Die Cushion Function: Precision Control in Press Forming

TL;DR

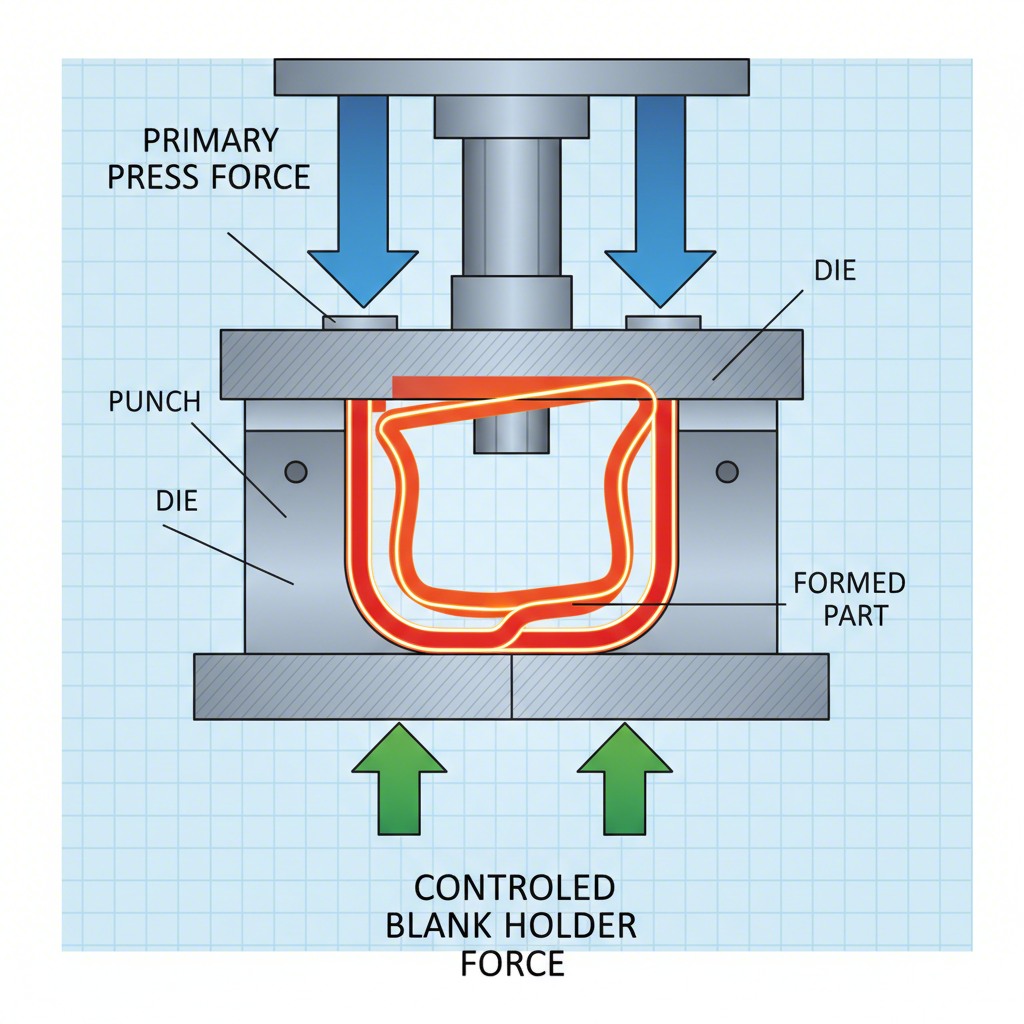

The primary function of a die cushion in press forming is to provide a flexible, controlled counterpressure, often called a blank holder force, on the workpiece. This precise force regulation is critical for managing material flow during forming operations, especially in deep drawing. By ensuring the material is held correctly, a die cushion prevents common defects like wrinkles, tears, and fractures, leading to higher-quality finished parts and greater process consistency.

Understanding the Core Function and Importance of a Die Cushion

A die cushion is an essential component in a power press, typically a hydraulic, pneumatic, or servo-mechanical system integrated into the press bed or ram. Its fundamental purpose is to generate a controlled and adjustable counterpressure against the workpiece during the forming cycle. This force, known as the blank holder force, secures the sheet metal blank between the upper die and a blank holder, ensuring it flows smoothly and evenly into the die cavity as the press strokes. Without this control, the material could buckle or stretch unevenly, resulting in costly defects.

The importance of a die cushion becomes clear when contrasted with older, less reliable methods. Historically, press tools relied on components like coil springs or gas springs to provide blank holding force. However, these systems often deliver inconsistent performance. As noted by experts at N2-Tech, even minor differences between individual springs can lead to deviations in the forming process, causing wrinkles, tears, or other shape defects. A die cushion, being a unified and adjustable system, overcomes these limitations by providing a stable and repeatable force curve, regardless of tool design, cycle time, or temperature fluctuations.

This precise control over material flow is what makes the die cushion indispensable for complex forming tasks. During an operation like deep drawing, the material undergoes significant stretching and deformation. The die cushion applies just enough force to prevent the flange of the blank from wrinkling while still allowing it to be drawn into the die. Too little force results in wrinkles, while too much force restricts material flow and causes the part to tear or fracture. By enabling operators to fine-tune this force, die cushions directly contribute to higher part quality, reduced scrap rates, and improved tool longevity.

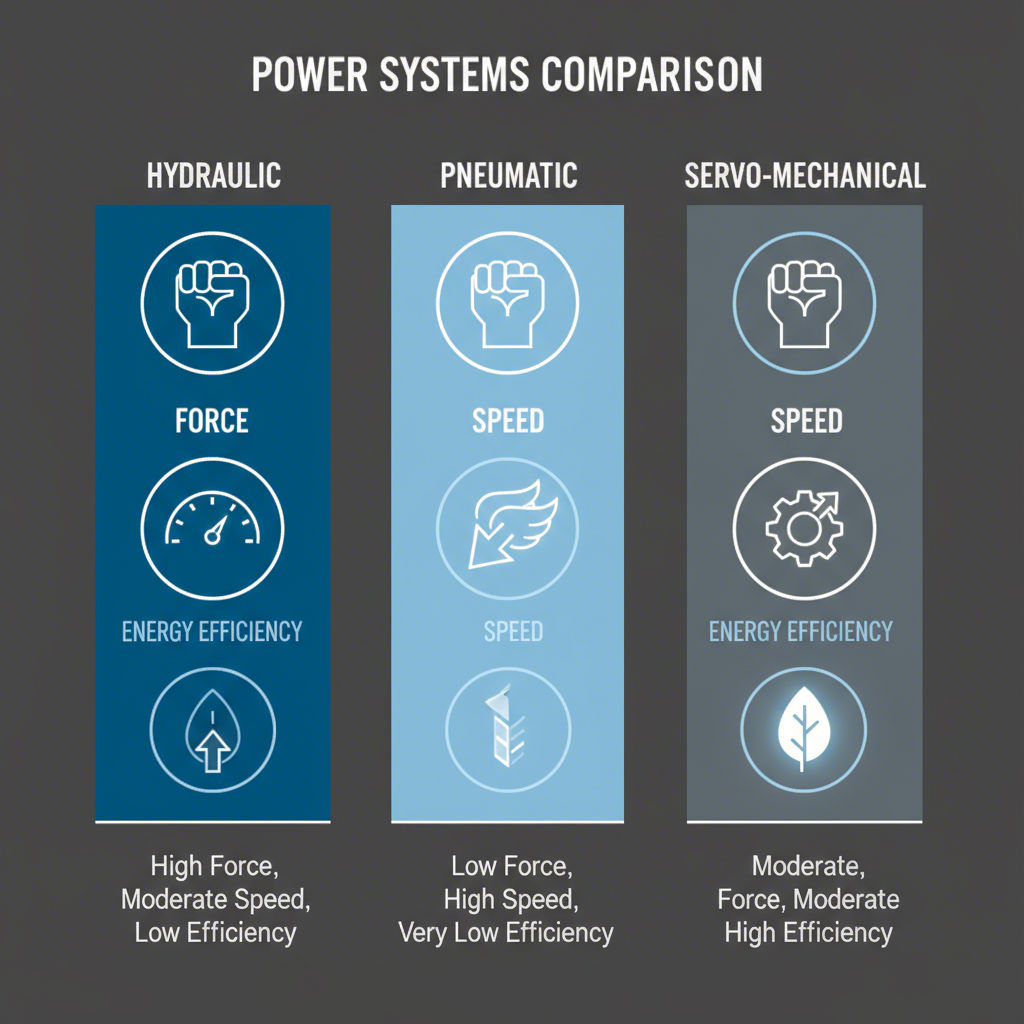

Types of Die Cushion Systems: Hydraulic, Pneumatic, and Servo-Mechanical

Die cushions are not a one-size-fits-all solution; they come in several distinct types, each with unique characteristics suited to different applications. The most common systems are hydraulic, pneumatic, and the more recent servo-mechanical designs. Understanding their differences is key to optimizing a press forming operation for specific materials, part complexities, and production demands.

Hydraulic die cushions are the most prevalent type, especially in heavy-duty applications. They use hydraulic fluid controlled by proportional valves to generate high forces with exceptional precision. As detailed by industry leader The Fabricator, modern hydraulic systems allow for programmable force profiles, meaning the blank holder force can be varied throughout the drawing stroke to accommodate the changing needs of the part geometry. This level of control is crucial for forming high-strength steels or complex automotive components.

Pneumatic die cushions utilize compressed air to generate force. They are generally simpler and less expensive than their hydraulic counterparts, making them suitable for lighter-duty applications where the force requirements are lower and the need for precision is less stringent. While they offer good speed, their force control is typically less accurate than hydraulic systems due to the compressibility of air.

Servo-mechanical die cushions, often called 'e-cushions', represent the latest evolution in this technology. These systems replace hydraulic or pneumatic components with electric servo motors and mechanical actuators like rack-and-pinion systems. According to innovators at Fagor Arrasate, e-cushions offer the highest degree of control, speed, and energy efficiency. They can even apply retention force during the press slide's ascent, a feature valuable for controlling spring-back in advanced materials. While the initial investment is higher, their reduced energy consumption and maintenance can lead to a rapid return on investment.

To clarify these differences, the table below provides a direct comparison:

| Feature | Hydraulic Cushion | Pneumatic Cushion | Servo-Mechanical (E-Cushion) |

|---|---|---|---|

| Force Control | High and precise; programmable profiles | Moderate; less precise | Highest precision; dynamic control |

| Energy Efficiency | Moderate; can be improved with advanced systems | Low to moderate | Very high; regenerative capabilities |

| Speed | Good; capable of pre-acceleration | Good | Very high and highly controllable |

| Cost | Moderate to high | Low | High initial investment |

| Ideal Applications | Heavy-duty deep drawing, complex parts | Lighter-duty forming, simpler parts | High-speed production, advanced materials, energy-conscious operations |

The Critical Role of Die Cushions in Deep Drawing Applications

While die cushions are beneficial in many press forming operations, they are absolutely critical for successful deep drawing. This process, used to create parts like automotive body panels, kitchen sinks, and complex housings, involves stretching a flat sheet metal blank into a three-dimensional shape. The material undergoes extreme deformation, and without precise control over its flow into the die, failure is almost certain.

The mechanics of deep drawing highlight the cushion's importance. As the press punch pushes the blank into the die cavity, the outer portion of the blank, known as the flange, must be allowed to slide inward. The die cushion's function is to apply a carefully calibrated blank holder force to this flange. This force is a delicate balance: it must be strong enough to prevent the compressive stresses in the flange from causing wrinkles, yet gentle enough to allow the material to flow smoothly without tearing due to excessive tensile stress. This is why sources like Pressmachine-World.com emphasize their necessity for deep drawing.

Modern die cushions offer programmable force profiles that are particularly advantageous for complex draws. The required holding force is often not constant throughout the stroke. For example, more force may be needed at the beginning of the draw to prevent wrinkling, with the force tapering off as the draw deepens to prevent tearing. Advanced cushions can execute these complex force curves with high repeatability, ensuring consistent part quality from the first part to the last.

This level of precision is paramount in sectors like the automotive industry, where deep-drawn components must meet strict dimensional tolerances. Companies specializing in this area rely on advanced press technology to achieve these results. For instance, providers of custom automotive stamping dies, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., leverage sophisticated processes to manufacture high-quality components for OEMs and Tier 1 suppliers, a feat often enabled by the precise control that modern die cushion systems provide.

Advanced Features and Modern Die Cushion Technology

Contemporary die cushion systems have evolved far beyond simple pressure pads. They are now sophisticated, programmable mechatronic systems that offer a wide range of advanced features, giving operators unprecedented control over the forming process. These innovations are crucial for working with challenging materials like high-strength steel and aluminum, and for achieving the tight tolerances demanded by modern manufacturing.

One of the most significant advancements is the ability to program the entire cushion cycle. As outlined in a detailed analysis by The Fabricator, a modern cushion's operation can be broken down into several key phases, each independently controllable. This includes pre-acceleration, where the cushion moves to match the speed of the press slide just before impact. This function minimizes shock, reducing noise and wear on both the die and the press itself. It is followed by a rapid pressure buildup to the required blank holding force.

During the drawing process, the force can be programmed as a multi-step profile, varying as the punch descends. Furthermore, some systems offer a pull-down function at the bottom dead center (BDC) of the stroke. This brief downward movement prevents the part from being damaged by the cushion's resilience as the press slide begins to retract. Finally, the upstroke can be controlled to bring the finished part to a specific pickup position for automation, before returning to the start position for the next cycle.

Another key development is modularity and multi-point control. Instead of a single large cushion, systems can be built from multiple, independently controlled cylinder modules. This allows for tailored force distribution across the die. An operator can apply more or less force to specific corners or areas of the blank holder, providing a powerful tool to correct material flow issues in asymmetrical or unusually shaped parts. This multi-point pressure control is essential for optimizing the production of complex components and minimizing tryout time for new dies.

Frequently Asked Questions

1. What is a die cushion?

A die cushion is a component in a press machine, typically powered by hydraulic, pneumatic, or servo-electric systems, located in the press bed. Its function is to provide a controllable upward force (counterpressure) on the blank holder during forming operations. This controlled force is essential for regulating the flow of sheet metal into the die, thereby preventing defects such as wrinkles and tears, particularly in deep drawing processes.

2. What is cushion pressure in a press machine?

Cushion pressure refers to the force exerted by the die cushion system. This pressure is adjustable and can often be programmed to vary throughout the press stroke. It is a critical parameter in sheet metal forming, as it directly controls the friction and material flow at the blank holder. Proper cushion pressure ensures the workpiece is formed to the desired shape without defects.

3. What is the die in a press tool?

In a press tool, the die is the specialized tooling that shapes the workpiece. It typically consists of a male component (the punch) and a female component (the die cavity or die block). The sheet metal is placed between these components, and as the press closes, the punch forces the metal into the die cavity, giving the part its final shape. The die cushion works in conjunction with the die to control the forming process.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —