3D Printing for Automotive Dies: The New Competitive Edge

TL;DR

Additive manufacturing, commonly known as 3D printing, is fundamentally transforming the production of automotive dies. This technology enables the creation of highly complex tooling with features like internal conformal cooling channels, which significantly extend die lifespan, improve the quality of cast parts, and reduce manufacturing costs. For automotive professionals, the future of 3D printing in automotive dies represents a critical shift towards more agile, cost-effective, and innovative production cycles.

The Paradigm Shift: Why Additive Manufacturing is Replacing Traditional Tooling

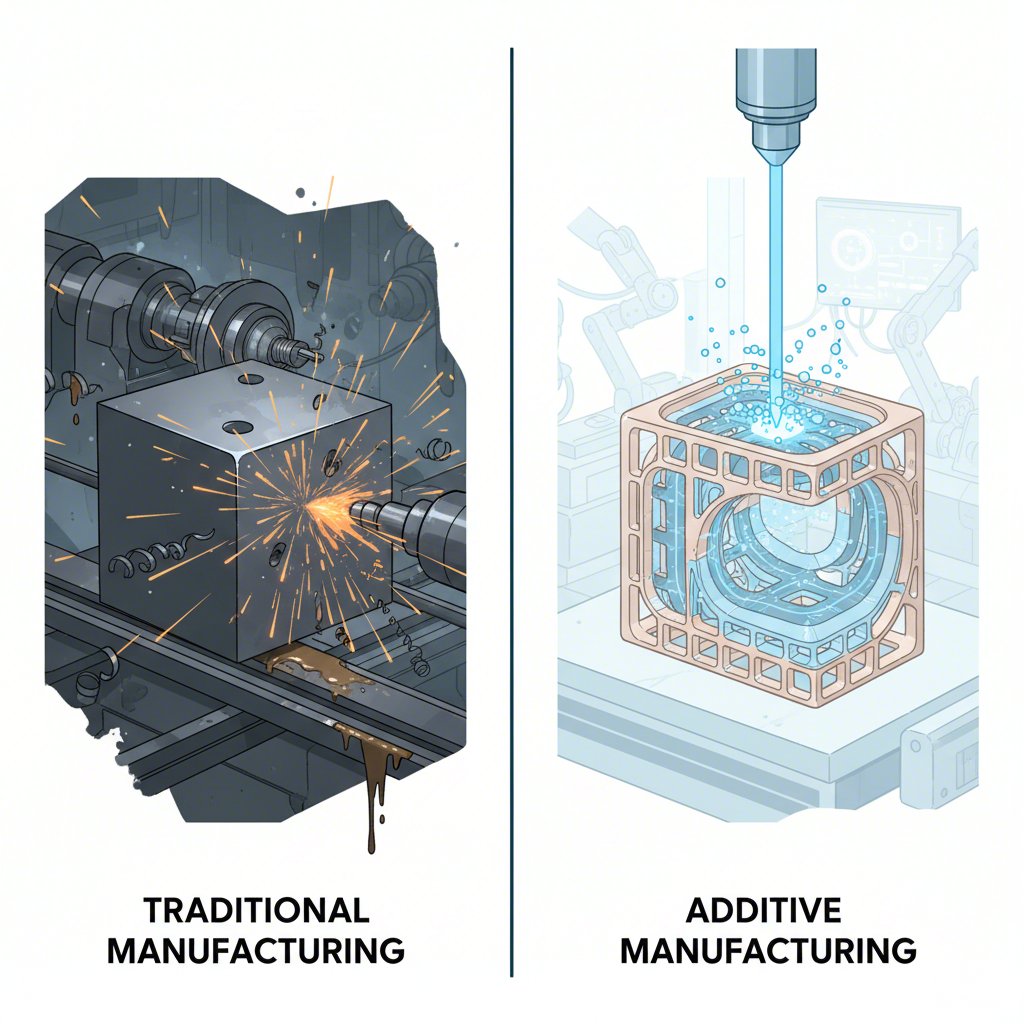

The manufacturing of automotive dies has long been dominated by traditional methods like CNC machining, a process that, while reliable, presents significant limitations in design and durability. These conventional techniques often struggle to create complex internal geometries, leading to dies with shorter lifespans due to thermal fatigue and inconsistent cooling. This results in frequent repairs, costly downtime, and potential defects in the final cast parts. The industry's reliance on these methods has created a bottleneck for innovation, slowing down production cycles and increasing costs.

Additive manufacturing (AM) directly addresses these challenges by building dies layer by layer from metal powder, allowing for unprecedented design freedom. Unlike subtractive machining, 3D printing can create intricate internal features, such as conformal cooling channels that precisely follow the mold's contours. As explained in a report by Sodick, this optimized thermal management prevents the formation of hot spots, a primary cause of cracking and wear. This leads to more consistent part quality and a dramatic extension of the tool's operational life.

A landmark example of this technology's impact is the collaboration between MacLean-Fogg and Fraunhofer ILT, which produced a massive 156 kg 3D-printed die casting insert for Toyota Europe. This component, used for the Yaris hybrid's transmission housing, demonstrates the scalability and industrial readiness of AM for large-scale automotive applications. By combining traditional and additive techniques into a hybrid manufacturing environment, companies can achieve on-demand production, reduce inventory, and minimize supply chain risks, creating a more resilient and agile operation.

This shift toward advanced tooling is being embraced by industry leaders. For instance, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. are at the forefront of providing high-precision automotive stamping dies and metal components, leveraging advanced simulations and project management to serve OEMs and Tier 1 suppliers. Their focus on quality and efficiency aligns with the core benefits that additive manufacturing brings to the entire tooling ecosystem.

| Metric | Traditional Die Manufacturing | 3D Printed Die Manufacturing |

|---|---|---|

| Lead Time | Weeks to months | Days to a few weeks |

| Design Complexity | Limited by machining constraints (e.g., straight-line cooling channels) | Nearly unlimited (e.g., conformal cooling, complex internal lattices) |

| Die Lifespan | Standard; prone to thermal fatigue and hot spots | Significantly extended due to superior thermal management |

| Part Quality | Susceptible to defects like porosity and warping from uneven cooling | Higher consistency, reduced defects, and improved surface finish |

Key Technical Innovations Driving the Change: Materials and Processes

The viability of 3D printing for demanding applications like automotive dies hinges on critical advancements in both printing processes and material science. It's not just about the ability to print metal, but the ability to print it with the precision, strength, and thermal properties required to withstand the brutal environment of die casting. These innovations are what elevate AM from a prototyping tool to a robust industrial manufacturing solution.

At the forefront of these processes is Laser Powder Bed Fusion (LPBF). As detailed by Sodick, systems like the LPM325 use high-powered lasers to selectively melt and fuse metallic powder layer by layer. This technique allows for the creation of dense, homogenous metal parts with extremely complex internal and external geometries. The precision of LPBF is what enables the fabrication of features like conformal cooling channels, which are impossible to produce with traditional drilling or milling.

Equally important is the development of specialized metal powders. MacLean-Fogg's patented L-40 tool steel powder, for example, was engineered specifically for the LPBF process. This material achieves high hardness and toughness with only moderate pre-heating, which minimizes the risk of cracking during the build process. Furthermore, it reduces the need for extensive post-build heat treatments, shortening the overall time-to-market. These advanced materials directly address common failure points in die casting, such as the soldering of aluminum to the tool surface and crack formation.

The combination of these technologies delivers tangible performance gains. According to Sodick, dies printed with optimized powders can last nearly three times longer than those made from traditional stainless steel in aluminum die casting applications. The benefits of these advanced materials include:

- Enhanced Durability: High resistance to thermal fatigue and wear extends the operational life of the die.

- Reduced Maintenance: Superior material properties minimize issues like soldering and cracking, leading to longer maintenance intervals.

- Improved Performance: Consistent thermal properties ensure higher-quality cast parts with fewer defects.

- Faster Production: Reduced need for post-processing and heat treatments accelerates the overall manufacturing workflow.

Measurable Benefits: Enhancing Performance, Quality, and ROI

The adoption of 3D printing for automotive dies is not just a technological curiosity; it is a strategic business decision driven by significant, quantifiable improvements in efficiency, cost, and product quality. By moving beyond the limitations of conventional manufacturing, automotive companies are realizing a substantial return on investment and gaining a powerful competitive edge in a rapidly evolving market.

The most immediate and impactful benefit is the radical reduction in lead times and costs. As reported by Industrial Equipment News, automation supplier Valiant TMS saw lead times for tooling components plummet from 4-6 weeks to just 3 days after integrating AM. This acceleration enables faster design iteration, quicker response to production line issues, and a more agile manufacturing process overall. The cost savings are equally compelling; a case study from Manufacturing Tomorrow highlights how Standard Motor Products reduced tooling costs by up to 90% and lead times by over 70% using 3D printing.

Beyond speed and cost, AM delivers superior performance and quality. The ability to design and print dies with conformal cooling channels provides uniform heat dissipation, which is critical for preventing defects like shrinkage porosity and warping in the final cast parts. This leads to higher yields, less scrap, and parts that meet tighter dimensional tolerances. Furthermore, the advanced metal alloys used in AM offer enhanced durability, resulting in dies that withstand more casting cycles before requiring maintenance or replacement.

These advantages create a cascading effect across the entire production value chain, accelerating innovation cycles and mitigating supply chain vulnerabilities. The key benefits can be summarized as follows:

- Accelerated Time-to-Market: Drastically shorter lead times for tooling allow for faster product development and launch, a critical advantage in the competitive automotive sector.

- Significant Cost Reduction: By eliminating the need for complex machining setups and reducing material waste, AM lowers both upfront tooling costs and the total cost of ownership.

- Enhanced Part Quality and Consistency: Superior thermal management from conformal cooling results in dimensionally accurate parts with better mechanical properties and fewer defects.

- Extended Tool Life: Advanced materials and optimized designs reduce thermal fatigue and wear, increasing the number of shots per die and minimizing downtime for repairs.

- Greater Design Freedom: Engineers can create lightweight, complex, and highly optimized dies that were previously impossible to manufacture, unlocking new performance possibilities.

Challenges and Future Outlook: The Road to Full Industrialization

Despite the transformative potential of additive manufacturing, its complete industrialization within the automotive sector remains an ongoing process with several hurdles to overcome. While early adopters have demonstrated remarkable success, widespread integration requires addressing challenges related to quality, materials, and workforce skills. Acknowledging these obstacles is the first step toward unlocking the technology's full potential and shaping its future trajectory.

Manufacturers must navigate a few key challenges to fully leverage AM. Ensuring that 3D-printed parts consistently meet the rigorous durability and quality standards of the automotive industry requires intensive testing and validation protocols. Furthermore, while the range of printable metals is growing, there is still a need for more high-performance materials that can serve as direct substitutes for certain specialized alloys used in traditional manufacturing. Finally, there is a significant skills gap; a new generation of engineers must be trained in Design for Additive Manufacturing (DfAM) to think beyond the constraints of conventional methods.

Looking ahead, the future of 3D printing in automotive manufacturing is bright and will be driven by the convergence of several key technological trends. The integration of AM systems with AI and the Internet of Things (IoT) will enable real-time process monitoring and predictive maintenance, further enhancing efficiency and quality control. Continued advancements in material science will expand the palette of available alloys, opening up new applications for even more demanding components. As seen in the MacLean-Fogg case, the technology is already pushing into new frontiers like structural die casting and massive "giga-casting" tools.

To navigate this landscape, strategic planning is essential. Success will require investment in workforce training, collaboration with technology partners, and a clear vision for integrating AM into core production strategies. The road to full industrialization is a journey, but one that promises to redefine automotive manufacturing for decades to come.

Frequently Asked Questions

1. What is the future of 3D printing in the automotive industry?

The future of 3D printing in the automotive industry is expansive, moving from prototyping to full-scale production of tools, fixtures, and end-use parts. Key trends include the use of AM for lightweighting components in electric vehicles, creating complex tooling like automotive dies with conformal cooling, and enabling on-demand production of spare parts to create more resilient supply chains. It is also a key driver of sustainability by reducing material waste and allowing for the use of recycled or bio-based materials.

2. Is there a market for 3D printed car parts?

Yes, there is a significant and rapidly growing market for 3D printed car parts. The global automotive 3D printing market was valued in the billions in recent years and is projected to experience substantial growth. This market includes everything from prototypes and custom interior components to performance-critical parts and complex tooling. Major OEMs like GM, Ford, and Toyota already use 3D printing extensively. For example, General Motors produced 60,000 spoiler seals for a single SUV model in just five weeks, validating its commercial viability.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —