Why IATF 16949 Certification Is a Mandate for Tier 1 Suppliers

TL;DR

Tier 1 automotive suppliers require IATF 16949 certification primarily because it is a non-negotiable customer mandate from Original Equipment Manufacturers (OEMs). This standard is designed to ensure superior quality, mitigate supply chain risks, and validate a supplier's entire quality management system (QMS). More than just a set of rules, IATF 16949 provides a holistic framework for continuous improvement, risk management, and operational efficiency, which is essential for competing in the global automotive market.

The Primary Driver: A Non-Negotiable Customer Mandate

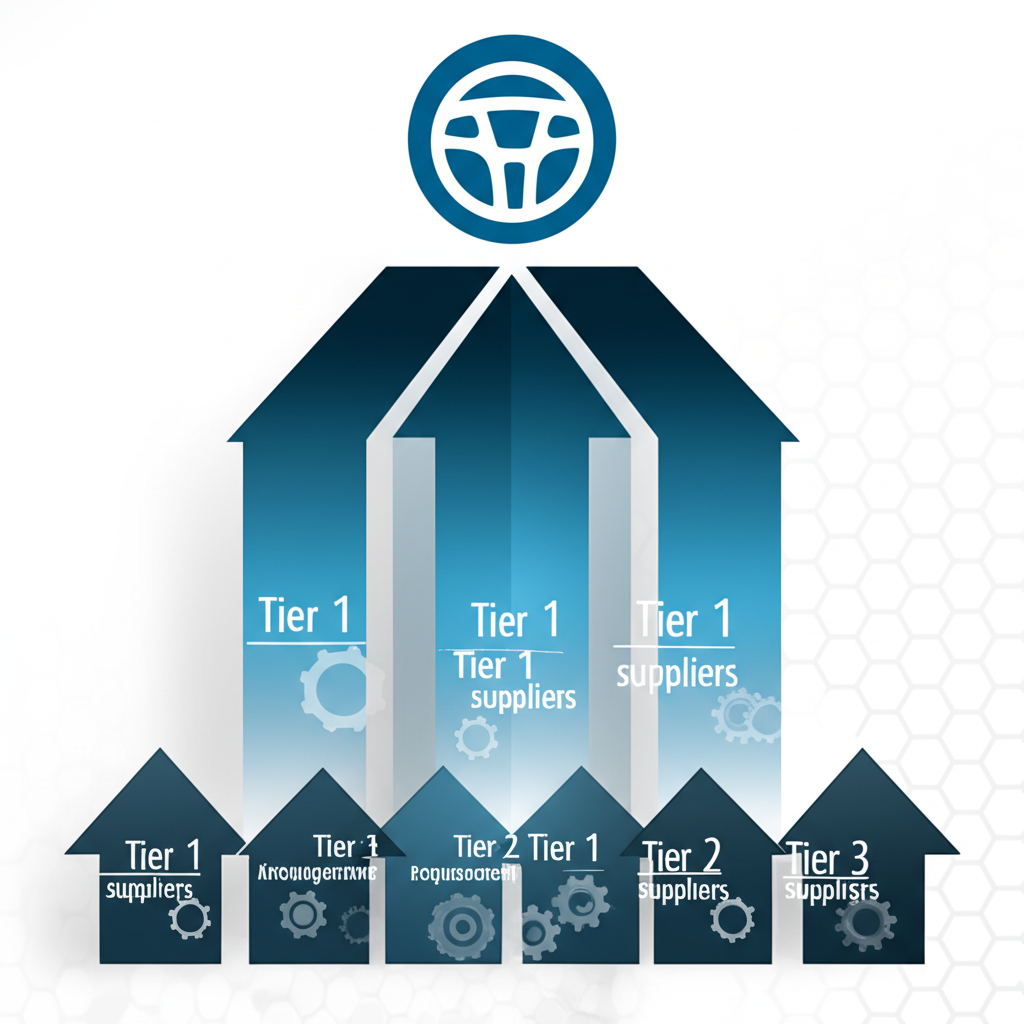

The foremost reason Tier 1 suppliers must achieve IATF 16949 certification is straightforward: their customers demand it. Automotive OEMs, the final assemblers of vehicles, sit at the top of a complex supply chain and bear the ultimate responsibility for product safety and quality. To manage this responsibility, they mandate IATF 16949 compliance for their direct—or Tier 1—suppliers. This certification is not a recommendation but a prerequisite for doing business, often required simply to be eligible to bid on a contract.

This requirement creates a cascading effect throughout the supply chain. Tier 1 suppliers, in turn, often push these same quality expectations down to their own suppliers (Tier 2 and Tier 3) to ensure consistency and reliability from the ground up. As detailed by quality experts, this system ensures that every component, no matter how small, is produced under a verifiable and robust quality management system. The standard, developed by the International Automotive Task Force (IATF), unifies various national quality standards into a single, globally recognized framework, making it the definitive benchmark for automotive quality.

Beyond a Checklist: A Holistic Framework for Quality and Risk Management

A common misconception is that IATF 16949 is merely a quality audit or a procedural checklist. In reality, it is a comprehensive framework for business excellence. As explained in an article by Chase Corporation, the standard is a holistic review of a supplier's entire operational system. It moves beyond basic process control to address systemic issues that can impact the modern automotive industry.

The core pillars of this holistic approach include:

- Risk Management: The standard requires proactive identification and mitigation of risks throughout the design and manufacturing processes. This includes tools like Failure Mode and Effects Analysis (FMEA) and developing contingency plans for potential disruptions, such as raw material shortages or logistics issues.

- Continuous Improvement: IATF 16949 is built on a philosophy of continual enhancement. It demands that suppliers not only maintain quality but consistently seek opportunities to improve processes, reduce waste, and increase efficiency. This commitment ensures that suppliers evolve with the industry's ever-increasing demands.

- Supply Chain Management: The standard places significant emphasis on managing the entire supply chain. Certified suppliers are responsible for ensuring their own vendors meet specific quality standards, thereby strengthening the entire network against potential failures.

- Leadership Engagement: Unlike other standards that can be siloed within a quality department, IATF 16949 requires active involvement from top management. This ensures that a culture of quality is driven from the highest levels of the organization.

Achieving this level of operational excellence requires precision in every component. For robust and reliable automotive components, suppliers often turn to specialized services. For instance, the custom forging services from Shaoyi Metal Technology demonstrate this principle in action. They specialize in high-quality, IATF 16949 certified hot forging, ensuring that critical automotive parts meet the most stringent safety and quality requirements from initial prototype to mass production.

Tangible Benefits: Ensuring Quality, Efficiency, and Customer Confidence

While IATF 16949 certification is primarily driven by customer requirements, its implementation delivers significant internal and external benefits. Adhering to this rigorous standard transforms a supplier's operations, leading to measurable improvements in performance and market position. The commitment to quality becomes a powerful competitive advantage.

Key benefits include:

- Enhanced Product Quality and Safety: By focusing on defect prevention and the reduction of variation and waste, the standard directly leads to more reliable and safer products. This is critical in an industry where component failure can have severe consequences.

- Increased Operational Efficiency: The emphasis on process optimization and waste reduction helps streamline operations. As noted by Eines Vision Systems, this focus on efficiency can lead to significant cost savings through reduced scrap, rework, and warranty claims.

- Strengthened Customer Trust: Certification acts as a globally recognized seal of approval. It demonstrates a supplier's commitment to quality, building immense trust and credibility with OEMs and making the certified company a preferred partner.

- Access to the Global Automotive Market: As a universal standard, IATF 16949 certification is a passport to the global automotive industry. It opens doors to new business opportunities with OEMs worldwide who require this level of quality assurance.

Understanding the Tiers: IATF 16949's Role Across the Supply Chain

The automotive supply chain is structured in tiers, and understanding this hierarchy is key to grasping the importance of IATF 16949. Each tier represents a different level of proximity to the final vehicle assembly, and the standard's application varies accordingly.

- Tier 1 Suppliers: These companies supply parts or systems directly to the OEMs. Examples include manufacturers of engines, transmissions, or electronic control units. For this tier, IATF 16949 certification is almost always mandatory, as they are a direct and critical link in the production process.

- Tier 2 Suppliers: These organizations supply components to Tier 1 suppliers. For example, a company that manufactures pistons for an engine builder is a Tier 2 supplier. While not always mandated by the OEM, Tier 1 customers frequently require their Tier 2 suppliers to be certified to ensure the quality of the components they receive.

- Tier 3 Suppliers: These companies provide raw materials or basic parts to Tier 2 suppliers, such as the provider of the metal alloy used to make the pistons. While direct IATF 16949 certification is less common at this level, the quality requirements of the standard are often passed down contractually.

According to certification body PRI, any tier can be registered as long as it has a direct customer in the automotive supply chain. However, the pressure and necessity are highest for Tier 1 suppliers, who serve as the gatekeepers of quality for the OEMs.

Frequently Asked Questions About IATF 16949

1. Why do we need IATF 16949?

IATF 16949 is needed to establish a globally recognized quality management system for the automotive industry. It provides a definitive framework for meeting customer requirements, managing risk, and driving continuous improvement, which enhances customer satisfaction and ensures product safety.

2. Why is an IATF audit required?

An IATF audit is required to verify that a supplier's quality management system conforms to the stringent requirements of the standard. A successful audit by an approved third-party registrar results in certification, which builds confidence with potential and existing customers by proving the supplier's commitment to system and process quality.

3. Is certification to IATF 16949 mandatory?

While not a legal requirement, IATF 16949 certification is a mandatory commercial requirement for most Tier 1 suppliers wishing to do business with automotive OEMs. Many vehicle manufacturers and their primary suppliers will not accept quotes or award contracts to companies that are not certified, making it an essential prerequisite for market entry and retention.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —