Progressive Stamping Process Exposed: 9 Stations That Cut Your Costs

What Is Progressive Stamping and Why It Dominates Metal Forming

Wondering how manufacturers produce millions of identical metal parts with remarkable speed and precision? The answer lies in the progressive stamping process—a manufacturing method that has revolutionized high-volume metal forming across countless industries.

Progressive die stamping is a metal forming process where a coil of sheet metal feeds through a series of sequential die stations, with each station performing a specific operation—such as punching, bending, or coining—until a fully formed part emerges at the final station.

Unlike single-stage operations that require multiple machine setups, progressive metal stamping consolidates everything into one continuous workflow. The result? Faster production, tighter tolerances, and significantly lower per-part costs when you're manufacturing at scale.

The Core Mechanics of Strip Progression

Imagine a long ribbon of sheet metal—called a strip or coil—feeding into a stamping press. As the press cycles up and down, this strip advances incrementally through a carefully engineered prog die. Each press stroke moves the material forward by a precise distance, ensuring perfect alignment at every station.

Here's what makes this system so effective:

- Continuous feeding: The coil provides an uninterrupted supply of raw material, eliminating manual loading between operations

- Simultaneous operations: Multiple stations work on different parts of the strip at the same time during each press stroke

- Automatic progression: The strip carries partially formed parts through the die until they reach completion

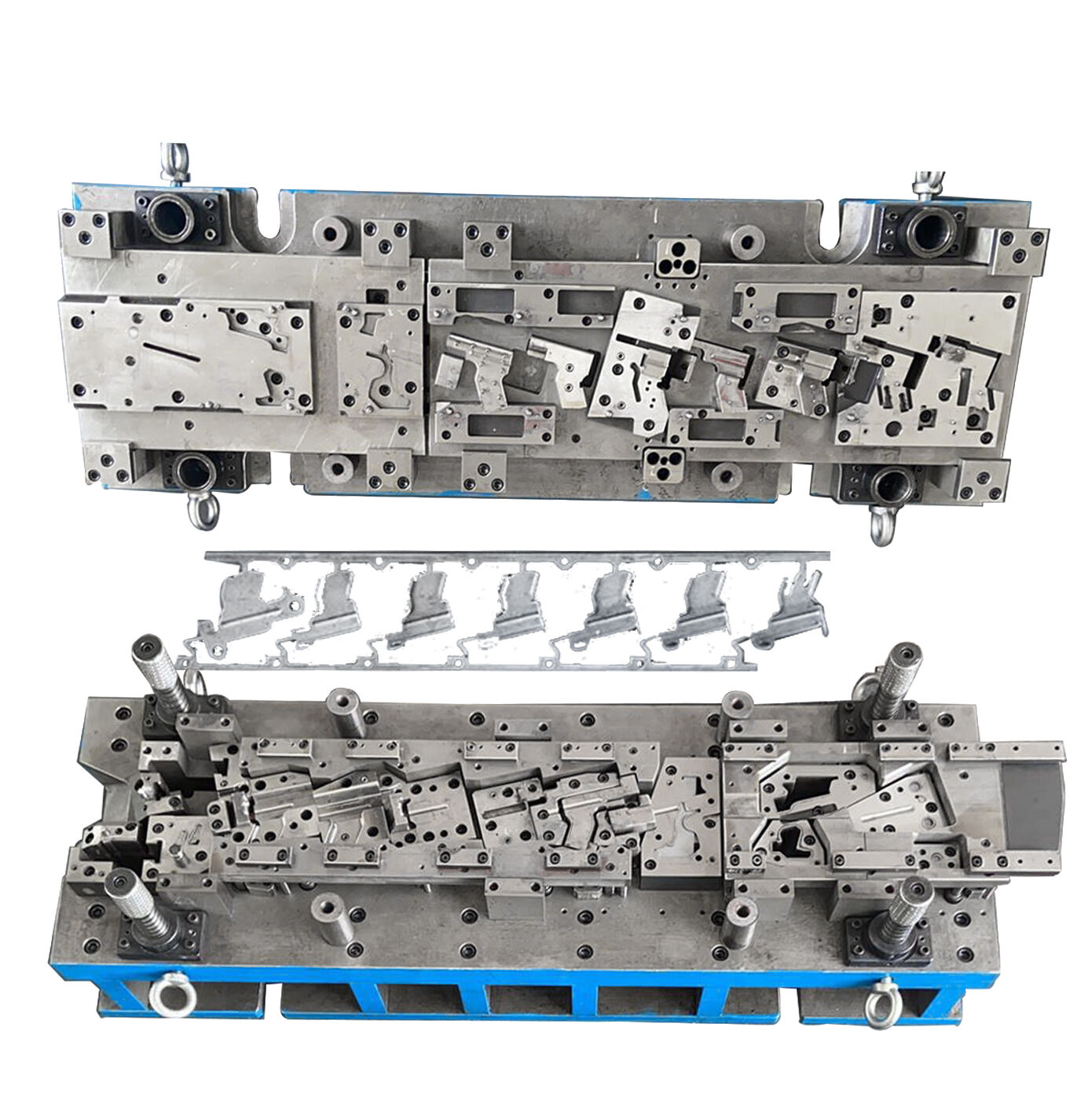

When asking "what is dies in manufacturing," think of progressive dies as sophisticated multi-tool systems. They contain all the cutting, forming, and shaping elements needed to transform flat sheet metal pressings into complex three-dimensional components—all within a single tool assembly.

How Multiple Stations Create Complete Parts

Each station in a progressive die performs one specialized task. The first station might punch pilot holes for alignment. The next could cut the part's outline. Subsequent stations bend flanges, form features, and add embossed details. The final station separates the completed part from the carrier strip.

This station-by-station approach delivers three major advantages for high-volume manufacturing:

- Speed: Production rates can reach thousands of parts per hour since all operations happen with each press cycle

- Consistency: Hard tooling ensures every part matches the first one, even after millions of cycles

- Cost-efficiency: Consolidating operations eliminates secondary handling, reduces labor requirements, and minimizes scrap material

Progressive die stamping particularly excels when you need small-to-medium sized parts in quantities ranging from thousands to millions. The upfront tooling investment pays dividends quickly as production volumes increase, making this method the go-to choice for automotive connectors, electronic terminals, appliance brackets, and countless other precision components.

Breaking Down Each Station in the Progressive Die Sequence

So how does a flat strip of metal transform into a precisely formed component? The secret lies in the orchestrated sequence of stations within progressive dies. Each station performs one carefully calculated operation, building upon the work of previous stations to create geometries that would be impossible with single-stage methods. Let's walk through the complete journey your material takes—from raw coil to finished part.

Piercing and Pilot Hole Functions Explained

Before any forming begins, the first stations in a progressive die establish the foundation for everything that follows. This is where piercing operations create pilot holes—small, precisely positioned openings that serve as the alignment reference for the entire process.

Why are pilot holes so critical? As noted by engineering experts at Jeelix, these holes act as the "North Star" of the progressive stamping process. They provide the absolute reference point that keeps every subsequent station in perfect alignment. Without them, microscopic feeding errors would accumulate across stations, eventually producing out-of-tolerance parts.

Here's how the correction mechanism works:

- The feeder advances the strip to an approximate position

- Tapered pilot pins mounted on the upper die descend into the pilot holes

- As each pin enters its hole, the tapered surface generates lateral force

- This force nudges the strip into precise X-Y alignment before any forming tools make contact

This "lock-and-correct" approach resets the strip position with every press stroke, effectively breaking the chain of accumulated deviation. Among the various types of stamping dies, progressive dies stand apart specifically because of this built-in error correction capability.

From Blanking to Final Forming Operations

Once pilot holes establish alignment, the strip advances through a carefully sequenced series of operations. Each station transforms the material incrementally, and understanding this sequence reveals why progressive dies achieve such remarkable precision and complexity.

- Piercing: Beyond pilot holes, additional piercing stations create internal features—mounting holes, slots, and cutouts that define the part's functional geometry. The progressive punch cuts cleanly through the material, with slugs dropping through clearance channels below the die.

- Blanking: This operation cuts the external profile of the part. However, in most progressive dies, blanking happens partially at first—trimming and notching operations remove excess material progressively while keeping the part attached to the carrier strip for continued processing.

- Bending: Now the flat workpiece begins its transformation into three dimensions. Bending stations create angles and flanges by forcing material around precisely shaped punch surfaces. The strip's carrier section holds everything steady while these forces are applied.

- Drawing: For parts requiring depth or cavity features, drawing stations stretch the material into cup-like or box-like shapes. This operation demands careful control—too aggressive, and the metal tears; too gentle, and you can't achieve the required depth. Progressive dies often use multiple shallow drawing stages rather than one deep draw.

- Coining: When you need exceptional dimensional accuracy, coining stations apply extreme pressure to specific areas. This re-striking operation compresses the metal, achieving tighter tolerances on critical dimensions, angles, and surface flatness than forming alone can deliver.

- Forming: Complex three-dimensional shapes emerge through specialized forming stations. Embossing adds stiffening ribs or identification marks. Flanging creates edges. Each forming operation builds on previous work, gradually sculpting the final component geometry.

- Cutoff: At the final station, the completed part separates from the carrier strip. This decisive cut releases the finished component, which exits via chutes or conveyors while the skeletal scrap continues for recycling.

Consider this example of stamping in action: an automotive terminal connector might require pilot hole piercing, multiple internal hole piercings, partial blanking, two bending operations for contact springs, coining for critical contact surfaces, and final cutoff—all within a single progressive die running at hundreds of strokes per minute.

The stamping die components work together as an integrated system. Die buttons guide punches with micron-level precision. Strippers hold material flat while punches retract. Pilots continuously correct position. This ecosystem of precision elements enables progressive dies to maintain tolerances as tight as ±0.01 mm across millions of production cycles.

What makes this sequential approach so powerful? Each operation remains relatively simple, reducing stress on individual stations while collectively achieving complexity no single-stage die could match. The material flows predictably, deformation happens gradually, and quality stays consistent from the first part to the millionth.

Progressive Die Design and Engineering Fundamentals

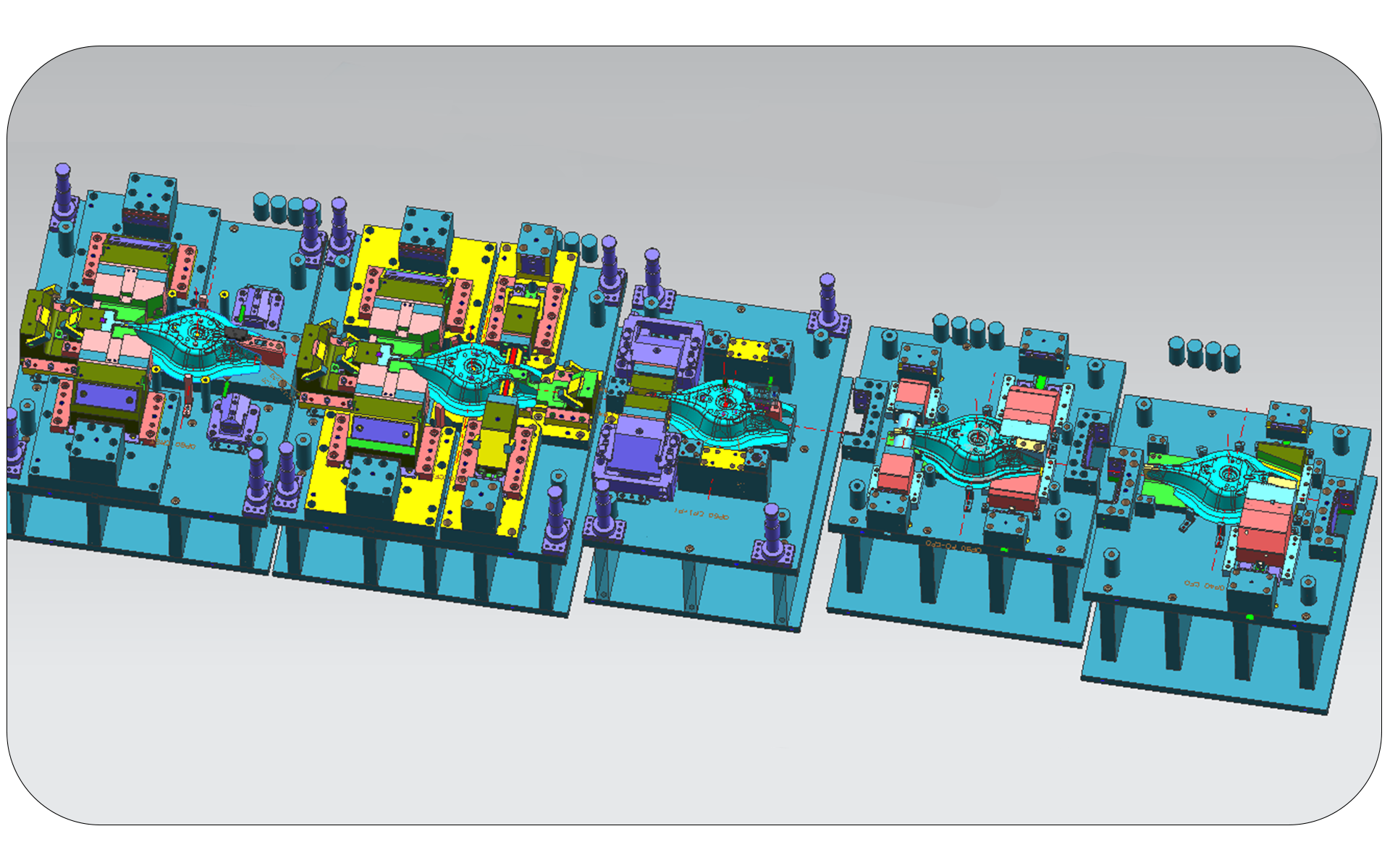

You've seen how progressive dies work station by station—but how do engineers actually design these sophisticated tools? The truth is, the magic happens long before any metal gets stamped. Progressive die design represents one of manufacturing's most demanding engineering disciplines, where decisions made during conceptualization directly determine production success or costly failure.

Think of it this way: building a progressive die without proper engineering is like constructing a skyscraper without blueprints. The upfront investment in stamping die design pays dividends throughout the tool's entire lifecycle—often spanning millions of production cycles.

Engineering Considerations for Die Layout

Every progressive die tooling project begins with strip layout design. According to Industry Tooling, the strip layout is essentially the blueprint of your entire production process. It defines how material flows, where each operation occurs, and how much scrap you'll generate.

What makes strip layout so critical? Consider these factors that engineers must balance:

- Material flow analysis: Engineers map exactly how the metal strip will deform, stretch, and move through each station—anticipating stress points before they become problems

- Springback compensation: Metals naturally "spring back" after bending, so die designers must over-bend to achieve final target dimensions

- Station load balancing: Distributing forces evenly across stations prevents premature wear and ensures consistent press operation

The carrier strip design deserves special attention. Engineers choose between single-sided carriers (offering easy access for three-sided processing) and double-sided carriers (providing optimal force balance for large or high-precision parts). For parts requiring deep drawing, stretch-web designs incorporate strategic slits that allow material to flow during forming—preventing cracking in complex geometries.

Design for Manufacturability principles guide every decision. Can the proposed geometry actually be formed without tearing? Will the station sequence create interference between progressive die components? Does the pitch distance allow adequate forming room while minimizing material waste? These questions must be answered definitively before any tool steel gets machined.

Real-world impact? One documented case study showed that redesigning a suboptimal strip layout reduced material waste from 12% to under 5%, saving thousands of dollars per production batch—simply through smarter metal stamping die design.

CAE Simulation in Modern Die Development

Before digital simulation existed, developing a sheet metal die was essentially expensive trial-and-error. Engineers built tooling based on experience, mounted it in a press, and discovered problems only after significant investment. Today, Computer-Aided Engineering has transformed this "build-and-test" approach into a "predict-and-optimize" scientific method.

What does CAE simulation actually reveal? According to manufacturing research from Jeelix, virtual simulation delivers several critical capabilities:

- Forming feasibility prediction: Identify potential tearing, wrinkling, or thinning before cutting any tool steel

- Springback calculation: Precisely predict elastic recovery so compensation can be built into die geometry

- Force requirements: Determine exact tonnage needs at each station for proper press selection

- Material flow visualization: Watch how metal moves during each operation, revealing hidden stress concentrations

Finite Element Analysis takes this further by breaking the forming process into thousands of tiny calculations. Engineers can virtually "stamp" a part hundreds of times, testing different approaches without wasting material or machine time. This simulation-first approach has fundamentally changed progressive die design economics—reducing costly physical iterations while improving first-article success rates.

The practical benefit? Engineers validate that their progressive die components will work together harmoniously before committing to expensive machining. They can optimize station sequencing, adjust forming radii, and refine material utilization—all in the virtual environment where changes cost nothing but time.

For manufacturers evaluating progressive stamping, understanding these engineering fundamentals matters. A supplier with robust CAE capabilities and proven DFM expertise will deliver tooling that runs reliably from day one. The alternative—discovering design flaws during tryout—means delays, rework costs, and frustration that proper upfront engineering could have prevented.

Material Selection and Thickness Considerations for Progressive Stamping

Here's a question that can make or break your progressive stamping project: have you chosen the right material? While die design and station sequencing get plenty of attention, material selection often gets overlooked—even though it directly impacts everything from tooling longevity to production speed and final part quality.

The reality? Not every metal performs equally in sheet metal stamping dies. Some materials glide through progressive operations like butter, while others fight you at every station. Understanding these differences before tooling begins saves costly surprises later.

Optimal Material Selection for Progressive Operations

Progressive stamping accommodates a wide variety of metals, but each brings distinct characteristics that influence how your metal stamping die must be designed. According to material specialists at American Industrial Company, manufacturers must balance several key factors when selecting materials:

- Formability: How easily the metal bends, draws, and shapes without cracking

- Tensile strength: The force the material withstands before breaking

- Work hardening rate: How quickly the metal becomes brittle during deformation

- Machinability: How cleanly the material cuts and how much tool wear it causes

Let's examine the materials you'll encounter most frequently in steel stamping dies and other progressive tooling:

Carbon Steel remains the workhorse of progressive stamping. This iron-carbon alloy delivers exceptional strength, design flexibility, and cost-effectiveness. It responds predictably to forming operations and works well across multiple stamping techniques. For corrosion-sensitive applications, zinc, chrome, or nickel coatings extend service life significantly.

Stainless Steel offers corrosion resistance and an attractive finish—making it ideal for food handling, medical devices, and visible components. However, as Ulbrich's metallurgical experts note, austenitic stainless steel presents unique challenges. It has a high cold hardening index (0.34% for SS), and during plastic deformation, it can transform into brittle martensite phase that's prone to cracking. Careful die design and sometimes intermediate annealing become necessary.

Aluminum appeals when weight matters. This silvery-white metal offers an excellent strength-to-weight ratio, outstanding formability, and thermal conductivity. It's the go-to choice for lightweight stamped components in aerospace, electronics, and automotive applications where reducing mass improves efficiency.

Brass progressive stamping leverages this copper-zinc alloy's exceptional versatility. Brass provides good malleability, attractive visual appeal for decorative hardware, and solid electrical conductivity. It's commonly specified for bearings, locks, gears, and valves where these properties matter.

Copper progressive stamping excels in electrical and thermal applications. This soft, ductile metal offers superior conductivity—making it the preferred choice for electrical connectors, terminals, and heat transfer components. Its easy-to-clean surfaces also suit food processing and medical applications.

Thickness Ranges and Formability Factors

Material thickness directly determines what your progressive stamping process can achieve. Too thin, and handling becomes problematic. Too thick, and you'll need massive tonnage or alternative processes entirely.

| Material Type | Typical Thickness Range | Formability Rating | Common Applications |

|---|---|---|---|

| Carbon Steel | 0.2 mm – 6.0 mm | Excellent | Brackets, structural components, automotive panels |

| Stainless Steel | 0.1 mm – 4.0 mm | Good (requires care) | Medical devices, food equipment, corrosion-resistant parts |

| Aluminum | 0.2 mm – 5.0 mm | Excellent | Lightweight housings, heat sinks, aerospace components |

| Brass | 0.1 mm – 3.0 mm | Very Good | Decorative hardware, electrical contacts, plumbing fittings |

| Copper | 0.1 mm – 3.0 mm | Excellent | Electrical terminals, connectors, thermal conductors |

How do material properties affect your die stations? Consider these practical implications:

- Press tonnage requirements: Stronger materials like stainless steel demand higher forming forces, requiring larger presses and more robust die construction

- Production speeds: Softer materials like aluminum and copper allow faster cycle times, while work-hardening metals may need slower progression to prevent cracking

- Die wear rates: Abrasive materials accelerate tool wear, increasing maintenance frequency and replacement costs for sheet metal stamping dies

- Lubrication needs: Each material has optimal lubricant requirements—neglecting this causes galling, surface defects, and premature tool failure

What about limitations? Progressive stamping isn't universally suitable. Very thick materials—typically beyond 6 mm for steel—often exceed practical tonnage limits for standard progressive operations. Exotic alloys like titanium, while excellent for aerospace applications, require specialized tooling and much slower production rates. Materials with poor formability may crack during complex bending or drawing sequences, necessitating alternative methods like transfer stamping or multi-stage operations with intermediate annealing.

As Manor Tool emphasizes, selecting the wrong materials leads to premature tool wear, poor-quality stamping, and cascading production problems. The solution? Match material properties carefully to your application requirements, consult with metallurgical experts when uncertainty exists, and verify formability through simulation before committing to tooling.

With material selection properly addressed, the next critical decision involves choosing between progressive stamping and alternative forming methods—a comparison that reveals exactly where this process delivers maximum value.

Progressive Stamping Compared to Alternative Methods

Now that you understand materials and thickness considerations, a bigger question emerges: is progressive stamping actually the right choice for your project? The answer depends on factors like part complexity, production volume, and budget constraints. Let's cut through the confusion by comparing the major die stamping methods head-to-head—so you can make informed manufacturing decisions rather than relying on guesswork.

Progressive vs Transfer Die Stamping Decision Factors

These two methods often compete for the same projects, but they excel in distinctly different scenarios. Understanding when to choose each saves you from costly mismatches between your requirements and your tooling investment.

Progressive die stamping keeps your part attached to the carrier strip throughout the entire forming sequence. Each press stroke advances the strip, performing operations simultaneously across all stations. According to manufacturing experts at Die-Matic, this makes progressive stamping ideal for high-speed production of complex parts at medium to high volumes—particularly when components are small to medium-sized.

Transfer die stamping takes a fundamentally different approach. As noted by Worthy Hardware, transfer stamping either begins with a blank or separates the part from the metal strip early in the process. Mechanical transfer systems then move each piece independently from station to station—like an assembly line where each workstation contributes something specific.

Why does this distinction matter? Consider these practical implications:

- Part size: Transfer die operations accommodate larger, heavier parts that would be impractical to carry on a strip

- Draw depth: When you need deep draws or cup-like shapes, transfer stamping's independent handling allows more aggressive forming than strip-fed methods

- Orientation flexibility: Transfer systems can rotate or reposition parts between stations—enabling complex geometries impossible when parts remain strip-attached

- Cycle time: Progressive stamping typically runs faster because there's no mechanical transfer between stations

Think of it this way: if your parts are small connectors, terminals, or brackets produced by the millions, progressive stamping delivers unmatched efficiency. If you're forming large automotive body panels or deep-drawn housings, transfer stamping's flexibility justifies its slightly slower pace and higher operational complexity.

When Compound Dies Make More Sense

Sometimes the simplest solution wins. Compound die stamping performs multiple operations—such as cutting and punching—in a single press stroke. Unlike progressive dies with their sequential stations, compound dies complete everything at once.

According to Larson Tool, compound dies are commonly used for simple, flat parts where multiple cutting operations can happen simultaneously. They're generally less expensive to design and produce than progressive dies, making them attractive for lower-volume projects or straightforward geometries.

But here's the trade-off: compound dies lack the forming capabilities of progressive or transfer methods. You won't create bends, draws, or complex three-dimensional shapes with compound tooling. The parts that emerge are essentially flat—punched, blanked, and ready for use or secondary processing.

The table below summarizes key decision factors across all major methods:

| Method Type | Best For (Part Complexity) | Volume Sweet Spot | Tooling Investment | Cycle Time |

|---|---|---|---|---|

| Progressive Die Stamping | Simple to moderately complex; small-to-medium parts | High volume (100,000+ parts) | Higher upfront; lowest per-part at scale | Fastest |

| Transfer Die Stamping | Large or intricate parts; deep draws | Medium to high volume | Higher tooling and setup costs | Moderate |

| Compound Die Stamping | Simple, flat parts; precision cutting | Low to medium volume | Lower upfront investment | Moderate |

| Single-Stage Operations | Very simple geometries; prototypes | Low volume or testing | Lowest initial cost | Slowest (multiple setups) |

Notice how the economics shift dramatically based on volume. Progressive stamping's higher upfront tooling cost becomes increasingly irrelevant as production quantities rise—the per-part savings compound with every cycle. Meanwhile, compound dies offer cost advantages for simpler projects where you don't need progressive complexity.

What about single-stage operations? These basic stamping methods perform one operation per press setup. They're excellent for prototyping, very low volumes, or extremely simple parts. However, producing complex die stamped components this way requires multiple machine setups, repeated handling, and significantly higher labor costs—making it impractical for anything beyond short runs.

Here's the decision framework experienced manufacturers use:

- Choose progressive stamping when: You need small-to-medium parts in high volumes with multiple forming operations, and speed matters

- Choose transfer stamping when: Parts are too large for strip feeding, require deep draws, or need repositioning between operations

- Choose compound dies when: Your parts are flat, require precise cutting operations, and volumes don't justify progressive tooling investment

- Choose single-stage operations when: You're prototyping, testing designs, or producing very limited quantities

As industry analysts emphasize, transfer stamping's flexibility comes with trade-offs: operational costs can be higher due to complex setups and skilled labor requirements. Setup time runs longer for intricate parts. And maintaining consistent quality demands precision in both die design and transfer mechanism calibration.

The bottom line? There's no universally "best" stamping method—only the best method for your specific combination of part geometry, volume requirements, and budget constraints. Understanding these trade-offs upfront prevents expensive mismatches between your manufacturing needs and your tooling decisions.

With process selection clarified, the next consideration becomes equally critical: understanding the true cost picture and calculating when progressive stamping's tooling investment actually pays off.

Cost Analysis and ROI Factors for Progressive Stamping Investment

You've compared the methods—now let's talk money. The progressive stamping process demands significant upfront investment, which understandably makes manufacturers hesitant. But here's what many cost analyses miss: the economic model of progressive stamping fundamentally differs from other manufacturing approaches. Understanding this difference transforms how you evaluate tooling decisions.

Think of progressive stamping dies as capital assets, not expenses. You're essentially "buying" an extremely low per-part cost for the life of the tool. The question isn't whether progressive stamping costs more upfront—it always does. The real question is: at what volume does that investment start paying dividends?

Calculating Break-Even Points for Tooling Investment

According to manufacturing cost analysts at Okdor, automotive stamping tooling typically costs $100,000 to $500,000 depending on part complexity and production requirements. Simple brackets sit at the lower end, while complex body panels requiring multiple forming operations reach higher investment levels.

But here's where the economics get interesting. Those same analysts document that sheet metal fabricated parts costing $15 each can drop to $3-12 through progressive stamping—depending on complexity. That's potentially an 80% cost reduction per part. When you're running hundreds of thousands of parts annually, those savings accumulate rapidly.

So when does progressive stamping make financial sense? The data points to clear thresholds:

- Minimum viable volume: Target at least 10,000 parts monthly (120,000+ annually) to justify tooling investment

- Optimal payback zone: Projects exceeding 50,000 annual parts typically achieve 18-month payback on tooling costs

- Maximum efficiency: The more parts you produce, the lower your effective per-part tooling cost becomes

Consider this framework: if your current fabrication cost is $15 per part and stamping reduces that to $5, you're saving $10 per unit. With $150,000 in tooling costs, you break even at 15,000 parts. Everything beyond that point represents pure savings—and those savings compound with every production cycle.

Long-Run Economics and Per-Part Cost Reduction

The initial ROI calculation only tells part of the story. Progressive stamping's true economic advantage emerges over the tool's entire productive lifecycle—which can span millions of cycles when properly maintained.

As precision tooling specialists at U-Need emphasize, die processing involves ongoing maintenance considerations that significantly impact total cost of ownership. Dies operate under enormous stress through millions of high-impact cycles. Critical components—punches, pilots, and forming inserts—eventually wear, chip, or break.

What factors should you evaluate when calculating true ROI? Consider this comprehensive cost framework:

- Die longevity: Quality tooling built with premium materials can produce millions of parts before requiring major refurbishment

- Maintenance requirements: Proactive maintenance extends tool life dramatically compared to reactive repair-only approaches

- Progressive scrap metal rates: Well-designed dies minimize material waste through optimized strip layouts—some projects achieve scrap rates under 5%

- Secondary operation elimination: Progressive stamping consolidates multiple fabrication steps, eliminating handling, setup time, and labor costs between operations

- Lead time reduction: Documented cases show lead times shrinking from 10 weeks (fabrication) to 4 weeks (stamping)—accelerating time-to-market

The hidden cost savings often surprise manufacturers. According to Die-Matic's manufacturing experts, eliminating rework, improving inventory management, and reducing assembly time contribute secondary benefits that amplify the primary per-part savings. These operational improvements rarely appear in initial cost comparisons but significantly impact actual ROI.

What about modification costs? This represents a genuine risk. Design changes after tooling completion typically cost $5,000-15,000 for minor adjustments—or 30-50% of the original investment for major rework. This reality makes thorough design validation and prototyping essential before committing to production dies. Budget the base tooling cost plus 20-30% contingency for potential modifications.

The bottom line on progressive stamping economics: high upfront investment, dramatically lower ongoing costs, and ROI that improves with every part produced. For high-volume manufacturing, the math almost always favors this approach—but only when you understand the complete cost picture beyond the initial tooling quote.

With cost factors clarified, the next critical consideration becomes quality assurance—because the cheapest parts mean nothing if they don't meet your industry's demanding standards.

Quality Standards and Certifications in Progressive Stamping

You've crunched the numbers and the ROI looks promising—but here's a question that can derail even the most cost-effective project: can your stamping partner actually deliver parts that meet your industry's quality requirements? In precision die stamping, the difference between a certified manufacturer and an uncertified one often determines whether your components pass inspection or create expensive production delays.

Quality certifications aren't just wall decorations. They represent verified systems for preventing defects, maintaining traceability, and ensuring every progressive precision metal stamping meets documented specifications. Understanding what these certifications mean—and why they matter for your specific industry—helps you select partners who deliver consistent excellence rather than inconsistent headaches.

Understanding IATF 16949 for Automotive Stamping

If you're sourcing automotive stamping dies or stamped components for vehicle applications, one certification matters above all others: IATF 16949. Developed by the International Automotive Task Force, this standard builds upon ISO 9001's quality management foundation with automotive-specific requirements.

What makes IATF 16949 different from general quality systems? According to Xometry's certification experts, this framework "doubles down on creating consistency, safety, and quality across automotive products." Unlike approaches such as Six Sigma (which focuses on statistical analysis) or TQM (which emphasizes continuous improvement processes), IATF 16949 provides a standardized regulatory framework specifically designed for automotive manufacturing realities.

Here's what this certification signals about a precision die and stamping supplier:

- Defect prevention focus: Certified organizations must demonstrate their ability and commitment to limiting defects—reducing waste and eliminating rework

- Process documentation: Every procedure affecting quality gets documented, reviewed, and continuously validated

- Supply chain accountability: The certification covers the entire production ecosystem, not just final assembly

- Continuous audit compliance: Both internal and external audits verify ongoing adherence to requirements

Why does this matter practically? Many automotive OEMs and Tier 1 suppliers won't even consider partnerships with uncertified stamping providers. As industry analysts note, "While it's not necessarily required or enforced, you might find that suppliers, contractors, and customers won't want to collaborate or work with you if you aren't registered and adhering to these quality standards."

For precision stamp applications in automotive—think connectors, brackets, terminals, and structural reinforcements—IATF 16949 certification essentially functions as your quality insurance policy.

Quality Metrics That Define Production Excellence

Beyond certifications, specific performance metrics separate world-class stamping operations from adequate ones. When evaluating potential partners for automotive stamping dies or other precision applications, these measurable indicators reveal actual capability rather than marketing claims.

Tolerance capabilities define what's achievable. Precision die stamping operations routinely maintain tolerances of ±0.05 mm on critical dimensions, with some advanced operations achieving ±0.01 mm on specific features. Ask potential suppliers for documented capability studies—not just claimed tolerances, but statistically verified process capability indices (Cpk values).

First-pass approval rates measure how often parts meet specifications on initial inspection—without rework, adjustment, or re-runs. Industry leaders achieve first-pass rates exceeding 90%, with some precision operations reporting 93% or higher. Low first-pass rates signal process variability that eventually affects your production schedules.

Aerospace standards (AS9100) apply similar rigor to aviation and defense applications. This certification addresses the aerospace industry's zero-tolerance approach to defects—where component failures can have catastrophic consequences. Progressive precision metal stampings destined for aircraft require documented traceability from raw material through final inspection.

Medical device requirements add biocompatibility and cleanliness considerations. ISO 13485 certification indicates a quality management system designed specifically for medical device manufacturing, covering everything from material selection to contamination prevention.

When selecting stamping partners, evaluate these key quality indicators:

- Certification currency: Verify certifications are current and cover relevant scopes—not expired or limited to unrelated operations

- Statistical process control: Look for documented SPC programs that monitor critical dimensions in real-time during production

- Inspection capabilities: Advanced CMM (coordinate measuring machine) equipment and optical inspection systems indicate commitment to verification accuracy

- Traceability systems: From raw material heat numbers through finished part serialization, complete traceability protects both parties

- Corrective action processes: When issues occur (and they will), documented CAPA systems ensure problems get resolved systematically rather than repeatedly

- Audit history: Request recent audit results—suppliers confident in their quality systems share this information readily

The investment in certified, quality-focused stamping partners pays dividends throughout your product lifecycle. Fewer incoming inspection failures mean smoother production. Better traceability simplifies any warranty investigations. And documented quality systems provide the evidence regulators increasingly require for automotive, aerospace, and medical applications.

With quality standards clarified, the next consideration becomes understanding exactly where progressive stamping delivers maximum value—the specific industries and applications where this process truly excels.

Industry Applications Where Progressive Stamping Excels

You understand the quality standards—now let's explore where progressive stamping actually delivers results in the real world. While this process serves numerous sectors, one industry stands out as the undisputed leader: automotive manufacturing. The combination of extreme volume requirements, tight tolerances, and complex geometries makes progressive die metal stamping the go-to solution for vehicle component production worldwide.

But automotive is just the beginning. From life-saving medical devices to the electronics powering your daily life, progressive stamping shapes components you interact with constantly—often without realizing it. Let's examine exactly why this process dominates these critical applications.

Automotive Structural and Electrical Components

Think about the complexity inside a modern vehicle. Thousands of metal components must fit together perfectly, conduct electricity reliably, and withstand years of vibration, temperature extremes, and mechanical stress. Automotive components progressive stamping addresses all these challenges simultaneously—which explains why automakers consume more stamped parts than any other industry.

What specific parts rely on progressive stamped automotive parts? The list spans virtually every vehicle system:

- Electrical terminals and connectors: According to Wiegel's engineering documentation, stamped terminals serve applications from battery management systems and fuel injectors to infotainment displays and power seat motors. These precision components manage functions including ADAS cameras, anti-lock braking controllers, climate control modules, and lane assist systems.

- Brackets and structural reinforcements: Body panels, door assemblies, and chassis components require mounting brackets that combine strength with precise dimensional control. Progressive stamping produces these parts economically at automotive volumes.

- Heat shields: Protecting critical components from exhaust system temperatures demands stamped metal barriers with complex contours and mounting features—ideal progressive stamping applications.

- Sensor housings: Airbag sensors, temperature sensors, humidity sensors, and vehicle stability sensors all require precisely formed housings that progressive dies deliver consistently.

- Wire harness components: From engine harnesses to airbag harnesses, the connectors and terminals linking vehicle electrical systems originate in progressive stamping operations.

Why does progressive stamping dominate oem progressive stamping for automotive applications? The economics become compelling at automotive volumes. When you're producing hundreds of thousands—or millions—of identical components annually, the per-part cost advantages of progressive dies outweigh virtually every alternative. Add the consistency that hard tooling delivers across multi-million part production runs, and you understand why major automakers specify this process.

For manufacturers seeking automotive stamping die capabilities that meet these demanding requirements, suppliers like Shaoyi demonstrate what's achievable with proper engineering. Their IATF 16949 certification validates quality systems designed specifically for automotive production. CAE simulation capabilities catch potential issues before tooling begins. And their documented 93% first-pass approval rate reflects the precision that automotive OEMs demand—proving that quality standards discussed earlier translate directly into production reality.

Medical Device and Electronics Applications

Beyond automotive, medical progressive stamping represents one of the most demanding applications for precision metal forming. When components end up inside the human body or controlling life-critical equipment, quality standards escalate dramatically.

According to Paragon Medical's manufacturing experts, technological advances are driving demand for miniature, complex parts created from difficult-to-form materials. Medical devices frequently require more than just precise metal forming—they demand tight tolerance micro-stamped components that allow device engineers to create unique geometries for implants, electrical circuit paths, robotic platforms, and instrumentation pushing physical boundaries to microscopic levels.

What makes medical progressive stamping so challenging? Consider the requirements:

- Surgical instruments: Precision stampings form critical components of laparoscopic and endoscopic devices where dimensional accuracy directly impacts surgical outcomes

- Implantable components: Parts destined for permanent placement inside patients require exceptional surface quality, biocompatible materials, and zero-defect manufacturing

- Battery contacts: Medical device power systems depend on stamped contacts delivering reliable electrical connections throughout product lifecycles

- Titanium ligation clips: Specialized stamping operations form these critical surgical components from demanding materials

The electronics industry presents parallel challenges at different scales. Consumer devices demand smaller, lighter, more complex components produced in enormous quantities. Progressive stamping delivers:

- Connector terminals: The tiny contacts inside USB ports, charging connectors, and circuit board headers originate as progressive stamped components

- Lead frames: Semiconductor packaging relies on precisely stamped frames that position and connect integrated circuits

- EMI shielding: Electronic shielding components protect sensitive circuits from electromagnetic interference

- Battery contacts: From smartphones to power tools, stamped battery contacts ensure reliable power transfer

What capabilities enable success in these demanding applications? Industry specialists emphasize handling material thicknesses from 0.002 to 0.100 inches for flat stock and wire diameters from 0.008 to 0.090 inches. Progressive dies for medical and electronics applications often incorporate sophisticated features—precision stamping of micro-size components with complex geometries requires tooling engineered to tolerances measured in thousandths of an inch.

The common thread across all these applications? Progressive stamping excels when you need complex geometries, tight tolerances, and high volumes—whether you're producing millions of automotive terminals or thousands of precision medical components. The process adapts to industry-specific requirements while delivering the speed and consistency that make modern manufacturing economically viable.

Understanding these applications helps clarify what progressive stamping can achieve. But knowing what's possible is only the first step—the next challenge involves evaluating whether this process fits your specific project and finding the right partner to execute it successfully.

Selecting the Right Progressive Stamping Partner for Your Project

You've explored the technology, compared the methods, and understood the economics. Now comes the decision that determines whether your project succeeds or struggles: choosing the right stamping die manufacturing partner. This choice matters more than most manufacturers realize—because even the best progressive die stamping process design fails without competent execution.

Think of supplier selection as the final link in a chain. All the engineering knowledge, material science, and cost analysis you've gathered means nothing if your tooling partner can't translate requirements into production reality. Let's bridge that gap with actionable guidance you can apply immediately.

Evaluating Your Part Design for Progressive Feasibility

Before contacting potential progressive die manufacturers, honestly assess whether your part actually suits progressive stamping. Not every component benefits from this process—and discovering that mismatch after tooling investment creates expensive problems.

According to manufacturing partnership experts at Colab Software, Design for Manufacturing sessions should happen early—inviting manufacturing partners to review initial CAD concepts before finalizing details. This early engagement validates that every hole, rib, and fillet can be produced reliably, repeatedly, and at scale.

What DFM considerations should you evaluate? Start with these critical factors:

- Feature spacing: Operations need adequate separation between features. Punches placed too close together weaken die sections and accelerate wear. Your stamping die should accommodate minimum web widths appropriate for material thickness.

- Material utilization: Progressive dies excel when strip layouts maximize usable material while minimizing scrap. Parts with irregular geometries or features requiring extensive carrier width may waste material—reducing cost advantages.

- Tolerance requirements: Standard progressive stamping achieves ±0.05 mm on most features. If your design demands ±0.01 mm across multiple critical dimensions, discuss these requirements explicitly—not all progressive stamping press operations deliver ultra-precision tolerances economically.

- Volume thresholds: As established earlier, progressive die stampings become cost-effective above roughly 20,000-50,000 annual units. Below this threshold, alternative methods may deliver better value despite higher per-part costs.

What makes a part particularly well-suited for progressive tooling? Look for these characteristics:

- Multiple operations (piercing, bending, forming) that benefit from consolidation

- Small to medium size allowing strip-fed processing

- Consistent production requirements enabling tooling amortization

- Geometries achievable without repositioning between stations

Feasibility checks serve as your insurance policy against late-stage discoveries. As industry guidance emphasizes, these reviews confirm that designs can be manufactured at target volumes and costs—addressing the "what ifs" before committing to tooling investment.

Partnering with the Right Tooling Supplier

Once you've validated progressive feasibility, selecting your stamping die manufacturers becomes the pivotal decision. The right partner brings engineering expertise, production capability, and quality systems that transform your design into consistent production reality.

What separates capable suppliers from the rest? According to supply chain experts at YISHANG, great stamping partners don't just hit tolerances—they help you build better, faster, and more economically. That means evaluating capabilities beyond basic machining.

Use this decision checklist when evaluating progressive die manufacturers:

- Verify engineering capabilities: Does the supplier offer in-house tool design and fabrication, or do they outsource? Internal capability speeds iterations, protects intellectual property, and improves accountability. Ask specifically about CAE simulation—suppliers who validate designs virtually before cutting steel save you costly physical iterations.

- Assess prototyping speed: Time-to-market often determines competitive advantage. Capable suppliers offer rapid prototyping that delivers functional samples quickly for design validation. For example, Shaoyi's engineering team provides prototyping in as little as 5 days—enabling design verification before committing to production tooling. This speed lets you test, refine, and confirm feasibility without project timeline delays.

- Evaluate production scalability: Your partner must handle current volumes while accommodating growth. Review press capacity and tonnage range—progressive dies may require presses from 25T to over 600T depending on part size and material. Look for suppliers with quick-change tooling systems that minimize changeover time.

- Confirm quality certifications: ISO 9001 certification represents the baseline. Automotive projects require IATF 16949. Medical and aerospace applications may demand additional certifications. Request documentation—don't accept verbal assurances.

- Review tooling ownership terms: Clarify who owns the progressive stamping die after payment. Define maintenance responsibilities, storage arrangements, and transfer clauses before issuing purchase orders. Vague terms create leverage issues later.

- Examine maintenance programs: Quality suppliers implement predictive maintenance and store tools in climate-controlled environments. Request die maintenance documentation including sharpening logs, component replacement history, and calibration reports.

- Request similar project samples: Ask for parts from projects matching your material, geometry, and volume requirements. Inspect dimensional reports, surface finish, and edge quality. Documented capability studies (Cpk values) reveal actual process control rather than theoretical claims.

What does a comprehensive mold design service look like in practice? Suppliers like Shaoyi demonstrate the integrated approach that delivers results: their engineering team combines CAE simulation with cost-effective tooling tailored to OEM standards. This means designs get validated before fabrication, potential issues get resolved during planning rather than tryout, and production tooling runs reliably from the first stroke.

The distinction matters because great engineering translates directly into production success. That 93% first-pass approval rate mentioned earlier? It results from upfront simulation, meticulous tool design, and quality systems that prevent defects rather than detecting them after the fact.

Here's the bottom line on supplier selection: treat it as a partnership decision, not a procurement transaction. The stamping die manufacturers you choose become extensions of your manufacturing capability. Their engineering expertise compensates for gaps in your internal knowledge. Their quality systems protect your reputation. Their production capacity enables your growth.

Invest time in thorough evaluation now. The manufacturers ready to explore progressive stamping should approach potential partners with specific questions, clear requirements, and realistic volume projections. The right partner responds with solutions, not excuses—helping you transform progressive stamping from a process option into a competitive advantage.

Frequently Asked Questions About Progressive Stamping

1. What are the 7 steps in the stamping method?

The seven most common metal stamping operations include blanking (cutting the initial shape), piercing (creating holes and slots), drawing (forming depth and cavities), bending (creating angles and flanges), air bending (flexible angle formation), bottoming and coining (precision finishing under high pressure), and pinch trimming (final edge refinement). In progressive stamping, these operations occur sequentially across multiple die stations during each press stroke, with pilot holes ensuring precise alignment throughout the process.

2. What is the difference between progressive and transfer stamping?

Progressive stamping keeps parts attached to a carrier strip throughout all forming stations, making it ideal for small-to-medium high-volume parts running at faster cycle times. Transfer stamping separates parts early and uses mechanical systems to move them independently between stations, allowing larger parts, deeper draws, and repositioning between operations. Choose progressive for volumes exceeding 100,000 parts annually with smaller components; select transfer for larger parts or geometries requiring orientation changes.

3. What is the stamping process?

Stamping is a manufacturing method using male and female dies to plastically deform sheet metal into desired shapes through applied pressure. Progressive stamping advances this concept by feeding coil stock through multiple sequential stations—each performing specific operations like piercing, blanking, bending, and forming—until complete parts emerge. This consolidated approach eliminates secondary handling, reduces labor costs, and achieves production rates of thousands of parts per hour.

4. How much does progressive die tooling cost and when does it pay off?

Progressive die tooling typically costs between $100,000 and $500,000 depending on part complexity. However, per-part costs can drop by up to 80% compared to fabrication methods. Break-even generally occurs around 15,000-50,000 parts, with optimal ROI achieved when annual volumes exceed 100,000 units. Suppliers like Shaoyi offer rapid prototyping in as little as 5 days, allowing design validation before committing to full production tooling investment.

5. What certifications should a progressive stamping partner have?

For automotive applications, IATF 16949 certification is essential—it validates defect prevention systems, process documentation, and supply chain accountability that major OEMs require. Aerospace projects need AS9100 certification, while medical device components require ISO 13485. Beyond certifications, evaluate suppliers for CAE simulation capabilities, documented first-pass approval rates (industry leaders achieve 93%+), and statistical process control programs that ensure consistent quality across millions of production cycles.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —