Custom Forged Wheel Spoke Designs: From Concept To Curb Appeal

Understanding Custom Forged Wheel Spoke Designs

When you're browsing aftermarket wheels, you'll notice something immediately: most retailers showcase stunning product photos but rarely explain why one spoke design outperforms another. Custom forged wheel spoke designs represent far more than visual statements—they're precision-engineered components where every angle, curve, and dimension directly impacts how your vehicle handles, accelerates, and stops.

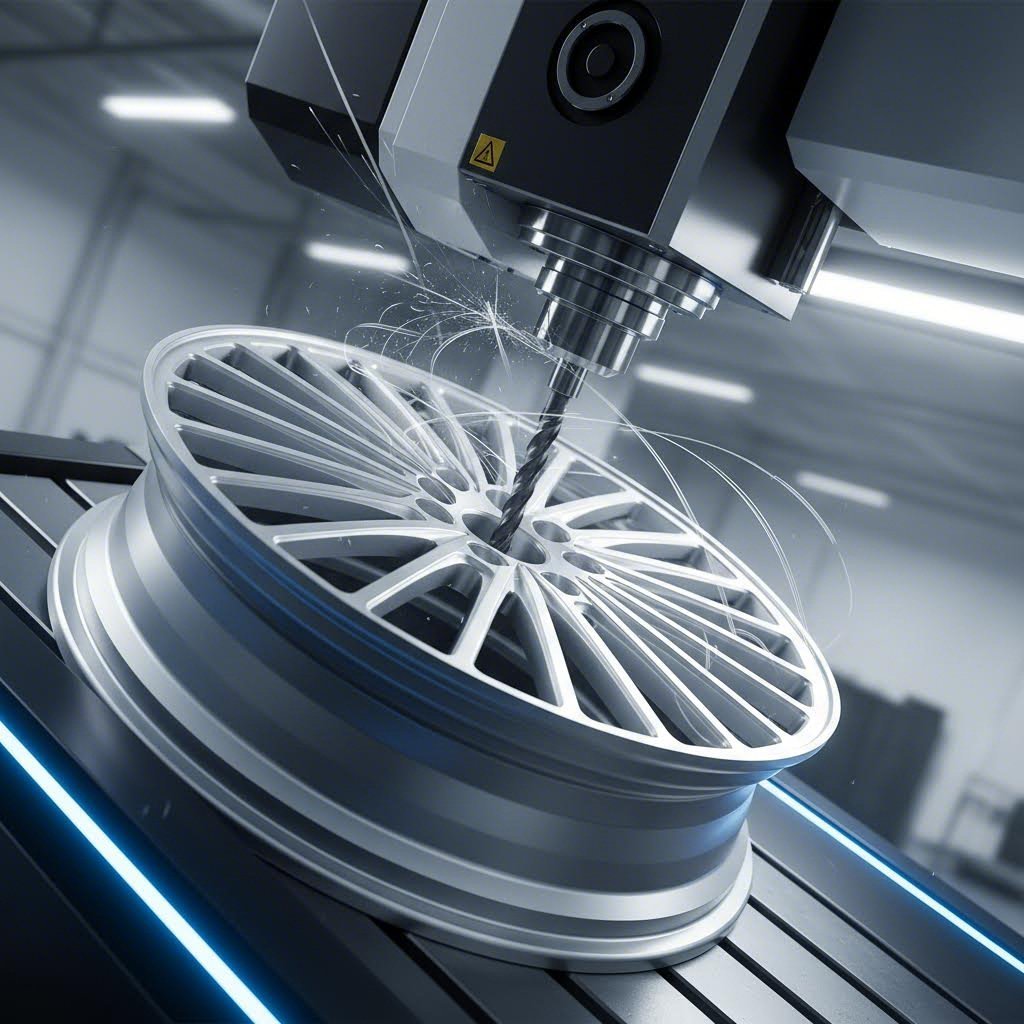

Unlike cast alternatives, forged wheels begin as a solid block of aluminum or steel that's compressed under immense pressure, aligning the metal's grain structure for superior strength. This manufacturing difference unlocks design possibilities that simply aren't achievable through casting methods.

The forging process allows for precise shaping and customization that manufacturers can tailor to meet specific performance requirements—including thickness, offset, and spoke configurations that cast manufacturing cannot reliably achieve.

What Makes Forged Spoke Designs Different

Picture a classic 5 spoke wheel. That seemingly simple design actually represents careful engineering calculations balancing weight reduction against structural demands. According to research published in AIP Advances, spoke pattern selection directly influences von Mises stress distribution, maximum deformation, and fatigue life—factors that determine whether your wheels perform flawlessly for years or develop stress cracks prematurely.

Five spoke wheels remain popular because they strike an excellent balance between aesthetic appeal and functional performance. The spoke 5 configuration provides adequate brake clearance while maintaining structural rigidity across the wheel face. However, custom forged options extend far beyond this classic arrangement, offering everything from intricate multi-spoke patterns to aggressive concave profiles.

The Engineering Behind Every Spoke

Here's what many enthusiasts overlook: spoke geometry affects three critical performance areas simultaneously. First, weight distribution across the wheel face determines rotational inertia—lighter wheels with optimized spoke placement accelerate and decelerate more responsively. Second, the angle and thickness of each spoke influence how forces transfer from the tire contact patch through the wheel to your suspension components. Third, spoke openings affect brake cooling efficiency and overall aerodynamic behavior.

The forging process creates a denser, stronger wheel structure that exhibits exceptional resistance to impact and fatigue compared to cast alternatives. This inherent strength means engineers can design thinner, lighter spokes without sacrificing durability—achieving performance characteristics impossible with conventional casting techniques. Whether you're prioritizing track-day performance or daily driving refinement, understanding these engineering principles helps you select spoke designs that genuinely enhance your vehicle rather than simply changing its appearance.

Spoke Design Types and Their Characteristics

Now that you understand why forged spoke engineering matters, let's explore the specific design types available. Walk into any performance shop, and you'll encounter terms like "split-spoke," "mesh," or "concave"—but what do these actually mean for your driving experience? Understanding each configuration helps you make informed decisions rather than simply picking what looks appealing in photos.

Here's a comprehensive breakdown of the most popular spoke design types and what makes each unique:

- Split-Spoke: Features spokes that branch into two or more segments near the outer rim, creating an elegant yet lightweight appearance. This design offers excellent visual appeal while maintaining structural integrity through its branching pattern.

- Multi-Spoke: Incorporates numerous thin spokes arranged around the wheel face, distributing load across more contact points. Multi spoke rims typically range from 10 to 20 or more individual spokes, providing a refined look popular in luxury applications.

- Mesh: Presents an intricate pattern of interconnected spokes resembling a woven net. These designs may feature interconnected squares, diamonds, or custom patterns that deliver both sporty aesthetics and rigid structural support.

- Y-Spoke: Shaped like the letter "Y," these spokes split from the hub into two branches before reaching the rim. This configuration balances aggressive styling with efficient weight distribution.

- Twisted Spoke: Features spokes that rotate or spiral from hub to rim, creating dynamic visual movement. The twisted pattern adds dimensional depth while maintaining spoke car wheels' structural requirements.

Split-Spoke and Multi-Spoke Configurations

When examining split-spoke designs, you'll notice the spoke branches create additional visual complexity without significantly increasing weight. The branching typically occurs at approximately two-thirds of the distance from hub to rim, allowing the primary spoke structure to handle the majority of stress loads before distributing forces across the split sections.

Multi spoke rims work on a different principle entirely. By increasing the number of individual spokes, manufacturers can reduce each spoke's thickness while maintaining—or even improving—overall wheel strength. This approach proves particularly effective for black 5 spoke wheels and their multi-spoke variants, where the contrast between dark finishes and intricate spoke patterns creates striking visual depth.

Spoke count directly influences three key factors:

- Weight: Fewer, thicker spokes generally weigh more than numerous thin spokes engineered for equivalent strength.

- Strength: Higher spoke counts distribute forces more evenly, reducing stress concentration at individual spoke roots.

- Brake Clearance: Fewer spokes provide larger openings between them, accommodating oversized brake calipers more easily.

Concave and Deep-Dish Spoke Profiles

Beyond spoke arrangement, the profile or depth of the wheel face dramatically changes both appearance and performance characteristics. Two terms you'll encounter frequently—concave and deep-dish—describe fundamentally different design approaches.

Concave wheels feature a center that recesses inward from the outer rim edge. According to Velgen Wheels, "the spokes of concave wheels often curve inward, adding depth and dimension to the overall design." When comparing concave up vs concave down orientations, the distinction refers to whether the spoke curvature creates a bowl-like depression (concave down) or an inverted dome appearance (concave up) when viewed from the side.

Deep-dish wheels take a different approach. Here, the hub sits further back into the wheel structure, creating a pronounced lip between the spoke face and the outer rim edge. This design gives 5 spoke deep dish wheels their aggressive, muscular stance. The deeper the dish, the more dramatic the visual impact—though this also affects offset and fitment considerations.

Understanding key terminology helps you communicate precisely with manufacturers:

- Spoke Width: The thickness of each spoke measured across its face, affecting both weight and strength.

- Spoke Angle: The degree at which spokes extend from hub to rim—radial designs go straight out, while angled designs create rotational visual effects.

- Spoke Depth: How far the spoke surface sits relative to the rim's outer edge, determining concave or convex profiles.

- Center Cap Integration: How the spoke design accommodates the central cap, ranging from flush-mount designs to raised or floating center sections.

For enthusiasts seeking the classic look of 5 spoke rims with modern performance, many manufacturers now offer concave variants that combine the timeless five-spoke aesthetic with contemporary depth profiles. These designs prove especially popular on sports cars and performance sedans where owners want recognizable styling enhanced by aggressive stance.

With these design types and terminology clarified, you're better equipped to understand how wheel construction methods—monoblock, 2-piece, and 3-piece—further expand or limit your spoke design options.

How Wheel Construction Affects Spoke Design Options

You've explored spoke types and profiles—but here's a question many enthusiasts overlook: how does the wheel's construction method determine which spoke designs are even possible? The relationship between spoke geometry and construction type is fundamental. Choose monoblock, and you get one set of possibilities. Opt for multi-piece construction, and entirely different spoke configurations become available.

Let's break down how each construction method shapes your custom forged wheel spoke design options.

Monoblock Forged Construction Benefits

Monoblock wheels are machined from a single piece of forged aluminum—no bolts, no seams, no separate components. According to Triton Motorsports, this manufacturing approach "yields unparalleled solidity, fortifying your vehicle with not just durability but also superior reliability."

What does this mean for spoke design? Single-piece construction creates seamless transitions between spokes, hub, and barrel. The grain structure flows continuously throughout the entire wheel, allowing for:

- Thinner spoke profiles: The continuous forged structure provides strength without requiring bulky spoke dimensions.

- Aggressive concave depths: Without joints to compromise structural integrity, manufacturers can push concave profiles deeper.

- Lightweight optimization: Material can be precisely removed from low-stress areas while maintaining strength where it matters.

Forgiato wheels and similar premium brands leverage monoblock construction to achieve designs where spokes appear impossibly thin yet maintain exceptional load-bearing capability. This construction type excels when you want a clean, unified aesthetic with no visible hardware between components.

However, monoblock designs come with trade-offs. Customization happens during manufacturing—once the wheel is forged and machined, you cannot change the width, offset, or barrel depth. If you're seeking something comparable to what you might find in an rvrn wheels review, monoblock options deliver excellent quality but within fixed parameters.

Multi-Piece Wheel Spoke Integration

Two-piece and three-piece construction take a fundamentally different approach. Rather than carving everything from one billet, these designs combine separately forged components—typically a center (containing the spokes), barrel sections, and sometimes a rear shell.

As Variant Wheels explains, multi-piece forged wheels offer "more flexibility in widths, offsets, finishes, and spoke profiles." This flexibility stems from how the components bolt together:

- Two-piece construction: Combines a forged center with a spun or forged barrel, joined using precision steel or titanium hardware.

- Three-piece construction: Separates the wheel into forged center, inner barrel, and outer lip—allowing maximum customization of each dimension.

For spoke design, multi-piece construction unlocks possibilities that monoblock simply cannot match. The Forged One Competition FF10 and similar performance-focused wheels often use multi-piece architecture to achieve specific spoke geometries optimized for racing applications. You can pair an aggressive split-spoke center with various barrel widths, dial in precise offsets, and even swap components later if your needs change.

Forgiato rims frequently utilize multi-piece construction for their most elaborate designs, where intricate spoke patterns benefit from the manufacturing flexibility of separate component production. Forged truck wheels also leverage this approach, combining heavy-duty centers with appropriately sized barrels for larger vehicle applications.

| Construction Type | Spoke Design Flexibility | Weight Characteristics | Customization Options | Typical Applications |

|---|---|---|---|---|

| Monoblock Forged | Fixed once manufactured; seamless spoke-to-barrel transitions | Lightest option due to single-piece efficiency | Finish and color only; dimensions set at production | Track cars, sports cars, daily performance drivers |

| 2-Piece Forged | Moderate flexibility; center design independent of barrel | Slightly heavier due to hardware; still lightweight overall | Width and offset adjustable within component ranges | Performance vehicles, stance builds, brake clearance needs |

| 3-Piece Forged | Maximum flexibility; spoke center fully independent | Heaviest multi-piece option; hardware adds weight | Fully customizable widths, offsets, lip depths, finishes | Show cars, luxury builds, custom fitment requirements |

Why does forging specifically enable certain spoke features that casting cannot? The answer lies in material density and grain alignment. When aluminum is forged under extreme pressure, the metal's grain structure compresses and aligns directionally—similar to how wood grain provides strength along its natural lines. This aligned structure allows forged spokes to be machined thinner while maintaining higher tensile strength than cast equivalents of greater thickness.

Cast wheels, by contrast, form when molten metal fills a mold and solidifies. The resulting grain structure is random rather than aligned, creating potential weak points throughout the material. Manufacturers must compensate with thicker spoke dimensions, limiting how aggressive or refined the spoke design can become.

Forgiato wheels and other premium forged brands exploit this material advantage to create spoke profiles that would crack or bend if attempted in cast construction. The sharper angles, deeper concavity, and refined spoke edges you see on high-end forged wheels simply aren't replicable through casting—the material cannot support those geometries under real-world stress.

Understanding these construction differences prepares you to evaluate how spoke design choices interact with another critical factor: performance. Next, we'll examine how spoke geometry directly influences aerodynamics, brake cooling, and vehicle fitment.

Performance Impact of Spoke Design Geometry

You've selected your preferred spoke configuration and construction type—but here's what separates informed enthusiasts from casual buyers: understanding how spoke geometry directly affects your vehicle's performance. Beyond aesthetics, those carefully designed openings between spokes determine how effectively your brakes cool, how air flows around your wheels, and whether your upgraded calipers will actually fit.

Let's explore the engineering principles that connect spoke design to real-world performance outcomes.

Spoke Geometry and Brake Cooling Efficiency

Imagine pushing your vehicle hard through a mountain pass or completing multiple track sessions. Your brakes generate tremendous heat—and that heat needs somewhere to go. According to automotive engineering analysis, "spoke configuration is a key determinant of brake cooling," with open or mesh-style spoke patterns known for promoting better ventilation and ensuring brakes operate within optimal temperature ranges.

How does this work in practice? As your wheel rotates, air enters through the spoke openings and flows across your brake rotors and calipers. Larger, more open spoke configurations allow greater airflow volume, while intricate multi-spoke patterns may restrict air movement despite their visual appeal. The relationship is straightforward: more open space between spokes equals more cooling capacity.

Several spoke design factors influence brake cooling efficiency:

- Spoke Opening Size: Larger gaps between spokes permit more air to reach brake components, dissipating heat faster during aggressive driving.

- Spoke Angle: Angled or curved spokes can act like fan blades, actively drawing air across the rotor surface as the wheel spins.

- Barrel Depth: Deeper dish designs may trap hot air within the wheel barrel, reducing cooling efficiency compared to flatter profiles.

- Material Properties: Lightweight aluminum alloys used in forged wheels reduce unsprung weight, allowing suspension components to respond more efficiently and contributing to overall brake system performance.

For vehicles equipped with beadlock wheels or rim beadlock configurations—common in off-road applications—spoke design becomes even more critical. The additional hardware around the rim edge can affect airflow patterns, making open spoke designs particularly valuable for maintaining adequate brake temperatures during demanding use.

Aerodynamic Considerations in Spoke Design

While brake cooling concerns airflow into the wheel, aerodynamics addresses how air moves around and past your wheels at speed. Every spoke creates turbulence as it rotates through the air stream. The cumulative effect of spoke shape, angle, and quantity influences drag characteristics and, consequently, fuel efficiency and high-speed stability.

Solid or covered wheel designs offer the lowest aerodynamic drag—but they eliminate brake cooling entirely. Custom forged spoke designs represent a calculated compromise, balancing the need for ventilation against aerodynamic efficiency. Thin, streamlined spokes generate less turbulence than chunky, squared-off profiles, which is one reason why premium forged wheels often feature refined spoke edges that cast alternatives cannot achieve.

Offset wheels and their positioning relative to the vehicle body also affect aerodynamic behavior. Wheels pushed outward beyond the fender line create additional turbulence and drag, while those tucked within the body profile allow smoother airflow along the vehicle's sides.

Fitment considerations extend well beyond appearance. When selecting spoke designs for your vehicle, these factors determine whether your chosen wheels will function properly:

- Brake Caliper Clearance: Aggressive concave spoke profiles or deep-dish designs may intrude into the space required by large brake calipers. As Velgen Wheels notes, "some wheel designs have aggressive concave spokes or thicker barrels that may intrude into the brake area."

- Custom Wheel Offset: Offset determines where the wheel mounting surface sits relative to the centerline. Higher positive offset brings the wheel closer to suspension and brake components, potentially limiting clearance.

- Hub Centric Rings: These ensure the wheel centers precisely on the hub rather than relying on lug nuts alone. Proper hub-centric fitment reduces vibration and ensures consistent spoke-to-caliper spacing.

- Wheel Spacers: While spacers can sometimes improve clearance between spokes and calipers, they alter the effective offset and may create other clearance issues with fenders or suspension components.

- Inner Barrel Depth: Even if the outer spoke design clears your calipers, the inner barrel structure must accommodate the caliper body—diameter alone doesn't guarantee compatibility.

For vehicles with aftermarket big brake kits or factory performance packages, standard wheel dimensions often prove inadequate. Larger calipers and rotors consume more space within the wheel barrel, requiring careful spoke design selection to maintain proper clearance.

The takeaway? Spoke design decisions ripple through multiple performance dimensions. A wheel that looks perfect in photos may overheat your brakes, create excessive aerodynamic drag, or simply refuse to mount over your calipers. Understanding these relationships helps you select custom forged spoke designs that deliver both the visual impact and the functional performance your vehicle deserves.

With performance considerations clarified, the next step is matching spoke designs to specific vehicle types and driving applications—ensuring your selection aligns with how you actually use your vehicle.

Choosing the Right Spoke Design for Your Vehicle

You understand spoke types, construction methods, and performance implications—but how do you actually match all this knowledge to your specific vehicle? The answer depends on three interconnected factors: what you drive, how you drive it, and the visual statement you want to make. A track-focused sports car demands different spoke characteristics than a luxury sedan or a truck built for hauling.

Let's translate spoke design principles into practical recommendations for real-world applications.

Matching Spoke Designs to Vehicle Applications

Different vehicle categories impose distinct demands on wheel design. According to industry guidance from NNX Wheels, "wheel selection directly determines the overall temperament of the car," and targeting your specific modification style ensures both aesthetic harmony and functional optimization.

Here's how spoke design priorities shift across vehicle types:

Sports Cars and Performance Vehicles: When you're chasing lap times or carving canyon roads, lightweight construction trumps everything else. One-piece forged multi-spoke wheels—typically featuring 7-10 narrow spokes—optimize both weight reduction and aerodynamic efficiency. For mustang wheels and similar muscle car applications, the classic 5-spoke configuration remains popular, delivering the aggressive stance these vehicles deserve while providing excellent brake clearance for upgraded calipers. Mustang rims often benefit from split-spoke designs that add visual complexity without sacrificing structural integrity.

Luxury Sedans: The priority shifts toward refined aesthetics and ride quality. Multi-spoke designs with dense, thin-spoke patterns create the sophisticated appearance that complements premium interiors. For bmw wheels and similar European luxury applications, electroplated finishes paired with intricate spoke arrangements deliver the understated elegance these vehicles demand. BMW rims frequently feature 15-20 spoke designs that project prestige while maintaining appropriate strength for spirited driving.

Trucks and Heavy-Duty Applications: Strength and durability take precedence over weight savings. Truck rims require robust spoke designs capable of handling heavy payloads and towing stress. F-150 wheels and similar applications often feature thicker, fewer spokes—typically 5-8—that distribute load effectively without sacrificing the bold appearance truck owners expect. For dually wheels, spoke designs must accommodate the unique mounting requirements and higher load ratings these configurations demand.

Off-Road Vehicles: Impact resistance and tire security become paramount. Jeep rims and similar off-road applications benefit from simple, thick spoke designs—often 5-spoke configurations—that withstand rock impacts and facilitate mud or debris cleaning. Beadlock-compatible spoke designs add an extra layer of security for extreme terrain, ensuring tires remain seated during aggressive wheeling.

| Vehicle Type | Recommended Spoke Styles | Key Considerations | Typical Sizing |

|---|---|---|---|

| Sports Cars | Multi-spoke (7-10), split-spoke, Y-spoke | Weight reduction, brake clearance, aerodynamics | 18-20 inch, ET25-35 |

| Luxury Sedans | Dense multi-spoke (12-20), mesh patterns | Visual refinement, ride comfort, finish quality | 18-22 inch, ET35-45 |

| Trucks (F150, etc.) | Thick 5-8 spoke, reinforced designs | Load capacity, durability, towing stress | 17-22 inch, 8-9J width |

| Off-Road (Jeep, etc.) | Simple 5-spoke, beadlock-compatible | Impact resistance, debris clearing, tire security | 15-17 inch, negative ET values |

| Muscle Cars | Classic 5-spoke, split-spoke variants | Aggressive stance, heritage styling, brake clearance | 18-20 inch, staggered fitment |

Balancing Aesthetics with Performance Needs

Sounds complex? Here's the reality: the best spoke design for your vehicle balances what you need against what you want. A visually stunning 20-spoke mesh pattern might look incredible on your luxury sedan but could compromise brake cooling if you're tracking that same vehicle on weekends.

Consider these guiding principles when making your selection:

- Driving Style First: If aggressive driving dominates your usage, prioritize open spoke designs that maximize brake cooling—even if a more intricate pattern appeals aesthetically.

- Weight Matters More for Performance: Track-focused mustang wheels benefit from every ounce saved, while luxury sedan applications can tolerate slightly heavier designs for visual impact.

- Match Spoke Proportions to Vehicle Scale: Thick, bold spokes suit trucks and SUVs; thin, refined spokes complement smaller sports cars and sedans.

- Consider Maintenance Realities: Intricate multi-spoke designs require more effort to clean. If you live in a region with harsh winters or frequently encounter brake dust, simpler spoke patterns ease maintenance.

The finish you select also interacts with spoke geometry to create distinct visual effects. Dark finishes—matte black or gunmetal—emphasize spoke depth and dimension, making concave profiles appear more aggressive. Bright finishes like chrome or polished aluminum highlight spoke detail and catch light, drawing attention to intricate patterns.

Remember that aftermarket wheels like those from established brands offer far wider finish and style options than OEM alternatives. Whether you're upgrading f-150 wheels for a more commanding presence or selecting refined bmw wheels for understated elegance, the aftermarket provides spoke designs purpose-built for your specific application.

With vehicle-specific recommendations established, you're ready to explore the customization options that transform standard spoke designs into truly personalized expressions of your automotive vision.

Customization Options for Forged Spoke Wheels

You've selected your spoke configuration and matched it to your vehicle—now comes the exciting part: making it unmistakably yours. Customization transforms quality forged wheels from excellent components into personal statements. Yet most retailers showcase finish swatches without explaining how these options interact with specific spoke geometries to create distinct visual effects.

Understanding these relationships helps you make customization choices that enhance rather than diminish your spoke design's impact.

Premium forged wheel manufacturers offer extensive customization categories that go far beyond basic color selection:

- Finish Types: Powder coat, brushed, anodized, polished, and specialized coatings—each creating different visual effects on spoke surfaces.

- Custom Engraving: Laser-etched logos, personal insignias, or text integrated into spoke faces, lips, or wheel center caps.

- Center-Lock Compatibility: Conversion hardware and spoke designs optimized for single-nut racing-style mounting systems.

- Color Matching: Paint-to-sample options that replicate your vehicle's exact body color or interior accent tones.

- Two-Tone and Split Finishes: Contrasting treatments between spoke faces and outer lips or between inner and outer spoke surfaces.

- Hardware Customization: Colored lug nuts, custom valve stems, and specialized wheel center caps that complement your chosen finish.

Finish Options That Complement Spoke Profiles

Here's what many enthusiasts miss: the same finish creates dramatically different effects depending on spoke geometry. According to PB Forged Wheels, finishes are "applied post-machining, with strict quality control and full customisation"—meaning your spoke design's edges, angles, and curves directly influence how light interacts with the final coating.

Consider how different finishes transform spoke appearance:

Satin and Gloss Powder Coats: These durable finishes work exceptionally well on bold, simple spoke designs. Black rims with gloss finishes create mirror-like reflections that emphasize clean lines, while satin variants soften aggressive angles for a more understated presence. Five spoke black wheels particularly benefit from satin finishes that highlight the classic geometry without excessive glare.

Brushed and Tinted Brushed: Directional brushed finishes add movement and depth by creating linear patterns across spoke surfaces. As industry experts note, combining brushed treatments with transparent tints like Smoked Graphite or Champagne Gold delivers a premium touch that catches light differently as wheels rotate. These finishes excel on multi-spoke designs where the directional grain creates visual flow across numerous surfaces.

Polished and Mirror Polished: High-lustre polishing creates show-spec aesthetics that demand attention. Chrome wheels and chrome rims achieve similar brilliance, though modern polished aluminum offers weight advantages. A 5 spoke chrome wheel showcases this finish beautifully—the simple geometry allows uninterrupted reflections across broad spoke faces. However, intricate multi-spoke designs can appear visually busy when fully polished, potentially overwhelming the eye.

Matte and Stealth Finishes: According to wheel finish analysis, matte finishes "absorb light for a stealthy look" while resisting visible dust and minor scratches better than gloss alternatives. For 5 spoke black rims, matte treatments emphasize dimension and depth within concave profiles—the absence of reflection draws the eye into the spoke recesses rather than across their surfaces.

Custom Engraving and Personalization Features

Beyond surface treatments, engraving options add another personalization layer. Laser-etched details can include manufacturer logos, personal monograms, vehicle specifications, or custom graphics integrated directly into the wheel surface.

Engraving placement interacts with spoke design in important ways:

- Spoke Face Engraving: Works best on wide, flat spoke surfaces where text or graphics remain legible. Thin multi-spoke designs lack adequate surface area for detailed engraving.

- Outer Lip Engraving: Popular on deep-dish designs where the pronounced lip provides a natural canvas for text or patterns visible from the side.

- Center Cap Customization: Wheel center caps offer prime real estate for logos and emblems, and custom cap designs complement overall spoke aesthetics without competing for attention.

Center-lock conversion represents another customization frontier. Originally developed for racing applications where rapid wheel changes matter, center-lock systems replace traditional multi-lug mounting with a single central nut. This modification affects spoke design considerations—the central hub area requires specific engineering to accommodate the larger locking mechanism, and spoke arrangements must clear the oversized center hardware.

For those pursuing two-tone aesthetics, split finishes create striking contrast. Imagine machined spoke faces paired with painted pockets, or polished lips contrasting against matte spoke centers. These treatments particularly enhance spoke designs with distinct surface planes—split-spoke configurations and deep-dish profiles provide natural visual boundaries for finish transitions.

The key principle? Match your finish complexity to your spoke complexity. Simple spoke geometries handle elaborate finishes well, while intricate multi-spoke patterns often look best with clean, uniform treatments that let the spoke design itself command attention.

With customization options clarified, the next consideration is how these designs scale across different wheel sizes—because a spoke pattern that looks perfect at 18 inches may appear entirely different at 22 inches.

Wheel Sizing and Spoke Design Proportions

Ever noticed how the same spoke pattern can look dramatically different across wheel sizes? A design that appears bold and aggressive on 17 inch wheels might seem stretched and sparse when scaled up to 22 inches. Understanding this relationship between wheel diameter and spoke geometry helps you select designs that maintain their visual impact—and structural integrity—at your target size.

The scaling challenge is straightforward: as wheel diameter increases, spoke length grows proportionally while spoke width typically remains constant. This fundamental geometry affects both aesthetics and engineering requirements in ways that many buyers overlook until their wheels arrive.

Spoke Proportions Across Wheel Sizes

Here's what happens as wheels grow larger: spokes must span greater distances from hub to rim. According to wheel engineering principles, longer spokes experience different stress distributions than shorter ones, and manufacturers must adjust spoke thickness, angle, and count to maintain structural integrity across size ranges.

Consider spoke design implications across popular wheel dimensions:

- 17 inch rims: The compact diameter allows for intricate multi-spoke patterns without appearing cluttered. Thin, delicate spoke profiles maintain visual balance, and the shorter spoke length reduces stress concentration. These 17 inch wheels suit sports cars and compact performance vehicles where nimble handling matters more than visual presence.

- 18 inch wheels: A versatile middle ground that accommodates most spoke configurations effectively. Both simple five-spoke designs and complex mesh patterns scale well at this diameter, making 18 inch wheels the most forgiving size for spoke design experimentation.

- 20 inch rims: Spoke designs begin requiring careful proportion consideration. Multi-spoke patterns may need thicker individual spokes to avoid appearing too delicate against the larger wheel face. Concave profiles become more dramatic at this size, creating significant visual depth.

- 22 inch rims: Simple, bold spoke geometries excel at this diameter. Those seeking 22 inch 5 spoke wheels find the classic configuration scales beautifully—the substantial spoke length creates commanding visual presence without appearing busy. Complex patterns risk looking stretched or losing their intended proportions.

- 24 inch rims: The largest common sizes demand robust spoke designs. Spoke thickness must increase to handle the extended leverage created by longer spoke lengths, and structural requirements often limit design options to fewer, more substantial spokes.

Sizing Impact on Spoke Aesthetics

Why do 5 spoke 22 inch rims remain so popular? The answer lies in proportion. Five-spoke configurations maintain balanced visual weight as wheel diameter increases—each spoke grows longer while the spaces between them expand proportionally, preserving the design's intended aesthetic. More complex patterns don't always scale this gracefully.

Several factors determine how spoke designs translate across sizes:

- Spoke Count Perception: A 10-spoke pattern that appears dense on 17 inch rims may look sparse and open on 22 inch versions. Manufacturers sometimes increase spoke count on larger diameter options to maintain visual density.

- Concave Depth Scaling: Concave profiles become more pronounced on larger wheels. A subtle dish at 18 inches transforms into a dramatic bowl shape at 22 inches—impressive if intended, but potentially overwhelming if unexpected.

- Edge Definition: Machined spoke edges and fine details become more visible on larger wheels, making manufacturing precision increasingly important as diameter grows.

- Structural Thickness: Longer spokes require additional material strength. Designs that work at 17 inches using thin, elegant spokes may need noticeably thicker profiles at 22 inches to meet safety requirements.

The relationship between wheel diameter and spoke geometry isn't merely cosmetic. As spoke engineering research demonstrates, spoke tension and stress distribution change with length—affecting durability, load capacity, and long-term wheel integrity. Premium forged construction partially compensates through superior material strength, but fundamental physics still applies.

For enthusiasts eyeing 22 inch 5 spoke wheels or similar large-diameter options, prioritize designs specifically engineered for those dimensions rather than scaled-up versions of smaller wheel patterns. Manufacturers who develop size-specific spoke geometries deliver better visual results and improved structural performance than those simply stretching existing designs.

With sizing considerations understood, you're ready to explore the manufacturing process itself—and what to look for when partnering with forged wheel producers to bring your custom spoke vision to reality.

Working with Forged Wheel Manufacturers

You've designed your ideal spoke configuration, selected the perfect finish, and determined your sizing requirements—but now comes the critical question: who actually builds your custom forged wheels? The manufacturing partner you choose determines whether your vision becomes reality or disappointment. Unlike purchasing off-the-shelf wheels, custom forged projects require collaboration with manufacturers who understand both your aesthetic goals and the engineering demands of spoke design.

Let's explore what this journey looks like and how to identify manufacturers capable of delivering affordable forged wheels without compromising quality.

From Concept to Custom Forged Reality

The path from initial design concept to finished wheel involves several distinct phases, each with its own timeline and quality considerations. Understanding this process helps you set realistic expectations and communicate effectively with potential manufacturing partners.

According to industry data from Tree Wheels, manufacturing timelines vary significantly based on design complexity: one-piece wheels typically require 15-20 days, two-piece designs need 20-25 days, and three-piece configurations take 25-30 days. For international buyers, shipping adds another 10-30 days depending on destination.

Here's what happens during each manufacturing stage:

Design Consultation and Engineering Review: Your spoke design concept undergoes feasibility analysis. Engineers evaluate whether your desired spoke geometry, concave depth, and offset combinations are structurally viable. This phase catches potential issues before expensive tooling begins—a critical advantage when pursuing forged customs with unique spoke patterns.

Prototyping and Validation: Before committing to full production, reputable manufacturers create prototype wheels for testing and approval. Some facilities offer rapid prototyping capabilities—with partners like Shaoyi delivering prototype components in as little as 10 days. This accelerated timeline proves invaluable when iterating on custom CNC wheels or refining spoke dimensions before final production.

Forging and Initial Machining: Premium aluminum billets undergo extreme pressure forging, creating the dense, aligned grain structure that enables thin yet strong spoke profiles. As manufacturing experts explain, this process involves heating aluminum to approximately 450-500°C and applying up to 10,000 tons of pressure—far exceeding what cast manufacturing achieves.

CNC Precision Machining: Computer-guided tools transform the forged blank into your exact spoke design. This stage is particularly time-intensive for complex patterns. Custom CNC wheels with intricate spoke geometries may require multiple machining operations, each demanding precise toolpath programming.

Finishing and Quality Control: Surface treatments, painting, and clear coating complete the visual transformation. Each wheel then undergoes rigorous testing before shipping—a process that separates reliable manufacturers from those cutting corners.

Quality Standards in Forged Wheel Manufacturing

Not all certifications carry equal weight. When evaluating potential manufacturing partners for custom forged or forged billet wheels, specific certifications indicate genuine quality commitment rather than marketing claims.

According to certification analysis from Flexiforge Wheel, reliable forged wheel companies should hold multiple relevant certifications that demonstrate comprehensive quality management.

Look for these essential certifications when vetting manufacturers:

- IATF 16949: This automotive-specific quality management certification covers the entire production process, emphasizing continuous improvement and defect prevention. It's essential for manufacturers supplying major automakers and indicates rigorous process control. Facilities like Shaoyi maintain IATF 16949 certification, ensuring every forged component meets automotive industry standards.

- ISO 9001: The global standard for quality management systems, demonstrating consistent quality control processes from design through final inspection.

- JWL and JWL-T: Japanese Light Alloy Wheel standards confirming wheels meet safety and quality requirements. Though originating in Japan, these standards are recognized worldwide.

- TÜV Certification: Particularly important for European markets, indicating products passed rigorous independent testing for safety and durability.

- VIA (Vehicle Inspection Association): Third-party verification that wheels exceed—not just meet—JWL requirements.

Beyond certifications, evaluate what testing protocols manufacturers actually perform. As NNX Wheels notes, comprehensive testing should include dynamic balance verification, runout measurement, bending fatigue testing, radial fatigue evaluation, and impact resistance assessment.

When evaluating manufacturing partners for forged offroad applications or 360 forged wheels, consider these additional factors:

- In-House Engineering Capability: Manufacturers with dedicated engineering teams can optimize your spoke design for both aesthetics and structural performance. Shaoyi's in-house engineering ensures precision hot forging solutions meet exact specifications rather than forcing designs into existing mold limitations.

- Material Traceability: Premium manufacturers maintain complete documentation of aluminum alloy sourcing, typically using aerospace-grade 6061-T6 or 7075 materials.

- Production Flexibility: Can the facility handle both prototype quantities and high-volume production? This flexibility matters whether you're developing a single set of forged billet wheels or establishing ongoing supply relationships.

- Geographic Considerations: Manufacturing location affects lead times and logistics costs. Facilities near major shipping hubs—like Shaoyi's location near Ningbo Port—streamline international delivery and reduce transit times.

- Communication and Responsiveness: Custom projects require ongoing dialogue. Manufacturers who respond promptly and clearly during the quoting phase typically maintain that responsiveness throughout production.

The investment in proper partner evaluation pays dividends throughout your project. Cutting corners on manufacturer selection often results in wheels that look acceptable in photos but reveal quality issues under real-world stress—spoke finishes that deteriorate prematurely, dimensional inconsistencies that cause vibration, or structural weaknesses that compromise safety.

For those pursuing truly custom spoke configurations, working with manufacturers who maintain rigorous quality control and offer precision forging capabilities ensures your design vision translates into wheels that perform as impressively as they appear. Whether you're developing affordable forged wheels for a specific vehicle application or creating show-stopping forged customs, the manufacturing partnership you establish determines your project's ultimate success.

With manufacturing considerations addressed, you're equipped to make informed decisions about your custom spoke design journey—from initial concept through final installation.

Making Your Custom Spoke Design Decision

You've journeyed from understanding spoke geometry fundamentals through construction methods, performance implications, and manufacturing considerations. Now it's time to synthesize everything into a decision framework that serves you—regardless of which brand or manufacturer you ultimately choose. The principles you've learned apply universally, empowering you to evaluate any custom forged wheel spoke design with confidence.

The best spoke design balances what you need functionally with what you want aesthetically—never sacrifice brake cooling for visual appeal on a track-driven vehicle, and never settle for generic styling when your luxury sedan deserves refined multi-spoke elegance.

Key Takeaways for Spoke Design Selection

Let's distill the core principles that should guide every spoke design decision:

- Construction Determines Possibility: Monoblock delivers seamless aesthetics and maximum weight savings; multi-piece offers unmatched customization flexibility. Your priority between these factors shapes your construction choice.

- Spoke Count Affects More Than Appearance: Fewer spokes mean larger openings for brake cooling and easier caliper clearance. More spokes distribute stress across additional contact points. Match your count to your driving demands.

- Size Changes Everything: Spoke designs that excel on 18 inch wheels may appear stretched or structurally compromised at 22 inches. Always evaluate designs at your target diameter.

- Finish Interacts with Geometry: Simple spoke patterns handle complex finishes well; intricate multi-spoke designs often look best with uniform treatments that let the spoke geometry command attention.

- Certifications Matter: IATF 16949, JWL, and TÜV certifications indicate genuine quality commitment—not just marketing claims.

Whether you're drawn to vossen wheels for their aggressive styling, admire the craftsmanship of work wheels, appreciate the prestige of hre rims, or respect the heritage of bbs rims, these selection principles remain constant. Brand preference is personal; engineering requirements are universal.

Your Path to the Perfect Forged Wheels

Ready to move forward? Here's your action plan:

Start with function. Define how you'll use your vehicle—daily driving, weekend track sessions, show appearances, or off-road adventures. This determines your spoke design priorities before aesthetics enter the conversation.

Match spoke geometry to vehicle type. Sports cars benefit from lightweight multi-spoke or forged 5 spoke wheels that prioritize brake cooling. Luxury sedans deserve refined patterns that project sophistication. Trucks demand robust configurations built for heavy loads.

Verify fitment early. Confirm brake caliper clearance, offset requirements, and hub-centric specifications before falling in love with a design that won't physically work on your vehicle.

Partner wisely. The manufacturer you select determines whether your vision becomes reality. Look for rapid prototyping capability, rigorous quality certifications, and proven engineering expertise.

For enthusiasts ready to explore precision-forged components with rigorous quality control, partners like Shaoyi—located near Ningbo Port for streamlined global logistics—deliver IATF 16949-certified manufacturing with prototyping in as little as 10 days and the in-house engineering to bring complex spoke designs to life. Those exploring manufacturing options can learn more about precision forging capabilities designed for demanding automotive applications.

The journey from concept to curb appeal requires patience, education, and partnership with capable manufacturers. But armed with the principles you've learned—from spoke geometry and construction methods through performance considerations and customization options—you're now equipped to make decisions that deliver both the visual impact and functional performance your vehicle deserves.

Your perfect custom forged spoke design isn't a compromise. It's the intersection of engineering excellence and personal expression, built to perform as impressively as it appears.

Frequently Asked Questions About Custom Forged Wheel Spoke Designs

1. How much does it cost to have custom forged wheels made?

Custom forged wheel pricing varies significantly based on construction type, spoke complexity, and finish options. Budget aluminum rims typically cost $200-$800 per set, while mid-range flow-formed options run $560-$2,200. Premium forged aluminum wheels with multi-piece construction range from $4,000-$8,000 per set, with high-end custom designs exceeding these figures. Factors affecting price include spoke intricacy, customization level, and manufacturer certifications like IATF 16949 that ensure quality standards.

2. What is the typical lifespan of forged wheels?

Forged aluminum wheels typically last 10 years or more when properly maintained, significantly outperforming cast alternatives. The forging process creates a denser, stronger grain structure that resists impact damage and fatigue cracking. Lifespan depends on driving conditions, maintenance practices, and exposure to corrosive elements. Wheels from IATF 16949-certified manufacturers undergo rigorous testing including bending fatigue and radial fatigue evaluation, ensuring extended durability under demanding conditions.

3. What spoke count is best for brake cooling and performance?

Fewer spokes with larger openings provide superior brake cooling by allowing greater airflow across rotors and calipers during aggressive driving. Five-spoke configurations offer an excellent balance between cooling efficiency, structural integrity, and brake caliper clearance for upgraded systems. Multi-spoke designs with 10+ thin spokes may restrict airflow despite their refined appearance. For track use or spirited driving, prioritize open spoke patterns; for luxury applications where cooling demands are lower, intricate multi-spoke designs work well.

4. What is the difference between monoblock and multi-piece forged wheels?

Monoblock wheels are machined from a single forged aluminum billet, creating seamless spoke-to-barrel transitions with the lightest weight possible. Multi-piece construction (2-piece or 3-piece) combines separately forged components bolted together, offering greater customization of width, offset, and lip depth. Monoblock suits track-focused applications prioritizing weight reduction, while multi-piece excels when precise fitment adjustments or component replacement is needed. Both construction types enable spoke designs impossible with cast manufacturing.

5. How long does it take to manufacture custom forged wheels?

Manufacturing timelines vary by construction complexity: monoblock wheels require 15-20 days, two-piece designs need 20-25 days, and three-piece configurations take 25-30 days. International shipping adds 10-30 days depending on destination. Some manufacturers like Shaoyi offer rapid prototyping in as little as 10 days, accelerating the design validation phase before full production. Total project duration from concept approval to delivery typically ranges 4-8 weeks for most custom forged wheel orders.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —