Custom Forged Wheel Backspacing Guide: Avoid Costly Fitment Mistakes

Understanding Backspacing for Custom Forged Wheel Orders

Ever wondered why some aftermarket wheels fit perfectly while others rub against suspension components or stick out awkwardly from the fender? The answer often comes down to one critical measurement: wheel backspacing. When you're investing in custom forged wheels, understanding this specification isn't just helpful - it's essential for protecting your investment.

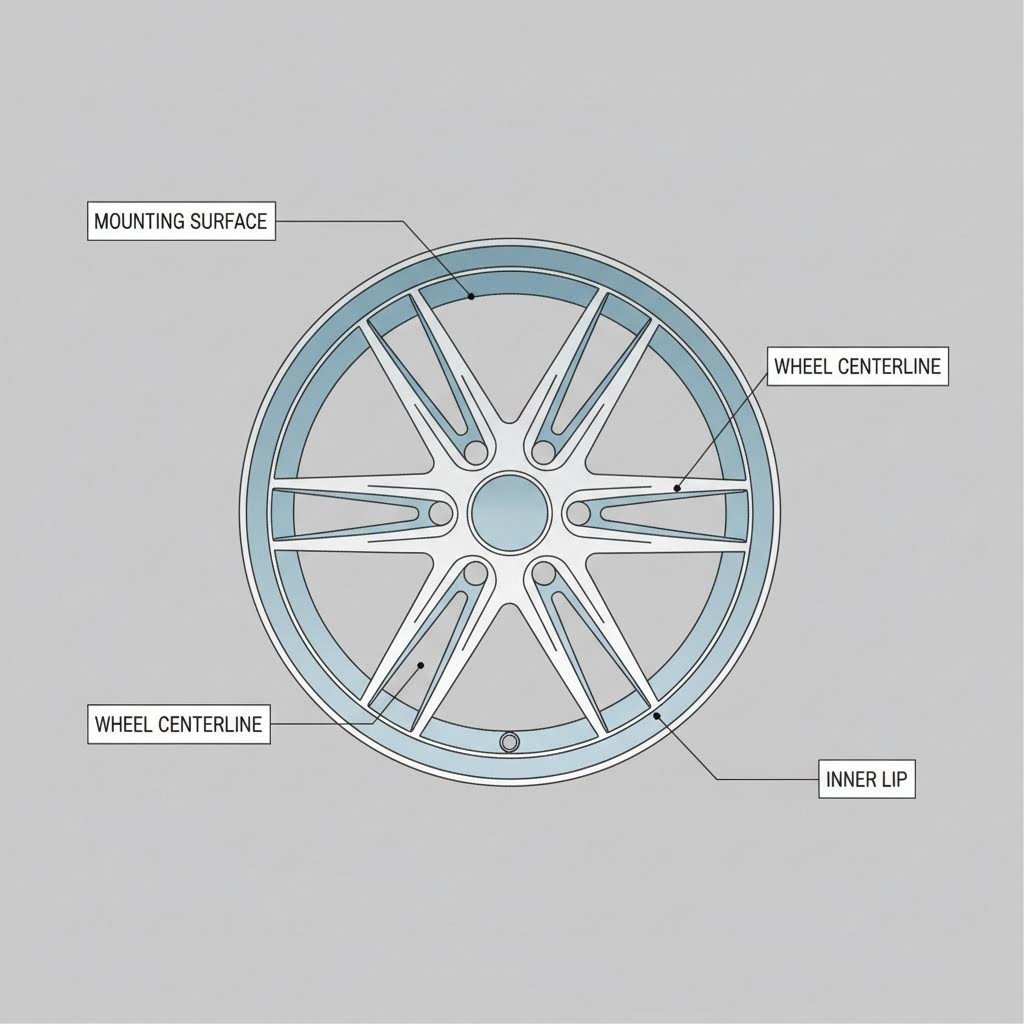

So, what is wheel backspacing exactly? It refers to the distance from the wheel's mounting surface (where it bolts to your hub) to the inner lip of the wheel, measured in inches. This measurement works hand-in-hand with wheel offset and width to determine exactly how your wheels will sit within the wheel wells. While offset measures from the mounting surface to the wheel's centerline in millimeters, backspacing gives you the complete picture of inward clearance.

Why Backspacing Matters More for Forged Wheels

You might be asking, "What is the offset of a wheel, and why should I care about backspacing when ordering forged wheels specifically?" Here's the thing - forged wheels represent a significant step up from cast or flow-formed alternatives. The manufacturing process creates a denser, stronger wheel that commands a premium price. Unlike off-the-shelf cast wheels where you simply pick from available sizes, custom forged wheels are built to your exact specifications.

This customization capability is both a blessing and a responsibility. Forged wheel manufacturers can dial in precise backspacing measurements that might not be available in mass-produced wheels. However, once your custom forged wheels enter production, there's no returning them if you provided incorrect specifications. The interconnected relationship between wheel width, offset, and backspacing means getting even one measurement wrong can throw off the entire fitment equation.

The Cost of Getting It Wrong

Consider what's at stake when ordering custom forged wheels. A quality set can easily run several thousand dollars - sometimes exceeding the cost of the vehicle's original wheels by five to ten times. When you factor in custom finishes, specific designs, and precision engineering, the investment grows even larger.

Incorrect backspacing on custom forged wheels doesn't just mean poor aesthetics - it can result in tire rubbing, accelerated wear, compromised handling, and in worst-case scenarios, damage to brake components and suspension parts that turns a wheel fitment mistake into a safety concern.

Understanding what is tire offset and how it relates to backspacing becomes crucial when you realize that these measurements directly affect whether your wheels clear everything they need to clear. Too little backspacing pushes the wheel outward, potentially causing fender contact. Too much backspacing tucks the wheel inward, risking interference with suspension arms, brake calipers, and inner fender wells.

Throughout this custom forged wheel backspacing guide, you'll learn exactly how to measure your current wheels, calculate the specifications you need, and communicate effectively with manufacturers. Whether you're upgrading a daily driver, building a show car, or outfitting a performance vehicle, mastering these measurements ensures your premium forged wheels deliver the perfect fitment you're paying for.

Backspacing vs Offset Explained Simply

Now that you understand why these measurements matter for your custom forged wheel investment, let's break down exactly what is backspacing on a wheel versus offset. While both measurements describe wheel positioning, they approach the concept from different reference points - and understanding this distinction is crucial when communicating specifications to manufacturers.

Backspacing Measured in Inches

Imagine laying your wheel face-down on a flat surface. Backspacing is the distance from the mounting surface (the flat area where your wheel bolts to the hub) to the very back edge of the wheel - its inner lip. This measurement is expressed in inches and tells you exactly how far the wheel extends inward toward your vehicle's suspension and brake components.

Here's a practical way to visualize it: if you have a wheel with 4 inches of backspacing, the mounting surface sits 4 inches away from the innermost edge of the wheel. A wheel with 6 inches of backspacing has its mounting surface positioned 6 inches from that inner lip, meaning more of the wheel sits behind the mounting point and closer to your suspension components.

To measure backspacing yourself, place the wheel face-down on a protected surface. Lay a straight edge across the back of the wheel so it touches both outer edges. Then measure from the mounting surface up to the bottom of that straight edge. That distance is your backspacing measurement - simple and straightforward.

Offset Measured in Millimeters

When comparing wheel offset vs backspacing, think of offset as the measurement from the mounting surface to an imaginary line running through the exact center of the wheel's width. Unlike backspacing, offset is expressed in millimeters and can be positive, negative, or zero depending on where that mounting surface falls relative to the centerline.

With offset wheels explained in simpler terms, imagine slicing your wheel perfectly in half down its width. That center point is your reference. The offset number tells you how far the mounting surface deviates from that centerline - and in which direction.

- Positive Offset: The mounting surface sits closer to the wheel's face (street side), pushing the wheel inward under the fender. Most modern passenger vehicles and front-wheel-drive cars use positive offset wheels for proper clearance and handling characteristics.

- Zero Offset: The mounting surface aligns exactly with the wheel's centerline. This neutral position was common on older vehicles and some rear-wheel-drive applications.

- Negative Offset: The mounting surface sits closer to the wheel's back (brake side), pushing the wheel outward toward or past the fender. Trucks, off-road vehicles, and aggressive stance builds often use negative offset for that "poked" look.

When you see wheel offsets explained with notation like "+45mm" or "-25mm," the sign indicates direction. A +45mm offset means the mounting surface is 45 millimeters toward the street side of center, while -25mm means it's 25 millimeters toward the brake side of center.

How Forged Construction Affects Your Options

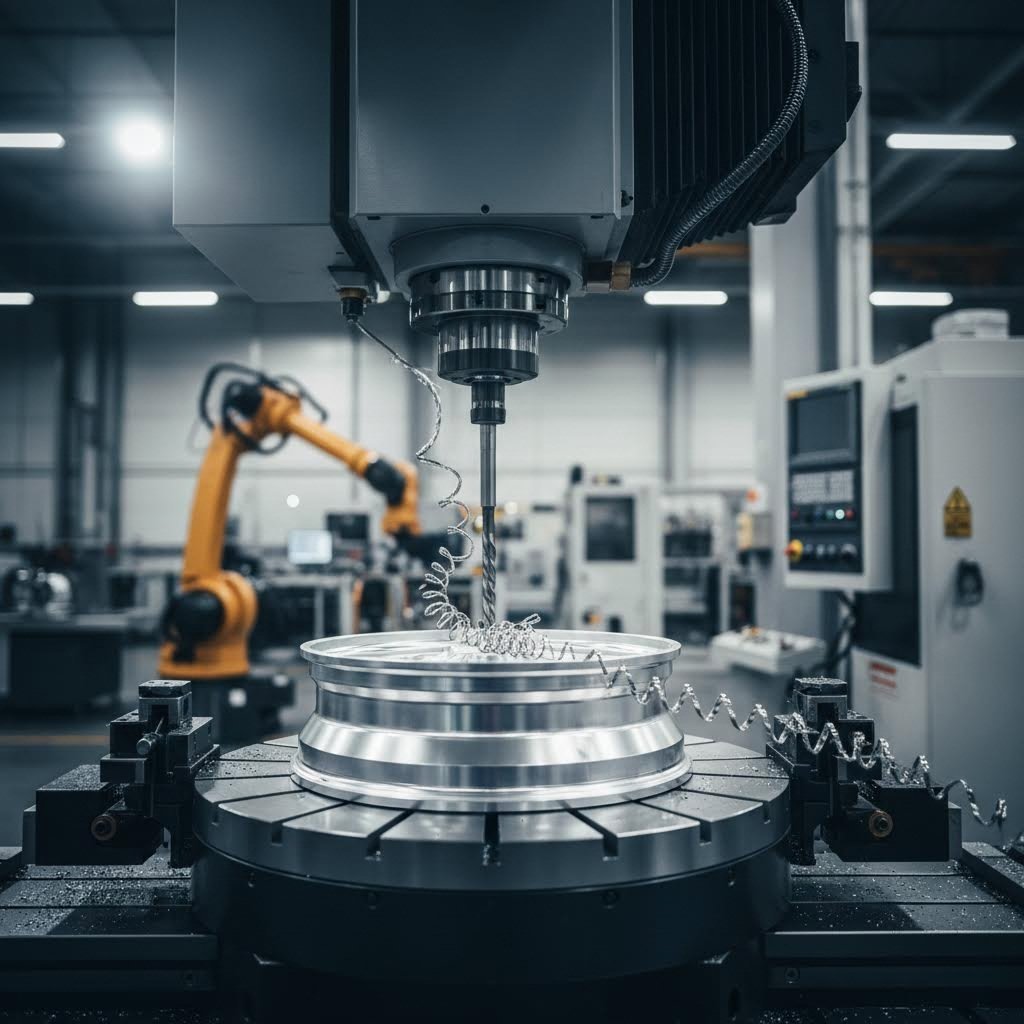

Here's where understanding backspace vs offset becomes especially valuable for custom forged wheel buyers. Unlike cast wheels produced in fixed molds or flow-formed wheels with limited customization, forged wheels are machined from solid aluminum billets with exceptional precision.

This manufacturing process means forged wheel producers can accommodate backspacing and offset specifications that simply aren't available in mass-produced alternatives. Need a specific 4.75-inch backspacing instead of the standard 4.5 or 5.0 inches? Forged construction makes that possible. Looking for an unusual offset that perfectly clears your big brake kit while maintaining your desired stance? A quality forged wheel manufacturer can deliver exactly that.

The tighter tolerances achievable with forged construction - often within fractions of a millimeter - ensure the specifications you order are the specifications you receive. Cast wheels, by comparison, can vary slightly from their stated measurements due to the nature of the casting process. When you're working with tight clearances around performance suspension components or oversized brakes, that precision difference matters significantly.

This flexibility does come with responsibility. Since forged wheels are built to your exact specifications, there's no room for measurement errors. The relationship between positive offset vs negative offset choices, wheel width, and resulting backspacing must be calculated correctly before production begins. In the next section, you'll learn the exact formulas and calculations needed to determine these specifications with confidence.

How to Calculate Backspacing and Offset

Ready to move beyond definitions and get into the actual math? Don't worry - the calculations connecting wheel width, offset, and backspacing are straightforward once you understand the formula. Whether you're using an offset to backspacing calculator or working through the numbers yourself, mastering these conversions ensures you order custom forged wheels with confidence.

The Backspacing Formula Explained

The standard formula for calculating backspacing accounts for the wheel's total width, including the flanges that hold the tire bead in place. Here's the formula you'll use:

Backspacing = ((Wheel Width + 1) ÷ 2) + Offset (converted to inches)

Why add 1 inch to the wheel width? The stated wheel width (like "9 inches" or "10 inches") measures only the bead seat - the area where your tire actually mounts. The wheel flanges extending on both sides add approximately 1 inch to the overall width. This adjustment gives you the true centerline position needed for accurate backspacing calculations.

Let's walk through a real example. Suppose you're ordering a 9-inch wide forged wheel with a +25mm offset:

- Add 1 inch to the stated wheel width: 9 + 1 = 10 inches (overall width)

- Divide by 2 to find the centerline: 10 ÷ 2 = 5 inches

- Convert offset from millimeters to inches: 25mm ÷ 25.4 = 0.98 inches

- Add the converted offset to the centerline: 5 + 0.98 = 5.98 inches of backspacing

Since this wheel has a positive offset, you add the converted value. For negative offsets, you subtract instead. An 9-inch wheel with -25mm offset would calculate as: 5 - 0.98 = 4.02 inches of backspacing.

Converting Between Offset and Backspacing

Sometimes you know the backspacing you need but must communicate the offset to a manufacturer who works primarily in metric measurements. The backspace to offset calculator process simply reverses the formula:

Offset (inches) = Backspacing - ((Wheel Width + 1) ÷ 2)

Then convert to millimeters by multiplying by 25.4.

For example, if you need 6.5 inches of backspacing on a 10-inch wide wheel:

- Calculate the centerline: (10 + 1) ÷ 2 = 5.5 inches

- Subtract centerline from backspacing: 6.5 - 5.5 = 1.0 inch

- Convert to millimeters: 1.0 × 25.4 = +25.4mm offset

The positive result indicates a positive offset. If your calculation yields a negative number, the wheel has a negative offset - meaning the mounting surface sits inboard of the centerline, pushing the wheel outward.

When comparing specifications across different manufacturers, a reliable wheel offset backspace calculator eliminates conversion errors. Some manufacturers list offset exclusively, while others prefer backspacing. Being able to convert between the two ensures you're comparing apples to apples when evaluating fitment options.

Sample Calculations for Common Wheel Sizes

Rather than calculating every configuration manually, an offset to backspace chart provides quick reference values for popular wheel sizes. The table below covers wheel widths from 8 to 12 inches across commonly used offset ranges:

| Wheel Width | Offset (mm) | Offset (inches) | Backspacing |

|---|---|---|---|

| 8.0" | +38mm | +1.50" | 6.00" |

| 8.0" | +25mm | +0.98" | 5.48" |

| 8.0" | 0mm | 0.00" | 4.50" |

| 9.0" | +38mm | +1.50" | 6.50" |

| 9.0" | +22mm | +0.87" | 5.87" |

| 9.0" | -25mm | -0.98" | 4.02" |

| 10.0" | +25mm | +0.98" | 6.48" |

| 10.0" | 0mm | 0.00" | 5.50" |

| 10.0" | -44mm | -1.73" | 3.77" |

| 11.0" | +22mm | +0.87" | 6.87" |

| 11.0" | -25mm | -0.98" | 5.02" |

| 12.0" | +25mm | +0.98" | 7.48" |

| 12.0" | -44mm | -1.73" | 4.77" |

Notice the pattern? As wheel width increases, you need more positive offset (or less negative offset) to maintain the same backspacing. A 12-inch wide wheel with -44mm offset provides 4.77 inches of backspacing - similar to what an 8-inch wheel achieves with zero offset. This relationship is critical when upgrading to wider wheels while trying to preserve existing clearances.

Using an offset and backspace calculator alongside reference charts like this helps you quickly evaluate whether a particular wheel configuration will work for your application. You'll notice that aggressive truck and off-road builds often use those deep negative offsets (-44mm to -76mm) to achieve that "poked" stance, while performance street cars typically stay in the positive offset range to maintain proper suspension geometry.

With these calculations mastered, you're ready to measure your existing wheels and gather the specifications needed for your custom forged wheel order.

Measuring Backspacing on Your Existing Wheels

Now that you understand the formulas, it's time to get hands-on. Before ordering custom forged wheels, you'll need accurate measurements from your current setup. Knowing how to measure backspacing on wheels - and gathering all related specifications - prevents costly ordering mistakes and ensures your new wheels fit perfectly the first time.

Measuring Your Current Wheels

Wondering how do you measure backspacing on a wheel? The process is straightforward and requires only basic tools. The straight-edge method remains the most reliable approach, and you can complete it in just a few minutes per wheel.

Here's what you'll need:

- A straight edge (a metal ruler, level, or piece of straight lumber works well)

- A tape measure with inch markings

- A flat, protected surface to work on

- Ideally, the wheel without the tire mounted (though measurement is possible with the tire in place)

Follow these steps to measure accurately:

- Position the wheel correctly: Lay the wheel face-down on a protected surface so the back side (where it mounts to your vehicle) faces upward. If the tire is still mounted, ensure the wheel sits level.

- Place the straight edge across the wheel: Lay your straight edge diagonally across the inboard flange - the inner lip of the wheel. The straight edge should rest on both sides of the wheel's rear edge, spanning across the entire opening.

- Measure to the mounting surface: Using your tape measure, find the distance from where the straight edge contacts the inboard flange down to the hub mounting pad. This is the flat machined surface where your wheel bolts to the hub.

- Record your measurement: The distance you just measured is your backspacing, expressed in inches. A typical reading might be 4.5 inches, 5.75 inches, or similar.

When learning how to measure rim offset, remember that you'll need to perform a quick calculation rather than a direct measurement. Once you have the backspacing, use the reverse formula from the previous section: subtract half the overall wheel width from your backspacing measurement, then multiply by 25.4 to convert to millimeters.

For the most accurate results when figuring out how to determine rim offset, measure each wheel in your current setup. Manufacturing tolerances mean slight variations can exist even among wheels from the same set. Recording all four measurements gives you a complete picture and helps identify if any wheels have been replaced with non-matching specifications.

Hub-Centric vs Lug-Centric Considerations

Before finalizing your custom forged wheel specifications, you need to understand how your wheels center on the vehicle's hub. This distinction affects both fitment quality and the measurements you'll provide to manufacturers.

Hub-centric wheels feature a center bore machined to match your vehicle's hub diameter exactly. The hub itself supports the wheel's weight and keeps everything perfectly centered. Most factory-original wheels are hub-centric because automakers design the wheels specifically for each vehicle platform. This precise fit reduces vibration and ensures the wheel rotates true around the axle's center point.

Lug-centric wheels have an oversized center bore designed to fit multiple vehicles with different hub diameters. The lug nuts alone handle centering duties, which can work but requires extremely precise installation. Many aftermarket wheels use this approach because manufacturing one wheel size that fits dozens of vehicle applications is more economical than creating hub-specific versions for each.

When ordering custom forged wheels, you have an advantage: manufacturers can machine the center bore to your exact hub diameter, making your wheels truly hub-centric. This means you'll need to measure or verify your vehicle's hub diameter (also called center bore) and provide this specification with your order.

If you're currently running lug-centric aftermarket wheels with hub-centric rings, measure carefully. The rings fill the gap between the oversized wheel bore and your actual hub. Your new custom forged wheels should be machined to your vehicle's true hub size, eliminating the need for adapter rings and ensuring optimal balance and fitment.

What Specifications to Gather Before Ordering

When you're ready to communicate with a forged wheel manufacturer, having complete specifications prevents delays and misunderstandings. Here's your comprehensive checklist of measurements to gather:

- Wheel diameter: Confirm the diameter you want in inches (17", 18", 20", etc.). Consider brake clearance requirements if upsizing.

- Wheel width: Determine your desired width in inches. Remember that wider wheels may require different backspacing to maintain proper clearance.

- Backspacing or offset: Provide either measurement - manufacturers can convert between them. If you've measured your current wheels, share those numbers as a baseline.

- Bolt pattern (PCD): Express this as lug count times diameter, such as 5x114.3 or 6x139.7. Verify this specification matches your vehicle exactly.

- Center bore (hub diameter): Measure your hub or reference your vehicle's specifications. Common sizes include 73.1mm for many European vehicles and 67.1mm for various Japanese applications.

- Clearance constraints: Document any obstacles like oversized brake calipers, suspension arms, or inner fender modifications. Photos with measurements help manufacturers understand your specific situation.

- Intended tire size: Share the tire width and sidewall ratio you plan to run. This helps manufacturers confirm your backspacing choice provides adequate clearance.

Understanding how to figure out wheel offset and how to measure wheel rim offset from your existing setup gives you a proven starting point. If your current wheels fit well, matching or slightly adjusting those specifications reduces fitment risk. If you're changing wheel width significantly, recalculate the backspacing needed to maintain similar positioning within the wheel well.

With all these measurements documented, you're prepared to discuss fitment factors that go beyond the basic numbers - including how tire choices and vehicle application affect your ideal backspacing specification.

Fitment Factors Beyond the Numbers

You've measured your wheels, calculated the formulas, and gathered your specifications. But here's where theory meets reality: backspacing on wheels doesn't exist in isolation. The number you choose directly impacts whether your tires clear critical components - or create expensive problems. Understanding how does offset work on wheels in real-world applications means considering everything from inner fender wells to suspension travel.

Inner Fender and Suspension Clearance

Think about what happens when you turn your steering wheel hard to one side. Your front tires don't just rotate - they arc inward toward the inner fender well. Now add suspension compression when hitting a bump mid-turn. This dynamic movement is exactly why static measurements alone can't guarantee proper fitment.

More backspacing pushes your wheel and tire assembly inward toward three critical areas:

- Inner fender wells: The sheet metal or plastic liner inside your wheel wells has limited space. Too much backspacing causes tire contact during full steering lock or suspension compression.

- Suspension components: Control arms, struts, coilovers, and sway bar links occupy space near the wheel's inboard side. Independent front suspension vehicles are particularly sensitive to backspacing choices.

- Brake assemblies: Calipers, especially aftermarket big brake kits, extend outward from the hub. Insufficient clearance between wheel spokes and caliper bodies creates dangerous interference.

Conversely, less backspacing pushes the wheel outward. While this solves inboard clearance issues, it creates new challenges. The tire's outer edge moves closer to - or past - the fender lip. You'll experience rubbing during suspension compression, cornering, or when carrying heavy loads that cause additional squat.

How does rim offset work to affect this balance? Since offset on wheels determines mounting surface position, changing offset while maintaining the same wheel width shifts the entire tire footprint either inward or outward. A more positive offset tucks everything in; a more negative offset pushes everything out. This is why understanding what is backspacing on wheels becomes essential - it tells you exactly how much inboard space you're working with.

Tire Width and Backspacing Relationships

Here's where many enthusiasts make costly mistakes: they focus on wheel specifications while forgetting that tires occupy the actual space. A 275mm wide tire on a 9-inch wheel behaves very differently than a 305mm tire on that same wheel - even with identical backspacing.

Consider this relationship: your backspacing measurement tells you where the wheel's inner lip sits relative to the mounting surface. But the tire's sidewall bulges beyond that lip on both sides. A wider tire extends further inboard and outboard than a narrower one, regardless of wheel specifications.

When upgrading to wider tires, you often need to reduce backspacing to compensate for the additional inboard tire width. Otherwise, that extra rubber presses against suspension components or inner fender wells. The reverse applies when downsizing - you may have room for additional backspacing that tucks the wheel closer to factory positioning.

Wheel width also factors into this equation. Mounting a tire on a wider wheel stretches the sidewall more horizontally, reducing its vertical bulge. The same 275mm tire on an 11-inch wheel presents a different clearance profile than on a 9-inch wheel. This interaction between tire size, wheel width, and backspacing requires careful consideration before finalizing custom forged wheel specifications.

Application-Specific Backspacing Considerations

Different vehicles demand different backspacing strategies based on their intended use. What works perfectly for a daily-driven sedan creates problems on a lifted truck or track-focused sports car.

Trucks and SUVs: These vehicles often run aftermarket wheels with significantly less backspacing than stock - typically 3.5 to 5 inches on wheels 9 inches wide or wider. The reduced backspacing creates that popular wide-stance look while providing clearance for larger suspension components. However, according to 4 Wheel Parts, going too aggressive with minimal backspacing (2 to 3 inches on 10 to 12-inch wide wheels) can cause unpredictable "darty" steering and other handling quirks, especially on rough roads.

Performance cars: Street performance and track vehicles typically maintain backspacing closer to factory specifications. The priority here is preserving proper suspension geometry, scrub radius, and steering feel. Moving the wheel centerline too far outward increases load on steering components, ball joints, and tie rods - components that experience even greater stress during aggressive cornering.

Off-road vehicles: Lifted trucks and dedicated off-road rigs face unique challenges. Suspension lifts change the geometry, and larger tires require careful backspacing selection. Many suspension manufacturers specify exact backspacing requirements for their lift kits, particularly on independent front suspension applications where A-arms could contact wheels with excessive backspacing.

The table below illustrates how different backspacing values affect clearance in various directions:

| Backspacing | Inboard Clearance | Outboard Clearance | Typical Application |

|---|---|---|---|

| 6.0"+ (high) | Minimal - risk of suspension/brake contact | Maximum - wheel tucked under fender | Factory stock, some front-wheel-drive |

| 5.0" - 5.5" (moderate-high) | Adequate for most stock components | Good fender clearance | Performance cars, mild upgrades |

| 4.0" - 4.5" (moderate) | Good clearance for aftermarket suspension | May approach fender lip | Trucks, lifted SUVs, aggressive fitment |

| 3.5" - 4.0" (low) | Maximum clearance for wide suspension | Wheel pokes past fender | Wide-stance trucks, off-road builds |

| Below 3.5" (very low) | Excessive - potential handling issues | Significant poke, fender mods likely needed | Show vehicles, extreme stance builds |

How does offset wheels work to achieve these different backspacing values? Remember that wider wheels need more negative offset to maintain the same backspacing as narrower wheels. A 10-inch wide wheel with -25mm offset provides similar backspacing to an 8-inch wheel with zero offset. This relationship explains why aggressive off-road wheels often show deeply negative offset numbers - it's the only way to achieve workable backspacing on extra-wide wheel widths.

Understanding these application-specific requirements helps you make informed decisions when specifying your custom forged wheels. The next consideration? Avoiding the common ordering mistakes that turn perfect specifications into fitment failures.

Avoiding Costly Custom Wheel Ordering Mistakes

You've done the math, measured your wheels, and researched your fitment options. But here's the reality - even experienced enthusiasts make ordering errors that turn their custom forged wheel investment into an expensive lesson. Understanding the most common mistakes before you finalize specifications can save you thousands of dollars and weeks of frustration.

When it comes to offset in wheels and backspacing specifications, small errors create big problems. Unlike ordering cast wheels from a catalog where returns might be possible, custom forged wheels are manufactured specifically for your order. Once production begins, there's no going back. Let's examine the pitfalls that trip up buyers most frequently.

- Confusing metric offset with imperial backspacing: Mixing millimeters and inches leads to wheels that don't fit as expected.

- Ignoring tire size changes: New tire dimensions alter clearance requirements even with identical wheel specs.

- Copying specs from different wheel widths: A 9-inch wheel's offset doesn't translate directly to a 10-inch wheel.

- Poor communication with manufacturers: Vague or incomplete specifications create room for interpretation errors.

- Skipping pre-production verification: Assuming everything is correct without confirming details before manufacturing begins.

Metric vs Imperial Confusion

This mistake happens more often than you'd expect, even among seasoned wheel buyers. Offset is measured in millimeters while backspacing uses inches - and confusing the two creates wildly incorrect specifications. Imagine ordering wheels with what you think is 5.5 inches of backspacing, but the manufacturer interprets that as 5.5mm of offset. The resulting wheels would be nothing close to what you needed.

The confusion compounds when referencing an offset and backspacing chart from different sources. Some charts list both measurements side by side, while others show only one format. If you're pulling specifications from multiple references, verify which unit of measurement each source uses before combining information.

Here's a practical safeguard: always specify the unit explicitly when communicating with manufacturers. Instead of writing "offset: 25," write "offset: +25mm" or "backspacing: 5.5 inches." This eliminates ambiguity and forces you to confirm you're using the correct measurement system. When offset explained in documentation uses one format but your notes use another, take time to convert properly rather than assuming.

Another common issue involves the offset to backspacing conversion itself. The formula requires adding 1 inch to the stated wheel width before dividing by 2 - a step that's easy to forget. Missing this adjustment throws off your calculation by half an inch, which is enough to cause rubbing issues or excessive poke depending on the direction of the error.

Tire Size Changes Affect Fitment

Picture this scenario: your current 275/40R20 tires fit perfectly on your existing wheels with specific backspacing. You order new custom forged wheels with identical specifications, planning to upgrade to 305/35R20 tires for a more aggressive look. When everything arrives and gets mounted, the tires rub against the inner fender well during suspension compression. What went wrong?

The offset to backspacing relationship you calculated was correct for your old tire size - not your new one. That 305mm tire is 30mm (about 1.2 inches) wider than your previous 275mm rubber. Even on the same wheel, the extra width extends both inboard and outboard, consuming clearance that existed with narrower tires.

According to guidance from Custom Wheel Offset, many buyers focus entirely on wheel specifications while underestimating how critical tire selection becomes. The width, sidewall height, and even brand-specific construction differences affect how much space the mounted tire actually occupies.

When planning a tire size upgrade alongside new wheels, factor in both dimensions. Wider tires typically require reduced backspacing (achieved through more negative offset) to maintain the same inboard clearance. Taller sidewalls increase overall tire diameter, potentially creating clearance issues at full suspension compression that didn't exist with lower-profile rubber.

Before finalizing wheel specifications, determine your exact tire size first. Then use a backspace to offset chart that accounts for your specific tire width. If you're unsure how a new tire size will affect clearance, consult with your wheel manufacturer - reputable companies understand these relationships and can advise on appropriate backspacing adjustments.

Verifying Specifications Before Production

Communication errors between buyers and manufacturers cause more fitment failures than calculation mistakes. You might know exactly what you need, but if that information doesn't transfer accurately to the production team, the resulting wheels won't match your requirements.

Common communication breakdowns include:

- Incomplete specification lists: Providing wheel width and offset but forgetting to specify center bore or bolt pattern details.

- Assumed versus confirmed measurements: Telling a manufacturer "I need the same as my current wheels" without providing actual numbers.

- Verbal-only specifications: Discussing requirements by phone without following up with written confirmation.

- Unverified "standard" specifications: Assuming your vehicle uses common specifications without actually measuring or confirming.

The solution? Request written confirmation of every specification before production begins. Quality forged wheel manufacturers typically provide order confirmations or specification sheets listing every detail - wheel diameter, width, offset, backspacing, bolt pattern, center bore, and any custom features. Review this documentation carefully, comparing each number against your original requirements.

If anything looks unfamiliar or doesn't match your notes, stop and clarify immediately. A simple phone call or email exchange before manufacturing starts costs nothing. Discovering an error after your wheels are machined means starting over with new materials and additional lead time.

Some buyers find it helpful to create a specification sheet of their own, including reference photos showing current wheel positioning, measurements of clearance areas, and explicit statements of their goals ("wheels should sit flush with fender" or "need 1 inch of additional poke compared to stock"). This gives manufacturers context beyond raw numbers and helps them spot potential issues you might have overlooked.

The investment you're making in custom forged wheels deserves thorough verification at every step. With specifications confirmed and potential mistakes avoided, you're ready to work with manufacturers who can bring your vision to reality with precision engineering.

Working with Custom Forged Wheel Manufacturers

You've calculated your specifications, avoided common mistakes, and documented everything carefully. Now comes the critical step - translating all that preparation into a successful custom wheel order. Understanding wheel offset meaning and how to communicate your requirements effectively separates smooth transactions from frustrating back-and-forth exchanges that delay your project.

The custom forged wheel ordering process differs significantly from purchasing off-the-shelf wheels. You're not selecting from existing inventory - you're commissioning precision components manufactured to your exact specifications. This collaborative approach requires clear communication, realistic expectations about timelines, and partnership with manufacturers who truly understand automotive fitment requirements.

Communicating with Forged Wheel Manufacturers

Think of your initial manufacturer contact as a consultation rather than a simple transaction. Quality forged wheel producers want to understand your complete project, not just process an order. The more context you provide upfront, the better positioned they are to advise on optimal specifications for your specific application.

Start your communication with these essential details:

- Vehicle information: Year, make, model, and trim level. Include any modifications affecting wheel fitment - suspension lifts, lowering kits, brake upgrades, or fender modifications.

- Current wheel specifications: Share your measured backspacing, calculated offset, bolt pattern, and center bore from existing wheels that fit well.

- Desired changes: Clearly state what you want different from your current setup - wider wheels, more aggressive stance, flush fitment, or additional brake clearance.

- Tire specifications: Provide the exact tire size you plan to mount, including brand if you've already selected one.

- Intended use: Daily driving, weekend cruising, track days, off-road adventures, or show display affects optimal specification recommendations.

When discussing custom wheels offset with manufacturers, don't hesitate to ask questions. What does wheel offset mean for your specific vehicle platform? What backspacing do they recommend for similar builds? Experienced manufacturers have likely worked on vehicles identical to yours and can share valuable insights about clearance challenges or optimal fitment approaches.

According to Poly Performance's wheel fitment guide, backspacing is often preferred over offset in the 4WD industry because it directly relates to inboard component clearance - exactly what suspension manufacturers specify when determining wheel compatibility. Understanding which measurement format your manufacturer prefers helps streamline communication.

What to Expect During the Custom Order Process

Once you've established specifications with your manufacturer, the ordering process typically follows a structured sequence. Knowing what to expect at each stage helps you stay engaged and catch potential issues before they become expensive problems.

Specification confirmation: Before any manufacturing begins, you should receive written confirmation of every detail - diameter, width, offset, backspacing, bolt pattern, center bore, finish, and design elements. Review this document carefully against your original requirements. This is your last opportunity to catch errors without financial consequences.

Engineering review: Quality manufacturers evaluate your specifications against known fitment parameters for your vehicle. They may flag potential clearance concerns or suggest adjustments based on their experience with similar applications. This expertise is invaluable - don't dismiss their recommendations without careful consideration.

Production timeline: Custom forged wheels require time to manufacture properly. Standard lead times typically range from 4 to 12 weeks depending on complexity, finish requirements, and current production schedules. Rush orders may be possible but often carry premium pricing.

Progress updates: Reputable manufacturers keep you informed throughout production. You might receive photos showing machining progress, finish application, or quality control inspections. This transparency builds confidence and provides documentation of your wheels' construction.

Final inspection: Before shipping, completed wheels should undergo thorough quality verification - dimensional checks confirming specifications match your order, finish inspection for defects, and balance testing. Some manufacturers provide inspection reports or certificates documenting this process.

Why Manufacturing Expertise Matters

Not all forged wheel manufacturers possess equal capability or understanding of automotive applications. When you're investing in custom wheels offset specifications that must integrate precisely with your vehicle, the manufacturer's expertise directly affects your outcome.

Look for these indicators of manufacturing competence:

- Industry certifications: Quality management certifications like IATF 16949 indicate manufacturers meeting rigorous automotive industry standards. These certifications require documented processes, consistent quality control, and continuous improvement systems.

- In-house engineering: Manufacturers with dedicated engineering teams can analyze your specifications, identify potential fitment issues, and recommend solutions before production begins.

- Precision equipment: Modern CNC machining centers achieve tolerances within fractions of a millimeter - essential when your custom wheel offsets must clear brake calipers by specific margins.

- Application knowledge: Manufacturers familiar with various vehicle platforms understand platform-specific challenges and can anticipate issues you might not know to ask about.

For those exploring precision forging partners for automotive applications, manufacturers like Shaoyi (Ningbo) Metal Technology demonstrate the capabilities serious wheel projects demand. Their IATF 16949 certification ensures components meet exact specifications, while rapid prototyping capabilities - sometimes in as little as 10 days - accelerate custom projects that would otherwise face extended timelines. You can explore their automotive forging solutions as a resource for understanding what precision hot forging can deliver.

The value of manufacturing expertise extends beyond simply producing wheels to specification. Experienced manufacturers become partners in your project, offering guidance on optimal backspacing for your application, identifying potential clearance concerns before production, and ensuring the finished product delivers the performance and aesthetics you're investing in.

Understanding wheel offset meaning and communicating your requirements clearly positions you for success. But even with careful planning, fitment issues occasionally arise. The next section addresses how to diagnose and resolve backspacing-related problems if your custom forged wheels don't perform exactly as expected.

Troubleshooting Backspacing Fitment Issues

So your custom forged wheels have arrived, you've mounted them with excitement - and something isn't right. Maybe there's an unsettling scraping sound during turns, or you've noticed unusual wear patterns developing on your new tires. Before panic sets in, understand that fitment issues related to rim backspacing and offset on rims can often be diagnosed and corrected. The key is identifying exactly what's happening and choosing the appropriate solution.

Even with careful planning, real-world fitment sometimes differs from calculations. Suspension geometry under load, manufacturing tolerances in various components, and the dynamic nature of driving create scenarios that static measurements can't always predict. Let's work through how to identify backspacing-related problems, evaluate your correction options, and determine when a complete reorder becomes necessary.

Diagnosing Backspacing-Related Fitment Problems

The first step in solving any fitment issue is confirming what's actually happening. Different symptoms point to different causes, and understanding these patterns helps you target the right solution.

Common symptoms and their likely backspacing-related causes include:

- Tire rubbing on outer fender during turns: Backspacing is too low (wheel positioned too far outward). The tire's outer edge contacts the fender lip when steering approaches full lock or during cornering.

- Tire rubbing on inner fender well during compression: Backspacing is too high (wheel positioned too far inward). When suspension compresses over bumps or during heavy braking, the tire contacts the inner fender liner or sheet metal.

- Contact with suspension components: Excessive backspacing pushes the wheel too close to control arms, struts, or sway bar links. You might hear scraping during suspension travel or notice witness marks on components.

- Brake caliper interference: Insufficient clearance between wheel spokes and caliper body. This can create grinding sounds or visible contact marks on the caliper.

- Uneven tire wear on inner or outer edges: Chronic rubbing that you might not always hear creates accelerated wear patterns. According to Apex Wheels' technical guide, tire rubbing leads to premature tire wear and can become a safety hazard if left unaddressed.

- Steering vibration or pull: Rim offset issues affecting scrub radius can manifest as steering feel changes, particularly noticeable during acceleration or braking.

To properly diagnose the issue, get your vehicle on a lift or jack stands and perform a thorough inspection. Look for shiny spots on tire sidewalls indicating contact. Check inner fender liners for scrape marks or torn plastic. Examine suspension arms and brake components for witness marks. Have someone turn the steering wheel to full lock in both directions while you observe clearances.

Don't forget to check with the vehicle loaded normally - passengers, cargo, or towing weight compress the suspension and reduce clearances that appeared adequate when the car sat empty on the lift.

Spacers and Other Correction Options

Once you've identified the problem, several correction approaches exist depending on the severity and direction of the fitment issue.

Wheel spacers address situations where your rim backspacing is too high - the wheel sits too far inward and contacts suspension components or inner fender areas. Quality hub-centric spacers push the wheel outward, effectively reducing backspacing without requiring new wheels.

According to Orion Motor Tech's comparison guide, wheel spacers require specific maintenance attention that integrated offset solutions don't. You'll need to retorque the bolts every 6,000-10,000 miles and confirm your existing studs provide adequate thread engagement with the added spacer thickness. Most spacer-related failures stem from installation issues rather than inherent design problems, so proper installation is critical.

Spacers work best for minor corrections - typically 5 to 25mm of adjustment. Larger corrections introduce greater leverage on suspension components and wheel bearings, potentially accelerating wear. If you need more than 25mm of spacer thickness to achieve proper fitment, reconsidering your wheel specifications might be the wiser long-term solution.

Fender modifications address the opposite problem - wheels positioned too far outward that contact fender lips during suspension compression or steering. Options include:

- Fender rolling: A professional uses heat and specialized tools to gently curl the fender lip inward, creating additional clearance without visible exterior changes. This works well for minor rubbing situations.

- Fender pulling: More aggressive than rolling, this technique reshapes the fender to provide additional clearance. Results are more dramatic but carry higher risk of paint damage.

- Inner liner trimming: When rubbing occurs on plastic fender liners rather than sheet metal, careful trimming can eliminate contact points without affecting appearance.

As noted by Apex Wheels, fender rolling should be performed by professionals using proper heat guns and rolling tools - not improvised solutions that risk damaging your vehicle's finish.

Suspension adjustments offer another avenue for minor corrections. If you're running adjustable coilovers, raising ride height by 5-10mm can create enough clearance to eliminate rubbing without dramatically affecting appearance or handling. Some vehicles also allow camber adjustments that angle the tire inward at the top, providing additional fender clearance at the expense of slightly increased inner tire wear.

When to Reorder with Correct Specifications

Sometimes correction methods can't adequately address the fitment problem, or the compromises they require aren't acceptable for your application. Consider reordering with corrected specifications when:

- Clearance issues are severe: More than 25mm of spacer would be required, or fender modifications would be extensive and visible.

- Multiple contact points exist: The wheel rubs on both inner and outer areas, meaning no single adjustment direction solves everything.

- Safety concerns arise: Brake caliper contact, severe suspension component interference, or situations where rubbing could lead to sudden tire failure.

- Performance is compromised: Changes required to achieve clearance significantly alter handling characteristics, tire wear patterns, or vehicle dynamics beyond acceptable limits.

- Aesthetic goals aren't met: Spacers or fender modifications result in a look significantly different from your original vision.

If reordering becomes necessary, thorough documentation of the fitment problem helps ensure the replacement wheels arrive with correct specifications. Take photographs showing exactly where contact occurs. Measure the gap (or overlap) between tire and obstruction. Note whether the issue occurs at rest, during steering input, under suspension compression, or only when loaded.

When communicating with your manufacturer about fitment failures:

- Provide photographic evidence: Clear images showing contact points, wear marks, and clearance gaps give manufacturers visual context for the problem.

- Include measurements: Quantify how much adjustment is needed - "the tire contacts the fender by approximately 8mm at full compression" is more actionable than "the wheel rubs."

- Reference original specifications: Include the order confirmation showing what specifications were requested versus what may have been manufactured.

- Describe your correction attempts: If you've tried spacers or other adjustments, explain what was attempted and why it proved insufficient.

- State your desired outcome: Clearly communicate whether you want revised specifications for a replacement order or need guidance on alternative solutions.

Quality manufacturers understand that even carefully specified custom wheels occasionally require adjustment. Their response to fitment issues reveals their commitment to customer satisfaction and their depth of technical expertise. A manufacturer willing to analyze your documentation, discuss potential causes, and work toward a solution demonstrates the partnership approach that complex custom projects require.

With fitment issues diagnosed and correction paths evaluated, you're better prepared to either resolve current problems or specify your next custom forged wheel order with even greater precision.

Preparing for Your Custom Forged Wheel Order

You've made it through the calculations, measurements, and troubleshooting guidance. Now it's time to bring everything together before you click that order button. Whether you've referenced a backspacing chart dozens of times or used an offset vs backspacing chart to compare manufacturer specifications, the preparation you've done positions you for success - but only if you execute the final steps correctly.

The difference between a flawless custom forged wheel installation and a frustrating fitment failure often comes down to three things: accurate measurements verified multiple times, calculations double-checked against reliable references, and crystal-clear communication with your chosen manufacturer. Skip any of these steps, and you're gambling with an investment that can easily exceed several thousand dollars.

Your Pre-Order Specification Checklist

Before contacting any manufacturer, gather every specification you'll need. Having this information organized and verified eliminates back-and-forth delays and reduces the chance of miscommunication. Use this comprehensive checklist to confirm you're ready:

- Wheel diameter: Confirm your target size in inches (17", 18", 20", etc.) and verify brake clearance requirements if upsizing from stock.

- Wheel width: Document your desired width and understand how it affects backspacing calculations compared to your current wheels.

- Offset specification: Record in millimeters with the correct sign (+ or -). Cross-reference using a wheel offset chart to verify the number makes sense for your application.

- Backspacing measurement: Calculate from your offset or measure directly from existing wheels. Use a rim offset chart to confirm your calculations align with industry standards.

- Bolt pattern (PCD): Verify exact lug count and diameter (example: 5x114.3). Never assume - measure or confirm from manufacturer documentation.

- Center bore diameter: Measure your hub or reference vehicle specifications. Custom forged wheels should be machined hub-centric for optimal balance.

- Tire specifications: Document the exact tire size you'll mount, including width, aspect ratio, and diameter (example: 275/40R20).

- Clearance documentation: Note any aftermarket components affecting fitment - big brake kits, suspension modifications, or fender alterations.

- Current wheel measurements: If your existing wheels fit well, record their specifications as a proven baseline reference.

- Intended use description: Daily driving, track use, off-road, or show display - this context helps manufacturers recommend optimal specifications.

Having this checklist completed before your first manufacturer conversation demonstrates you're a serious buyer who understands the process. It also protects you - when specifications are documented in writing, there's no ambiguity about what you ordered versus what gets manufactured.

Partnering with Quality-Focused Manufacturers

Your custom forged wheels are only as good as the manufacturer producing them. When you're trusting a company to machine precision components that affect both your vehicle's appearance and safety, certifications and quality control processes matter significantly.

Look for manufacturers holding recognized industry certifications. According to FlexiForge Wheel's certification guide, IATF 16949:2016 certification is particularly vital for wheel manufacturers supplying major automakers - it covers the entire production process and focuses on continuous improvement and defect prevention. This same standard applies when you're ordering custom wheels; certified manufacturers maintain documented processes that ensure consistency from order to delivery.

Beyond certifications, evaluate these quality indicators:

- In-house engineering capabilities: Manufacturers with dedicated engineering teams can review your specifications, identify potential issues, and suggest optimizations before production begins.

- Precision manufacturing equipment: Modern CNC machining achieves tolerances within fractions of a millimeter - essential when your wheel backspace calculator results require exact execution.

- Transparent communication: Quality manufacturers provide written specification confirmations, progress updates, and final inspection documentation.

- Prototyping capabilities: For complex projects, rapid prototyping allows verification before committing to full production runs.

For those seeking precision forging solutions for automotive applications, manufacturers like Shaoyi (Ningbo) Metal Technology exemplify the capabilities serious custom projects demand. Their IATF 16949 certification and in-house engineering ensure components meet exact specifications, while rapid prototyping capabilities - sometimes in as little as 10 days - accelerate custom projects that might otherwise face extended timelines. With convenient global shipping from their location near Ningbo Port, they serve as a valuable resource for enthusiasts and businesses alike exploring precision forging partners for automotive applications.

The investment you're making in custom forged wheels deserves a manufacturing partner who matches your commitment to getting every detail right. Armed with your completed specification checklist, verified calculations from your backspacing calculator work, and a quality-focused manufacturer, you're positioned to receive wheels that fit perfectly, perform flawlessly, and deliver the exact aesthetic you envisioned. That 30 to 60 minutes spent on preparation translates directly into thousands of dollars protected and months of frustration avoided.

Frequently Asked Questions About Custom Forged Wheel Backspacing

1. What does 4.75 backspacing mean?

A 4.75-inch backspacing means the distance from the wheel's mounting surface to its inner lip measures 4.75 inches. This measurement indicates how far the wheel extends inward toward your suspension and brake components. More backspacing pulls wheels closer to these parts, while less backspacing pushes them outward toward the fender. For custom forged wheels, this specification is critical because manufacturers machine wheels to your exact measurement, making accuracy essential before ordering.

2. What offset is 7.5 backspacing?

The offset for 7.5-inch backspacing depends on wheel width. For example, on an 8-inch wide wheel, 7.5-inch backspacing equals approximately +51mm offset. On a 10-inch wheel, that same backspacing translates to about +25mm offset. Use the formula: Offset (inches) = Backspacing - ((Wheel Width + 1) ÷ 2), then multiply by 25.4 for millimeters. Always verify calculations with a backspace to offset chart when ordering custom forged wheels.

3. How do I measure wheel backspacing at home?

Place your wheel face-down on a protected surface. Lay a straight edge across the back of the wheel, resting on both sides of the inner lip. Measure from the hub mounting pad (the flat surface where bolts attach) up to the straight edge. This distance in inches is your backspacing. For accuracy, measure all four wheels since manufacturing tolerances can cause slight variations. This measurement becomes your baseline when ordering custom forged wheels.

4. What is the difference between wheel offset and backspacing?

Offset measures from the mounting surface to the wheel's centerline in millimeters and can be positive, negative, or zero. Backspacing measures from the mounting surface to the inner lip in inches. Both describe wheel positioning differently - offset tells you how far the mounting point deviates from center, while backspacing tells you exactly how much inboard clearance exists. Custom forged wheel manufacturers can work with either measurement since they're mathematically related.

5. Can I use wheel spacers to fix incorrect backspacing on custom wheels?

Wheel spacers can correct backspacing that's too high by pushing wheels outward, but they work best for minor adjustments of 5-25mm. Quality hub-centric spacers require retorquing every 6,000-10,000 miles and adequate stud thread engagement. For corrections exceeding 25mm, reordering custom forged wheels with correct specifications is often the safer, more reliable solution. Spacers cannot fix backspacing that's too low - that requires fender modifications or new wheels.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —