High Strength Steel Stamping Automotive: Essential Engineering Guide

TL;DR

High-Strength Steel (HSS) stamping is the critical manufacturing process enabling the automotive industry's dual goals: maximizing fuel efficiency through lightweighting while meeting stringent crash safety standards. By utilizing advanced grades like Dual Phase (DP) and TRIP steels, manufacturers can use thinner gauges without sacrificing structural integrity.

However, this strength comes at a price: reduced formability and significant elastic recovery (springback). Successful execution requires a holistic upgrade of the press line—from higher tonnage capacity and specialized feed straighteners to advanced simulation software for springback compensation. This guide explores the material science, equipment requirements, and process strategies needed to master high strength steel stamping automotive applications.

The Material Landscape: From HSLA to UHSS

The term "high-strength steel" is a broad umbrella covering several distinct generations of metallurgical development. For automotive engineers, distinguishing between these categories is vital for correct application and die design.

HSLA (High-Strength Low-Alloy)

HSLA steels act as the baseline for modern structural components. Grades like HSLA 50XF (350/450) offer yield strengths around 50,000 PSI (350 MPa). They achieve this through micro-alloying with elements like vanadium or niobium rather than just carbon. While stronger than mild steel, they generally retain good formability and weldability, making them suitable for chassis components and reinforcements.

AHSS (Advanced High-Strength Steel)

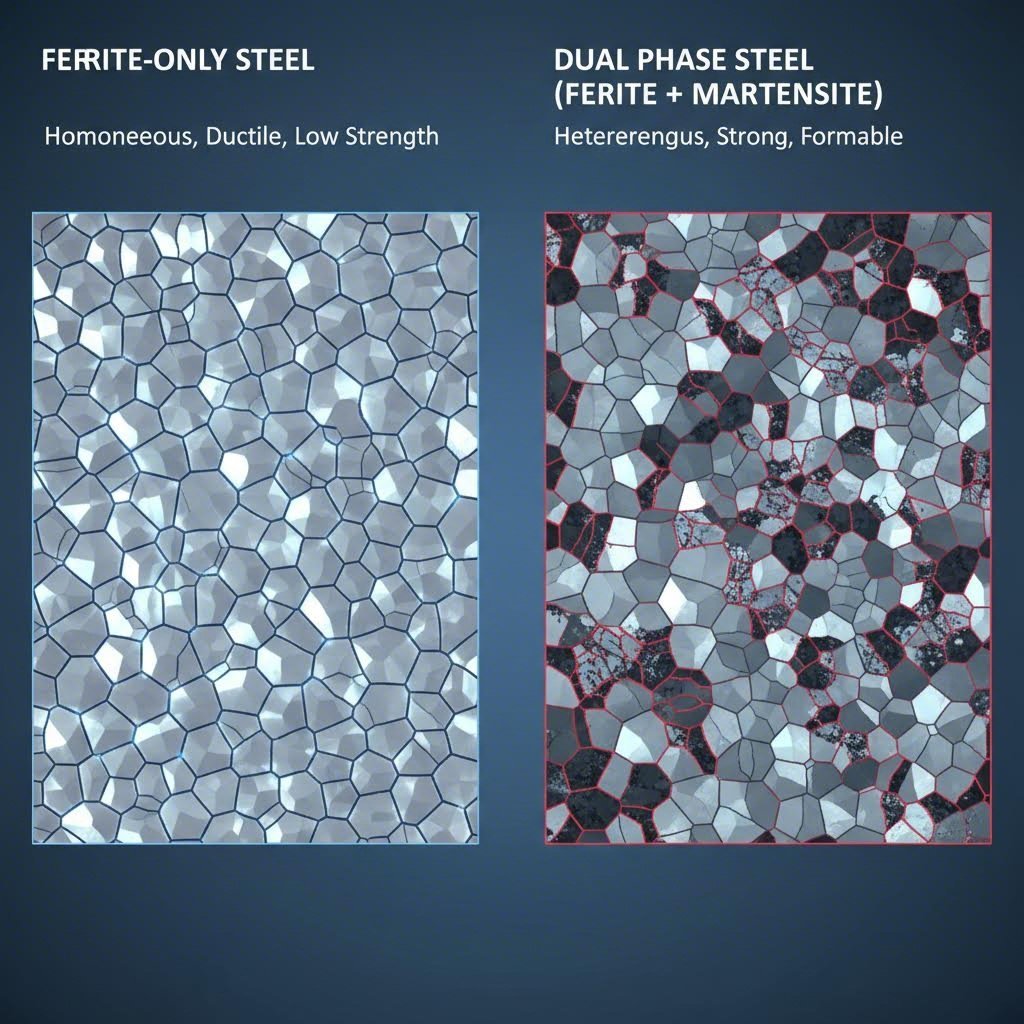

AHSS represents the true leap in automotive capability. These steels possess multiphase microstructures that allow for unique mechanical properties.

- Dual Phase (DP): The current "workhorse" of the industry (e.g., DP350/600). Its microstructure consists of hard martensite islands dispersed in a soft ferrite matrix. This combination provides low yield strength for forming initiation but high work-hardening rates for final part strength.

- TRIP (Transformation-Induced Plasticity): These steels contain retained austenite that transforms into martensite during deformation. This allows for exceptional elongation and energy absorption, making them ideal for crash zones.

UHSS (Ultra-High-Strength Steel)

When tensile strengths exceed 700–800 MPa, we enter the UHSS territory. Martensitic grades and Press Hardening Steels (PHS) like Boron steel fall here. These materials are often so strong that they cannot be cold stamped effectively without fracturing, leading to the adoption of hot stamping technologies.

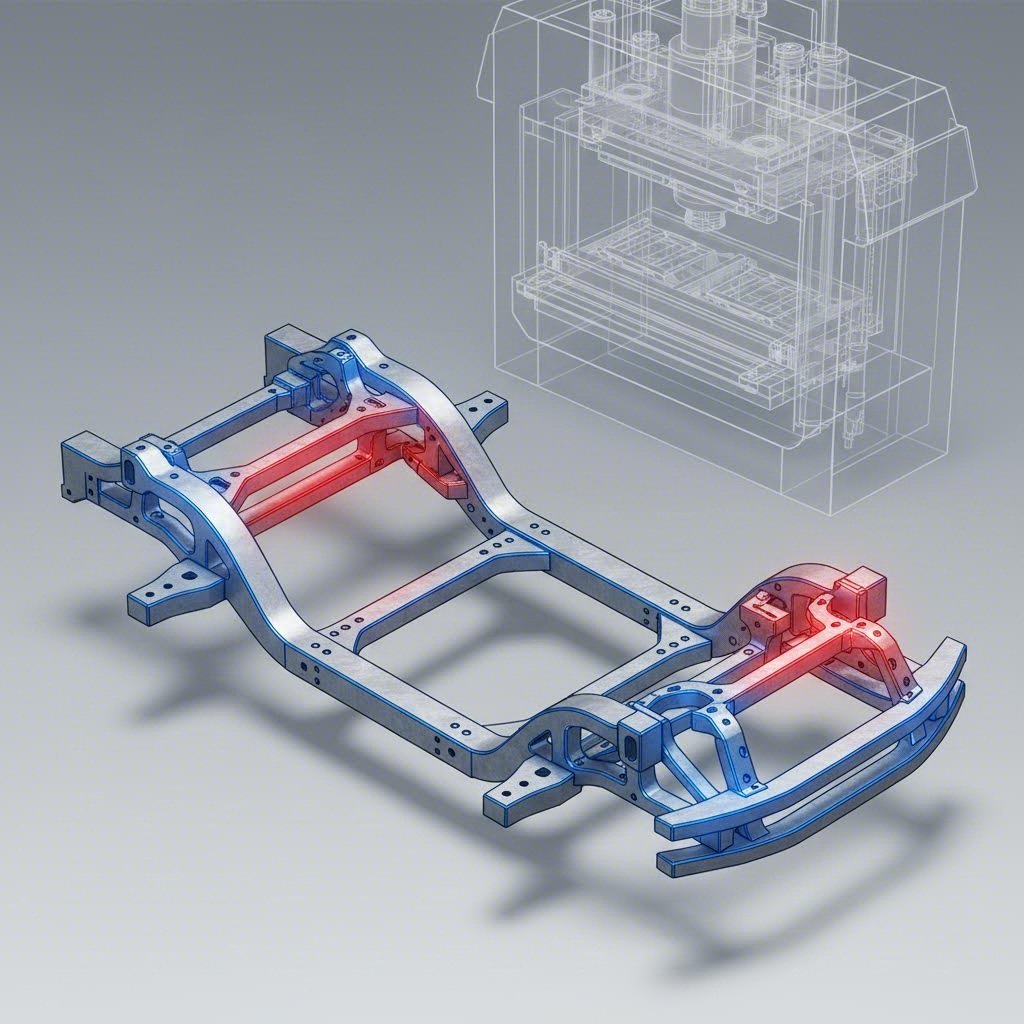

Press & Equipment Requirements: The Hidden Costs

Transitioning from mild steel to high strength steel stamping automotive applications requires more than just stronger dies; it demands a comprehensive facility audit.

The Tonnage Multiplier

The strength of the material directly correlates to the force required to deform it. A general rule of thumb for engineers is that stamping DP800 requires approximately twice the tonnage of HSLA 50XF for the same part geometry. Mechanical presses that were sufficient for mild steel often stall or lack the energy capacity at the bottom of the stroke when processing these grades.

Managing Snap-Through Shock

One of the most damaging phenomena in HSS stamping is "snap-through" or negative tonnage. When a high-strength blank fractures (is cut), the stored potential energy releases instantaneously. This sends a severe shockwave back through the press structure, putting tie rods and bearings in tension/compression cycles they weren't designed for. Reducing snap-through often requires hydraulic dampers or slowing down the press, which impacts throughput.

Feed Line Upgrades

The coil feeding system is often an overlooked bottleneck. Standard straighteners designed for mild steel cannot effectively remove the coil set from high-strength materials. Processing HSS requires straighteners with:

- Smaller diameter work rolls: To bend the material more sharply.

- Closer roll spacing: To apply sufficient alternating stress.

- Larger backup rolls: To prevent the work rolls from deflecting under the immense pressure.

Process Challenges: Heat, Wear, and Formability

The physics of forming changes drastically as yield strengths rise. Friction generates significantly more heat, and the window for error narrows.

Thermal Build-Up and Friction

In stamping, energy doesn't just disappear; it transforms into heat. According to industry data, while forming 2mm mild steel might generate temperatures around 120°F (50°C) at the die corner, forming DP1000 can drive temperatures up to 210°F (100°C) or higher. This thermal spike can break down standard lubricants, leading to direct metal-to-metal contact.

Tool Wear and Galling

The higher contact pressures required to form AHSS lead to accelerated tool wear. "Galling"—where material from the sheet adheres to the tool—is a frequent failure mode. Once a tool begins to gall, part quality plummets. Studies indicate that worn tools can reduce the hole expansion capacity (a measure of edge stretchability) of DP and TRIP grades by up to 50%, leading to edge splitting during flanging operations.

Selecting the Right Partner

Given these complexities, selecting a manufacturing partner with the right equipment portfolio is crucial. Manufacturers like Shaoyi Metal Technology bridge this gap by offering precision press capabilities up to 600 tons, specifically catering to the high-tonnage demands of automotive structural components. Their IATF 16949 certification ensures that the rigorous process controls needed for AHSS—from prototype to mass production—are strictly maintained.

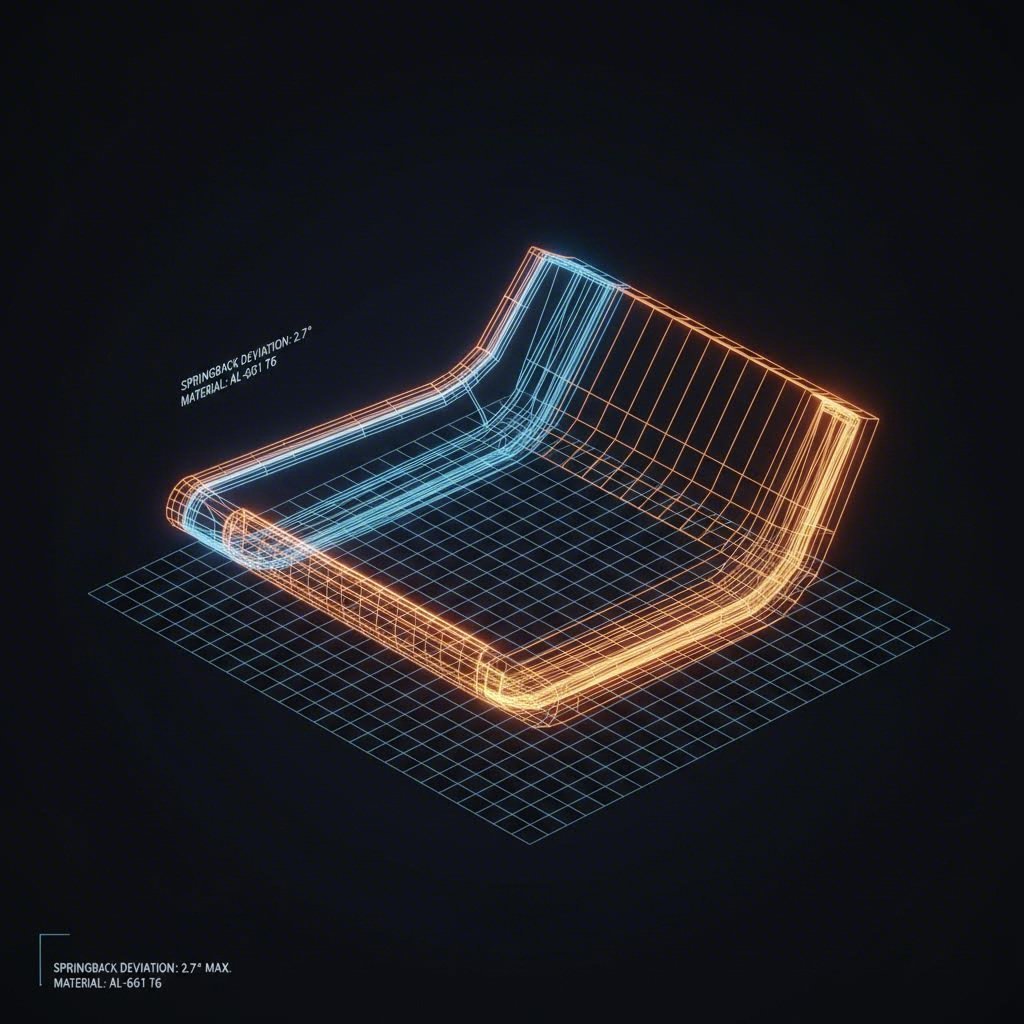

Springback: The Nemesis of Precision

Springback is the geometric change a part undergoes at the end of the forming process when the forming forces are released. For high-strength steels, this is the primary quality challenge.

The Physics of Elastic Recovery

Elastic recovery is proportional to the material's yield strength. Since AHSS has a yield strength 3–5 times that of mild steel, the springback is proportionally more severe. A side-wall curl or angular change that was negligible in mild steel becomes a gross tolerance failure in DP600.

Simulation is Mandatory

Trial-and-error is no longer a viable methodology. Modern tool design relies on advanced simulation software (such as AutoForm) to predict springback before steel is ever cut. These "Digital Process Twins" allow engineers to test compensation strategies—like overbending or displacing material—virtually. The industry standard is now to run full springback compensation loops in software to generate a "windage" surface for the die machinery.

Future Trends: Hot Stamping & Multi-Part Integration

As safety standards evolve, the industry is moving beyond cold stamping for its most critical applications.

Hot Stamping (Press Hardening)

For parts like A-pillars and B-pillars that require tensile strengths above 1500 MPa, cold stamping is often impossible. The solution is Hot Stamping, where boron steel (e.g., Usibor) is heated to ~900°C, formed while soft, and then quenched inside the water-cooled die. This process produces parts with extreme strength and virtually no springback.

Laser Welded Blanks (LWB)

Manufacturers like ArcelorMittal are championing Multi-Part Integration (MPI) using Laser Welded Blanks. By welding different grades of steel (e.g., a soft deep-drawing grade and a rigid UHSS grade) into a single blank before stamping, engineers can tune the performance of specific areas of a part. This reduces the total part count, eliminates assembly steps, and optimizes weight distribution.

Conclusion: The Path to Lightweighting Mastery

Mastering high strength steel stamping automotive processes is no longer just a competitive advantage; it is a baseline requirement for Tier 1 suppliers. The transition from mild steel to AHSS and UHSS demands a cultural shift in manufacturing—moving from empirical "tryout" methods to data-driven, simulation-led engineering.

Success in this arena relies on three pillars: robust equipment capable of handling high tonnage and shock; advanced simulation to predict and compensate for springback; and material expertise to navigate the trade-offs between strength and formability. As vehicle designs continue to push for lighter, safer structures, the ability to stamp these difficult materials efficiently will define the leaders of the next generation of automotive manufacturing.

Frequently Asked Questions

1. What is the best metal for automotive metal stamping?

There is no single "best" metal; the choice depends on the specific application. HSLA is excellent for general structural parts due to its balance of cost and strength. Dual Phase (DP) steel is often preferred for crash-relevant parts like rails and cross-members because of its high energy absorption. For skin panels (fenders, hoods), softer Bake Hardenable (BH) steels are used to ensure surface quality and dent resistance.

2. Can you repair high-strength steel vehicle parts?

Generally, no. Parts made from Ultra-High-Strength Steel (UHSS) or press-hardened boron steel should typically not be repaired, heated, or sectioned. The heat from welding or straightening can destroy the carefully engineered microstructure, significantly reducing the part's crash safety performance. OEM repair guidelines usually mandate full replacement of these components.

3. What is the main difference between HSLA and AHSS?

The main difference lies in their microstructure and strengthening mechanism. HSLA (High-Strength Low-Alloy) relies on micro-alloying elements (like niobium) to increase strength in a single-phase ferrite structure. AHSS (Advanced High-Strength Steel) utilizes complex multi-phase microstructures (like ferrite plus martensite in DP steel) to achieve a superior combination of high strength and formability that HSLA cannot match.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —