Forged Wheel Construction Types: Which One Matches Your Build?

Understanding Forged Wheel Construction Fundamentals

Ever wondered what does forged wheels mean when browsing high-performance wheel options? Here's the essential answer: forged wheels are manufactured by compressing solid aluminum billets under extreme pressure, typically between 8,000 to 10,000 tons, to create a denser and significantly stronger molecular structure than any other manufacturing method can achieve.

Unlike cast wheels where molten aluminum is poured into molds and allowed to cool, forging transforms a solid cylindrical block of aerospace-grade 6061-T6 aluminum into a wheel through controlled heat and immense pressure. The aluminum never melts during this process. Instead, it becomes pliable enough to reshape while maintaining its crystalline integrity. This fundamental difference separates forged construction from casting and explains why these wheels command premium pricing.

The Science Behind Forged Aluminum Strength

When you're comparing forged wheels vs cast wheels, the critical distinction lies in grain structure. Think of it like wood grain. Cutting with the grain requires far less effort than cutting across it. Metal behaves similarly, and forging takes advantage of this principle.

During the forging process, aluminum's internal grain structure undergoes molecular reorganization. The grains elongate, straighten, and orient themselves along the direction of applied force. This creates continuous, directional pathways for stress to travel through the material. According to industry testing, this aligned grain structure enables forged wheels to achieve approximately 2-3 times the fatigue life of cast counterparts under identical loading conditions.

What are forged rims actually offering beyond raw strength? The answer is near-zero porosity. Cast wheels inherently contain microscopic air pockets and voids that form when molten metal cools unevenly. These imperfections become potential failure points under repeated stress. Forged wheels eliminate this weakness entirely, creating a homogeneous structure throughout the material.

The forged wheels definition ultimately comes down to this: wheels engineered at the molecular level for superior tensile strength, fatigue resistance, and impact performance. They're typically 25-30% lighter than cast equivalents while maintaining or exceeding strength requirements.

Why Construction Type Determines Performance

Understanding what are forged wheels is just the starting point. The construction method, how the forged components are assembled, determines everything from customization options to long-term serviceability.

When examining cast vs forged wheels, you'll discover that forged construction itself branches into three distinct categories:

- Monoblock (one-piece) - Machined entirely from a single aluminum billet for maximum structural integrity and minimum weight

- Two-piece - Combines a forged center with a forged barrel, offering enhanced fitment flexibility

- Three-piece - Features separate forged components (center, inner barrel, outer barrel) joined by aerospace-grade hardware for ultimate customization

Each construction type delivers specific advantages depending on your application. Track enthusiasts prioritize different characteristics than show car builders. Daily drivers have unique requirements compared to weekend canyon carvers. The following sections break down each category so you can match the right construction type to your specific build goals.

Monoblock Forged Wheels Explained

So what is a forged wheel in its purest form? The answer is monoblock construction. Also known as 1 piece forged wheels, monoblocks represent the most straightforward yet technically demanding approach to forged wheel manufacturing. A single aluminum billet transforms into a complete wheel through precision machining, with no joints, fasteners, or assembled components to compromise structural integrity.

The forged wheels meaning becomes crystal clear when examining monoblock design. Every millimeter of the finished wheel originated from one solid block of metal, compressed and shaped under extreme pressure before CNC machines sculpt the final form. This unified construction establishes the performance benchmark against which all other forged wheel types are measured.

Single-Billet Manufacturing Process

Monoblock wheels begin life as cylindrical aluminum billets, typically weighing 40-80 pounds depending on the final wheel size. Manufacturers overwhelmingly choose 6061-T6 forged aluminum for this process, and understanding why reveals the engineering philosophy behind premium forged rim construction.

The 6061 designation refers to the aluminum alloy composition. This particular blend includes:

- Aluminum - The primary base providing lightweight properties and general strength

- Magnesium - Enhances overall strength through solid solution strengthening

- Silicon - Works synergistically with magnesium to improve strength while lowering melting temperature for easier forging

- Copper - Added in minor amounts to boost corrosion resistance and additional strength

But what about that T6 designation? This indicates the specific heat treatment process that transforms good aluminum into exceptional wheel material. The T6 treatment involves two critical stages. First, solution heat treatment heats the alloy to high temperatures before rapid quenching, allowing magnesium and silicon to dissolve into the aluminum and form a supersaturated solid solution. Second, controlled aging at elevated temperatures causes these dissolved elements to precipitate in a manner that dramatically increases yield strength and hardness.

According to 3030 Autosport, this combination of composition and heat treatment makes 6061-T6 the premier choice in demanding sectors including military applications, aerospace, Formula 1, and drag racing. The same properties that protect aircraft components at 40,000 feet translate directly to forged rim performance on the street or track.

Once the billet undergoes forging and heat treatment, precision CNC machining removes material to create spoke patterns, mounting surfaces, and final dimensions. Each wheel is essentially carved from within the compressed billet, and this subtractive process is what enables the lightest possible weight while maintaining the forged rims meaning of strength and reliability.

Structural Advantages of Unified Construction

Why do motorsport teams and performance enthusiasts gravitate toward monoblock construction? The absence of joints answers that question immediately.

Every connection point in a multi-piece wheel represents a potential failure location. Bolts can loosen under repeated thermal cycling. Welds can develop stress fractures over thousands of miles. Seals between components can degrade, allowing air leakage in tubeless setups. Monoblock wheels eliminate every single one of these concerns because there simply are no assembled components to fail.

Research indicates that forged wheels can be up to 30% stronger than cast aluminum wheels of equivalent weight. When that forged material exists as one continuous piece, stress transfers seamlessly from spoke to barrel to hub without interruption. Imagine the difference between a solid wooden beam versus boards nailed together. Both might support similar loads initially, but the solid beam maintains integrity under dynamic, repeated stress far longer.

This unified construction delivers measurable performance benefits:

- Maximum structural integrity - No joints, seams, or fasteners to become failure points under repeated stress cycles

- Lowest weight potential - No hardware weight added; material can be removed anywhere without compromising component connections

- Simplified maintenance - Nothing to tighten, no seals to inspect, no hardware to replace during routine service

- No seal degradation concerns - Tubeless tire beads seat against continuous forged material rather than assembled sections

The weight advantage deserves additional emphasis. Because monoblock wheels require no bolts, nuts, or connecting hardware, manufacturers can engineer thinner wall sections and more aggressive spoke profiles. Every gram counts in unsprung weight reduction. According to performance data, each pound saved in unsprung weight improves acceleration, braking response, and suspension compliance more than equivalent reductions in sprung vehicle mass.

For drivers prioritizing outright performance over maximum customization flexibility, monoblock construction delivers the ideal balance. However, this optimized design does limit fitment options compared to multi-piece alternatives. The next section explores how two-piece construction addresses that trade-off while maintaining forged wheel performance credentials.

Two-Piece Forged Construction Methods

What happens when you need monoblock-level strength but require fitment flexibility that single-billet construction simply cannot deliver? Two-piece forged wheels answer that question by separating the wheel into two primary components: the center section (face and spokes) and the outer barrel where the tire mounts.

This modular approach opens doors that remain firmly closed with monoblock designs. When comparing forged vs cast options, two-piece forged construction maintains the superior grain structure and material density of forging while adding customization possibilities that appeal to enthusiasts with heavily modified vehicles or unique fitment requirements.

According to industry specifications, two-piece forged wheels use high-quality forged aluminum alloy for both components, making them stronger and more durable than cast alternatives. But the real distinction lies in how those components come together.

Welded vs Bolted Assembly Methods

Here's the critical detail most wheel discussions overlook entirely: not all two-piece wheels are assembled the same way. The joining method fundamentally changes the wheel's characteristics, and understanding this distinction helps you make informed decisions when choosing between forged or cast wheels for your specific application.

Welded two-piece construction permanently fuses the barrel and center section into a single unit. After precision machining, skilled technicians use specialized TIG welding techniques to join the components along their mating surfaces. The weld penetrates deep enough to create molecular bonding between the two forged sections, resulting in structural integrity approaching monoblock levels.

Think of it this way: once welded, these components essentially become one piece again. The joint area, when properly executed, matches or even exceeds the surrounding material's strength because welding actually refines the grain structure at the fusion point.

Bolted two-piece construction takes the opposite approach. High-strength aerospace-grade fasteners secure the barrel to the center section, maintaining the wheel's modularity throughout its service life. This design philosophy prioritizes serviceability over maximum structural simplicity.

According to research on wheel construction, bolted wheels tend to fail less often when reparability and adjustability matter most, though these setups might need more regular maintenance because bolts can come loose over time from thermal cycling and vibration.

When deciding between cast or forged wheels, remember that both welded and bolted two-piece options maintain forged material properties. The assembly method affects serviceability and long-term maintenance requirements rather than the fundamental forged rims vs cast strength advantage.

| Factor | Welded Two-Piece | Bolted Two-Piece |

|---|---|---|

| Structural Strength | Near-monoblock integrity; permanent fusion eliminates joint flex | Excellent when properly torqued; requires periodic hardware inspection |

| Repairability | Damaged sections require cutting and re-welding; specialized equipment needed | Individual components can be unbolted and replaced independently |

| Weight | Lighter overall; no fastener hardware adds mass | Slightly heavier due to bolts, nuts, and required material thickness at mounting points |

| Maintenance | Minimal; no hardware to inspect or re-torque | Periodic bolt torque verification recommended every 12,000 miles |

| Customization After Purchase | Limited; modifications require professional cutting and welding | High; components can be swapped for different widths or offsets |

| Relative Cost | Moderate; simpler long-term ownership but harder repairs | Higher initial; lower long-term if component replacement becomes necessary |

Barrel and Center Construction Dynamics

Understanding how two-piece wheels are manufactured reveals why they offer advantages that monoblock designs cannot match. Each component begins as a separate forged aluminum billet, processed and heat-treated independently before precision machining shapes the final form.

The center section houses the spokes and hub mounting surface. Manufacturers machine this component from a forged block, creating the visual design elements and the critical interface with your vehicle's hub assembly. This is where spoke patterns, lug holes, and centerbore dimensions take shape.

The barrel forms the outer circumference where your tire mounts. According to manufacturing specifications, barrel sections are also forged for maximum strength, then precision-machined to exact dimensions for tire bead seating and valve stem positioning.

Here's where fitment flexibility becomes significant. With monoblock construction, changing the wheel's width or offset requires manufacturing an entirely new wheel from scratch. Two-piece construction changes that equation dramatically.

Manufacturers can pair the same center section with barrels of varying depths and widths. Want a wider rear wheel with more aggressive offset? The center design remains identical while a different barrel specification achieves the desired dimensions. This modular approach enables:

- Broader offset ranges - The same center works with multiple barrel configurations to achieve offsets that monoblock tooling cannot economically produce

- More width combinations - Barrel depth variations create width options without redesigning spoke geometry

- Staggered fitments - Front and rear wheels can share center designs while using different barrel specifications

- Future adaptability - Changing vehicles or modifying suspension geometry doesn't necessarily mean replacing entire wheel sets

The repair angle deserves attention too. When curb damage gouges a barrel section, bolted two-piece construction allows replacement of just that component. The undamaged center section continues serving your vehicle while a new barrel restores the wheel to perfect condition. Compare that to monoblock construction, where similar damage often means discarding the entire wheel.

This serviceability extends to cosmetic updates as well. Enthusiasts can refinish or replace center sections to refresh their wheel appearance without purchasing complete new wheels. For those evaluating cast vs forged options, two-piece forged construction delivers both the material strength advantages and the practical flexibility that daily-driven vehicles often require.

The three-piece construction method takes this modular philosophy even further, separating the barrel itself into inner and outer sections for maximum customization potential.

Three-Piece Forged Wheel Architecture

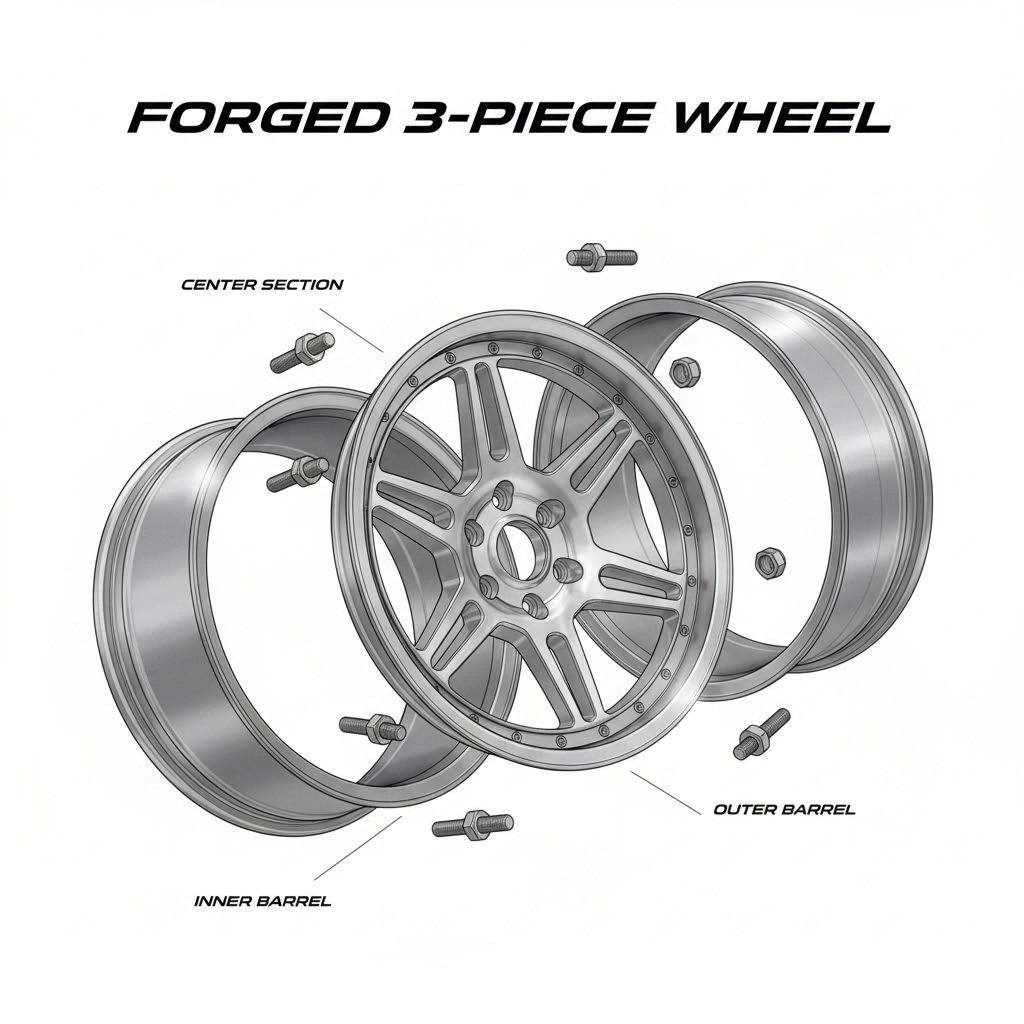

What if you could build your ideal wheel specification from scratch, adjusting width, offset, and backspacing to exact millimeter precision? That's precisely what three-piece forged wheels deliver. Representing the pinnacle of fully forged wheels technology, this construction method separates the wheel into three distinct forged components, each manufactured independently before assembly with aerospace-grade hardware.

For enthusiasts running custom forged setups on show cars, track builds, or forged wheels for trucks requiring aggressive fitments, three-piece construction offers possibilities that monoblock and two-piece designs simply cannot match. But this flexibility comes with trade-offs worth understanding before committing to this premium construction type.

Modular Design Philosophy

Three-piece wheels break down into three separate forged aluminum components:

- Center section - Houses the spokes, hub mounting surface, and defines the wheel's visual character

- Inner barrel (rear half) - Forms the backside of the wheel where it interfaces with brake components and suspension

- Outer barrel (front half) - Creates the visible lip and front tire bead mounting surface

Each component begins as a separate forged billet, processed through the same heat treatment and precision machining that defines all forged wheel construction. The magic happens during assembly. According to Forgeline's manufacturing specifications, three-piece wheels can even be finished with different custom color combinations on the center, inner rim, and outer rim, creating visual possibilities unavailable with any other construction method.

But how do these components become one functional wheel? Aerospace-grade stainless steel hardware, typically high-strength bolts or specialized fasteners, secures the three sections together around the circumference. This hardware must withstand enormous forces: acceleration loads, braking stress, cornering G-forces, and constant vibration from road surfaces.

When someone asks what is stronger billet or forged aluminum, the answer becomes nuanced with three-piece construction. The forged components themselves maintain the same superior grain structure and material density as monoblock wheels. However, the overall assembly's strength now depends on hardware quality, proper torque specifications, and seal integrity between sections.

The Customization Advantage

Imagine needing 24x14 forged wheels with a very specific offset to clear your truck's custom suspension while tucking massive tires under widened fenders. With monoblock construction, a manufacturer would need dedicated tooling for that exact specification. With three-piece construction, they combine existing barrel and center components in new configurations.

This modular approach enables virtually unlimited combinations:

- Width adjustments - Swapping inner or outer barrels of different depths changes overall wheel width without affecting the center design

- Offset fine-tuning - Barrel depth ratios can shift the mounting surface position relative to the wheel's centerline

- Backspacing precision - Critical for forged rims for trucks and aggressive stance builds where millimeters matter for tire clearance

- Lip depth variations - Show car builders can specify deeper outer barrels for that dramatic stepped lip appearance

As noted in Hot Rod's wheel fitment guide, two- and three-piece wheels offer the most flexibility when it comes to fitment, and when you want the widest tires possible, it's all about having fitment options. This flexibility extends beyond initial purchase. Changed vehicles? Modified your suspension geometry? Three-piece construction allows reconfiguration rather than replacement.

The repair and serviceability angle represents another significant advantage. Curbed that outer lip on a parking garage pillar? Replace just the outer barrel while keeping your center and inner barrel. Need to refinish after track day damage? Individual components can be disassembled, repaired or replaced, then reassembled. This rebuildability transforms three-piece wheels from consumable items into long-term investments.

Honest Trade-Offs to Consider

Three-piece construction isn't universally superior. Understanding its limitations helps you determine whether this architecture matches your specific needs:

- Increased weight - Those aerospace-grade bolts and the additional material required for fastening add mass. Expect three-piece wheels to weigh 10-20% more than equivalent monoblock designs

- Seal maintenance requirements - The junction between barrel sections requires silicone or O-ring seals for tubeless tire applications. These seals can degrade over time, potentially causing slow air leaks

- Hardware inspection needs - Fasteners require periodic torque verification, especially after thermal cycling from aggressive driving or brake heat soak

- Higher manufacturing costs - More components, more machining operations, more assembly labor, and premium hardware all contribute to elevated pricing

- Complexity in damage assessment - Impact damage may affect multiple components, complicating repair decisions

Ideal Applications for Three-Piece Construction

Given these characteristics, three-piece forged wheels excel in specific scenarios where their advantages outweigh the trade-offs:

- Show cars requiring precise fitment - When your build demands exact specifications for that perfect flush stance, three-piece construction delivers millimeter-accurate results that standard wheel offerings cannot match

- Collectors wanting rebuildable wheels - Classic car enthusiasts and collectors value the ability to restore rather than replace. Individual component availability means these wheels can be maintained indefinitely

- Enthusiasts who may change vehicle platforms - Planning to transfer your investment to a future build? Three-piece wheels can potentially be reconfigured with different barrel specifications for new applications

- Custom truck and SUV builds - Forged wheels for trucks often require extreme widths and offsets. Three-piece construction makes specifications like 24x14 forged wheels achievable without prohibitive custom tooling costs

- Rotating show and street configurations - Some enthusiasts maintain multiple barrel sets, allowing quick changes between show-ready deep lips and more practical street configurations

The decision between construction types ultimately depends on your priorities. Track-focused drivers typically favor monoblock's weight advantage and structural simplicity. Daily drivers often appreciate two-piece flexibility with reduced maintenance requirements. Show car builders and customization enthusiasts find three-piece construction's unlimited configuration potential worth the added complexity and cost.

Between fully forged multi-piece designs and standard cast alternatives, another category exists: hybrid construction methods that blend forging and casting principles to achieve different performance and cost targets.

Flow Formed and Rotary Forged Alternatives

What if you want better-than-cast performance but fully forged wheels stretch your budget too far? This is where hybrid construction methods enter the conversation. Flow formed wheels, rotary forged wheels, and similar technologies occupy the middle ground between traditional casting and full forging, delivering improved characteristics at more accessible price points.

Here's the critical distinction you need to understand: despite marketing terms like "flow forged wheels" or "rotary forged," these are not true forged wheels. They begin life as cast components. However, the additional processing they undergo genuinely enhances their metallurgical properties beyond what standard casting achieves.

The Flow-Forming Process Demystified

Imagine a pottery wheel, but instead of clay and gentle hands, you have heated aluminum and powerful hydraulic rollers. That mental image captures the essence of flow forming, a relatively new manufacturing technique that emerged more recently compared to traditional cast and forged methods.

The process works like this:

- Step 1: Cast the preform - Manufacturers begin with a low-pressure cast aluminum wheel, typically featuring a thicker-than-normal barrel section

- Step 2: Heat the barrel - The cast wheel mounts onto a specialized spinning machine, and the barrel section is heated to make the aluminum pliable

- Step 3: Apply rolling pressure - Hydraulic rollers press against the rotating barrel, stretching and compressing the material simultaneously

- Step 4: Form the final shape - The rollers progressively thin the barrel while elongating it to achieve the desired width and profile

According to flow forming research, this process stretches the metal's grain structure longitudinally, greatly increasing its strength and fatigue resistance. The rollers' compressive effects cause material grains to align during processing, similar to what happens during true forging.

But here's the metallurgical reality that marketing materials often obscure: only the barrel section undergoes this transformation. The center of the wheel, including the spokes and hub mounting area, remains cast aluminum with its original grain structure intact. You're getting forged-like properties in the barrel where your tire mounts, while the center retains cast characteristics.

This hybrid nature explains why flow form wheels cost significantly less than fully forged alternatives. The expensive forging presses and extensive machining required for monoblock construction are replaced with a more economical spinning operation applied to a cast starting point.

Where Hybrids Fit in the Construction Spectrum

So where do flowform wheels actually belong in the performance hierarchy? Think of them as occupying valuable middle territory. According to industry analysis, flow formed wheels are 15% to 25% lighter than equivalent cast wheels, with increased shock resistance and higher load capacity from the compressed barrel section.

The terminology can get confusing. You'll encounter names like:

- Flow formed - The most accurate technical description

- Rotary forged - A marketing term some manufacturers use to emphasize the spinning and compression process

- Flow forged - Another marketing variation suggesting forged-like properties

- Spun forged - Yet another term describing the same basic process

As noted by wheel manufacturing experts, when you hear names like "rotary forged," it's worth double-checking how the wheel is actually manufactured. It's likely a marketing term that a company has given their flow-formed wheels to indicate increased strength, even though they're not forged at all.

This distinction matters when you're evaluating flow formed vs forged options for your specific application. Both deliver genuine performance benefits, but the underlying construction and resulting characteristics differ significantly.

| Characteristic | Flow Formed / Rotary Forged | Fully Forged (Monoblock) |

|---|---|---|

| Starting Material | Cast aluminum preform | Solid forged aluminum billet |

| Barrel Grain Structure | Compressed and aligned (forged-like) | Fully forged throughout |

| Center Grain Structure | Remains cast (potential porosity) | Fully forged (no porosity) |

| Weight Reduction vs Cast | 15-25% lighter | 25-30% lighter |

| Strength Improvement | Significant in barrel; cast-level in center | Maximum throughout entire wheel |

| Manufacturing Complexity | Moderate (cast + spinning operation) | High (forging press + extensive CNC) |

| Relative Cost | Mid-range (more than cast, less than forged) | Premium pricing |

| Ideal Application | Street performance, occasional track use | Motorsport, maximum performance demands |

For many enthusiasts, rotary forged wheels represent an intelligent compromise. You're gaining measurable improvements in weight, strength, and performance over standard cast wheels without the significant cost increase of full forging. Track day participants who aren't competing professionally, street performance builds, and daily drivers seeking upgraded wheels often find flow forming hits their sweet spot.

However, when maximum strength, minimum weight, and complete structural consistency matter most, fully forged construction remains the definitive choice. Professional racing teams, dedicated track cars, and enthusiasts demanding absolute performance still gravitate toward true forged wheels for good reason.

With all these construction types now defined, how do they actually compare when placed side by side across the factors that matter most to your build?

Comparing Forged Construction Types Side by Side

You've now explored each different type of wheels in the forged category individually. But when you're actually making a purchasing decision, seeing them compared directly reveals which construction method aligns with your specific priorities. This side-by-side analysis cuts through marketing language to deliver the honest comparison you need.

When comparing aluminum vs alloy wheels in general conversations, people often conflate terms. Here's a quick clarification: aluminum wheels and alloy wheels describe the same thing, as wheel alloys are aluminum-based. The real performance distinction lies not in aluminum vs alloy rims terminology, but in how that aluminum alloy is manufactured and assembled. That's where construction type becomes the determining factor.

Performance Characteristics by Construction Type

How do the different wheel types actually perform when pushed to their limits? Understanding structural integrity, weight efficiency, and impact resistance across monoblock, two-piece, and three-piece designs helps you match construction to application.

Structural Integrity

Monoblock construction delivers the highest structural integrity because stress transfers seamlessly through one continuous piece of forged material. According to Performance Plus Tire, single-piece construction creates exceptional structural integrity that handles extreme stress and demanding load requirements. No joints, fasteners, or seams exist to become potential failure points.

Two-piece forged wheels maintain approximately 2.5 times the strength of cast alternatives. Welded two-piece designs approach monoblock integrity since the weld creates molecular bonding between components. Bolted versions introduce hardware that requires proper torque maintenance but still significantly outperform cast construction.

Three-piece wheels, while still far stronger than cast options, introduce the most potential stress points through their hardware-dependent assembly. The 30-35 fasteners connecting the components must maintain proper torque specifications to preserve structural integrity under dynamic loads.

Weight Efficiency

Weight reduction directly impacts acceleration, braking response, and handling precision. Each construction type achieves different weight targets:

- Monoblock - Achieves the lightest possible weight since no fastener hardware adds mass. Manufacturers can remove material anywhere without compromising component connections

- Two-piece - Typically weighs 1-2 pounds more per wheel than equivalent monoblock designs due to joining hardware and material requirements at connection points

- Three-piece - Carries the most weight penalty, typically 10-20% heavier than monoblock equivalents due to extensive hardware and thicker material at fastening locations

All types of wheel construction in the forged category still deliver substantial weight savings over cast alternatives. According to industry data, forged wheels are approximately 25-30% lighter than cast wheels of the same size regardless of construction method.

Impact Resistance

How wheels respond to pothole strikes, curb impacts, and road debris differs by construction type. Monoblock wheels distribute impact forces throughout the unified structure, making them highly resistant to localized damage. However, severe impacts that do cause damage often affect the entire wheel.

Multi-piece designs can actually offer advantages in impact scenarios. As noted by Vivid Racing, damage to individual components can potentially be addressed without replacing the entire wheel. A curb strike that damages an outer barrel leaves the center section and inner barrel intact and reusable.

Cost-to-Benefit Analysis for Each Category

Understanding what you're actually paying for helps justify the investment in any forged wheel construction type. Let's examine where your money goes and what returns you can expect.

Monoblock Value Proposition

Entry-level monoblock forged wheels typically start around $2,095 per set, with individual wheel prices scaling by size: 17-inch at base pricing, increasing through 18-inch ($2,150), 19-inch ($2,250), 20-inch ($2,295), and beyond. Premium brands command significantly higher prices, with HRE Performance Wheels sets ranging from $6,000-$15,000.

What justifies this investment? You're paying for:

- Maximum strength-to-weight ratio available in wheel construction

- Zero maintenance requirements beyond normal tire service

- Longest potential service life due to unified structure

- Best thermal stability under demanding brake heat conditions

Two-Piece Value Proposition

Two-piece construction enters the market around $1,100 per wheel, occupying middle ground between monoblock and three-piece pricing. The modular design means you're investing in both performance and practical serviceability.

The long-term cost advantage becomes apparent when damage occurs. Replacing a damaged rim section typically costs $400-$800 compared to $2,000+ for complete monoblock wheel replacement. For vehicles in urban environments with higher curb damage risk, this serviceability advantage can offset the initial investment over several years of ownership.

Three-Piece Value Proposition

Three-piece forged wheels command premium pricing starting around $1,680 per wheel, with costs escalating rapidly based on size, finish complexity, and brand prestige. Complete sets from premium manufacturers like HRE can range from $8,000-$20,000.

You're paying for maximum flexibility:

- Virtually unlimited width, offset, and backspacing combinations

- Component-level replacement capability

- Potential reconfiguration for different vehicles or specifications

- Individual refinishing without replacing entire wheels

Complete Comparison: All Construction Types

This comprehensive table consolidates the key factors across all forged wheel construction types, giving you a single reference for decision-making:

| Factor | Monoblock (One-Piece) | Two-Piece Forged | Three-Piece Forged |

|---|---|---|---|

| Typical Weight Range | Lightest; 25-30% less than equivalent cast | 1-2 lbs more than monoblock per wheel | 10-20% heavier than monoblock |

| Structural Strength | Maximum; approximately 3x stronger than cast | Approximately 2.5x stronger than cast | Approximately 2x stronger than cast |

| Customization Flexibility | Limited to available tooling; fewer offset options | Moderate; varied offsets through barrel selection | Maximum; virtually unlimited combinations |

| Repairability | Difficult; damage often requires full replacement | Moderate; barrel replacement possible on bolted designs | Excellent; individual components replaceable |

| Maintenance Requirements | Minimal; no hardware to inspect | Low to moderate; bolted versions need torque checks | Higher; periodic hardware inspection and seal verification |

| Relative Cost Tier | $2,095+ per set entry; $6,000-$15,000 premium | $1,100+ per wheel; $2,800-$6,500 premium sets | $1,680+ per wheel; $8,000-$20,000 premium sets |

| Ideal Use Cases | Track cars, motorsport, maximum performance street | Street performance, daily drivers, balanced builds | Show cars, collectors, extreme fitment requirements |

| Finish Options | Single finish per wheel standard | Two-tone possible (center vs barrel) | Three-zone finishing; hardware accent options |

| Long-Term Value | Highest durability; lowest ongoing costs | Balanced; component replacement reduces total cost of ownership | Rebuildable; potential reconfiguration for future vehicles |

Each forged wheel construction type excels in specific scenarios. There is no universally "best" option—only the right match for your priorities, application, and budget.

This neutral analysis reveals why monoblock dominates motorsport applications while three-piece construction appeals to show car builders and stance enthusiasts. Two-piece designs capture the practical middle ground that suits the largest number of performance-oriented daily drivers.

With these different type of wheels now clearly compared, the next step is matching the right construction type to your specific vehicle application and driving requirements.

Matching Construction Types to Your Application

You've seen the specifications and comparisons. Now comes the practical question: which forged wheel construction type actually belongs on your vehicle? The answer depends entirely on how you'll use your car, truck, or performance build. Choosing the wrong construction type doesn't just waste money—it can compromise safety, degrade handling, or leave you with wheels that don't survive their intended application.

When enthusiasts ask what is better alloy or forged wheels, they're often missing the deeper question. All forged wheels outperform cast alternatives in strength-to-weight ratio. But within the forged category, matching construction type to application determines whether you're maximizing that advantage or paying premium prices for characteristics you'll never use.

Let's break down the decision by examining how each construction type performs in real-world scenarios you might actually encounter.

Track and Competition Applications

When milliseconds matter and failure isn't an option, why does monoblock construction dominate professional motorsport? The answer comes down to two non-negotiable factors: weight and predictability.

Are forged wheels lighter than cast wheels? Absolutely—by 25-30% in most comparisons. But monoblock forged wheels are also the lightest within the forged category itself, since no fastener hardware adds mass. According to Performance Plus Tire research, forged wheels can deliver 0.3-0.4 seconds faster lap times even on small courses due to reduced rotating mass improving acceleration, braking, and handling response.

Structural predictability matters equally for competition use. Monoblock wheels behave consistently under repeated stress cycles because there are no assembled components that could shift, loosen, or develop micro-movements. When you're pushing a vehicle to its absolute limits corner after corner, you need wheels that respond identically on lap 50 as they did on lap 1.

Decision criteria for track and competition:

- Weight sensitivity - If you're chasing lap times, every gram of unsprung weight reduction translates to measurable performance gains

- Thermal cycling tolerance - Repeated heat soak from aggressive braking demands unified construction that won't develop hardware loosening issues

- Structural consistency - No joints or fasteners means no variables that could affect handling balance mid-session

- Replacement philosophy - Serious competitors often replace rather than repair wheels after significant impacts; monoblock's lower repairability becomes irrelevant

- Budget priority - Track-focused builds typically allocate more budget to performance components; monoblock's premium pricing aligns with this priority structure

For dedicated track cars, time attack builds, and professional racing applications, monoblock construction remains the clear choice. The characteristics that make it less practical for street use—limited offset options, difficult repair, premium pricing—simply don't matter when outright performance is the only metric.

Daily Driving and Street Performance Considerations

Your daily driver faces challenges that track cars never encounter. Potholes. Parking garage curbs. Months between tire rotations. Construction zones. The occasional valet who treats your wheels like rental equipment. These realities shift the construction type calculation significantly.

Are cast aluminum wheels strong enough for daily driving? For purely stock vehicles driven conservatively, standard cast wheels perform adequately. But when you're asking whether cast aluminium wheels match forged durability for performance-oriented street use, the answer becomes more nuanced.

Two-piece forged construction often provides the optimal balance for street performance applications. You're getting forged material strength—approximately 2.5 times stronger than cast alternatives—combined with practical serviceability advantages that matter over years of ownership.

Decision criteria for daily driving and street performance:

- Pothole resistance - Forged construction handles impacts that would crack cast wheels, but multi-piece designs allow damaged components to be replaced rather than discarding entire wheels

- Curb damage probability - Urban driving increases cosmetic damage risk; bolted two-piece construction enables barrel replacement at a fraction of complete wheel cost

- Maintenance commitment - Consider your realistic maintenance habits; bolted multi-piece wheels require periodic hardware inspection that monoblock designs don't need

- Long-term ownership - If you keep vehicles for many years, two-piece serviceability can reduce total cost of ownership despite higher initial investment

- Performance-to-practicality ratio - You want meaningful weight savings and strength improvements without the maintenance demands of three-piece construction

The question of are forged wheels lighter deserves context here. Yes, forged wheels save substantial weight compared to cast alternatives. But for street use, the 1-2 pound per wheel difference between monoblock and two-piece construction rarely creates perceptible performance differences. The serviceability advantage of two-piece designs typically outweighs that minimal weight penalty for street-driven vehicles.

Show Cars and Custom Builds

When you're building a show car or pursuing an aggressive stance setup, the priorities flip completely. Fitment precision becomes paramount. Visual impact matters. The ability to achieve exact specifications that no off-the-shelf wheel provides drives the entire wheel selection process.

This is where three-piece forged construction earns its premium pricing. As noted in industry analysis, forged wheels offer a wide range of customization options that elevate a vehicle's appearance—and three-piece construction maximizes this advantage through its modular design philosophy.

Decision criteria for show cars and custom builds:

- Fitment requirements - If your build demands specific width, offset, and backspacing combinations that standard wheels don't offer, three-piece construction provides virtually unlimited specifications

- Visual customization - Separate finishing options for centers, inner barrels, and outer barrels create visual possibilities unavailable with other construction types

- Rebuildability value - Show cars often undergo multiple refinishing cycles; individual component replacement and refinishing reduces long-term costs

- Future flexibility - Planning to transfer wheels to a future build? Three-piece designs can potentially be reconfigured with different barrel specifications

- Hardware aesthetic - The visible bolts around three-piece wheels become a design element; some builders specifically want this mechanical appearance

The trade-offs of three-piece construction—increased weight, maintenance requirements, and higher cost—become acceptable when the primary goal is achieving impossible-to-find specifications and maintaining long-term serviceability.

Consequences of Mismatched Construction Types

What actually happens when you choose the wrong construction type for your application? Understanding these consequences helps reinforce why matching matters.

Monoblock on a daily driver in poor road conditions: You get maximum strength but zero serviceability. That curb strike that would cost $400-$800 to repair on a two-piece wheel now costs $2,000+ for complete replacement. The wheel performs beautifully, but ownership costs compound every time urban driving claims another victim.

Three-piece on a serious track car: You're carrying extra weight from hardware that provides customization flexibility you'll never use. More critically, the multiple fasteners require torque verification that track day heat cycling makes essential—adding maintenance burden that monoblock construction eliminates entirely.

Two-piece on a show car requiring extreme specifications: The offset and width combinations available in two-piece catalogs may not achieve your exact fitment goals. You compromise the stance you envisioned because you chose a construction type that doesn't support your actual requirements.

Forged wheels of any type for purely stock commuter vehicles: You're paying premium prices for performance advantages you'll never utilize. Standard cast wheel technology, while inferior in absolute terms, often provides adequate service for vehicles that never exceed highway speeds or encounter significant stress loads.

The lightest wheels for car performance applications aren't always the right wheels for every car. Match construction type to actual use, not aspirational use.

Whether you're chasing lap times, building a show-stopping stance machine, or simply want improved performance from your daily driver, construction type selection determines whether your forged wheel investment delivers on its potential. The manufacturing process that creates these wheels is equally important to understand—it reveals why forged construction commands premium pricing and how quality varies between manufacturers.

Inside the Forged Wheel Manufacturing Process

Ever wondered how are forged wheels made? The journey from raw aluminum billet to finished performance wheel involves specialized machinery, precise temperature control, and quality verification that justifies premium pricing. Understanding this manufacturing process reveals why forged construction delivers superior performance—and helps you evaluate manufacturer quality claims.

Unlike wheel casting or casting wheels methods where molten aluminum simply fills a mold, aluminum wheel forging subjects solid metal to extreme forces that fundamentally transform its internal structure. This metal forming approach creates the density and grain alignment that separate forged wheels from every other manufacturing method.

From Aluminum Billet to Precision Component

The manufacturing journey begins with cylindrical aluminum billets, typically weighing 40-80 pounds depending on final wheel specifications. These solid blocks of 6061 aluminum alloy serve as the raw material for forging rims that will eventually support your vehicle.

Pre-Heating Stage

Before any pressing occurs, billets must reach precise temperatures that make the aluminum pliable without melting it. According to forging process specifications, material is heated to temperatures typically ranging from 400°C to 480°C (750°F to 900°F) for optimal metal flow characteristics.

Temperature uniformity matters critically during this stage. Uneven heating creates temperature gradients within the billet that cause material inconsistency and potential defects in the finished wheel. Quality manufacturers use calibrated temperature sensors or infrared thermometers to verify uniform heating throughout the billet before proceeding.

The forging dies themselves require preheating to prevent thermal shock when the heated billet contacts them. This die preparation ensures smooth material flow during the pressing operation and prevents premature cooling that could compromise the forging quality.

The Pressing Operation

Here's where forging rims diverges dramatically from standard casting. According to Rusch Wheels manufacturing data, wheel forgings are produced using presses delivering extreme pressure of 12,000 tons—while MP Wheels utilizes a 10,000-ton press for their forged magnesium wheels. These enormous forces compress the aluminum billet into a dense, refined structure impossible to achieve through any other metal forming method.

What happens during pressing?

- Die alignment verification - Precision alignment prevents dimensional inaccuracies or uneven surface finish that would compromise the finished wheel

- Pressure monitoring - Press load is continuously monitored to ensure it stays within specified ranges; over or under-pressurizing causes part deformation or incomplete die filling

- Material flow inspection - Visual or machine-assisted checks confirm proper material flow into all die cavity areas, identifying potential issues like incomplete fills or cold shuts

- Initial geometry verification - After pressing, the wheel blank undergoes visual inspection for correct shape including rim profile, hub dimensions, and overall symmetry

This pressing operation eliminates the voids and weak spots that appear in cast wheels. The result is what are wheels made of when performance matters most: dense, homogeneous aluminum with aligned grain structure throughout.

Flash Removal and Trimming

Forging produces excess material called "flash" around the wheel blank's edges. According to quality control specifications, flash removal must be clean without leaving irregularities or damage to the part. Precision trimming tools remove this excess material while maintaining dimensional accuracy at critical surfaces.

After trimming, dimensional inspection verifies that hub, bore, and rim measurements fall within specified tolerances. Surface finish inspection identifies any imperfections like burrs or rough edges that could interfere with wheel performance or tire mounting.

Heat Treatment and Machining Stages

The pressed wheel blank now enters heat treatment—the process that transforms good aluminum into exceptional wheel material through the T6 tempering designation you've seen on quality forged wheels.

T6 Heat Treatment Process

According to industry manufacturing specifications, after pressing, forgings pass through T6 heat treatment to create a high integrity, multi-directional grain structure. This treatment involves two distinct phases:

Solution heat treatment heats the aluminum to elevated temperatures, allowing magnesium and silicon within the alloy to dissolve into a supersaturated solid solution. The wheel is then rapidly quenched—cooled quickly to lock these elements in their dissolved state.

Controlled aging follows, where the wheel is held at specific elevated temperatures for precise time periods. This causes the dissolved alloying elements to precipitate in ways that dramatically increase yield strength, hardness, and toughness without adding unnecessary weight.

According to heat treatment quality protocols, thermocouples monitor temperature accuracy throughout this process. Hardness testing using Rockwell or Vickers methods verifies that final wheel hardness meets specifications. Microstructure inspection through metallographic analysis confirms uniformity and absence of defects like cracks or unwanted material phases.

CNC Precision Machining

The heat-treated forging now resembles a rough wheel shape, but final dimensions and design details require precision machining. According to Rusch Wheels, their factory operates 11 CNC machines specifically for forged wheel production—lathes achieving high concentricity for cylindrical surfaces, and milling machines with high rigidity and spindle speed providing smoother finished surfaces.

The machining process unfolds in stages:

- Face design machining - CNC mills sculpt the spoke patterns, creating the visual design that distinguishes each wheel model

- Back pad milling - After rotating the wheel 180 degrees, lightening pockets are milled into the rear, removing weight wherever possible

- Hub and bore precision - Critical mounting surfaces are machined to exact specifications for proper vehicle fitment

- Rim profile finishing - Tire bead mounting surfaces receive final machining for proper tire seating

According to manufacturing quality standards, the use of high-quality CNC machines achieves highest tolerances while minimizing surface defects on the forgings. Each wheel's CAD model is programmed using computer manufacturing software (CAM) to develop G-Code that guides precise tool paths.

Hand Finishing and Coating

Precision machining leaves edges that require human attention. According to industry practices, each milled section goes through multiple stages of deburring, hand filing, buffing, and polishing before coating preparation. Craftsmen sculpt each profile to perfection—every edge receives careful attention before final finishing.

The coating process follows a multi-stage protocol. Quality manufacturers utilize combination liquid paint and powder coating processes: powder coating followed by baking, then paint coating and baking, then powder clear coating and final baking—three complete coating and baking cycles for maximum durability and appearance.

Quality Control: Why It Justifies Premium Pricing

Every step described above includes verification procedures that separate quality forged wheels from inferior products. Understanding these quality control measures helps you evaluate manufacturer credibility.

Non-Destructive Testing (NDT)

According to inspection protocols, non-destructive testing detects internal defects that could affect wheel performance:

- Ultrasonic Testing (UT) - Uses ultrasonic waves to detect internal cracks or porosity invisible to visual inspection

- Magnetic Particle Testing (MPT) - Identifies surface and near-surface cracks affecting structural integrity

- Dye Penetrant Testing (PT) - Highlights visible surface cracks or flaws through dye penetration

- X-ray or Radiographic Inspection - For maximum sensitivity, X-ray testing detects hidden internal defects

Dimensional Verification

Final wheels undergo comprehensive measurement using Coordinate Measuring Machines (CMMs), precision calipers, and micrometers. According to Rusch Wheels quality specifications, runout—the measurement of a rotating wheel's roundness—is the most critical measurement. Wheels are checked against international quality standards SAE-J and JWL to confirm all dimensions fall within tolerance.

Performance Testing

According to engineering validation protocols, every wheel design undergoes physical testing in compliance with SAE, JWL, VIA, and TUV standards. Finite Element Analysis (FEA) software simulates cornering, radial, and impact testing specific to each vehicle application before production begins.

This rigorous quality control framework explains why reputable forged wheel manufacturers invest significantly in testing infrastructure. Companies maintaining certifications like IATF 16949—the quality management standard for automotive production—demonstrate commitment to these verification standards. For example, precision hot forging specialists like Shaoyi (Ningbo) Metal Technology apply similar IATF 16949-certified quality control protocols to automotive suspension arms and drive shafts, demonstrating how the same metallurgical principles and verification standards govern high-performance forged components across the automotive industry.

The manufacturing process that creates forged wheels involves temperatures exceeding 1000°C, pressures reaching 12,000 tons, and quality verification protocols matching aerospace standards. This explains both the premium pricing and superior performance characteristics.

Understanding how forged wheels are manufactured provides context for evaluating manufacturers and making informed purchasing decisions. The final section addresses how to identify quality indicators and select the right construction type for your specific build requirements.

Selecting the Right Forged Wheel Construction

You've explored the science behind forging, examined each construction type's characteristics, and matched applications to specific designs. Now comes the practical step: actually purchasing forged wheels without falling prey to marketing exaggerations or quality compromises. Whether you're hunting for the best forged wheels for track duty or seeking affordable forged wheels that deliver genuine value, this buying guidance helps you navigate the market confidently.

When comparing forged wheels vs alloy wheels in general discussions, remember that all forged wheels are aluminum alloy wheels—the distinction lies in manufacturing method, not base material. This clarifies a common point of confusion: are forged wheels aluminium? Yes, absolutely. The performance advantage comes from how that aluminum alloy is processed, not from exotic materials.

The question of alloy vs forged wheels ultimately concerns whether the aluminum was cast (poured molten into molds) or forged (compressed from solid billets under extreme pressure). Both use aluminum alloys; forging simply creates superior material properties through mechanical processing rather than relying on the natural cooling characteristics of casting.

Evaluating Quality Indicators

How do you separate legitimate forged wheels brands from companies making exaggerated claims? Certifications, testing standards, and material documentation provide objective quality verification that cuts through marketing language.

Essential Certifications to Verify

According to industry certification standards, reputable forged wheel manufacturers should maintain several key certifications:

- ISO 9001 - The global standard for quality management systems, ensuring consistent quality control processes from design through inspection

- JWL and JWL-T - Japanese standards for alloy wheels confirming safety and quality requirements; widely accepted worldwide despite their Japanese origin

- VIA Certification - Independent third-party testing from Japan's Vehicle Inspection Association, providing additional verification beyond manufacturer claims

- TÜV Certification - Highly regarded in European markets, signifying rigorous quality and safety testing compliance

- IATF 16949 - The automotive industry's quality management standard covering entire production processes with focus on continuous improvement and defect prevention

IATF 16949 certification deserves particular attention. This standard, maintained by automotive forging specialists like Shaoyi (Ningbo) Metal Technology, indicates that a manufacturer operates under quality systems specifically designed for automotive-grade components. When a forging company maintains this certification for products like suspension arms and drive shafts, they're demonstrating the same metallurgical expertise and quality verification protocols that premium wheel manufacturing demands.

Testing Standards and Documentation

Beyond certifications, request evidence of actual testing performed on wheel designs. According to wheel buying guidance, authentic forged wheels should come with forging certificates showing press tonnage and heat treatment logs. Manufacturers who cannot provide metallurgical test reports or X-ray inspection results may not be delivering genuine forged construction.

Key testing documentation includes:

- Impact testing results - Verifies wheel performance under simulated pothole or curb strike conditions

- Fatigue testing data - Confirms long-term durability under repeated stress cycles

- Radial load testing - Ensures wheels handle specified weight loads without deformation

- Cornering fatigue verification - Tests structural integrity under lateral forces experienced during aggressive driving

According to quality assessment protocols, by performing these tests, manufacturers can guarantee the structural integrity and safety of their wheels, providing customers with confidence that they are investing in reliable products.

Supply Chain Considerations

For custom wheel projects or bulk procurement, manufacturer location affects lead times and logistics costs. Established forging partners near major shipping hubs like Ningbo Port can streamline procurement significantly. Companies like Shaoyi Metal Technology, located near this strategic port, demonstrate how geographic positioning combined with certified manufacturing capabilities enables efficient global delivery of precision-forged automotive components.

Making Your Construction Type Decision

With quality indicators understood, the final step involves systematically matching construction type to your specific requirements. This decision framework prevents costly mismatches between wheel characteristics and actual use cases.

- Define your primary application - Be honest about how you'll actually use the vehicle, not how you aspire to use it. Track-focused builds prioritize different characteristics than daily drivers. Show cars have unique requirements compared to weekend performance vehicles. Your application determines which construction type trade-offs matter most.

- Establish budget parameters - According to market pricing analysis, expect realistic price tiers for authentic forged wheels: entry-level monoblock sets start around $2,095, mid-tier two-piece wheels begin at approximately $1,100 per wheel, and premium three-piece construction commands $1,680+ per wheel. Factor in long-term costs including potential repairs, maintenance, and component replacement.

- Determine fitment requirements - Standard offset and width combinations work with monoblock or two-piece construction. Extreme specifications requiring precise millimeter-level customization typically require three-piece construction. According to fitment guidance, always verify fitment using a digital configurator before purchasing, and confirm minimum caliper clearance using manufacturer templates.

- Evaluate maintenance commitment - Monoblock wheels require minimal ongoing attention beyond normal tire service. Two-piece bolted designs need periodic torque verification. Three-piece construction demands regular hardware inspection and potential seal maintenance. Match construction type to your realistic maintenance habits.

- Verify manufacturer credentials - Request certification documentation, testing results, and material specifications before purchasing. Manufacturers unable or unwilling to provide this documentation may not deliver advertised quality levels. Look for ISO 9001, JWL, VIA, and ideally IATF 16949 certifications as quality indicators.

Common Buyer Misconceptions Addressed

Marketing language and competitor claims perpetuate several misconceptions that lead to poor purchasing decisions. Understanding these helps you evaluate wheels objectively.

"Rotary forged" and "flow forged" are true forged wheels

As established earlier, these terms describe hybrid manufacturing where cast wheel centers receive barrel processing that improves properties. They're not fully forged construction. The barrel section achieves forged-like characteristics, but the center remains cast aluminum. They offer legitimate performance improvements over standard casting at lower cost than true forging—but they're not equivalent to fully forged wheels.

"Cheap forged wheels" deliver the same performance as premium options

Price differences in forged wheels reflect real quality variations. According to buyer research, budget buyers frequently regret skipping professional installation and overlooking quality verification. Suspiciously low pricing often indicates corners cut in material quality, heat treatment, or testing verification. Affordable forged wheels exist, but the cheapest options rarely deliver genuine forged performance.

"All forged wheels are interchangeable regardless of brand"

Different forged wheels brands maintain different quality standards, testing protocols, and material specifications. According to verification guidance, request the manufacturer's forging certificate showing press tonnage and heat treatment logs. Authentic forged wheels have seamless grain flow visible under magnification and lack casting seams. Avoid sellers who cannot provide metallurgical test reports.

"Construction type doesn't matter if the wheel is forged"

This article has demonstrated extensively that construction type determines customization flexibility, serviceability, maintenance requirements, and weight characteristics. Monoblock, two-piece, and three-piece construction serve different applications optimally. Choosing based solely on "forged" designation without considering construction type leads to mismatched expectations.

"Forged wheels are only for race cars"

According to application analysis, forged wheels deliver measurable benefits for daily drivers too: improved fuel efficiency (approximately 0.5-1 MPG improvement in non-EVs), enhanced handling response, and superior durability against road hazards. They're justified for vehicles producing over 300 horsepower or those carrying significant payloads where rotational mass reduction directly enhances efficiency and control.

The best forged wheels for your build are the ones that match your actual application, budget, and maintenance commitment—not necessarily the most expensive or lightest option available.

Armed with this comprehensive understanding of forged wheel construction types, quality indicators, and practical selection criteria, you're equipped to make informed decisions that deliver lasting value. Whether you're building a dedicated track weapon, a head-turning show car, or a daily driver that performs above its class, matching the right forged construction type to your specific requirements ensures your investment pays dividends every time you drive.

Frequently Asked Questions About Forged Wheel Construction Types

1. What is the best type of wheel construction?

Monoblock forged wheels are considered the pinnacle for performance applications due to their superior strength-to-weight ratio and structural integrity. They're approximately 25-30% lighter than cast wheels and up to 3 times stronger. However, the 'best' construction depends on your application—monoblock excels for track use, two-piece offers balanced performance with serviceability for daily drivers, and three-piece provides maximum customization for show cars and unique fitment requirements.

2. Are OEM wheels cast or forged?

Most factory OEM wheels are cast aluminum. Forged wheels typically appear only on high-performance variants or luxury vehicles where manufacturers justify the premium cost. For example, BMW's full M models often feature forged wheels, while standard variants use cast construction. You can verify your specific wheel's construction through manufacturer specifications or material documentation.

3. What is the difference between forged and flow formed wheels?

Fully forged wheels are machined entirely from solid aluminum billets compressed under 8,000-12,000 tons of pressure, creating superior grain structure throughout. Flow formed wheels start as cast aluminum, then only the barrel section is heated and stretched under rollers, achieving forged-like properties in that area while the center remains cast. Flow formed wheels cost less and offer 15-25% weight savings over cast, but fully forged wheels deliver 25-30% weight reduction with complete structural consistency.

4. Are forged wheels worth the extra cost?

Forged wheels justify their premium pricing for vehicles producing over 300 horsepower, track-focused builds, or applications demanding maximum performance. They deliver measurable benefits including 0.3-0.4 seconds faster lap times from reduced unsprung weight, improved fuel efficiency of 0.5-1 MPG, enhanced brake response, and significantly greater durability against road hazards. For purely stock commuter vehicles driven conservatively, standard cast wheels may provide adequate service at lower cost.

5. Can damaged forged wheels be repaired?

Repairability depends on construction type. Monoblock forged wheels are difficult to repair—significant damage often requires complete replacement. Two-piece bolted designs allow barrel replacement at $400-$800 versus $2,000+ for full wheel replacement. Three-piece construction offers the best repairability, with individual center, inner barrel, or outer barrel components replaceable independently. This makes three-piece wheels ideal for enthusiasts who value long-term rebuildability.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —