Key Automotive Die Lubrication Strategies for Performance

TL;DR

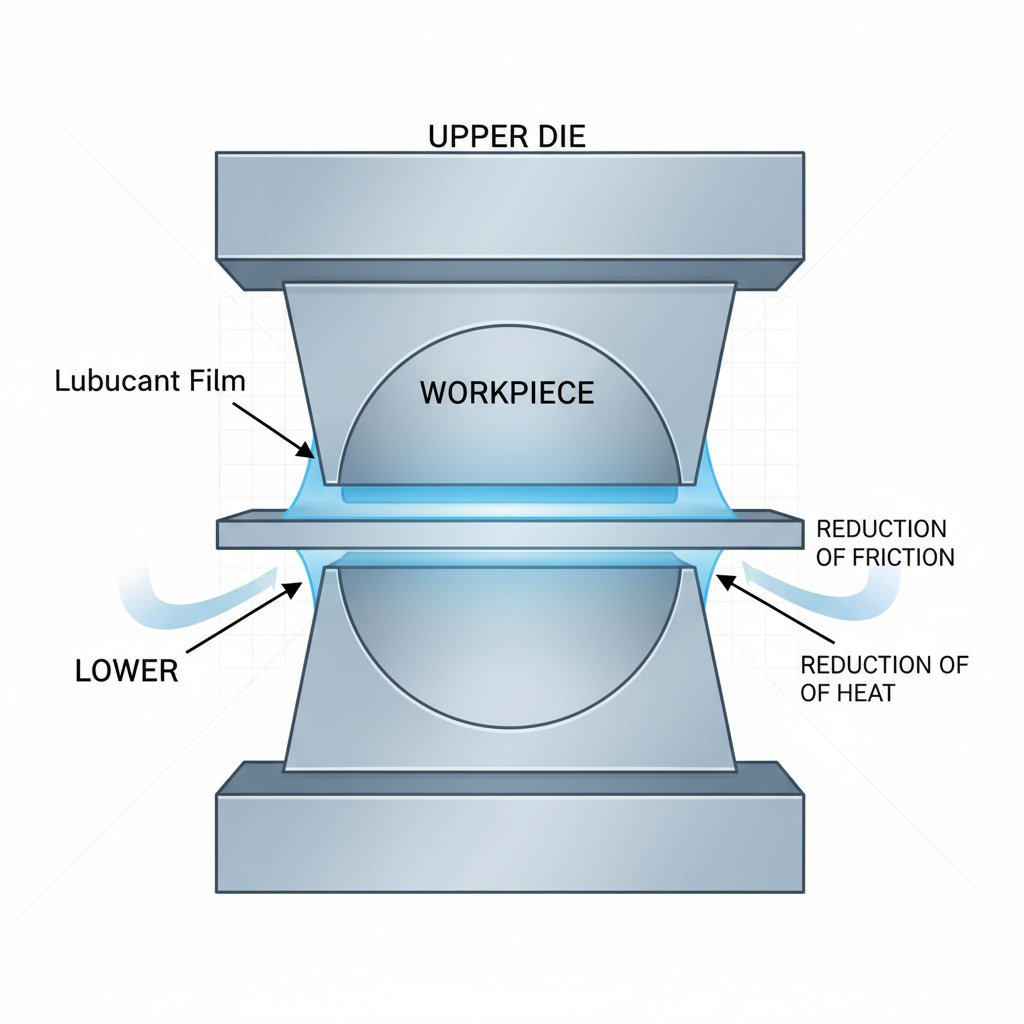

Automotive die lubrication is the critical process of applying a specialized compound to form a protective film between the die and workpiece during stamping or casting operations. An effective lubrication strategy is essential for reducing friction and heat, preventing premature tool wear, ensuring the high-quality release of manufactured parts, and maximizing the operational life of expensive dies.

The Crucial Role of Lubrication in Automotive Die Operations

In any stamping, forming, or fabricating facility, the interaction between the tool and the workpiece is a moment of intense friction and heat generation. The primary goal of die lubrication is to introduce a resilient film at this interface to manage these forces. This process is not merely about applying a fluid; it's a foundational element of a successful manufacturing operation that impacts everything from part quality to operational costs. When executed correctly, a well-planned lubrication strategy can drive significant efficiencies throughout the entire production cycle.

The functions of die lubrication are multifaceted, extending far beyond simple friction reduction. A proper lubricant creates a physical separation between the die surface and the part, which is critical for preventing damage and ensuring a clean release. The longevity of high-precision tooling, such as the custom automotive stamping dies developed by specialists like Shaoyi (Ningbo) Metal Technology Co., Ltd., is directly dependent on a meticulously executed lubrication program. Without it, even the most robust dies will suffer from premature wear.

Effective die lubrication delivers several key benefits:

- Friction and Heat Management: By minimizing the resistance between the die and the workpiece, lubricants dissipate the intense heat generated during forming, which is crucial for maintaining the dimensional stability of both the tool and the part.

- Die Protection: The lubricant film acts as a shield, preventing galling, scoring, and other forms of wear that result from direct metal-to-metal contact. This directly translates to longer tool life and reduced maintenance downtime.

- Improved Part Quality: Proper lubrication ensures a smooth material flow over the die surface, preventing tears, cracks, and cosmetic defects. It also facilitates a clean release of the part from the die, avoiding distortion.

- Corrosion Control: Many forming lubricants contain additives that protect both the die and the finished part from oxidation and rust during and after the manufacturing process.

Conversely, the consequences of inadequate lubrication are severe. Insufficient or incorrect fluid application leads to increased scrap rates, costly die repairs, and unplanned production stoppages. In the automotive industry, where lightweight materials like aluminum are increasingly used to improve fuel efficiency, the demands on lubrication technology are even greater. These materials require specialized lubrication strategies to handle their unique forming characteristics and prevent issues like soldering in die casting operations.

Developing a Holistic Lubrication Strategy

Achieving lubrication excellence requires moving beyond a haphazard, reactive approach to a planned, holistic strategy. When developing a lubrication plan, especially in a Quick Die Change (QDC) environment, companies should never consider a component in isolation. An effective strategy ensures that all elements—from lubricant selection and dilution to application methods and process controls—work in concert to shorten setups and prevent errors.

A comprehensive strategy begins with understanding that different jobs have different requirements. For instance, automotive OEMs often have specific, approved fluids for their tools. A key part of the strategy involves choosing between a reactive, schedule-based approach and a more advanced, condition-based system. While scheduled lubrication is simpler, a condition-based strategy monitors the actual state of the lubricant and machinery to optimize application, reducing waste and improving performance. This proactive mindset is crucial for modern, high-mix manufacturing.

To build a robust lubrication strategy, consider the following checklist:

- Analyze the Application: Evaluate the workpiece material (e.g., high-strength steel, aluminum), the complexity of the part, and the type of operation (e.g., stamping, deep drawing, die casting).

- Consult with Suppliers: Work with your lubricant supplier to select the right fluid. They can provide crucial information on forming characteristics and compatibility with post-processing like painting or plating.

- Define Application Parameters: Determine the optimal application method (e.g., spray, roller), nozzle placement, volume, and timing. Intelligent controllers can store these “spray profiles” to ensure repeatability and eliminate guesswork during changeovers.

- Establish Proper Dilution and Monitoring: Use the concentration chart provided by the lubricant supplier to establish the correct dilution ratio. Regularly check the concentration with a refractometer to ensure consistency.

- Integrate with Press Operations: For maximum efficiency, especially with QDC, use systems like quick-disconnect manifolds for lubricant lines. This not only speeds up changeover but also prevents errors like connecting the wrong hose to the wrong nozzle.

The table below contrasts two strategic mindsets, highlighting the benefits of a proactive, systems-based approach.

| Factor | Reactive (Component-Focused) Strategy | Proactive (System-Focused) Strategy |

|---|---|---|

| Lubricant Application | Manual or fixed-schedule application; often results in over- or under-lubrication. | Automated, condition-based application with precise volume and timing control. |

| Changeover Process | Individual hose connections; high potential for human error and contamination. | Use of quick-disconnect manifolds and programmed recipes; minimizes errors and downtime. |

| Monitoring | Infrequent or non-existent checks on lubricant concentration and condition. | Regular monitoring of dilution ratios and system performance; data-driven adjustments. |

| Outcome | Inconsistent part quality, higher lubricant waste, increased die wear, and longer downtime. | Consistent part quality, reduced waste, extended die life, and improved operational efficiency. |

Choosing the Right Lubricant: A Guide to Types and Properties

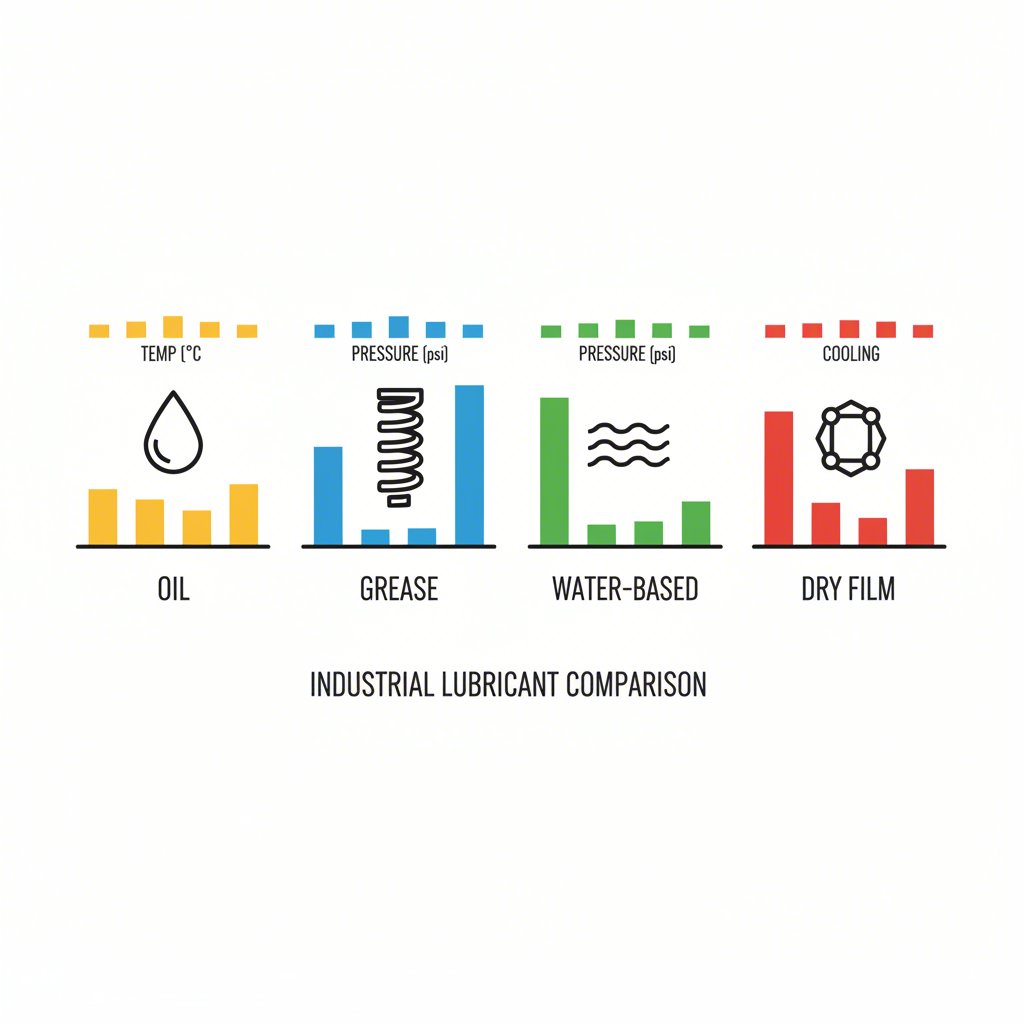

The lubricant itself is the cornerstone of any die lubrication strategy. Selecting the appropriate type is critical and depends heavily on the specific application, including the material being formed, operating temperatures, and pressures. The four main categories of industrial lubricants each offer distinct properties suited for different scenarios.

The primary types include oils, greases, dry lubricants, and penetrating lubricants. For most automotive die applications, oils and specialized synthetic compounds are the most common. For example, in high-temperature aluminum die casting, water-based die lubricants are engineered to cool the die surface effectively and prevent soldering, a common issue caused by the Leidenfrost effect where liquid vaporizes before it can wet the hot surface. Similarly, for stamping aluminum body-in-white (BIW) parts, hot-melt lubricants can provide superior boundary lubrication compared to conventional oils.

Making the right choice requires a careful evaluation of several factors. A lubricant that performs well at low temperatures may break down under the extreme heat of a forging or die-casting operation. The following table provides a comparison of common lubricant types used in metal forming:

| Lubricant Type | Key Properties | Best For | Considerations |

|---|---|---|---|

| Oil-Based (Mineral/Synthetic) | Excellent cooling, wide range of viscosities, can contain extreme pressure (EP) additives. | General stamping, drawing, high-speed operations. | Can cause housekeeping issues; viscosity changes with temperature. |

| Water-Based Emulsions/Synthetics | Superior cooling properties, clean, non-flammable. | High-temperature die casting, applications where fire resistance is needed. | Requires careful monitoring of concentration; potential for bacterial growth. |

| Dry Film Lubricants (Graphite, PTFE) | Withstands extreme temperatures and pressures; provides a clean, non-oily surface. | Forging, extrusion, and applications where liquid contamination is a concern. | Can be difficult to apply uniformly; may require surface preparation. |

| Hot-Melt Lubricants | Applied as a solid and melts with heat; provides excellent boundary lubrication. | Stamping challenging materials like aluminum alloys. | Requires specialized application equipment. |

To guide your selection process, ask the following questions:

- What is the workpiece material and its thickness?

- What are the maximum temperatures and pressures involved in the operation?

- Are there specific requirements for the final part's surface finish?

- What are the environmental, health, and safety considerations?

- Is the lubricant compatible with downstream processes like welding, painting, or plating?

Optimizing Performance Through Strategic Lubrication

Ultimately, effective automotive die lubrication is far more than a maintenance task—it is a strategic imperative for any modern metal forming operation. Moving from a mindset of simply applying fluid to one of managing a complete lubrication system is essential for achieving peak performance. A successful strategy acknowledges that lubricant selection, application method, and process monitoring are interconnected elements that directly influence productivity, quality, and profitability.

By carefully analyzing the specific demands of each application, collaborating with knowledgeable suppliers, and leveraging technology to ensure precision and repeatability, manufacturers can unlock significant benefits. The results are tangible: extended die life, reduced scrap rates, faster changeovers, and a cleaner, safer working environment. In a competitive automotive landscape, mastering die lubrication is a key differentiator that drives operational excellence.

Frequently Asked Questions About Die Lubrication

1. What is the lubricant for die casting?

For die casting, especially with high-temperature metals like aluminum, specialized water-based lubricants are typically used. These products are designed to both lubricate the die for easy part release and, critically, to cool the die surfaces between cycles. They must withstand extreme temperatures and prevent issues like soldering. Some specialized products, such as those containing graphite, are also used for their high-temperature stability.

2. What are the 4 types of lubricants?

The four main types of industrial lubricants are oil, grease, penetrating lubricants, and dry lubricants. Oils are liquid and excellent for heat transfer. Greases are semi-solids that adhere well to surfaces. Penetrating lubricants have very low viscosity to seep into tight crevices. Dry lubricants, like graphite or PTFE, are solids that reduce friction in high-temperature or clean environments.

3. What is a type 3 lubrication method?

This generally refers to one of three common methods for lubricating machinery like gears. The primary methods are grease lubrication, splash lubrication (where components dip into an oil bath), and forced oil circulation (where a pump actively distributes oil to critical points). The choice of method depends on the machine's speed, load, and design requirements.

4. What are the three or four types of lubrication systems?

In the context of industrial machinery, lubrication systems are about the method of delivery. These include manual systems (e.g., grease gun), centralized systems that automatically deliver lubricant to multiple points from a single reservoir, oil mist systems that spray an atomized lubricant, and circulation systems that continuously filter and reuse oil. In die applications, the system is often an automated spray or roller system designed for precise application.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —