Machining Services Decoded: From Quote Request To Finished Part

Understanding Modern Machining Services and Their Role in Manufacturing

Ever wondered how a solid block of aluminum transforms into a precision aerospace bracket? Or how medical implants achieve tolerances measured in thousandths of an inch? The answer lies in machining services—a cornerstone of modern manufacturing that turns raw materials into functional components with remarkable accuracy.

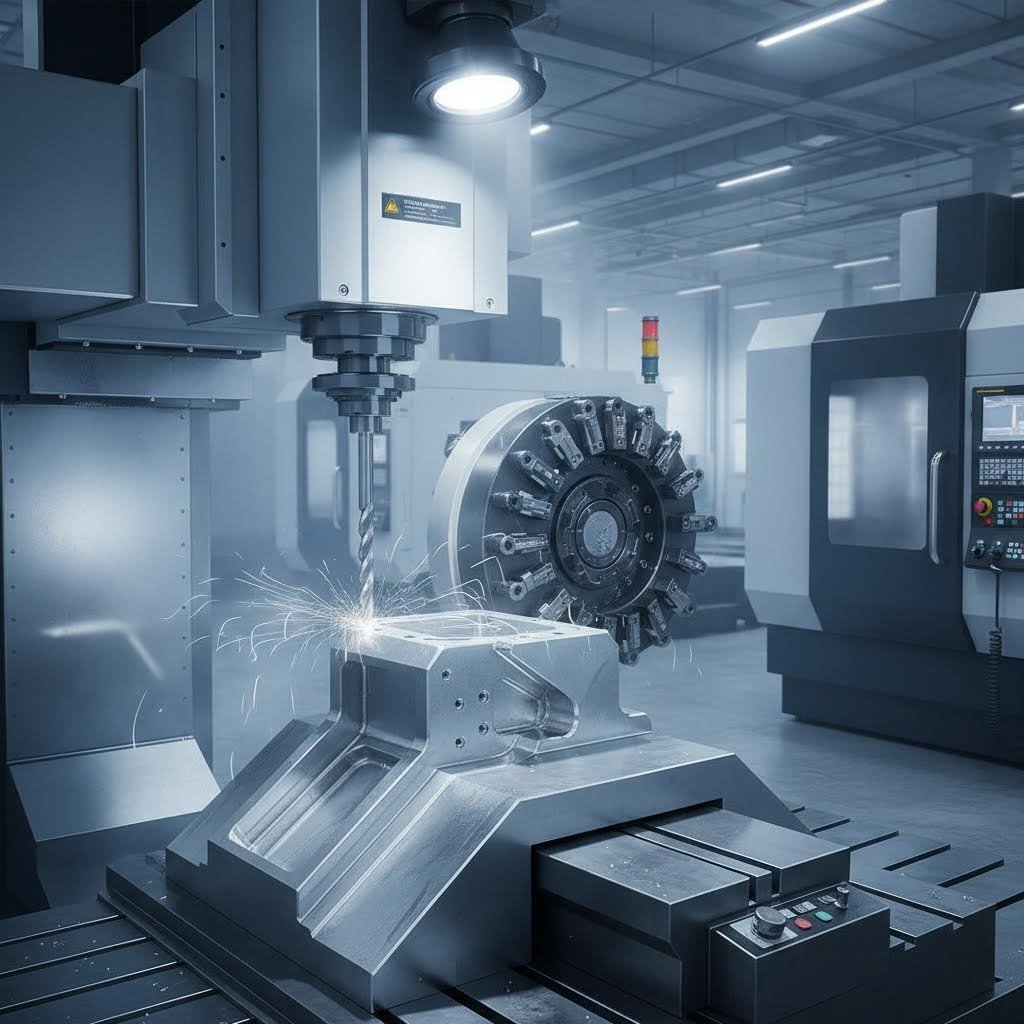

At its core, machining is a subtractive manufacturing process where computer-controlled tools remove material from a workpiece to create the desired shape. Unlike 3D printing, which builds parts layer by layer, CNC machining cuts away excess material following precise digital instructions called G-code. This approach delivers exceptional strength, surface quality, and dimensional accuracy that industries depend on daily.

What Machining Services Actually Deliver

When you partner with a machining provider, you're accessing sophisticated metal machining capabilities powered by Computer Numerical Control technology. CNC machines interpret CAD designs through CAM software, translating your 3D models into exact cutting paths. The result? Parts manufactured with tolerances of ±0.001 inches or better—precision impossible to achieve by hand.

These services span multiple industries: aerospace components requiring certified traceability, automotive parts demanding high-volume consistency, medical devices needing biocompatible materials, and electronics requiring intricate geometries. Whether you need a single prototype or thousands of production units, CNC metal processing adapts to your requirements.

From Raw Material to Precision Component

Understanding the primary machining operations helps you communicate effectively with suppliers and make informed design decisions. Here are the four fundamental processes you'll encounter:

- CNC Turning: The workpiece rotates while a stationary cutting tool shapes it. Ideal for cylindrical parts like shafts, bushings, and threaded components. Achieves accuracy grades of IT10-IT7.

- Milling: A rotating multi-tooth cutter moves across the workpiece to create flat surfaces, slots, pockets, and complex 3D contours. This versatile process handles everything from simple plates to intricate aerospace brackets.

- Drilling: Specialized drill bits create precise holes—through holes, blind holes, counterbores, and countersinks. Often the first step in hole machining before reaming or tapping operations.

- Grinding: High-speed abrasive wheels remove minimal material to achieve superior surface finishes (Ra 1.6-0.1μm) and tight tolerances (IT6-IT5). Essential for hardened parts and precision finishing.

Many projects combine these operations. CNC cutting and cnc fabrication workflows often integrate turning, milling, and drilling in multi-axis machines that reduce setup time and improve accuracy.

Throughout this guide, you'll learn how to navigate the complete machining journey—from requesting your first quote to receiving finished parts. We'll cover material selection, tolerance specifications, cost factors, and how to choose the right manufacturing partner. Whether you're an engineer designing your first machined component or a procurement professional evaluating suppliers, this knowledge will help you make confident decisions.

Material Selection Guide for Machined Components

Choosing the wrong material for your CNC project can cost thousands in wasted parts and extended machine downtime. Imagine specifying aluminum when your application demands stainless steel's corrosion resistance—or paying premium prices for exotic alloys when mild steel performs equally well at a fraction of the cost. Material selection isn't just a technical decision; it directly impacts part performance, production efficiency, and your bottom line.

The good news? Understanding how material properties affect machinability helps you balance performance requirements against budget constraints. Let's explore the metals and plastics that dominate precision manufacturing—and when each makes economic sense.

Metals That Machine Best

Metals remain the backbone of machining services, offering strength, durability, and thermal resistance that plastics simply can't match. However, not all metals behave the same under cutting tools.

Aluminum alloys dominate general-purpose applications for good reason. According to industry research, aluminum accounts for 43% of all CNC machining operations in high-volume production. Aluminum 6061 delivers excellent machinability, good strength-to-weight ratio, and natural corrosion resistance. You can run cutting speeds 3-4 times faster than with steel, which directly reduces cycle time and cost. For higher-strength requirements, 7075 aluminum offers 83,000 psi tensile strength—nearly double that of 6061—making it ideal for aerospace structural parts.

Stainless steel enters the picture when corrosion resistance becomes non-negotiable. The 304 grade serves food processing equipment and medical instruments, while 316 stainless adds molybdenum for enhanced chemical resistance in marine environments. Expect machining to take 2-3 times longer than aluminum due to work-hardening characteristics that require sharp tools and proper feeds.

When you need to machine bronze for bearing surfaces or electrical applications, CNC bronze components deliver excellent wear resistance and low friction. Brass C36000 offers high tensile strength with natural corrosion resistance and ranks among the most easily machinable materials—perfect for high-volume applications requiring consistent chip formation.

When Plastics Outperform Metal Components

Engineering plastics offer advantages that metals simply cannot provide: lightweight construction, chemical resistance, electrical insulation, and lower material costs. The key lies in matching plastic properties to your specific application.

Delrin (POM/Acetal) machines beautifully and provides the lowest friction coefficient among engineering plastics. This delrin material excels in gears, bushings, and sliding components where metal-on-metal contact causes wear. Delrin plastic maintains dimensional stability at elevated temperatures with very low water absorption—critical for precision assemblies.

When machining nylon components, remember that this versatile thermoplastic offers excellent impact resistance and fatigue life. However, nylon for machining presents one challenge: it absorbs moisture (up to 2.5% by weight), causing dimensional changes. Parts must be machined oversized and stabilized before final dimensions. Despite this consideration, nylon remains popular for mechanical equipment assemblies requiring toughness.

PEEK represents the high-performance end of engineering plastics. It withstands temperatures up to 480°F while maintaining dimensional stability, tolerates repeated steam sterilization, and offers chemical resistance surpassing most metals. Medical device manufacturers increasingly specify PEEK for spinal fusion cages and surgical guides because it doesn't create artifacts in CT or MRI imaging.

Specialty materials like zinc alloy metal serve applications requiring excellent castability combined with machining for final dimensions. These alloys (Zamak 3, Zamak 5) offer good strength and are frequently used for decorative hardware and precision components.

| Material Type | Machinability Rating | Typical Applications | Cost Considerations |

|---|---|---|---|

| Aluminum 6061 | Excellent (90%) | Prototypes, aerospace brackets, consumer products | Low material cost ($8-12/kg); fastest machining speeds reduce labor costs |

| Aluminum 7075 | Good (70%) | Aircraft structural parts, high-stress automotive components | Moderate material cost; heat treatable to high strength |

| Stainless Steel 304 | Moderate (45%) | Food processing, medical instruments, marine hardware | Higher material cost ($15-25/kg); 2-3x longer cycle times than aluminum |

| Stainless Steel 316 | Moderate (40%) | Chemical processing, marine environments, surgical tools | Premium pricing for enhanced corrosion resistance |

| Bronze C95400 | Good (65%) | Bearings, bushings, marine fittings, electrical connectors | Moderate cost; excellent for wear applications |

| Brass C36000 | Excellent (100%) | High-volume fasteners, decorative hardware, electrical components | Baseline machinability; very cost-effective for production runs |

| Delrin (POM) | Excellent (85%) | Gears, bushings, precision mechanical parts | Moderate plastic cost; machines like aluminum at 1/7 the weight |

| Nylon 6/66 | Good (70%) | Wear components, structural parts, food-contact applications | Low material cost; requires moisture stabilization planning |

| PEEK | Moderate (55%) | Medical implants, aerospace components, chemical processing | High material cost ($150-200/kg); justified by unique properties |

| Titanium Grade 5 | Poor (22%) | Aerospace structures, medical implants, marine hardware | Very high cost ($50-80/kg); 5-8x machining costs vs. aluminum |

Material selection represents the single most impactful decision in product development—it affects every downstream manufacturing process and ultimately determines product success or failure.

Here's a practical decision framework: Start with aluminum unless you need corrosion resistance in harsh chemical environments, temperatures above 200°C, or yield strength exceeding 40,000 psi. According to manufacturing efficiency data, aluminum reduces total manufacturing cost by 40-60% compared to stainless steel when both materials meet functional requirements. Consider anodized aluminum as a middle ground—it provides enhanced corrosion protection while maintaining aluminum's production speed advantages.

With your material selected, the next critical step is understanding how the machining process transforms your design file into a finished component. From quote request through final inspection, each stage builds toward delivering parts that meet your exact specifications.

How the Machining Process Works From Quote to Delivery

You've selected your material and finalized your CAD design. Now what? For many engineers and procurement professionals, the journey from quote request to receiving cnc machined parts feels like a black box. You submit files, wait for a price, approve the order—and somehow finished components arrive weeks later. Understanding what happens during each stage helps you set realistic timelines, avoid costly delays, and communicate more effectively with your machining partner.

The reality? A well-prepared project moves through the production pipeline smoothly, while missing information or design issues can stall progress for days. Let's walk through each phase so you know exactly what to expect—and how to prepare your project for manufacturing success.

The Quote-to-Part Journey

Every machining project follows a predictable sequence of steps. Knowing these stages helps you plan timelines accurately and identify potential bottlenecks before they impact your schedule. Here's the complete workflow from initial inquiry to final delivery:

- Design File Submission: You upload your 3D CAD files through the supplier's portal or email. Most shops accept STEP (.step/.stp), IGES (.iges/.igs), Solidworks (.sldprt), and native CAD formats. According to industry best practices, always accompany your primary CAD file with a technical drawing in PDF format—especially when you have critical tolerances, surface finish requirements, or assembly instructions.

- Manufacturability Review (DFM): Engineers analyze your design for potential machining challenges. They check for tool clearance issues, undercuts that require special fixturing, wall thicknesses below minimum recommendations (typically 1.5-2mm for plastics), and tolerances that may require secondary operations. This early review prevents expensive mid-production changes.

- Quoting: The supplier calculates material costs, machine time, setup requirements, and any secondary operations. Many providers now offer a cnc quote online within hours rather than days. Quantities, material selection, tolerance requirements, and lead time urgency all factor into the final price.

- Order Confirmation and Scheduling: Once you approve the quote, production scheduling begins. Your job enters the queue based on machine availability, material procurement status, and requested delivery date. Rush orders may receive priority scheduling at premium rates.

- Material Procurement: Standard materials like 6061 aluminum or 304 stainless steel typically ship from distributors within 1-2 days. Specialty alloys—aerospace-grade titanium, medical-grade PEEK, or certified material with full traceability—may require 1-3 weeks of lead time.

- Machining Operations: CNC machines execute the programmed toolpaths, removing material to create your part geometry. Complex parts may require multiple setups across different machines—turning operations on a lathe, followed by milling for features perpendicular to the axis of rotation.

- Quality Inspection: Finished machining parts undergo dimensional verification against your specifications. First article inspection confirms the setup produces conforming parts before full production runs. CMM measurements, surface finish checks, and visual inspection ensure every dimension falls within tolerance.

- Post-Processing and Finishing: Parts receive any specified secondary treatments—deburring, anodizing, plating, heat treatment, or assembly operations. These steps must be coordinated in advance to avoid delivery delays.

- Packaging and Shipping: Components are cleaned, protected, and packaged appropriately for transit. Documentation including inspection reports, material certifications, and conformance statements accompanies the shipment.

What Happens After You Submit Your CAD File

The hours immediately following file submission determine how quickly your project advances—or stalls. Here's what occurs behind the scenes and how to accelerate the process.

First, your files undergo automated geometry checks. The system verifies file integrity, confirms the model is watertight (no missing surfaces), and flags obvious issues like zero-thickness walls or intersecting bodies. Corrupt files or incompatible formats trigger immediate requests for resubmission.

Next, a manufacturing engineer reviews your design against machining constraints. They're checking questions you may not have considered: Can standard tooling reach all features? Will the part deflect under cutting forces? Are internal corners specified with radii matching available end mills? According to production planning experts, the most common source of delay in CNC machining workflows is late-stage design revisions triggered by geometry issues that only surface when toolpaths are generated.

For cnc prototyping and rapid cnc prototyping projects, this review phase compresses significantly. Experienced suppliers apply design-for-manufacturability principles early, identifying potential issues before they become production problems. The best partners provide feedback within hours—not days—allowing you to iterate quickly.

A well-prepared file with complete specifications moves through the quoting process in hours. Missing dimensions, unclear tolerances, or ambiguous notes can delay your quote by days while engineers seek clarification.

Here's how to prepare your project for the fastest possible turnaround when requesting online machining quotes:

- Use industry-standard file formats: STEP files preserve mathematical surface definitions better than STL files, which approximate geometry using triangles and can introduce inaccuracies.

- Include a 2D drawing: Even with perfect 3D models, a drawing clarifies tolerances, surface finishes, thread specifications, and critical dimensions that aren't obvious from geometry alone.

- Specify units clearly: Confirm whether dimensions are in millimeters or inches. Scaling errors from unit confusion waste time and material.

- Identify critical features: Flag the dimensions that matter most. GD&T callouts communicate design intent better than blanket tolerance statements.

- Note material and quantity: Providing this information upfront eliminates back-and-forth communication and speeds quote generation.

Understanding tolerances—and their impact on cost and lead time—becomes your next advantage. The specifications you choose directly influence which inspection methods apply to your parts and how much precision costs.

Tolerances and Surface Finishes That Define Part Quality

Here's a scenario every engineer encounters: You specify ±0.001 inches on every dimension because tighter tolerances mean better quality, right? Not exactly. That blanket tolerance specification just increased your machining costs by 40% and added a week to your lead time—without improving part function. Understanding when precision matters (and when it doesn't) separates cost-effective designs from budget-busting ones.

Tolerances define the permissible variation in a part's dimensions. According to precision manufacturing experts, no manufacturing process produces geometrically exact parts. Tolerances communicate acceptable deviation from nominal specifications, ensuring parts function as intended within their mechanical context. The key lies in specifying only the precision your application actually requires.

Standard vs Tight Tolerances Explained

Machining services typically offer tolerance tiers that balance capability against cost. Standard tolerances—around ±0.005 inches (±0.127mm)—cover most general-purpose applications without special process controls. These tolerances result from well-maintained CNC equipment running proven programs with quality cutting tools.

Tight tolerances enter different territory. When you specify ±0.001 inches (±0.025mm) or tighter, several cost factors compound quickly:

- Slower cutting speeds: Machines must reduce feed rates and spindle speeds to maintain accuracy, extending cycle time significantly.

- Premium tooling: Precision cutting tools with tighter runout specifications cost more and require more frequent replacement.

- Environmental controls: Temperature variations affect both machine geometry and workpiece dimensions. Tight-tolerance work often requires climate-controlled environments.

- Enhanced inspection: Every precision cnc machining operation requires verification. CMM measurements add time and cost compared to simple gauge checks.

- Higher scrap rates: Tighter tolerance bands mean more parts fall outside acceptable limits, increasing material waste.

For cnc milling parts and cnc machining milling operations, industry guidelines recommend standard bilateral tolerances of ±0.005 inches for most features. This specification works for the majority of machined parts and custom machined parts that don't require interference fits or precision assembly.

| Tolerance Class | Typical Range | Common Applications | Cost Impact |

|---|---|---|---|

| Commercial | ±0.010" (±0.25mm) | Brackets, covers, non-critical structural parts | Baseline cost; fastest production |

| Standard | ±0.005" (±0.127mm) | General mechanical components, housings, fixtures | 10-15% above commercial; standard inspection |

| Precision | ±0.002" (±0.05mm) | Bearing fits, assembly interfaces, sliding components | 25-40% above standard; CMM verification required |

| High Precision | ±0.001" (±0.025mm) | Aerospace interfaces, medical devices, optical mounts | 50-100% above standard; climate control often needed |

| Ultra-Precision | ±0.0005" (±0.013mm) | Metrology equipment, semiconductor tooling, master gauges | 2-3x standard cost; specialized equipment required |

When Microns Matter in Your Design

Tight tolerances aren't arbitrary quality markers—they serve specific functional purposes. Precision machining services focus these specifications where they directly impact performance:

- Mating surfaces and interference fits: Bearing seats, shaft shoulders, and press-fit connections require controlled dimensions for proper function.

- Sealing surfaces: O-ring grooves and gasket faces demand flatness and dimensional accuracy to prevent leakage.

- Rotating assemblies: Concentricity and runout specifications prevent vibration and premature wear in spinning components.

- Optical and alignment features: Mounting surfaces for lenses, sensors, or precision instruments need micron-level accuracy.

The most common tolerancing mistake? Applying tight specifications uniformly across all features. According to manufacturing cost analysis, engineers sometimes apply unnecessarily tight tolerances by default or due to lack of feedback from manufacturing teams. A strategic approach specifies precision only where function demands it—saving significant cost on non-critical dimensions.

GD&T (Geometric Dimensioning and Tolerancing) provides tools for communicating functional requirements precisely. Rather than specifying ±0.005" on a hole location using X and Y coordinates, true position callouts define the hole's location from reference datums with modifiers like MMC (maximum material condition). This approach often allows larger tolerances while still guaranteeing assembly fit.

Surface Finish Requirements and Ra Values

Surface roughness works alongside dimensional tolerances to define part quality. The Ra value—roughness average—measures the arithmetic mean of surface deviations from the mean line, expressed in micrometers (μm) or micro-inches (μ-in).

According to surface finish specifications, the standard as-machined finish of 3.2 μm Ra represents the most cost-effective option. This finish leaves visible tool marks but works perfectly for most mechanical applications. Achieving smoother finishes requires additional passes with finer cutting parameters or secondary operations like polishing—each step adding cost and time.

Here's a practical guide to Ra specifications:

- 3.2 μm Ra (125 μ-in): Standard machined finish; visible tool marks; suitable for non-cosmetic structural parts

- 1.6 μm Ra (63 μ-in): Fine machined finish; minimal visible marks; good for sliding surfaces and general assemblies

- 0.8 μm Ra (32 μ-in): Very fine finish; requires slower speeds or polishing; used for sealing surfaces and precision fits

- 0.4 μm Ra (16 μ-in): Near-mirror finish; requires lapping or extensive polishing; specified for optical applications

Manufacturing costs increase as surface roughness decreases. A 0.4 μm Ra finish can cost 3-5 times more than standard 3.2 μm Ra due to additional machining passes and manual polishing operations.

The relationship between tolerances and quality assurance runs deep. Tighter specifications demand more rigorous inspection protocols—CMM measurements instead of simple go/no-go gauges, first article reports documenting every critical dimension, and statistical process control tracking variation across production runs. These quality processes add value when precision matters, but represent unnecessary overhead when standard tolerances suffice.

With tolerance and surface finish specifications in hand, you're ready to evaluate whether CNC machining is the right manufacturing method for your project—or whether alternative processes might better serve your requirements.

Choosing Between CNC Machining and Alternative Manufacturing Methods

Should you machine it, print it, mold it, or cast it? This question haunts product developers at every stage—from early prototypes to full-scale production. Choose wrong, and you're stuck with parts that cost too much, take too long, or fail to meet performance requirements. Choose right, and you've optimized cost, quality, and timeline in one strategic decision.

The reality? No single manufacturing method wins every scenario. CNC machining parts excel in specific situations, while 3D printing, injection molding, and casting each claim distinct advantages. According to manufacturing process comparisons, selecting the right process depends on five key factors: volume requirements, lead time constraints, material needs, design complexity, and budget limitations. Let's break down when each method makes the most sense.

Machining vs Additive Manufacturing Decision Points

CNC machining and 3D printing represent opposite manufacturing philosophies—subtractive versus additive. Understanding their fundamental differences helps you match each process to appropriate applications.

CNC machining removes material from solid blocks using precision cutting tools. This approach delivers:

- Superior dimensional accuracy with tolerances reaching ±0.001 inches

- Excellent surface finishes directly off the machine

- Access to the broadest range of engineering materials—metals, plastics, and composites

- Mechanical properties identical to the base material (no layer lines or anisotropy)

3D printing builds parts layer by layer from powder or filament. Its strengths include:

- Virtually unlimited geometric freedom—internal channels, lattice structures, and organic shapes

- Zero tooling costs regardless of complexity

- Fastest turnaround for one-off parts (2-7 business days)

- Minimal material waste compared to subtractive processes

When does cnc prototype machining beat 3D printing? According to industry analysis, CNC becomes the preferred choice when you need production-grade materials, tight tolerances on critical features, or quantities between 10-100 units where printing time accumulates faster than machining setup amortizes.

For prototype machining specifically, consider this decision framework:

- Choose CNC prototyping when testing functional fit with production-intent materials, validating mechanical performance under load, or creating parts that must integrate with existing machined components.

- Choose 3D printing when exploring design variations quickly, testing form and ergonomics before committing to final geometry, or producing complex shapes that would require expensive multi-axis machining.

Many successful product development programs use both methods strategically. Early concepts might go through rapid 3D-printed iterations, while critical cnc prototype parts validate functional requirements before production tooling investments.

When Each Method Makes Economic Sense

Cost-per-part curves tell the real story. Each manufacturing process has a crossover point where it becomes more economical than alternatives—and understanding these thresholds prevents expensive mistakes.

| Manufacturing Method | Best For | Volume Range | Material Options | Lead Time |

|---|---|---|---|---|

| CNC Machining | Precision parts, functional prototypes, low-to-medium production | 1-5,000 units | 20+ metals and plastics; broadest engineering material access | 7-14 business days |

| 3D Printing (SLS/MJF) | Complex geometries, rapid iteration, small batches | 1-10,000 units | 5-10 plastics; limited metals via DMLS | 2-7 business days |

| Injection Molding | High-volume plastic production, consistent repeatability | 10,000+ units | 100+ thermoplastics and elastomers | 15-60 business days (includes tooling) |

| Metal Casting | Large parts, complex internal geometries, high volumes | 100-100,000+ units | Most castable alloys (aluminum, bronze, iron, steel) | 20-45 business days |

Injection molding economics: The £3,000+ tooling investment only makes sense when spread across thousands of parts. According to cost analysis data, injection molding achieves the lowest per-unit cost at scale—sometimes under £1 per part—but requires significant upfront commitment. For an electronic enclosure example, injection molding only becomes cost-competitive above 500 units when compared against 3D printing.

CNC machining economics: With setup fees typically ranging from £100-300, CNC occupies the middle ground. It's more expensive per-part than injection molding at high volumes but far more economical for quantities under 500 units. Cnc plastic machining offers an alternative when you need plastic parts without mold tooling investment—particularly valuable for medical devices or specialized equipment with lower volume requirements.

Casting economics: Similar to injection molding, casting requires tooling (patterns and molds) that amortize over larger production runs. Manufacturing comparisons suggest casting becomes cost-effective around 100+ units for metal parts, with advantages growing significantly at 1,000+ quantities.

The smartest approach is often hybrid: start with 3D printing to prove the concept, use CNC for critical functional prototypes, and move into injection molding when demand is ready.

Beyond pure economics, consider these additional decision factors:

- Design flexibility: 3D printing allows consequence-free design changes. CNC requires minimal reprogramming. Injection molding locks you into geometry once tooling is cut—modifications mean new molds at full cost.

- Material properties: CNC-machined parts have isotropic properties matching base material specifications. 3D-printed parts may show layer-dependent strength variations. Injection-molded parts achieve excellent consistency but are limited to thermoplastics.

- Surface quality: CNC delivers the best as-manufactured surface finish. 3D printing shows layer lines requiring post-processing. Injection molding produces excellent surfaces with proper tooling.

- Carbon fiber prototyping: When developing composite components, CNC machining carbon fiber sheet stock or blocks provides functional prototypes with actual material properties—something additive processes cannot replicate with the same fiber architecture.

For product developers facing volume uncertainty, start with CNC machining or 3D printing to validate market demand before committing to injection mold tooling. This approach minimizes financial risk while allowing rapid iteration based on customer feedback.

Understanding which manufacturing method fits your requirements is only half the equation. The next critical question: what will it actually cost? Machining pricing depends on factors you can influence through smart design choices.

Pricing Factors and Cost Optimization Strategies

You've received your machining quote—and the number seems higher than expected. Before questioning the supplier, consider this: every line item reflects real manufacturing variables you can influence. Understanding what drives cnc machining price helps you make design decisions that optimize your budget without sacrificing part performance.

The truth? Most cost overruns stem from specifications that seemed harmless during design but compound exponentially during production. According to manufacturing cost analysis, factors like design complexity, tolerances, and material selection don't add cost linearly—they multiply it. A part that machines in 20 minutes from aluminum might require 90 minutes in titanium, with tooling costs tripling along the way.

What Drives Machining Costs Up or Down

Every machining quote reflects a calculation balancing machine time, material costs, labor, and overhead. Here are the primary factors that influence your final machinist metal cost:

- Material Selection: Cnc machining materials vary dramatically in cost and machinability. Aluminum machines 3-4 times faster than stainless steel, meaning lower labor costs per part. Exotic alloys like Inconel or titanium require specialized tooling that wears quickly, adding both direct material costs and indirect tooling expenses. Choosing a more machinable material—when application requirements permit—delivers immediate savings.

- Part Complexity: Intricate geometries demand more machine time, specialized tooling, and often multiple setups. According to industry experts, complex toolpaths with more movements increase both programming time and cycle time. Deep pockets, thin walls, and tight internal corners require slower cutting speeds and more frequent tool changes—each adding minutes that accumulate into hours across production runs.

- Tolerance Requirements: Every step tighter in tolerance specification triggers exponential cost increases. Standard tolerances (±0.005") use proven processes with minimal inspection. Precision tolerances (±0.001") demand slower feeds, climate-controlled environments, and CMM verification. As noted in design-for-cost guidelines, tolerance optimization represents one of the highest-impact opportunities for cost reduction.

- Quantity and Batch Size: Setup costs remain fixed regardless of whether you order 1 part or 100. Larger production volumes spread programming, fixturing, and first-article inspection across more units, dramatically reducing per-piece cost. Small cnc machining projects for prototypes carry higher unit costs simply because these fixed expenses cannot be amortized.

- Surface Finish Specifications: Standard machined finishes come at baseline cost. Requesting mirror-like finishes (Ra 0.4 μm) requires additional finishing passes, specialized tooling, and potentially secondary operations like polishing—each step adding significant time and labor expense.

- Lead Time Urgency: Rush orders disrupt production schedules. According to manufacturing operations experts, short lead times drive cost due to overtime requirements and expedited material procurement. Standard lead times allow efficient scheduling and material sourcing at regular prices.

- Tooling Requirements: Standard tool sizes cost nothing extra. Non-standard radii, unusual thread specifications, or features requiring custom cutters add both tooling purchase costs and setup time. Proper tool selection matched to material and process—plus regular maintenance—reduces machining expenses and improves productivity.

Smart Strategies to Optimize Your Budget

Cost reduction doesn't mean compromising quality—it means eliminating waste. Here's how to design smarter and work more effectively with your custom cnc machining services provider:

- Simplify geometry where function permits: According to DFM specialists, a minor adjustment to pocket depths and corner radii—changes with no functional impact—can reduce cycle time by 30% or more. Use standard corner radii that match common end mill sizes (3mm, 6mm, 10mm) rather than arbitrary dimensions requiring custom tooling.

- Apply tight tolerances selectively: Reserve precision specifications for mating surfaces, bearing fits, and critical interfaces. Cost analysis shows that relaxing a non-critical tolerance from ±0.01mm to ±0.05mm can cut machining cost for that feature by over 50%.

- Consolidate features when possible: Designing a single complex part instead of multiple simple components eliminates assembly costs, reduces bill-of-materials complexity, and often improves final product accuracy by removing tolerance stack-up between mated parts.

- Choose materials strategically: If your application allows, aluminum delivers equivalent performance at 40-60% lower manufacturing cost compared to stainless steel. Consider material substitutions early in design when flexibility exists.

- Optimize batch sizes: If you anticipate ongoing demand, ordering larger quantities upfront spreads fixed costs across more parts. Even modest volume increases—from 10 to 50 units—can reduce per-part pricing by 20-30%.

- Engage suppliers early: According to manufacturing partners, early collaboration uncovers cost-saving opportunities before designs are finalized. A brief DFM review can identify expensive features that simple modifications eliminate.

- Plan realistic lead times: Standard scheduling avoids overtime premiums and expedited shipping charges. Building buffer time into your project timeline prevents rush fees that can add 25-50% to baseline costs.

The most successful projects balance design intent with manufacturing reality through early collaboration—transforming potential cost overruns into optimized production runs.

Understanding these cost drivers empowers you to make informed trade-offs. But pricing represents only part of the supplier evaluation equation. Industry-specific requirements—certifications, traceability standards, and quality protocols—add another layer of complexity that directly affects which machining partner can serve your needs.

Industry-Specific Requirements for Aerospace, Medical, and Automotive

Here's the scenario: You've designed a precision component that meets every functional requirement. Your supplier delivers parts within tolerance, on schedule, and at competitive pricing. Then your customer rejects the entire shipment because the machining provider lacks the required industry certification. This happens more often than you'd expect—and understanding sector-specific compliance requirements before selecting a machining partner prevents costly mistakes.

Different industries impose vastly different quality management demands on machining services. What works perfectly for general industrial applications fails immediately in aerospace, medical, or automotive contexts. These sectors require certified quality systems, documented material traceability, and specialized protocols that go far beyond standard manufacturing practices. Let's explore what each industry demands—and why these requirements exist.

Aerospace Machining Compliance Requirements

Aerospace components face operating conditions that leave zero margin for error. Parts must perform flawlessly at extreme temperatures, under significant stress loads, and often in applications where failure risks lives. This reality drives the most stringent quality requirements in manufacturing.

The AS9100D standard represents the gold standard for aerospace quality management systems. According to Americas Aerospace Quality Group (AAQG) Spring 2024 meeting statistics, 96% of AS9100 series certified companies have fewer than 500 employees—demonstrating that certification isn't exclusive to industry giants. Major manufacturers including Boeing, Airbus, Lockheed Martin, and Northrop Grumman require AS9100 compliance as a condition of doing business.

What makes AS9100D different from general quality standards? The certification builds upon ISO 9001 foundations while adding aerospace-specific requirements that address:

- Operational risk management: Organizations must implement systematic approaches to identifying, assessing, prioritizing, and controlling risks throughout product lifecycles—reflecting the industry's zero-tolerance approach to quality failures.

- Configuration management: Product integrity and traceability must be maintained from design through disposal, with systematic documentation at every lifecycle stage.

- Counterfeit parts prevention: Comprehensive systems must prevent, detect, and respond to unauthorized, fraudulent, or non-conforming components entering supply chains.

- Product safety assurance: Organizations must implement systematic approaches to identifying, assessing, and controlling safety risks where failures could result in loss of life or mission failure.

When sourcing aerospace cnc machining or precision cnc machining services for flight-critical applications, verify your supplier appears in the IAQG OASIS database—the official registry of AS9100-certified organizations. The certification process typically requires 6-18 months and involves rigorous multi-stage audits evaluating documentation, implementation, and effectiveness across all quality system elements.

Many aerospace programs also require 5 axis cnc machining services for complex geometric features common in turbine blades, structural brackets, and engine components. These multi-axis capabilities must operate within the same certified quality framework to maintain compliance.

Medical Device Manufacturing Standards

Medical machining demands precision that directly impacts patient safety. Whether producing surgical instruments, implantable devices, or diagnostic equipment components, manufacturers must demonstrate rigorous process control and complete traceability.

ISO 13485 establishes quality management system requirements specifically for medical device manufacturing. According to industry specialists, this standard regulates requirements similar to FDA regulations, ensuring medical device production happens under strictly controlled conditions.

The stakes in medical device manufacturing couldn't be higher. Consider implanted components for knee, hip, or spinal column replacements—any margin of error could cause these units to fail, cause pain, or require surgical replacement. This reality drives several unique requirements:

- Good Manufacturing Practices (GMP) framework: Industries affecting public health operate within GMP structures that ensure production under strictly controlled conditions with documented procedures at every step.

- Design controls and technical documentation: Complete traceability from design intent through final production, including validation testing, process verification, and change control protocols.

- Material certification: Medical-grade materials require certificates of conformance documenting chemical composition, mechanical properties, and biocompatibility testing—especially critical for cnc aluminum components used in surgical instruments or implant-grade titanium parts.

- Repeatability validation: Manufacturers must demonstrate the ability to create components again and again with unerring specifications for custom components, implanted devices, and surgical tools.

Swiss machining often rises to the top for medical applications due to its use of multiple axes—sometimes up to thirteen—providing expanded precision and tighter tolerances than conventional three-axis CNC machining. The tight bushing hold allows closer cutting without material deviation, enabling the miniaturization common in modern medical devices.

FDA regulations add another compliance layer for devices sold in the United States. Integrating FDA and ISO compliance into the design phase of each component is essential—starting with prototypes using materials that meet or exceed regulations while working well within the machining process. In-process inspections ensure each benchmark is met, while final part validation and complete documentation support regulatory audit requirements.

Automotive Sector Quality Standards

Automotive manufacturing operates at volumes and speeds that demand systematic quality management. The industry certification—IATF 16949—builds upon ISO 9001 while adding automotive-specific requirements for defect prevention, variation reduction, and supply chain control.

One core requirement distinguishes automotive quality systems: Statistical Process Control (SPC). According to IATF 16949 implementation guidance, SPC is an analytical decision-making tool that monitors manufacturing processes to ensure consistent quality. The methodology dates to Walter Shewhart's work at Bell Laboratories in the 1920s and gained wide adoption through military applications during World War II.

Why does SPC matter for machining services? The approach emphasizes early detection and prevention of problems rather than correction after they occur. Control charts monitor process variation over time, comparing output against upper and lower limits to identify when processes drift toward out-of-control conditions—before defective parts reach customers.

Key automotive quality requirements include:

- Advanced Product Quality Planning (APQP): Structured frameworks for developing products that satisfy customer requirements, with defined phases from concept through production launch.

- Production Part Approval Process (PPAP): Standardized documentation packages demonstrating that manufacturing processes can consistently produce parts meeting specifications during actual production runs.

- Failure Mode and Effects Analysis (FMEA): Systematic evaluation of potential failure modes, their causes, and effects—with action plans to reduce risk before production begins.

- Measurement System Analysis (MSA): Verification that measurement systems provide data accurate enough to support quality decisions.

- Control Plans: Documentation of process controls, inspection frequencies, and reaction plans that maintain quality throughout production.

For automotive components requiring stainless steel machining or other demanding materials, IATF 16949-certified suppliers demonstrate process capability through Cpk metrics—statistical measures showing how well processes center within specification limits. A Cpk of 1.33 or higher typically satisfies automotive OEM requirements.

When sourcing critical automotive components, providers with IATF 16949 certification and robust SPC implementation offer documented process control that general machine shops cannot match. Shaoyi Metal Technology exemplifies this approach—combining IATF 16949 certification with Statistical Process Control systems that deliver high-tolerance chassis assemblies and precision metal components. Their certified capabilities scale from rapid prototyping to mass production, with lead times as fast as one working day for urgent automotive projects.

Why Certifications Matter for Your Projects

Industry certifications aren't bureaucratic checkboxes—they represent verified quality systems that protect your projects from preventable failures. Here's what certifications guarantee:

- Documented processes: Certified organizations maintain written procedures for every quality-critical activity, ensuring consistency regardless of which operator runs your parts.

- Trained personnel: Certification requires demonstrated competency—operators, inspectors, and engineers must complete training programs and maintain qualifications.

- Continuous improvement: Certified quality systems require regular internal audits, management reviews, and corrective action processes that drive ongoing improvement.

- Supply chain control: Certifications extend requirements to purchased materials and outsourced processes, ensuring quality throughout your component's manufacturing journey.

- Audit readiness: Certified suppliers maintain documentation and records that support your own regulatory audits—critical when your customers require evidence of supply chain control.

Certification represents proven capability—not just claimed competence. When your application demands aerospace, medical, or automotive quality, verify certification before placing orders.

Material traceability requirements vary by industry but follow similar principles. Aerospace and medical applications typically require heat lot traceability—documentation linking finished parts to specific material batches with certified properties. Automotive applications emphasize lot traceability for containment purposes, enabling rapid identification of affected parts if quality issues emerge.

Understanding these industry-specific requirements helps you ask the right questions when evaluating machining partners. But certifications only establish baseline capability—the next critical factor is how suppliers actually verify part quality through inspection methods and documentation practices.

Quality Assurance and Inspection in Professional Machining

Your supplier claims parts meet specifications—but how do you know? Precision machining companies don't rely on assumptions. They implement systematic verification processes that catch deviations before parts ever ship. Understanding these quality assurance methods helps you evaluate suppliers effectively and know what documentation to request for your critical components.

According to manufacturing quality experts, an excellent quality department is only as strong as its processes and tools. Whether you're searching for machinist shops near me or evaluating global suppliers, the same quality principles apply: documented procedures, calibrated equipment, and trained personnel working within proven systems.

Inspection Methods That Verify Part Accuracy

Professional machining services deploy multiple inspection technologies matched to part requirements. Here's what happens behind the scenes to verify your precision machining parts meet specifications:

- Coordinate Measuring Machines (CMM): These machines use probing systems to take precise measurements of part geometry, ensuring even complex shapes meet required tolerances. Modern CMMs offer high accuracy, versatility, and speed—making them indispensable for inspecting intricate dimensions. CMM data provides objective, repeatable measurements that eliminate operator interpretation.

- First Article Inspection (FAI): According to industry standards, a First Article Inspection determines whether the manufacturing process can consistently deliver conforming parts. FAI evaluates one part comprehensively—from raw materials through machining, special processing, and functional testing. For suppliers, FAI validates manufacturability and establishes the production baseline. For buyers, it confirms design requirements are understood and production processes are capable.

- Statistical Process Control (SPC): Rather than inspecting every part after production, SPC monitors processes in real time. Control charts track variation continuously, detecting trends before they produce out-of-tolerance parts. This proactive approach catches problems early—preventing scrap rather than just identifying it.

- Vision Inspection Systems: High-resolution cameras combined with sophisticated algorithms inspect parts for surface defects, dimensional accuracy, and orientation without physical contact. Especially useful for detecting cosmetic issues and verifying features difficult to probe mechanically.

- Basic Measurement Tools: Calipers, micrometers, height gauges, and dial indicators remain essential for everyday quality control. Digital calipers offer precision to 0.001 inches, while micrometers achieve 0.0001 inches for critical dimensions. These tools enable quick in-process checks that catch issues before parts progress further.

When does each method apply? CMM inspection typically covers critical dimensions on complex parts where multiple features must relate precisely to datum references. First article inspection occurs whenever new parts enter production, designs change, or manufacturing processes shift. SPC runs continuously during production, providing real-time process health monitoring.

Documentation You Should Expect From Your Supplier

Quality isn't just about measurement—it's about proof. When evaluating local machine shops or cnc machine shops near me, ask what documentation accompanies finished parts. Professional suppliers provide verification packages appropriate to your application:

- Dimensional Inspection Reports: Documented measurements for all specified dimensions, including actual values, tolerances, and pass/fail status. Reports should identify the measuring equipment used and link to calibration records.

- Material Certifications: Mill test reports or Certificates of Conformance documenting material grade, chemical composition, mechanical properties, and heat lot traceability. According to FAI requirements, raw material records should include mill name, ASTM standard number, heat lot number, and country of origin.

- First Article Inspection Reports: Comprehensive documentation covering design records, ballooned drawings, dimensional data, special processing certifications, and functional test results. For aerospace applications, AS9102 format organizes this into three forms: Part Number Accountability, Product Accountability, and Characteristic Accountability.

- Calibration Records: Evidence that measuring equipment used for your parts traces to national standards. Each measurement should link to a specific gage ID with current calibration status.

- Process Certifications: Documentation for special processes like heat treatment, plating, or anodizing—including supplier certifications and conformance to specified standards.

The dimensional record alone—without raw material records and special processing documentation—may be meaningless. Complete traceability protects against functional failures that dimensional checks alone cannot prevent.

What triggers new inspection requirements? According to quality process standards, any change in part design, manufacturing process, outside processing vendor, factory location, or resumption of production after extended gaps requires renewed first article inspection. Some changes demand complete re-inspection; others may need only partial verification focused on affected features.

When searching machining shops near me, prioritize suppliers who explain their quality systems clearly. The best partners don't just promise quality—they demonstrate it through documented processes, calibrated equipment, and inspection records that give you confidence in every shipment. This foundation of verified quality enables the final step: selecting a machining partner who delivers consistent results across your projects.

Selecting the Right Machining Partner for Your Manufacturing Needs

You've done the research—understood tolerances, evaluated materials, and compared manufacturing methods. Now comes the decision that determines whether your project succeeds or stalls: choosing the right machining partner. This choice extends far beyond comparing quotes. The supplier you select becomes an extension of your engineering team, influencing quality, timeline, and ultimately your product's success in the market.

When searching for cnc machining near me or evaluating global suppliers, the same fundamental criteria apply. According to manufacturing partnership experts, successful supplier relationships balance six critical factors: project requirements alignment, capability verification, quality certifications, capacity planning, cost transparency, and communication responsiveness. Let's break down each element so you can evaluate machining services near me—or anywhere—with confidence.

Evaluating Machining Partners Beyond Price

Price matters, but it shouldn't dominate your decision. According to precision machining evaluation specialists, different industries require varying evaluation stringency—defense, semiconductor, and medical customers impose particularly demanding supplier qualification processes. Whatever your sector, these evaluation criteria help separate capable partners from risky choices:

- Equipment capabilities and capacity: Does the cnc shop near me have the right machines for your project? From high-speed to high-torque, multi-axis to Swiss-type—machine types must match your part requirements. Verify not just capability but available capacity. A shop running at 95% utilization may struggle to accommodate your timeline.

- Process optimization expertise: The best custom machine shop partners don't just run parts—they optimize them. Look for evidence of continuous improvement through Six Sigma, Lean, or Kaizen methodologies. These strategies deliver value through reduced cycle times and lower costs over time.

- Quality certifications: ISO 9001 certification represents baseline competence. Industry-specific certifications—AS9100 for aerospace, ISO 13485 for medical, IATF 16949 for automotive—demonstrate specialized capability. According to supplier evaluation experts, verify that daily discipline and documentation match certification claims, not just certificates hanging on walls.

- Business stability: Ask tough questions about annual revenue, profit margins, and long-term company goals. Putting faith in a financially troubled supplier can cause major supply chain disruptions. Understanding business health helps you assess partnership risk.

- Supply chain management: A capable machinist near me needs more than good machines—they need effective supply chain teams managing incoming materials and secondary operations. Don't overlook this portion of the manufacturing process.

- Engineering support: According to full-service machining partners, access to engineering managers and toolmakers means your questions go directly to technical experts rather than being translated through less experienced intermediaries.

- Technology systems: Comprehensive MRP or ERP systems are paramount for shops producing multiple part types. These systems manage supply chain, planning, routing, and shipping—ensuring proper delivery schedules are met consistently.

Preparing Your Project for Manufacturing Success

Even the best cnc machine shop near me can't rescue a poorly prepared project. Your preparation directly impacts quote accuracy, production efficiency, and final part quality. Here's how to set your project up for success:

File preparation essentials:

- Submit native CAD files alongside STEP exports—native files preserve design intent that translation sometimes loses

- Include 2D drawings with GD&T callouts for critical dimensions, even when providing complete 3D models

- Specify material grade precisely (6061-T6, not just "aluminum") to prevent substitution confusion

- Document surface finish requirements using standard Ra values rather than subjective descriptions

- Identify critical features that require 100% inspection versus statistical sampling

Communication best practices:

- Establish single points of contact on both sides to prevent information fragmentation

- Request DFM feedback before finalizing designs—early input prevents expensive late-stage changes

- Define inspection requirements upfront, including documentation packages needed for your quality records

- Communicate volume forecasts honestly—suppliers plan capacity based on your projections

- Build relationships with technical staff, not just sales contacts

The most successful manufacturing partnerships invest in communication infrastructure before problems arise—not after shipments fail inspection.

Scaling From Prototyping to Production

Finding a partner who handles the complete journey—from first prototype to high-volume production—eliminates transition friction that costs time and money. According to prototype-to-production specialists, leveraging a full-service precision machining shop delivers significant efficiency improvements gained from lessons learned throughout your project development.

Why does seamless scaling matter? Consider the alternative: developing prototypes with one supplier, then transitioning to a different production partner. Each transition requires new qualification, process development, and relationship building. Knowledge gained during prototyping stays with the original supplier rather than informing production optimization.

The advantages of integrated prototype-to-production capability include:

- Accumulated process knowledge: Insights from prototyping directly improve production efficiency and quality

- Simplified vendor management: One relationship replaces multiple supplier interactions

- Streamlined communication: Project history lives in one organization rather than fragmented across suppliers

- Faster production ramp: No relearning curve when moving from prototype to production volumes

- Consistent billing: Simplified procurement and payment processes

When evaluating cnc services near me for projects with production potential, verify the supplier can scale. Some shops excel at prototypes but lack capacity or process discipline for volume manufacturing. Others focus exclusively on high-volume work and struggle with the flexibility prototyping demands.

For automotive applications specifically, this scaling capability becomes critical. Shaoyi Metal Technology demonstrates how integrated capabilities accelerate supply chains—their precision CNC machining services scale seamlessly from rapid prototyping to mass production, with lead times as fast as one working day for urgent projects. Backed by IATF 16949 certification and Statistical Process Control systems, they deliver high-tolerance chassis assemblies and custom metal components with the process discipline automotive OEMs require.

Building Productive Supplier Relationships

The best machining partnerships extend beyond transactional ordering. Suppliers who understand your business—your quality requirements, volume patterns, and strategic priorities—deliver better outcomes than those treating each order as isolated work.

How do you build these relationships?

- Share context: Help suppliers understand how parts function in your products—this knowledge improves their manufacturing decisions

- Provide feedback: When parts exceed expectations or fall short, communicate clearly so suppliers can adjust

- Plan ahead: Share forecasts and development roadmaps so suppliers can prepare capacity

- Pay fairly and promptly: Reliable payment builds trust and prioritizes your work during capacity constraints

- Visit facilities: Nothing replaces walking the shop floor to understand true capabilities

Whether you're evaluating a local machinist near me or a global precision manufacturing partner, these principles apply universally. The machining services provider you choose today influences project outcomes for years. Invest the evaluation effort upfront—the returns compound across every part they produce for you.

Frequently Asked Questions About Machining Services

1. What is CNC machining and how does it work?

CNC machining is a subtractive manufacturing process where computer-controlled tools remove material from solid blocks to create precise components. The process uses G-code instructions generated from CAD designs through CAM software, enabling tolerances as tight as ±0.001 inches. Primary operations include turning for cylindrical parts, milling for complex geometries, drilling for holes, and grinding for superior surface finishes.

2. How much do CNC machining services cost?

CNC machining costs depend on material selection, part complexity, tolerance requirements, quantity, surface finish specifications, and lead time urgency. Aluminum parts cost 40-60% less than stainless steel equivalents. Tight tolerances can increase costs by 50-100% over standard specifications. Larger batch sizes reduce per-part costs by spreading fixed setup expenses across more units. Rush orders typically add 25-50% premium.

3. What materials can be CNC machined?

CNC machining works with metals including aluminum alloys (6061, 7075), stainless steel (304, 316), brass, bronze, and titanium. Engineering plastics like Delrin, nylon, and PEEK are also commonly machined. Aluminum accounts for 43% of high-volume CNC operations due to its excellent machinability, while specialty materials like medical-grade PEEK serve applications requiring biocompatibility or extreme temperature resistance.

4. How long does CNC machining take from quote to delivery?

Standard CNC machining lead times range from 7-14 business days after order confirmation. The process includes file submission, manufacturability review, quoting, material procurement, machining operations, quality inspection, and shipping. Some suppliers like Shaoyi Metal Technology offer lead times as fast as one working day for urgent projects. Specialty materials may require 1-3 weeks of additional procurement time.

5. What certifications should a CNC machining partner have?

Required certifications depend on your industry. Aerospace applications need AS9100D certification for flight-critical components. Medical device manufacturing requires ISO 13485 compliance. Automotive parts demand IATF 16949 certification with Statistical Process Control implementation. ISO 9001 represents baseline quality management competence for general applications. Always verify certifications in official registries before placing orders.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —