Fixing Galling in Stamping Dies: Actionable Solutions

TL;DR

Galling in stamping dies is a severe form of adhesive wear where high pressure and friction cause the die and workpiece surfaces to weld together, leading to material transfer, damage, and operational failure. Effectively solving galling requires a systematic approach, starting with fundamental die design and maintenance. The primary solutions include ensuring correct punch-to-die clearance, polishing surfaces to reduce friction, selecting appropriate tool materials and advanced anti-galling coatings, and applying proper lubrication while controlling machine speed.

What is Galling and Why Does it Occur in Stamping Dies?

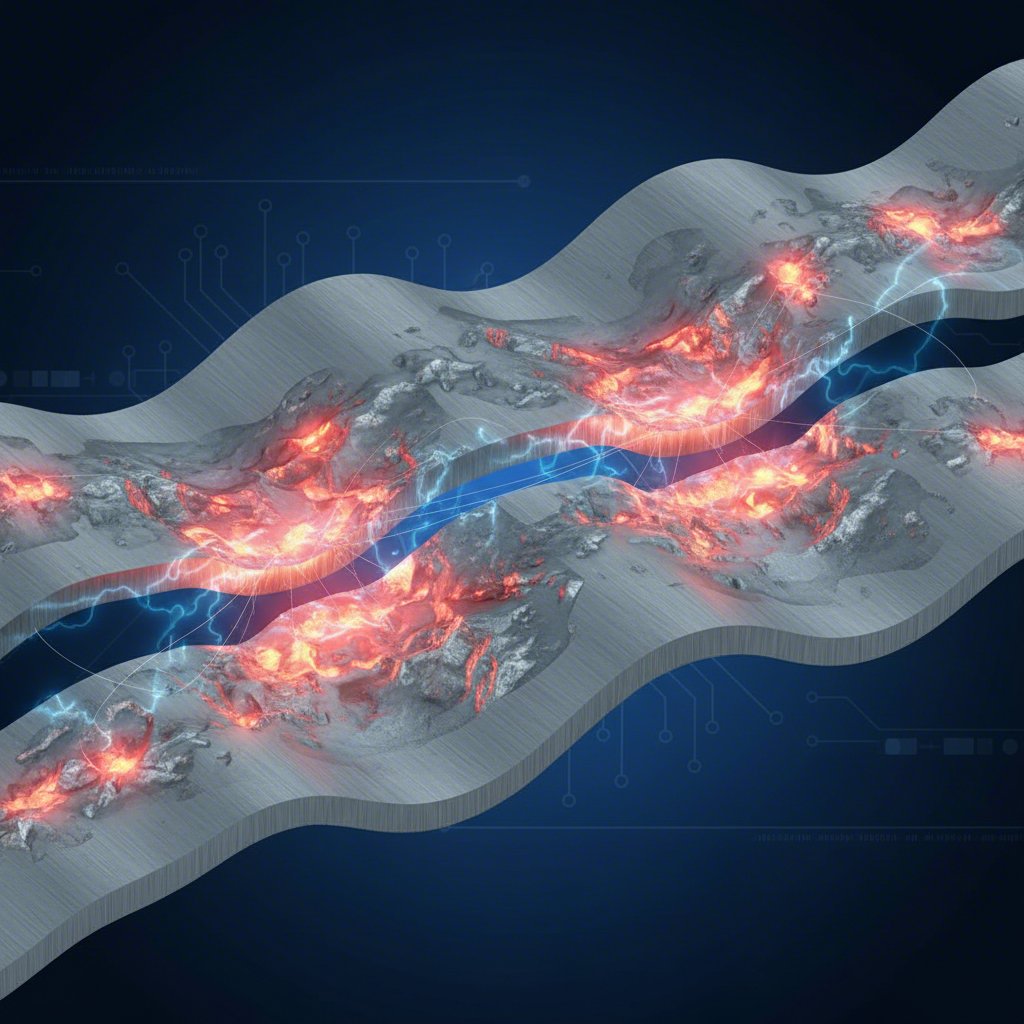

Galling is a form of severe adhesive wear that occurs when two metal surfaces in sliding contact experience high pressure and friction. In stamping operations, this phenomenon can quickly escalate from a minor issue to a major cause of downtime and tool failure. Unlike gradual abrasive wear, galling is a rapid process where the microscopic high points, or asperities, on the die and workpiece surfaces fuse together. This process is often described as a form of "cold welding." As the surfaces continue to move, this bond breaks, tearing and transferring material from one surface to the other, creating a distinctive raised lump known as a gall.

The root cause of galling is the combination of friction and adhesion at a microscopic level. As explained in an article by Fractory, even seemingly smooth metal surfaces have imperfections. Under the immense pressure of a stamping press, these asperities make contact, generating heat and breaking down any protective oxide layers. When the raw, reactive metal is exposed, the surfaces can form powerful metallic bonds. This adhesion causes material to be pulled from the weaker surface and deposited onto the stronger one, initiating a cycle of escalating damage. The newly formed gall creates even more friction, accelerating the wear process across the tool surface.

Several factors can trigger or worsen galling in stamping dies. Understanding these triggers is the first step toward effective prevention. Materials with high ductility and a tendency to form passive oxide layers, such as stainless steel and aluminum, are particularly susceptible. When this layer is compromised, the underlying metal is highly reactive and prone to bonding. The key triggers include:

- Poor Lubrication: Insufficient or incorrect lubrication fails to create an effective barrier between the sliding surfaces, allowing direct metal-to-metal contact.

- High Contact Pressure: Excessive force, often due to improper die clearance or part design, increases friction and the likelihood of asperities welding together.

- Similar or Soft Materials: Using similar metals for both the die and workpiece increases the chances of atomic bonding. Softer materials deform more easily, promoting adhesion.

- Debris and Contamination: Small metal particles or other contaminants trapped between surfaces can act as abrasives, scouring the protective layers and initiating galling.

- Excessive Heat: High operational speeds can generate significant heat, which softens the materials and makes them more likely to adhere.

Proactive Solutions: Die Design, Clearance, and Maintenance

Before turning to expensive coatings or specialized lubricants, the most effective and sustainable solutions for galling lie in fundamental die design and meticulous maintenance. As noted by experts in MetalForming Magazine, addressing the root mechanical causes is paramount. If the die's design is flawed, other solutions often just "coat the problem" without truly fixing it. A proactive approach focused on mechanics provides a robust foundation for a gall-free stamping operation.

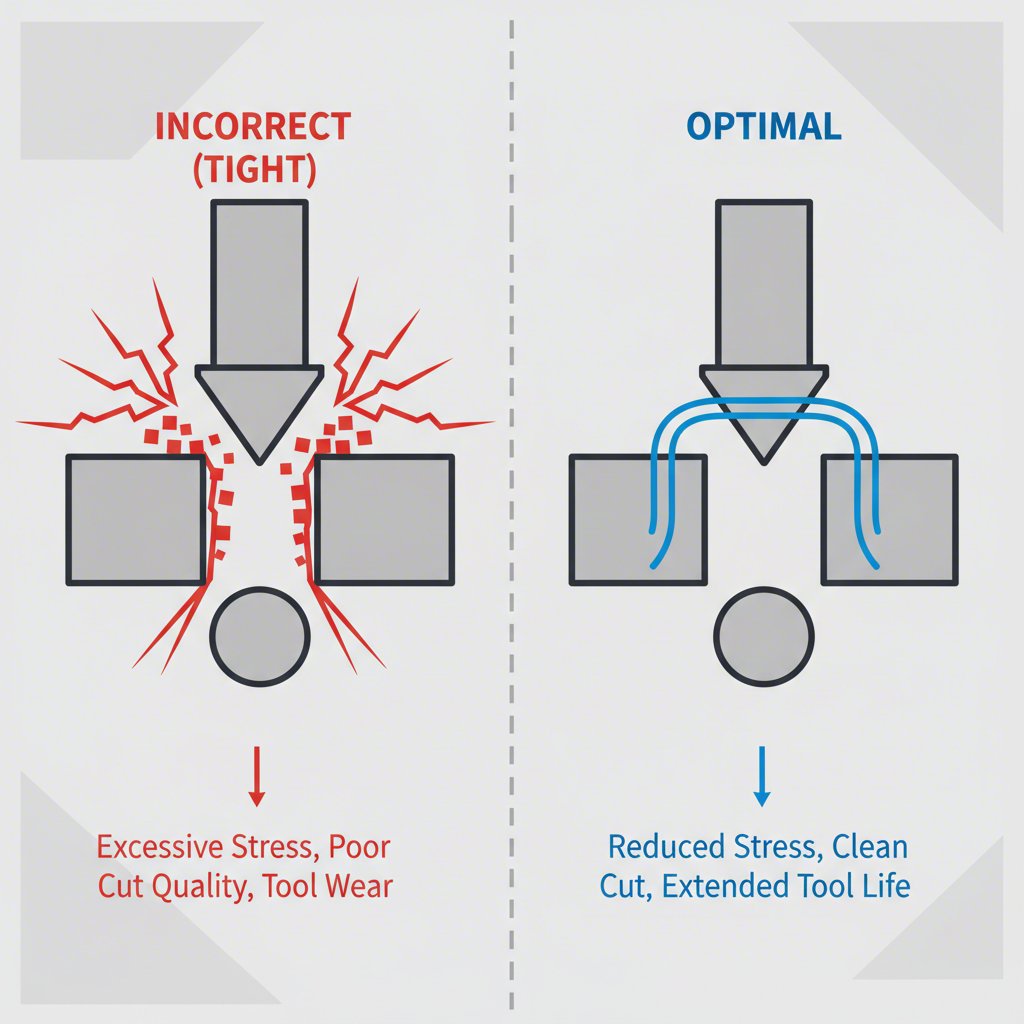

The single most critical factor in preventing galling is establishing the correct punch-to-die clearance. While designers typically account for material thickness, they sometimes overlook the fact that sheet metal thickens as it undergoes in-plane compression, especially in deep-drawn corners. This thickening can eliminate the intended clearance, causing the die to pinch the material and dramatically increase friction and pressure. To counteract this, additional clearance must be machined into the vertical walls of draw corners to accommodate material flow. For manufacturers focused on high-precision outcomes, leveraging advanced CAE simulations and extensive project management expertise is crucial. For instance, specialists in custom tooling like Shaoyi (Ningbo) Metal Technology Co., Ltd. build these design principles into their automotive stamping dies from the outset to ensure efficiency and component quality for OEMs and Tier 1 suppliers.

Beyond clearance, the surface finish of the die components plays a vital role. Polishing and stoning die sections reduces the microscopic peaks that initiate galling. The best practice is to polish surfaces parallel to the direction of the punching motion, which smooths the path for the workpiece material. The quality of this polishing should be as high as if the component were being prepped for an expensive surface coating. In many cases, the performance improvements attributed to a coating are actually the result of the superior surface preparation required for its application. Therefore, a rigorous polishing regimen is a cost-effective preventative measure.

A comprehensive maintenance strategy is essential for long-term prevention. This involves a series of repeatable steps that ensure the die remains in optimal condition. Key maintenance actions include:

- Verify and Adjust Clearance: Regularly measure punch-to-die clearance, paying special attention to wear in critical areas like draw corners. As a general tip, Rolleri suggests that slightly increasing die clearance (e.g., by 0.1mm) can sometimes alleviate galling issues.

- Maintain Surface Finish: Implement a regular schedule for stoning and polishing die surfaces that show signs of friction or material pickup.

- Ensure Tool Sharpness: Dull punches and die edges increase the force required for cutting and forming, which in turn generates more heat and pressure. Keeping tools sharp is a fundamental step in reducing galling.

Advanced Solutions: Material Selection, Hardening, and Surface Coatings

When sound die design and maintenance practices are in place, material science offers the next layer of defense against galling. By carefully selecting, hardening, and coating tool materials, you can create surfaces that are inherently resistant to the adhesive forces that cause galling. These advanced solutions are particularly effective when stamping challenging materials like stainless steel or aluminum.

One of the most effective strategies is to use dissimilar metals for the components in sliding contact. As detailed by 3ERP, materials with different atomic structures and hardness levels are less likely to form the microscopic welds that lead to galling. For example, using a bronze or brass bushing with a steel punch can significantly reduce friction and adhesion. When selecting tool steels, choosing a grade with higher hardness and wear resistance provides a stronger defense against the initial stages of material pickup.

Material hardening treatments further enhance a tool's resistance. These processes modify the surface of the steel to create an extremely hard outer layer while maintaining the core's toughness. Common treatments effective against galling include nitriding, carburizing, and through-hardening via heat treatment. Nitriding, for example, diffuses nitrogen into the surface of the steel, forming hard nitride compounds that dramatically increase surface hardness and lubricity, making it difficult for workpiece material to adhere.

For the most demanding applications, anti-galling coatings provide a final, robust barrier. These specialized surface treatments are designed to reduce friction and prevent adhesion. It's important to choose a coating suited to the specific application, as each has different properties and benefits.

| Coating Type | Description | Key Benefit |

|---|---|---|

| Diamond-Like Carbon (DLC) | An amorphous carbon material with a structure similar to diamond. | Provides extreme hardness and a very low coefficient of friction. |

| Tungsten Disulfide (WS2) | A dry film lubricant applied to the surface. | Offers excellent lubricity and prevents metal-to-metal contact without attracting debris. |

| Titanium Carbo-Nitride (TiCN) | A ceramic coating applied via Physical Vapor Deposition (PVD). | Increases surface hardness, wear resistance, and has a low affinity for workpiece materials. |

| Electroless Nickel / Chromium Plating | A layer of nickel or chromium is deposited on the surface without using an electric current. | Improves surface hardness and provides excellent corrosion resistance. |

While highly effective, these material-based solutions should be considered after mechanical issues like clearance and surface finish have been thoroughly addressed. They represent a significant investment and deliver the best return when applied to a fundamentally sound die design.

Operational Solutions: Lubrication and Machine Adjustments

While design and materials form the foundation of galling prevention, adjustments made during the stamping operation provide a critical, real-time method of control. Effective lubrication and proper machine settings can manage the immediate conditions—friction, heat, and pressure—that lead to galling. These operational solutions are the first line of defense for a press operator on the shop floor.

Lubrication is arguably the most crucial operational factor. A high-quality lubricant creates a protective film that prevents direct metal-to-metal contact, reduces friction, and helps dissipate heat. The key is to use a lubricant specifically designed for the stamping process and the materials involved. Anti-seize compounds, which often contain solid particles like graphite or copper, are particularly effective at preventing galling under high pressure. However, it's vital to remember that lubrication can be a short-lived solution if it's merely compensating for a root-cause issue like improper die clearance. Flooding an area with lubricant may temporarily solve the problem but can lead to housekeeping issues and increased costs without fixing the underlying mechanical flaw.

Machine settings also have a significant impact. Reducing the press's hit rate is a simple yet effective way to combat galling. Slower speeds generate less heat, giving lubricants more time to function and reducing the material's tendency to soften and adhere. This is especially important when working with materials like stainless steel, which work-harden rapidly and generate substantial heat during forming.

Finally, maintaining a clean operating environment is essential. A practical checklist for press operators to follow when galling is detected can help quickly diagnose and resolve the issue:

- Check Lubrication: Is the correct lubricant being applied in the right amount and location?

- Reduce Machine Speed: Slow the hit rate to lower the operational temperature.

- Clean the Tooling and Workpiece: Ensure no debris, slivers, or contaminants are present on the die surfaces or the incoming material.

- Verify Tool Condition: Check for dull edges on punches and dies, as they increase forming pressure and friction.

- Adjust Tooling Sequence: For some processes, like slitting, changing the sequence of operations to a "bridge" sequence can prevent material buildup and galling.

A Multi-Faceted Approach to Eliminating Galling

Effectively combating galling in stamping dies is not about finding a single magic bullet, but rather implementing a layered, systematic strategy. The most successful stamping operations recognize that lasting solutions begin with a solid foundation in die design and maintenance. Prioritizing correct punch-to-die clearance, especially in challenging draw corners, and maintaining a meticulously polished surface finish will always provide the greatest return on investment by addressing the problem at its mechanical root. Only after these fundamentals are perfected should attention turn to more advanced material science solutions.

Selecting dissimilar materials, applying hardening treatments like nitriding, or investing in advanced coatings such as DLC can provide the robust surface integrity needed for difficult applications. These are powerful tools, but they are most effective when enhancing a well-designed die, not compensating for a flawed one. Finally, disciplined operational practices—including the correct application of high-performance lubricants and the adjustment of machine speeds to manage heat—provide the real-time control necessary to keep galling at bay. By integrating these strategies, manufacturers can move from reactively fixing failures to proactively engineering a stable and efficient stamping process.

Frequently Asked Questions

1. How do you reduce galling?

Reducing galling requires a multi-pronged approach. Start by ensuring proper punch-to-die clearance and polishing die surfaces to minimize friction. Select harder or dissimilar tool materials and consider advanced surface treatments or coatings like TiCN or DLC. Operationally, apply an appropriate anti-seize lubricant, reduce the machine's hit rate to lower heat, and ensure both the die and workpiece are clean and free of debris.

2. Does anti-seize prevent galling?

Yes, anti-seize compounds are very effective at preventing galling. They function as a heavy-duty lubricant, creating a durable barrier between the sliding metal surfaces. This film withstands high pressure and temperature, preventing the direct metal-to-metal contact that leads to the microscopic welding and material transfer characteristic of galling.

3. What is the cause of galling?

The primary cause of galling is a combination of friction, high contact pressure, and adhesion between sliding metal surfaces. At a microscopic level, the high points (asperities) on the surfaces make contact, break through protective oxide layers, and weld together. As the surfaces continue to move, this bond is torn apart, transferring material from one surface to the other and creating escalating damage.

4. How to stop thread galling on stainless fasteners?

While this article focuses on stamping dies, the principles for preventing thread galling are similar. The most effective methods are to apply an anti-seize lubricant to the threads before assembly and to slow down the tightening speed. Using power tools at high speeds generates significant heat, which is a major contributor to galling in stainless steel fasteners. Using hand tools or controlled-speed power tools greatly reduces the risk.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —