexing or bending under significant load. Key symptoms of failure include clunking noises, unstable steering, excessive vibrations, and uneven tire wear. Solutions range from reinforcing the arm by 'boxing' it with welded plates to upgrading to stronger tubular or billet aftermarket replacements.

Understanding Stamped Steel Control Arms

A control arm is a critical suspension component that connects your vehicle's frame to the steering knuckle or wheel hub assembly. Its job is to manage the wheel's vertical movement over bumps while keeping it correctly aligned for stable handling. Stamped steel control arms are the most common type found in factory vehicles, chosen by manufacturers primarily for their cost-effectiveness. The term 'stamped' refers to their manufacturing process, where they are pressed from a single sheet of steel into a U-shaped or C-shaped channel. This open design is both a manufacturing advantage and the source of its main structural weakness: a tendency to flex under pressure.

This stamping process allows for rapid, high-volume production, which is essential for major automotive lines. For automotive manufacturers seeking unparalleled precision and reliability in metal stamping, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. deliver comprehensive solutions from rapid prototyping to mass production, ensuring high-quality components. While effective for average driving conditions, the inherent design of a stamped steel arm means it can become a limiting factor when the vehicle is subjected to higher stress from performance driving, heavy loads, or modified suspensions.

Identifying whether your vehicle has stamped steel control arms is straightforward. As noted by industry experts, the simplest method is the magnet test. If a magnet sticks firmly to the control arm, it's made of steel. This distinguishes it from cast aluminum arms, which are non-magnetic. Visually, they often have a distinct open-channel appearance, unlike the more solid look of forged or cast components.

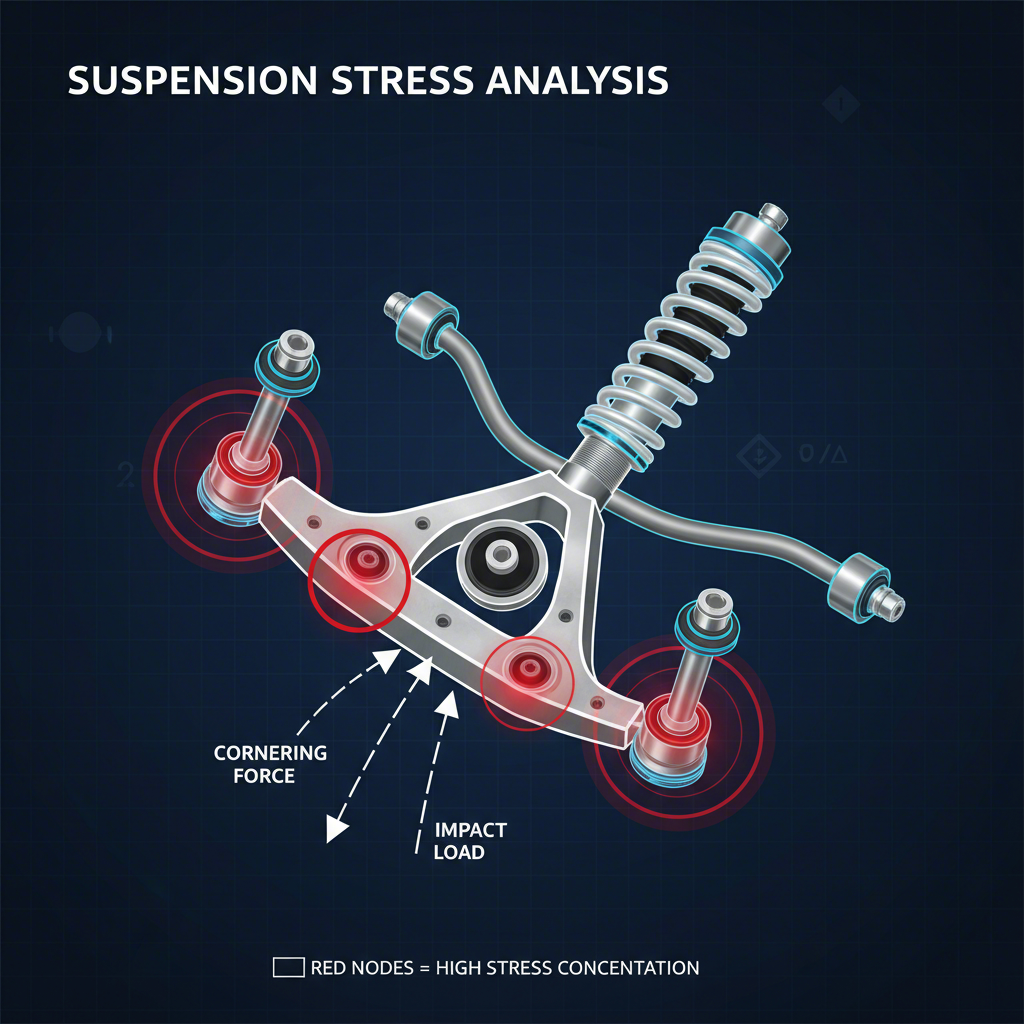

Identifying Critical Stress Points and Failure Modes

The design of stamped steel control arms creates specific areas that are susceptible to stress and eventual failure. Understanding these points is key to diagnosing suspension issues accurately. The primary weaknesses are concentrated at the connection points and within the structure of the arm itself.

The main stress points on a stamped steel control arm include:

- Control Arm Bushings: These rubber or polyurethane pivot points connect the control arm to the vehicle's frame. Over time, they absorb countless vibrations and movements, causing the rubber to crack, harden, and deteriorate. Worn bushings create excessive play, leading to alignment issues and noise.

- Ball Joints: This is the critical pivot that connects the control arm to the wheel's steering knuckle. It endures significant stress, especially on vehicles with leveling kits or modified suspensions that alter the joint's angle. A worn ball joint can cause clunking, steering instability, and in severe cases, can separate and lead to a total loss of control.

- Arm Flex and Bending: The open, C-channel design of a stamped arm is its greatest vulnerability. Under the stress of hard cornering, heavy braking, or impacts from potholes, the arm itself can flex. As detailed in a guide by Speedway Motors, this repeated flexing can lead to metal fatigue, bending, or even fracturing, compromising the vehicle's alignment and safety.

These failure modes are a direct trade-off for the low manufacturing cost of stamped steel. Aftermarket manufacturers often address these weak points with reinforced designs, such as adding strategic gusseting at high-stress areas to prevent flex and failure. An impact from hitting a curb or a large pothole can be enough to bend or fracture a stock arm, making a visual inspection after such an event crucial.

Common Symptoms of a Failing Control Arm

When a stamped steel control arm or its components begin to fail, the vehicle will provide several clear warning signs. Recognizing these symptoms early can prevent more severe damage and ensure your safety on the road. According to a detailed guide from AutoZone, the most common indicators point to issues with noise, steering, and tire wear.

Here are the primary symptoms of a failing control arm:

- Clunking or Knocking Noises: This is often the first and most noticeable symptom. The sound is typically caused by worn-out bushings allowing metal-on-metal contact or a loose ball joint. The noise is most apparent when driving over bumps, accelerating from a stop, or during sharp turns.

- Unstable Steering Response: A bent arm or severely worn bushings will alter the wheel's alignment, causing the steering to feel loose or to wander. You may find the vehicle pulls to one side, requiring constant correction to drive in a straight line. This creates an unpredictable and unsafe driving experience.

- Excessive Vibrations: As bushings fail, they lose their ability to absorb road vibrations, which are then transferred through the steering wheel and into the cabin. A bent control arm can also cause vibrations if it has led to uneven tire wear.

- Uneven or Premature Tire Wear: Misalignment caused by a faulty control arm is a leading cause of irregular tire wear. You might notice wear on the inner or outer edges of the tire tread (shoulder wear) or feathered patterns across the tread. This not only ruins your tires but also indicates a serious underlying suspension problem.

If you notice these symptoms, a visual inspection can often confirm the issue. Look for visible cracks or tears in the rubber bushings or any obvious bending in the arm itself. A simple 'bounce test'—pushing down firmly on a corner of the vehicle—can also reveal problems; if the car bounces excessively, it points to a worn suspension component, which could be the control arm.

Solutions and Upgrades: Reinforcing vs. Replacing

When faced with a weak or failing stamped steel control arm, you have two primary paths: reinforcing the existing component or replacing it with a superior aftermarket upgrade. The best choice depends on your budget, vehicle use, and performance goals. Reinforcement offers a cost-effective strength boost, while replacement provides the ultimate in durability and performance.

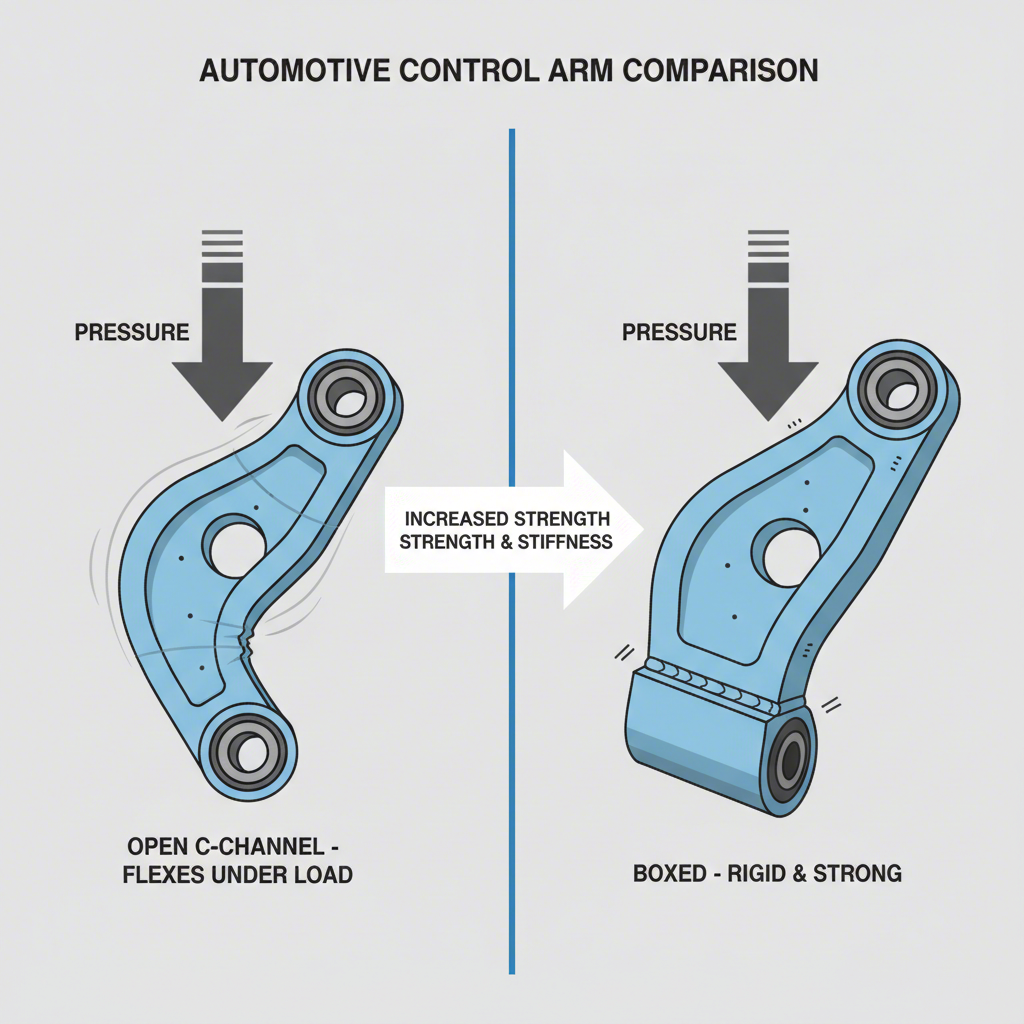

Reinforcing by 'Boxing'

For enthusiasts on a budget, especially in the classic car community, 'boxing' is a time-tested solution. This process involves welding a custom-fabricated steel plate to the open side of the C-channel arm, effectively turning it into a fully enclosed box structure. As explained by Speedway Motors, this modification dramatically increases the arm's rigidity and greatly reduces the flex that plagues the original stamped design. It's an effective way to strengthen the factory component without the cost of a full replacement.

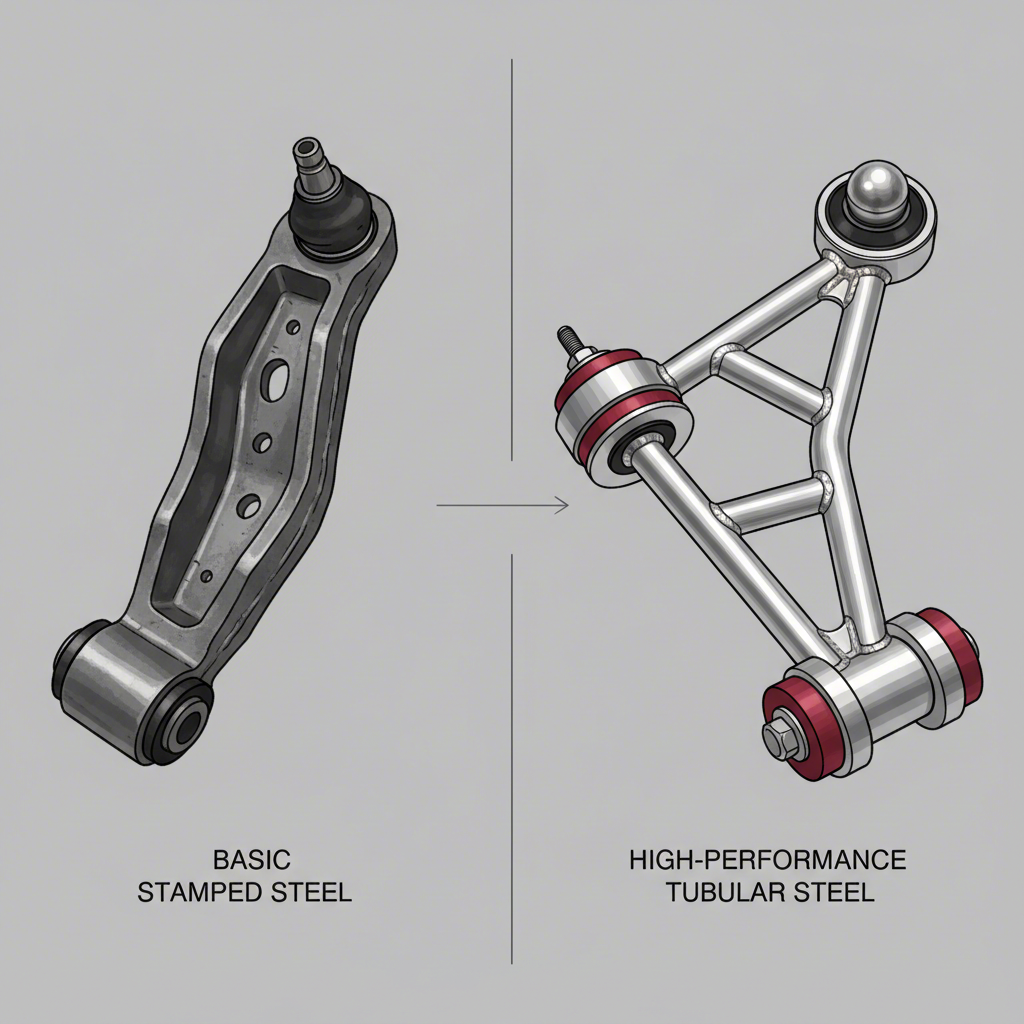

Upgrading with Aftermarket Replacements

For those seeking maximum performance, especially on lifted trucks or track-focused cars, replacing the stamped steel arms is the best option. Aftermarket solutions are typically made from stronger materials and feature improved designs. The most common types include tubular steel and billet aluminum arms, each with distinct advantages.

A comprehensive comparison from Shock Surplus highlights the differences in materials and joint types, from sealed ball joints to high-articulation uniballs. Similarly, an analysis of steel versus aluminum control arms shows that while steel offers raw strength, aluminum provides significant weight savings and superior corrosion resistance.

Here is a comparison of the different options:

| Control Arm Type | Primary Material | Pros | Cons | Best Use Case |

|---|---|---|---|---|

| Stamped Steel (Stock) | Sheet Steel | Very low cost, readily available | Prone to flexing and bending, weak points at bushings | Standard daily driving, unmodified vehicles |

| Boxed Stamped Steel | Reinforced Steel | Inexpensive upgrade, significantly increased rigidity | Requires fabrication/welding, adds some weight | Budget-conscious classic car restoration, mild performance |

| Tubular Steel | DOM or Chromoly Steel | Excellent strength-to-weight ratio, improved geometry | Higher cost than stock, can still rust if not coated | Off-roading, lifted trucks, street performance |

| Billet Aluminum | Machined Aluminum | Lightweight (reduces unsprung weight), corrosion resistant, high precision | Most expensive option, may not be as damage-tolerant as steel | High-performance track cars, show cars, environments with road salt |

Frequently Asked Questions

1. How do I tell if I have stamped steel control arms?

The easiest way to identify stamped steel control arms is with a magnet. If a magnet sticks to the control arm, it is made of steel. Aluminum arms are not magnetic. Visually, stamped steel arms often have an open C-shape or U-shape channel design, whereas forged or cast arms appear more solid.

2. Who makes good aftermarket upper control arms?

Many reputable brands produce high-quality aftermarket control arms designed to improve strength, adjustability, and suspension geometry. Some popular and well-regarded brands in the industry include SPC Performance, Camburg Engineering, Total Chaos Fabrication, Icon Vehicle Dynamics, and Bilstein. The best brand for you depends on your specific vehicle, how you use it (e.g., daily driving, off-roading, track use), and your budget.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —