Full-Service Forging and Machining: A Single-Source Solution

TL;DR

Full-service forging and machining is an integrated manufacturing solution that combines two critical processes. First, forging shapes metal using compressive force to create exceptionally strong and durable raw parts. Second, precision machining cuts the forged part to meet exact dimensional specifications and tight tolerances. This single-source approach streamlines the supply chain, enhances quality control, and delivers finished, high-performance components ready for assembly.

The Advantage of Integrated Forging and Machining

Choosing a full-service provider for forging and machining offers a strategic advantage over managing separate vendors for each process. This integrated approach combines the raw strength gained from forging with the high precision of modern machining, creating a seamless production workflow from raw material to finished component. The core value lies in a single point of accountability, ensuring that the final product meets the most demanding application requirements without compromise.

By consolidating these services, businesses can significantly reduce logistical complexity and lead times. Instead of coordinating shipments, schedules, and quality checks between a forge and a machine shop, a single partner manages the entire lifecycle. According to manufacturing experts at W.H. Tildesley, this consolidation directly improves communication, enhances quality oversight, and lowers overall costs by eliminating redundant administrative and shipping expenses.

The primary benefits of a unified forging and machining service include:

- Single-Source Accountability: One provider is responsible for the quality and delivery of the final part, simplifying supplier management and troubleshooting.

- Streamlined Supply Chain: Eliminates the time, cost, and risk associated with transporting semi-finished parts between different facilities.

- Optimized Quality Control: The provider has a holistic view of the manufacturing process, ensuring the forging is optimized for subsequent machining and that any issues are caught early.

- Cost and Time Efficiency: Reduced administrative overhead, combined logistics, and optimized production planning lead to faster turnaround times and better cost-effectiveness for complex projects.

Ultimately, this model is ideal for producing critical components where both material strength and dimensional accuracy are non-negotiable. Industries such as aerospace, defense, and medical devices rely on this integrated process to produce reliable, high-performance parts that can withstand extreme conditions.

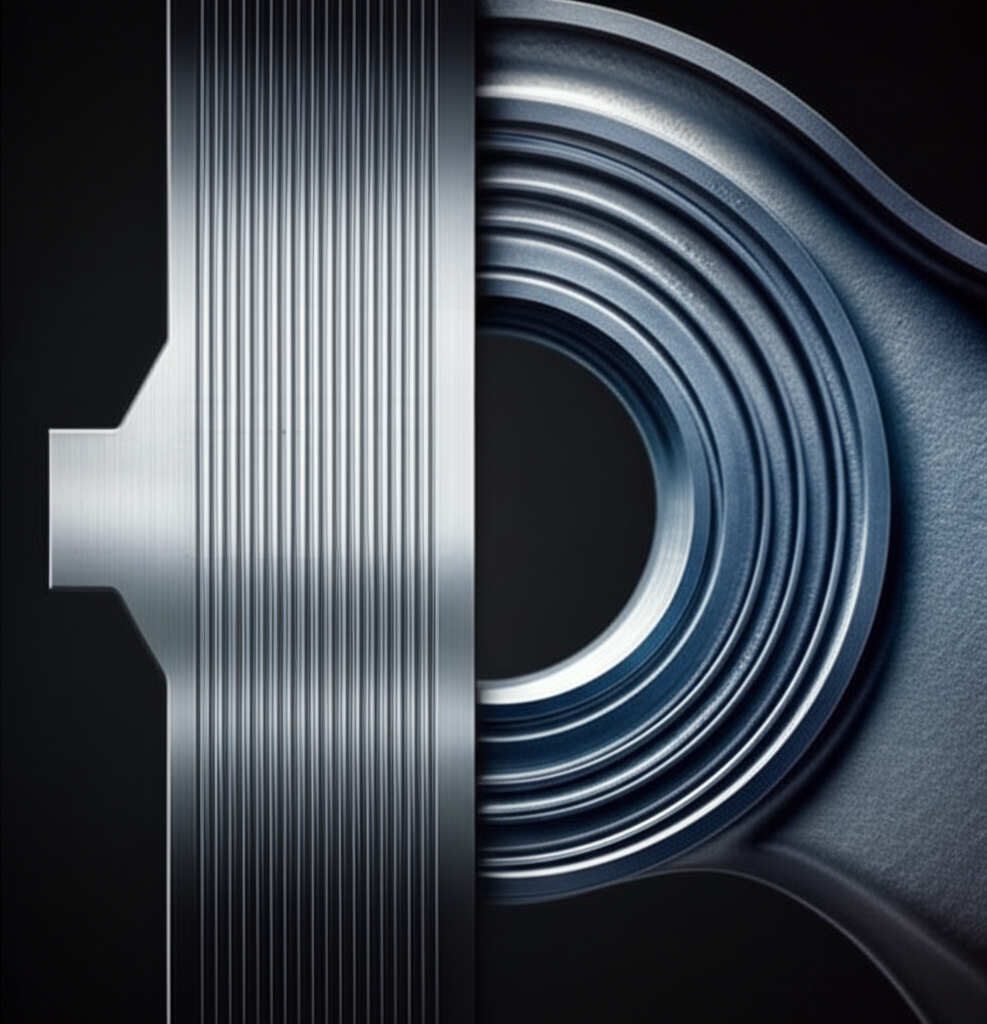

Core Forging Capabilities

Forging is the foundational process that imparts superior strength and structural integrity to metal components. Unlike casting or machining from bar stock, forging shapes the metal while it is in a solid state, refining the grain structure and aligning it with the part's final shape. This results in components that are tougher, more ductile, and highly resistant to impact and fatigue. A full-service provider offers various forging techniques tailored to specific part sizes, quantities, and complexities.

Two of the most common methods offered are open-die and closed-die forging. Understanding the distinction is key to selecting the right process for a project's requirements.

Closed-Die Forging

Also known as impression-die forging, this method involves pressing a heated metal workpiece between two custom dies that contain a precise impression of the desired part. As described by experts at Pegasus Manufacturing, the material flows and fills the die cavities, creating a near-net-shape part. This process is ideal for small-to-medium-sized components requiring tight tolerances and high repeatability, making it a cornerstone for high-volume production in the automotive and aerospace industries.

Open-Die Forging

In open-die forging, the workpiece is shaped between flat or simply contoured dies without being completely enclosed. The operator manipulates the workpiece between strikes to progressively form it into the desired shape, such as shafts, rings, or blocks. This technique offers greater flexibility for very large or custom one-off parts, where the cost of creating a closed die would be prohibitive. It is often used for heavy equipment, power generation, and marine applications where massive, high-strength components are required.

Advanced Precision Machining Services

After forging creates the strong, near-net-shape blank, precision machining provides the final form, features, and tight tolerances. This subtractive process removes material to achieve the exact specifications detailed in engineering blueprints. A truly full-service provider leverages a comprehensive suite of advanced machining technologies to handle parts of any complexity, transforming the raw forging into a component ready for assembly.

Modern machine shops employ computer numerical control (CNC) technology for unparalleled accuracy and repeatability. These capabilities often include:

- CNC Milling: Utilizes rotating multi-point cutting tools to remove material from the workpiece. Advanced 3, 4, and 5-axis milling centers can create highly complex geometries, contours, and cavities.

- CNC Turning: Involves rotating the workpiece while a cutting tool moves in a linear motion to create cylindrical parts with features like tapers, grooves, and threads. CNC chucking lathes and barfed lathes are common equipment.

- Mill-Turning Centers: These hybrid machines combine both milling and turning capabilities, allowing for the completion of complex parts with multiple features in a single setup, which increases efficiency and accuracy.

- Electrical Discharge Machining (EDM): A non-traditional machining process that uses electrical sparks to shape metal. It is particularly effective for creating intricate shapes in very hard materials or for features that are difficult to achieve with conventional cutting tools.

- Secondary and Finishing Processes: A complete solution often includes finishing operations such as grinding, polishing, deburring, and surface treatments like plating, anodizing, and heat treatment to meet all functional and cosmetic requirements.

Specialized Materials for Demanding Applications

The ability to work with a wide range of materials is a hallmark of a capable full-service forging and machining partner. Different applications demand specific material properties, such as high strength-to-weight ratio, corrosion resistance, or performance at extreme temperatures. Expertise in handling these materials, from forging through final machining, is critical for project success.

Providers typically have experience with a diverse portfolio of metals and alloys, which can be grouped into several key categories:

- Steel Alloys: Includes carbon steels (like 1018) and alloy steels (like 4130 and 4140) known for their strength, hardness, and durability, making them common in industrial and automotive applications.

- Stainless Steel: Grades such as 304 and 316 are selected for their excellent corrosion resistance and hygienic properties, making them essential in the medical, marine, and food processing industries.

- Superalloys: Nickel-based alloys like Inconel and cobalt-based alloys like Cobalt-Chrome offer superior performance under high heat, pressure, and corrosive environments. They are indispensable for components in aerospace engines and power generation turbines.

- Non-Ferrous Metals: This category includes Titanium, prized for its high strength-to-weight ratio in aerospace and medical implants, and Aluminum alloys, which are valued for their light weight and thermal conductivity. Copper and Brass are also commonly used for their electrical and anti-corrosive properties.

Key Industries Served

Integrated forging and machining services are essential for industries where component failure is not an option. The combination of strength from forging and precision from machining produces parts that meet the rigorous standards of the world's most demanding sectors. A provider's experience in a specific industry demonstrates an understanding of its unique challenges, quality standards, and material requirements.

Among the many sectors served, several stand out for their reliance on high-quality forged and machined components:

- Automotive: The automotive industry requires components that are both strong and lightweight for performance and safety. For robust and reliable parts, many turn to specialists in the field. For instance, some providers focus on high-quality, IATF16949 certified hot forging solutions. As an example, Shaoyi Metal Technology offers custom forging services, providing everything from rapid prototyping to mass production of critical automotive components.

- Aerospace and Defense: This is arguably the largest consumer of forged and machined parts. Components like landing gear, engine mounts, wing spars, and turbine disks must withstand incredible stress, making the refined grain structure of forging a necessity.

- Medical: The medical field uses forged and machined parts for orthopedic implants like hip and knee replacements. Materials such as titanium and cobalt-chrome are forged for strength and biocompatibility, then machined to precise, patient-specific dimensions.

- Oil and Gas: Components used in exploration, drilling, and refining—such as valves, flanges, and fittings—must endure high pressure and corrosive environments. Forging provides the necessary durability to ensure operational safety and longevity.

- Power Generation: From nuclear facilities to wind turbines, the energy sector relies on large, high-strength forged components like shafts, gears, and turbine blades that can operate reliably for decades.

Frequently Asked Questions

1. What are the 4 types of forging?

The four primary types of forging are impression die forging (or closed-die), open-die forging, cold forging, and seamless rolled ring forging. Impression and open-die forging involve shaping heated metal, while cold forging shapes metal at or near room temperature to achieve higher surface finish and dimensional accuracy.

2. Is forging cheaper than machining?

For large production volumes, forging is often cheaper per part than machining a component from solid stock. While the initial tooling cost for forging dies can be high, the process uses less raw material and is typically faster for creating the basic shape. For low-volume or one-off parts, machining from billet may be more cost-effective as it avoids high tooling costs.

3. What metals cannot be forged?

Metals with limited ductility or that are very brittle are difficult or impossible to forge. This includes materials like cast iron and certain high-carbon steels. Additionally, some high-strength alloys may be too brittle to withstand the compressive forces of the forging process without fracturing.

4. What is the highest paying machining job?

High-paying machining jobs often require specialized skills, extensive experience, and the ability to work with complex machinery or high-value components. Roles such as Master Machinist, Prototype Machinist, and Machine Shop Supervisor are typically among the highest earners, with salaries reflecting their advanced expertise and leadership responsibilities.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —