Forged Vs Cast Turbo Compressor Wheels: Pick Wrong And Pay Twice

Why Turbo Compressor Wheel Material Defines Your Build

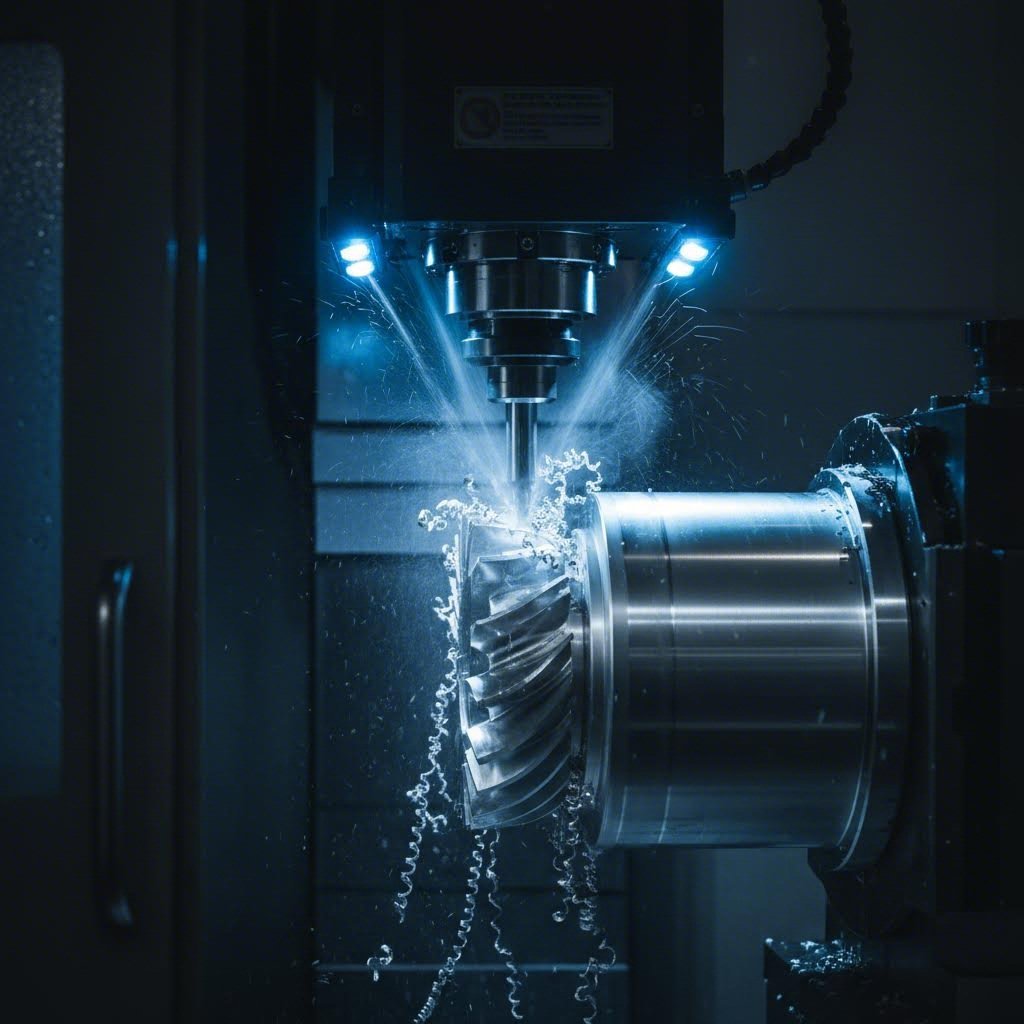

Imagine spinning a component at over 150,000 RPM while simultaneously exposing it to extreme heat and massive boost pressure. That's exactly what your turbo compressor wheel endures every time you push the throttle. When comparing forged vs cast turbo compressor wheels, you're not just choosing a part—you're making a decision that directly impacts your engine's power delivery, reliability, and longevity.

Why Your Compressor Wheel Material Matters More Than You Think

The compressor wheel sits at the heart of turbocharger performance. Its primary job is to compress external air and push it under high pressure into the intake manifold. More pressure means a larger volume of air enters the combustion chamber, translating directly to more power from your engine. But here's what many enthusiasts overlook: the material and manufacturing method of this critical component determines how well it handles the brutal operating environment inside your turbo.

When you're building for serious power—whether for street performance or racing applications—understanding the cast vs forged wheels debate becomes essential. These wheels experience rapid centrifugal force variations, especially during city driving when boost spools up and dumps repeatedly. This constant stress cycling can reveal weaknesses in inferior wheel construction faster than you might expect.

The Hidden Performance Factor in Turbo Selection

So what are forged wheels, and why do they command premium prices? Forged compressor wheels are machined from solid aluminum that has been compressed under extreme pressure, creating a denser, stronger material structure. Cast wheels, by contrast, are formed by pouring molten metal into molds—a process that can introduce microscopic faults and a less uniform grain structure.

The manufacturing method you choose doesn't just affect initial performance—it determines how your turbo responds to stress over thousands of boost cycles and whether it fails gracefully or catastrophically.

Understanding the Stakes of Wheel Material Choice

Here's where terminology confusion creates real problems. Many enthusiasts incorrectly use "billet" and "forged" interchangeably, but they describe different things entirely. According to Turbochargers Plus, billet wheels are technically MFS (Machined from Solid) components—precisely milled on 5-axis CNC machines from solid aluminum rods. The source material for that rod can be either cast or forged aluminum, dramatically affecting final performance characteristics.

This article cuts through forum speculation and marketing hype to deliver organized, actionable information. You'll learn exactly how each wheel type performs under stress, which applications suit each manufacturing method, and how to match your wheel choice to your specific power goals. Whether you're building a weekend track car or a reliable daily driver with moderate boost, making the right choice now prevents paying twice later—once for the wrong wheel, and again for the failure it causes.

How We Evaluated Compressor Wheel Performance

Before diving into specific recommendations, you need to understand how we assessed each compressor wheel type. Making an informed decision about the difference between forged and cast options requires a transparent evaluation framework—one that goes beyond marketing claims and examines real-world performance metrics.

Our Evaluation Criteria Explained

We consolidated technical specifications, real-world performance data, and application-specific requirements to create a comprehensive assessment methodology. Rather than relying on anecdotal forum posts or manufacturer marketing, our analysis focuses on measurable factors that directly impact your turbo's performance and longevity.

Here are the key criteria we used to evaluate each wheel type:

- Manufacturing Process Quality: How the production method affects material integrity, consistency, and potential defect rates

- Material Strength-to-Weight Ratio: The balance between structural durability and rotational mass—critical for spool characteristics

- Operational RPM Limits: Maximum safe rotational speeds before material fatigue or failure becomes a concern

- Temperature Tolerance: How well the wheel maintains structural integrity under sustained heat exposure

- Boost Pressure Capabilities: The relationship between wheel construction and maximum sustainable boost levels

- Failure Modes: How each wheel type typically fails and the associated safety implications

- Cost-Effectiveness: Value proposition considering initial investment versus performance gains and longevity

- Application Suitability: Matching wheel characteristics to specific use cases—street, track, or drag applications

How We Assessed Each Wheel Type

Understanding the forged wheels meaning starts with recognizing what happens during manufacturing. When you hear someone describe forged compressor wheels, they're referring to components created through a specific compression process that fundamentally alters the metal's internal structure.

According to SuperATV's technical analysis, the manufacturing process matters significantly—but perhaps not in the way you'd expect. Here's how each method works:

- Casting: Molten aluminum is poured into a mold and carefully cooled. This extra melting and cooling process disrupts the internal structure, or "grain," of the metal and creates opportunities to introduce voids and inclusions—all of which can lower strength. Modern casting minimizes these issues but rarely matches original material specifications perfectly.

- Forging: A forge presses solid metal into shape under extreme pressure. This process aligns the grain of the metal with the shape of the part, actually enhancing strength beyond the base material's specifications in certain stress directions.

- Billet Machining: A CNC mill carves the wheel from a single block of solid aluminum. The key advantage here is precision—engineers can create exactly what they design with perfect tolerances. However, the starting material (cast or forged bar stock) determines the final mechanical properties.

The Performance Metrics That Matter

When comparing aluminum alloys used in compressor wheels, two specifications deserve your attention: yield strength and tensile strength. Yield strength measures the force required to permanently deform the material—crucial for a component spinning at extreme speeds with tight gear mesh tolerances. Tensile strength indicates the maximum stress before complete failure.

For example, 6061-T6 aluminum commonly used in billet and forged applications shows higher yield strength and shear strength compared to A380 cast aluminum, even though the cast material has slightly higher ultimate tensile strength. This explains why forged and quality billet wheels maintain dimensional stability under stress while cast alternatives may experience micro-deformations that compound over time.

Our recommendations synthesize these technical specifications with documented real-world outcomes. We've examined how each wheel type performs across different power levels, boost pressures, and usage patterns to give you guidance that translates directly to your specific build goals.

Precision Forged Compressor Wheels for Maximum Performance

Now that you understand how we evaluate compressor wheel options, let's examine the premium tier: precision forged compressor wheels. When comparing forged wheels vs cast alternatives, forged technology consistently delivers the highest performance ceiling for serious turbo applications. But what does forged wheels mean in practical terms, and why do professional builders consistently choose this manufacturing method for high-stakes builds?

Manufacturing Excellence Through Compression

The aluminum wheel forging process transforms raw material into something fundamentally stronger than its original form. According to BorgWarner's technical documentation, forged milled wheel technology follows a precise sequence that maximizes material integrity:

- The process begins with a round piece of aluminum cut into desired lengths

- This material is either extruded or roll-formed into shape, refining the metal's grain structure

- During forging, the metal grain becomes finer, adding strength and fatigue resistance

- Once forged blanks are formed, they're machined into a predetermined shape

- Final milling produces much more consistent blade shapes vs casting—a highly repeatable process with less variation

- Every lot undergoes X-ray inspection to ensure the forging is defect-free

"Forging adds more steps to the manufacturing process, but improves the final turbo product durability," explains Seth Temple, Senior Application Engineer at BorgWarner. "It makes the material more dense and aligns the grain structure to improve durability. Forging also improves low cycle fatigue, which directly determines turbo life."

Strength Characteristics and Grain Structure Benefits

Imagine the difference between a bundle of randomly scattered sticks versus tightly aligned fibers running in the same direction. That's essentially what happens at the molecular level when you compare forged wheels against cast alternatives. The forging process physically aligns the metal's grain structure with the shape of the component, creating directional strength exactly where stress concentrations occur.

This grain alignment delivers several critical advantages for turbo compressor applications:

- Superior Fatigue Resistance: The aligned grain structure distributes stress more evenly across the wheel, preventing the micro-crack propagation that leads to catastrophic failures

- Higher Density: Compression during forging eliminates the porosity and voids that can occur in cast components, creating a more uniform material structure

- Enhanced Low-Cycle Fatigue Life: This metric directly determines how many boost cycles your turbo can handle before material degradation becomes a concern

- Improved Heat Dissipation: Denser material with fewer internal voids conducts heat more efficiently, helping maintain structural integrity under sustained high-temperature operation

The repeatable precision of forged milled wheels also means tighter manufacturing tolerances. Each blade matches the design specifications more consistently than cast alternatives, resulting in better aerodynamic performance and reduced vibration at extreme RPM levels.

Ideal Applications for Forged Compressor Wheels

Understanding what does forged wheels mean for your specific build helps determine whether the premium investment makes sense. Forged compressor wheels excel in applications where performance margins are thin and failure consequences are severe.

Pros

- Superior strength-to-weight ratio for faster spool and higher RPM capability

- Better fatigue resistance for extended service life under stress

- Higher operational RPM ceiling before material limits become a concern

- More consistent blade geometry for optimized aerodynamic performance

- Improved reliability in high-boost, high-heat applications

- X-ray inspection ensures defect-free components

Cons

- Higher initial cost compared to cast alternatives

- Longer lead times due to additional manufacturing steps

- Limited design flexibility—forging dies are expensive to modify

- May be overkill for moderate power street applications

Forged compressor wheels are best suited for:

- High-Boost Builds: Applications running 25+ psi where material stress is significant

- Track and Time Attack: Sustained high-RPM operation with repeated heat cycles

- Professional Racing: Where component failure means lost races and expensive engine damage

- High-Mileage Performance: Builds where long-term reliability justifies the upfront investment

For builders sourcing forged components, partnering with manufacturers who maintain IATF 16949 certification ensures the metallurgical integrity critical for high-performance compressor wheels. Companies like Shaoyi (Ningbo) Metal Technology offer precision hot forging solutions with in-house engineering capabilities that produce robust forged components meeting exact specifications—from rapid prototyping in as little as 10 days to high-volume mass production.

The bottom line? When your build demands maximum performance and you're pushing the limits of turbo technology, forged compressor wheels provide the material foundation to support your power goals. But what if your budget or application doesn't require this premium tier? That's where understanding cast aluminum options becomes essential.

Cast Aluminum Compressor Wheels for Budget Builds

Not every turbo build requires the premium price tag of forged components. Cast aluminum compressor wheels have served the automotive industry for decades, powering everything from economy car turbos to moderate performance builds. But are cast aluminum wheels strong enough for your application? And more importantly—are cast wheels bad, or just misunderstood? Let's examine exactly what casting offers and where its limitations become genuine concerns.

The Casting Process and Its Trade-offs

Casting creates compressor wheels by pouring molten aluminum into precision molds, then allowing the metal to cool and solidify into the desired shape. While this sounds straightforward, the physics of solidification introduce several material characteristics you need to understand.

According to the European Aluminium Association's technical documentation, aluminum shrinks during solidification because its density in the liquid state is 6.5% less than in the solid state. Cast parts generally solidify from the surface to the center, meaning any material deficiency appears internally if not properly compensated through careful mold design and temperature control.

This solidification behavior creates several inherent characteristics in cast wheels:

- Porosity Formation: Hydrogen dissolved in molten aluminum can form microscopic gas pockets as the metal solidifies. The amount and size of porosity depends on metallurgical factors like strontium content and cooling time.

- Less Uniform Grain Structure: Unlike forging's aligned grain flow, casting produces a more random internal structure. The mechanical properties vary with local freezing rates from location to location within a single casting.

- Potential for Inclusions: Oxides and other impurities can become trapped during the pouring process, creating stress concentration points.

- Secondary Dendrite Arm Spacing (DAS): This microstructural feature correlates directly with ductility and fatigue life—finer DAS generally indicates better mechanical properties.

The European Aluminium Association notes that "mechanical properties will vary with the local freezing rate" and that "exact mechanical performance data can be difficult to obtain in forms other than minimum and typical values." This variability is a fundamental characteristic of the casting process.

Where Cast Wheels Excel in Real-World Use

Despite these metallurgical trade-offs, cast aluminum wheels deliver genuine value for specific applications. The casting process offers advantages that make it the practical choice for many turbo builds:

- Cost Efficiency: Casting is the least costly manufacturing route for a wide range of parts, making cast wheels significantly more affordable than forged alternatives

- Design Flexibility: Complex three-dimensional shapes can be produced with intricate internal passages—powertrain components take maximum advantage of this feature

- Part Consolidation: A single casting can replace an assembly of parts, reducing tooling costs and ensuring close tolerances

- Faster Production: Fewer manufacturing steps translate to quicker availability and easier replacement

- Wide Availability: Cast wheels are standard equipment on most OEM turbos, meaning parts are readily accessible

For daily drivers running stock to moderate boost levels—typically under 15-18 psi—cast compressor wheels often provide perfectly adequate performance. The stress levels in these applications stay well within cast aluminum's material capabilities, and the cost savings can be redirected toward other build priorities.

Understanding Cast Wheel Limitations

Honest assessment requires acknowledging where cast wheels fall short. The same characteristics that make casting economical also impose real performance boundaries.

Pros

- Affordable pricing makes turbo upgrades accessible to budget-conscious builders

- Readily available as OEM replacement parts and aftermarket options

- Sufficient performance for stock to moderate boost applications

- Good design flexibility allows complex blade geometries

- Proven reliability in millions of production vehicles

Cons

- Heavier for equivalent strength compared to forged alternatives

- Lower RPM ceiling due to reduced fatigue resistance

- Potential for porosity-related failures under extreme stress

- Reduced fatigue life—the European Aluminium Association confirms that fatigue properties are "strongly impacted by porosity" and that "the largest pore size in a sample will limit the fatigue life"

- Variable mechanical properties between production runs

The failure modes of cast wheels differ significantly from forged components. According to DieselNet's turbocharger durability analysis, compressor wheel failures can occur through creep (gradual deformation under sustained stress) or fatigue cracking. Cast wheels are more susceptible to both failure modes because:

- Internal porosity creates stress concentration points where cracks initiate

- Random grain structure doesn't distribute load as effectively as aligned forged grain

- Higher weight increases centrifugal forces at equivalent RPM levels

When a cast wheel fails, it typically begins with micro-crack formation at porosity sites or inclusions, gradually propagating until catastrophic blade liberation occurs. This differs from forged wheels, which tend to show more gradual degradation with earlier warning signs.

Cast aluminum compressor wheels remain the sensible choice for:

- Daily Drivers: Reliable transportation with occasional spirited driving

- Mild Performance Builds: Modest power goals staying within OEM boost ranges

- Budget-Conscious Projects: When initial cost is the primary constraint

- Replacement Parts: Maintaining stock turbo systems at reasonable cost

The key is matching your wheel choice to your actual power goals and usage patterns. Cast wheels aren't inherently bad—they're simply optimized for different priorities than forged alternatives. But what about the middle ground? Billet-machined wheels offer another option worth understanding before you make your final decision.

Billet Machined Compressor Wheels Demystified

You've heard the term "billet" thrown around in performance circles—often in the same breath as "forged." But here's the critical distinction that separates informed builders from those who get burned: billet describes how the wheel is machined, not how the source material was formed. Understanding this difference is essential when choosing between forged or cast wheels for your turbo application.

Billet Machining Explained and Demystified

Picture a solid cylindrical bar of aluminum clamped into a sophisticated CNC machine. Over several hours, precision cutting tools carve away material layer by layer until a finished compressor wheel emerges. That's billet machining in its simplest form—subtractive manufacturing that creates components from solid metal stock rather than molding or pressing them into shape.

According to Garrett's turbo technology documentation, "Most billet compressor wheels on the market start out with this, a round piece of billet. This part is either extruded or roll formed into shape." The machining happens on 5-axis CNC machines—equipment with five degrees of freedom in cutting tool movement. This capability is critical for producing the complex underhangs and intricate blade geometries found in modern compressor wheel designs.

Here's where the forged cast confusion gets cleared up: the billet bar itself can originate from different manufacturing processes. Some manufacturers start with extruded aluminum rod stock, while others—like Garrett with their GTX line—begin with forged near-net-shape blanks. The source material fundamentally changes the finished wheel's mechanical properties, even though both qualify as "billet" wheels.

So what is the difference between forged wheels and alloy wheels in the billet context? All aluminum compressor wheels are technically alloy wheels—aluminum mixed with other elements for improved properties. The distinction lies in how that alloy was processed before machining. A billet wheel cut from forged stock inherits the superior grain structure and density of forging, while one machined from extruded or cast bar stock carries the limitations of those processes.

CNC Precision Meets Turbo Performance

The real advantage of billet machining isn't the source material—it's the manufacturing precision. CNC machining offers capabilities that casting simply cannot match:

- Exceptional Dimensional Accuracy: Tolerances measured in thousandths of an inch ensure each blade matches the engineering design exactly

- Design Flexibility: Engineers can optimize blade profiles, hub geometries, and inlet configurations without the constraints of mold-based production

- Repeatable Quality: Every wheel from a CNC program matches the previous one—no batch-to-batch variation from mold wear or pouring inconsistencies

- Superior Surface Finish: Machined surfaces reduce turbulence and improve aerodynamic efficiency compared to as-cast finishes

- Rapid Prototyping: New designs can be tested without expensive tooling investments

Garrett's documentation emphasizes that their billet wheels are "highly engineered pieces that can give an edge for both performance, user safety and long term durability." The precision machining allows thinner blade profiles and optimized aerodynamics that would be difficult or impossible to achieve through casting alone.

For turbo applications, this precision translates directly to performance. Consistent blade geometry means predictable airflow characteristics, reduced vibration at high RPM, and improved compressor efficiency. When you're pushing the limits of boost pressure, these small advantages compound into measurable power gains.

When Billet Makes Sense for Your Application

The billet manufacturing approach offers a middle path between forging compressor wheels from scratch and accepting cast component limitations. But understanding when this approach delivers genuine value requires honest assessment of both advantages and trade-offs.

Pros

- Precise tolerances enable optimized aerodynamic designs

- Custom blade configurations for specific turbo applications

- Excellent surface finish reduces aerodynamic losses

- Highly repeatable manufacturing process with consistent quality

- Faster design iteration compared to forging or casting tooling changes

- Can achieve lighter weight through optimized material placement

Cons

- Significant material waste during machining process—much of the original billet becomes chips

- Cost varies dramatically based on source material quality

- Requires high-quality bar stock for best mechanical results

- Not all "billet" wheels are equal—source material determines final properties

- Machining time increases production cost compared to casting

The critical question when evaluating any billet compressor wheel is straightforward: what was the source material? A billet wheel machined from forged aluminum bar stock combines the metallurgical benefits of forging with CNC precision. Conversely, a billet wheel from extruded stock—while still superior to casting—won't match the fatigue resistance and grain structure of truly forged components.

When shopping for billet wheels, ask manufacturers specifically about their bar stock source. Quality suppliers will readily provide this information. If a vendor can't or won't explain their source material, consider that a warning sign.

Billet machining has earned its popularity in performance applications because it delivers precision that casting cannot match while offering more design flexibility than traditional forging. For builders who prioritize aerodynamic optimization and consistent quality but aren't necessarily pushing maximum boost limits, billet wheels from quality source material represent an excellent choice.

But the compressor wheel landscape continues evolving. Flow-formed and hybrid manufacturing approaches now offer additional options that blend multiple production methods—each with its own performance trade-offs worth understanding.

Flow Formed and Hybrid Wheel Technologies

What if you could get closer to forged performance without paying the full forged premium? That's exactly the promise of flow-formed and hybrid manufacturing approaches—production methods that have gained significant traction as middle-ground options for performance-oriented builders. These technologies bridge the gap between cast alloy wheels and fully forged components, offering improved properties at more accessible price points.

Flow Forming Technology in Compressor Wheels

Flow forming represents a clever engineering solution that starts with casting but doesn't stop there. The process begins with a cast preform—essentially a basic wheel shape created through traditional casting wheels methods. But instead of calling that the finished product, manufacturers take an additional step that fundamentally changes the material's characteristics.

In wheel manufacturing, flow forming typically involves both compressing and stretching the cast metal, which changes its composition and increases tensile strength. During this mechanical working process, the wheel spins at high speed while pressure rollers progressively shape and thin the material—particularly in the barrel section where stress concentrations are highest.

Here's what happens at the material level during flow forming:

- The mechanical pressure compresses the cast aluminum, reducing internal porosity

- Stretching action aligns the grain structure in the direction of the applied force

- The combination produces a denser, stronger material than the original casting

- Final wall thickness can be reduced while maintaining—or even improving—strength

The result? AST reports that flow-formed wheels are typically 15% to 25% lighter than equivalent cast wheels while delivering increased shock resistance and higher load capacity. For turbo applications, this translates to reduced rotational mass for faster spool characteristics and improved fatigue life compared to standard wheels cast through traditional methods alone.

Hybrid Manufacturing Approaches

The term "hybrid" in wheel manufacturing describes various combinations of production techniques designed to capture benefits from multiple processes. Some manufacturers use cast preforms that undergo flow forming, while others apply different mechanical working methods to enhance base material properties.

According to Steinkjer Bilformidling's wheel technology overview, hybrid-forged wheels offer "close to the strength of fully forged wheels, but at a lower price" with benefits including lightweight construction for better handling and high wear resistance.

Common hybrid approaches include:

- Cast + Flow Formed: The most common hybrid method, starting with cast preforms then mechanically working critical sections

- Cast Core + Forged Elements: Some designs combine a cast center section with forged outer components

- Partial Forging: Selective forging of high-stress areas while leaving less critical sections in cast form

The terminology can get confusing quickly. You'll encounter marketing names like "Rotary Forged," "Flow Forged," and "Spun Forged"—all of which typically describe flow-formed wheels rather than truly forged components. As AST notes, "any wheel that starts as a cast wheel, and is then manipulated is not a forged wheel." These naming conventions often represent marketing differentiation rather than fundamental process differences.

The Best of Both Worlds?

Flow-formed and hybrid technologies genuinely deliver improved performance over standard casting, but honest assessment requires acknowledging their limitations compared to true forging.

Pros

- Cost positioned between cast and forged—making performance improvements accessible to more builders

- Significantly improved material properties over pure casting through mechanical working

- Good strength-to-weight ratio with 15-25% weight reduction versus cast alternatives

- Increased tensile strength and shock resistance from grain refinement

- Better fatigue characteristics than standard cast alloy wheels

- Wider availability than fully custom forged options

Cons

- Not as strong as true forging—the original cast structure still influences final properties

- Limited availability compared to standard cast options

- Quality varies significantly by manufacturer—process parameters dramatically affect outcomes

- Marketing terminology can obscure actual manufacturing methods

- Some "hybrid" claims may represent minimal processing beyond basic casting

When evaluating flow-formed or hybrid options for your turbo build, ask manufacturers these specific questions:

- What is your exact flow forming process? Pressure levels, temperatures, and number of passes all affect final properties.

- What percentage weight reduction do you achieve versus your cast baseline? This indicates how much mechanical working actually occurs.

- Do you have independent testing data for tensile strength and fatigue life? Reputable manufacturers will have this documentation.

- Which sections of the wheel receive mechanical working? Some processes only treat the barrel, leaving the center hub in as-cast condition.

- What quality control measures verify consistent flow forming? Batch-to-batch consistency matters for reliability.

Flow-formed wheels from reputable turbo component manufacturers offer genuine performance improvements for enthusiasts who want better-than-cast properties without the full forged investment. These companies have refined their processes over decades and stand behind their products with documented performance data.

For turbo applications where you're running moderate-to-aggressive boost but aren't quite pushing the limits that demand fully forged components, quality flow-formed options deserve serious consideration. They represent the practical middle ground many builders need—better performance than casting alone, at prices that leave budget for other build priorities. With the manufacturing options now clearly defined, the next step is matching these wheel types to specific power goals and applications.

Complete Performance Comparison by Application

You've now explored each manufacturing method individually—but how do these options actually stack up against each other when the rubber meets the road? Understanding the difference between cast and forged compressor wheels requires seeing them side by side, with clear performance boundaries and application guidelines. This comparison framework gives you the practical decision criteria needed to match your wheel choice to your specific build goals.

RPM and Boost Pressure Thresholds by Wheel Type

Every compressor wheel has operational limits—exceed them, and you're gambling with expensive engine damage. According to DieselNet's turbocharger durability research, turbocharger speed and temperature are among the primary parameters that must be limited to avoid failures including cracked compressor wheels and fatigue-related blade loss.

When comparing forged rims vs cast alternatives in turbo applications, the differences become most apparent at the extreme ends of the performance spectrum. Here's how each wheel type typically performs across key metrics:

| Manufacturing Method | Typical RPM Limit | Boost Tolerance | Weight Characteristics | Cost Range | Best Application |

|---|---|---|---|---|---|

| Forged | 150,000+ RPM | 30+ psi sustainable | Lightest for equivalent strength | $$$ - Premium | Track racing, high-boost builds, professional applications |

| Billet (from forged stock) | 140,000-150,000 RPM | 25-35 psi | Light with optimized material placement | $$ - $$$ | Custom builds, precision aerodynamics, performance street |

| Flow Formed | 120,000-140,000 RPM | 20-28 psi | Lighter than standard cast | $$ - Moderate | Enthusiast builds, moderate performance, value-focused upgrades |

| Billet (from extruded stock) | 110,000-130,000 RPM | 18-25 psi | Moderate weight | $$ - Moderate | Street performance, aesthetic customization |

| Cast Aluminum | 100,000-120,000 RPM | 15-20 psi | Heaviest for equivalent strength | $ - Budget | Daily drivers, mild builds, OEM replacement |

These figures represent general guidelines rather than absolute limits. Actual performance boundaries depend on specific alloy grades, manufacturing quality, and operating conditions. A precision-manufactured cast wheel from a reputable supplier may outperform a poorly-made "forged" wheel from a questionable source.

Matching Wheel Choice to Your Power Goals

So are forged wheels lighter and automatically the right choice for every application? Not necessarily. The key is matching wheel capabilities to your actual requirements—not buying more performance than you'll ever use, but also not undersizing for your power goals.

Consider this decision framework based on power targets and intended use:

Under 350 Horsepower (Stock to Mild Builds)

- Recommended: Cast aluminum or entry-level billet

- Reasoning: Stress levels stay well within cast material limits

- Priority: Cost savings redirect to supporting mods like intercoolers or fuel systems

- Risk level: Low—millions of OEM turbos run cast wheels reliably at these power levels

350-500 Horsepower (Moderate Performance)

- Recommended: Flow formed or quality billet from forged stock

- Reasoning: You're entering territory where cast wheel limitations start becoming relevant

- Priority: Balance between reliability margin and budget efficiency

- Risk level: Moderate—proper supporting mods and tuning become critical

500-700 Horsepower (Serious Performance)

- Recommended: Forged or premium billet from forged stock

- Reasoning: High boost pressures and RPM levels demand superior fatigue resistance

- Priority: Reliability and safety—turbo failure at these power levels causes expensive damage

- Risk level: High if using inadequate components

700+ Horsepower (Professional/Racing)

- Recommended: Premium forged only

- Reasoning: No margin for material compromise at extreme stress levels

- Priority: Maximum performance ceiling and proven durability

- Risk level: Catastrophic failure potential with substandard components

When comparing cast wheels vs forged for your specific situation, also factor in intended use patterns. A 400-horsepower street car driven occasionally might run cast wheels indefinitely, while the same power level on a track car experiencing repeated heat cycles and sustained high-RPM operation benefits significantly from forged construction.

Temperature and Stress Considerations

According to DieselNet's durability analysis, compressor wheel failures occur through several mechanisms: thermal cracking, creep (gradual deformation under sustained stress), and fatigue of rotating parts. Understanding these failure modes helps explain why cast aluminum vs forged aluminum choices matter differently depending on operating conditions.

The comparison between manufacturing methods becomes most significant under these stress factors:

- Compressor Outlet Temperature: Higher boost pressures generate more heat during compression. Forged wheels' denser grain structure dissipates heat more efficiently and resists creep deformation better than cast alternatives.

- Low-Cycle Fatigue: Every boost-on, boost-off cycle stresses the wheel material. City driving with frequent acceleration creates more fatigue cycles than highway cruising at steady state. Forged construction delivers superior low-cycle fatigue life—directly determining how many boost cycles your turbo handles before degradation.

- Centrifugal Loading: At 150,000 RPM, centrifugal forces become enormous. Lighter wheels experience proportionally less stress at equivalent speeds—one reason why the "are forged wheels lighter" question matters for high-RPM applications.

- Thermal Cycling: Track use involves repeated heating and cooling cycles that stress material interfaces. Cast wheels' internal porosity can propagate micro-cracks during these thermal excursions.

Busting the Myths: Balanced Assessment

Forum debates about compressor wheel materials often devolve into extreme positions—either dismissing cast wheels as guaranteed failures or treating forged options as unnecessarily expensive overkill. Reality sits somewhere in between.

Myth #1: Cast wheels always fail at high boost.

Reality: Many OEM turbos run cast wheels at 20+ psi for hundreds of thousands of miles. Quality matters more than manufacturing method alone. A well-engineered cast wheel from a reputable manufacturer often outperforms a cheap "forged" wheel of questionable origin.

Myth #2: Forged wheels are indestructible.

Reality: Forging improves material properties significantly, but no component is failure-proof. Improper boost control, foreign object damage, or oil starvation will destroy even premium forged wheels. The forging process provides superior fatigue resistance—not invincibility.

Myth #3: Billet always equals forged quality.

Reality: "Billet" describes machining method, not source material. A billet wheel machined from extruded aluminum bar stock won't match one machined from forged blanks, regardless of CNC precision.

Myth #4: Cast wheels are only for "budget builds."

Reality: Cast compressor wheels power most production turbocharged vehicles worldwide. They're engineered for specific applications and perform reliably within their design parameters. The question isn't whether cast wheels work—it's whether they're appropriate for your specific power and use requirements.

The smartest wheel choice isn't always the most expensive one—it's the one that matches your actual power goals, usage patterns, and reliability requirements without leaving performance margin on the table or money in your wallet that could fund other build priorities.

With these performance comparisons and application guidelines established, the final step is translating this knowledge into concrete recommendations for your specific turbo build situation.

Final Recommendations for Your Turbo Build

You've explored the manufacturing processes, compared material properties, and examined real-world performance boundaries. Now it's time to translate all that knowledge into actionable decisions for your specific situation. Whether you're building a weekend track weapon or a reliable daily driver with some extra punch, the right compressor wheel choice comes down to matching capabilities to your actual requirements.

Your Decision Framework Simplified

Choosing between cast or forged wheels doesn't need to feel overwhelming. Think of it as answering three fundamental questions: What are your power goals? How will you use the vehicle? And what happens if the turbo fails?

Here's your ranked recommendation list by application priority:

- Professional Racing and 700+ HP Builds: Forged compressor wheels—no compromise. At these stress levels, material fatigue resistance isn't optional. The investment in premium forged components protects against catastrophic failures that could sideline your race program or destroy an expensive engine.

- Track-Focused Performance (500-700 HP): Forged or premium billet machined from forged stock. Repeated heat cycles and sustained high-RPM operation demand superior grain structure and fatigue life. What is a forged wheel's advantage here? It's the difference between finishing events and trailer rides home.

- Aggressive Street Performance (350-500 HP): Quality billet from forged stock or flow-formed alternatives. You're pushing beyond OEM stress levels, so cast limitations become relevant—but you're not necessarily at the extreme end requiring premium forged construction.

- Mild Performance and Daily Driving (Under 350 HP): Cast aluminum or entry-level billet works reliably. Millions of production vehicles prove cast wheels handle these stress levels without issue. Save your budget for supporting modifications.

Matching Your Build Goals to the Right Wheel

Still uncertain? Walk through this decision tree based on your priorities:

If your primary concern is maximum performance and reliability: Choose forged. The superior fatigue resistance, higher RPM ceiling, and proven durability under extreme conditions justify the premium investment. For builds where a turbo failure means expensive engine damage or lost race results, forged wheels provide the material foundation your power goals demand.

If you're budget-conscious with moderate power targets: Cast may suffice—but be honest about your actual usage. A 400-horsepower daily driver rarely operated at redline differs fundamentally from the same power level on a track car experiencing repeated heat cycles. What are forged rims offering that cast alternatives cannot? It's the margin of safety under sustained stress that matters most when you're pushing limits.

If you want precision aerodynamics and custom optimization: Consider quality billet machined from forged stock. You'll get CNC precision for optimized blade geometries combined with the metallurgical benefits of forged source material. Just verify your supplier's actual bar stock origin—not all "billet" wheels deliver equivalent performance.

Many enthusiasts ask: are forged wheels aluminium? Yes—both forged and cast compressor wheels are aluminum alloys. The critical difference lies in how that aluminum was processed. When comparing forged wheels vs alloy wheels in general terms, remember that "alloy" simply means aluminum mixed with other elements for improved properties. Forging takes that alloy and compresses it under extreme pressure, fundamentally improving its grain structure and mechanical characteristics.

Investment Considerations for Long-Term Performance

Consider the true cost of your compressor wheel decision. A premium forged wheel might cost two or three times more than a cast alternative—but what's the replacement cost if an undersized wheel fails at 25 psi boost while you're making a pass?

The value proposition breaks down like this:

- Turbo rebuild cost: Often $500-$1,500+ depending on turbo size and configuration

- Engine damage from catastrophic failure: Potentially $5,000-$15,000+ for serious builds

- Lost track time or race results: Difficult to quantify, but significant for competitive applications

- Forged wheel premium: Typically $200-$600 additional over cast alternatives

When you frame the decision this way, the forged premium looks less like an expense and more like insurance—particularly for builds where you've already invested significant money in engine, fuel system, and supporting modifications.

The smartest compressor wheel investment matches your actual power goals and usage patterns. Spending extra on forged construction you'll never stress wastes budget, but undersizing for your application creates failure risk that costs far more than the initial savings.

Regardless of which wheel type you select, component quality depends heavily on manufacturing standards and quality control. Partnering with certified manufacturers ensures the metallurgical integrity critical for reliable turbo performance. For builders sourcing forged components, look for suppliers with IATF 16949 certification—the automotive industry's quality management standard.

Companies like Shaoyi (Ningbo) Metal Technology demonstrate how precision hot forging solutions combine rigorous quality control with practical manufacturing capabilities. Their approach includes rapid prototyping in as little as 10 days for development projects, plus high-volume mass production capacity when you're ready to scale. Located near Ningbo Port, they offer efficient global delivery for international sourcing—a practical consideration when you need components that meet exact specifications without extended lead times.

The bottom line? Your compressor wheel choice defines the ceiling of your turbo's performance and reliability. Match the manufacturing method to your power goals, verify component quality through reputable suppliers, and invest appropriately based on the consequences of failure. Get this decision right once, and you'll never pay twice.

Frequently Asked Questions About Turbo Compressor Wheels

1. What is the difference between billet and cast turbo compressor wheels?

Billet wheels are CNC-machined from solid aluminum bar stock, offering exceptional precision and consistent blade geometry. Cast wheels are formed by pouring molten aluminum into molds, which is more affordable but can introduce porosity and less uniform grain structure. The key distinction is that billet describes the machining method, not material origin—billet wheels can be machined from either cast or forged bar stock, affecting final strength and fatigue resistance.

2. Can you feel a difference with forged compressor wheels?

Yes, forged compressor wheels deliver noticeable performance improvements including faster turbo spool due to reduced rotational mass, improved throttle response, and more consistent boost delivery. The denser grain structure provides superior fatigue resistance for extended service life. These benefits become increasingly apparent in high-boost applications above 25 psi where material stress levels exceed cast wheel capabilities.

3. What is better, forged or flow-formed wheels?

Forged wheels offer superior strength and fatigue resistance for demanding applications, while flow-formed wheels provide a cost-effective middle ground with 15-25% weight reduction over cast alternatives. Choose forged for track racing, professional applications, and builds exceeding 500 horsepower. Flow-formed suits enthusiast builds with moderate power goals where budget efficiency matters alongside performance improvements.

4. Are cast aluminum compressor wheels strong enough for performance builds?

Cast aluminum wheels perform reliably for stock to moderate boost applications under 15-18 psi. Millions of OEM turbos use cast wheels successfully. However, they have lower RPM ceilings, reduced fatigue life, and potential porosity-related failures under extreme stress. For builds exceeding 350 horsepower or involving track use with repeated heat cycles, upgrading to forged or flow-formed options provides better reliability margins.

5. How do I choose the right compressor wheel for my turbo build?

Match wheel type to your power goals and usage patterns. Under 350 HP daily drivers work fine with cast wheels. Moderate performance builds (350-500 HP) benefit from flow-formed or quality billet options. Serious performance applications (500-700 HP) demand forged or premium billet from forged stock. Professional racing and 700+ HP builds require premium forged construction for maximum reliability under extreme stress conditions.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —