Forged Vs Cast Steering Components: 8 Essential Points Before You Buy

Why Steering Component Manufacturing Method Determines Your Safety

Imagine losing steering control at highway speed. Your vehicle drifts uncontrollably toward oncoming traffic, and nothing you do with the wheel changes direction. This nightmare scenario isn't hypothetical—it's the potential consequence of a failed steering knuckle or spindle. According to automotive safety experts, a malfunctioning steering system represents "a dangerous automotive defect capable of causing catastrophic injury or death." What many drivers don't realize is that the manufacturing method behind their steering components—forged vs cast—plays a decisive role in determining whether those parts will protect them or fail them when it matters most.

Why Your Steering Component's Birth Matters More Than You Think

The steering knuckle alone supports 1,000 to 1,500 pounds per front corner on a typical sedan. Every time you turn the wheel, hit a pothole, or brake hard, these components absorb tremendous forces that would shatter lesser materials. The difference between forged and cast manufacturing isn't just technical jargon—it determines how your steering components handle stress, resist fatigue, and ultimately keep you safe on the road. Just as recognizing signs of a bad alternator helps you avoid being stranded, understanding the difference between forged and cast steering parts helps you avoid far more dangerous situations.

The Hidden Safety Factor in Every Turn You Make

Your steering system functions as the central integration point where multiple safety-critical systems converge. When you navigate a sharp turn, your steering knuckles simultaneously handle steering input, suspension movement, braking force, and wheel rotation. A component manufactured through automotive forging processes offers continuous grain flow that follows the part's contours—creating superior fatigue resistance under repeated stress cycles. Cast components, while cost-effective, may contain microscopic porosity that concentrates stress at critical points. The cast vs forged debate isn't about preference; it's about physics and metallurgy working either for or against your safety. Much like how bad alternator symptoms warn you of electrical system failure, understanding manufacturing methods helps you identify potential steering system weaknesses before they become dangerous.

Setting the Stage for Smarter Component Selection

Whether you're an automotive professional specifying OEM replacements, a restoration enthusiast seeking authentic specifications for a classic build, or a performance builder pushing vehicles to their limits, this guide delivers what scattered forum discussions and generic manufacturing comparisons cannot. You'll discover systematic evaluation criteria covering tensile strength, fatigue performance, grain structure integrity, failure mode safety, and cost-effectiveness across different applications. We'll examine specific component types—from steering knuckles and spindles to tie rod ends, pitman arms, and control arms—with clear recommendations matched to your application requirements. By the time you finish reading, you'll possess the knowledge to make informed decisions that balance performance, safety, and budget for any steering component purchase.

How We Evaluated Forged and Cast Steering Components

You wouldn't judge a race car by the same standards you'd apply to a grocery-getter, right? The same principle applies when comparing forged vs cast steel in steering applications. Generic manufacturing comparisons fall short because steering components face unique challenges—dynamic loading patterns, safety-critical failure consequences, and stringent regulatory requirements that demand specialized evaluation criteria. That's why we developed a systematic framework specifically designed to assess forged steel vs cast steel steering components on the metrics that actually matter for your safety and performance.

Our Five-Point Evaluation Framework

When examining cast vs forged steel for steering applications, we needed criteria that go beyond basic material properties. Think of this framework as your diagnostic checklist—similar to how a mechanic might check an intake manifold gasket when troubleshooting engine issues, we're methodically examining every factor that determines steering component reliability.

- Tensile and Fatigue Strength Performance: Steering components endure thousands of stress cycles daily. We evaluated how each manufacturing method affects ultimate tensile strength and, more importantly, fatigue life under repeated loading conditions typical of steering applications.

- Grain Structure Integrity: The internal crystalline structure of metal determines how it responds to stress. Forging strength comes from aligned grain flow, while casting produces random grain orientation. We assessed how these differences impact real-world performance.

- Failure Mode Safety: Not all failures are equal. Some components crack gradually, providing warning signs, while others fracture suddenly. We examined how each manufacturing method influences failure behavior and driver safety.

- Cost-Effectiveness Across Volume Ranges: Budget matters, but so does value. We analyzed when cast vs forged economics favor each method, considering production volumes, tooling costs, and long-term reliability.

- Certification Compliance: Industry standards like IATF 16949 define quality management requirements for automotive components. We evaluated how manufacturing methods align with these critical safety and quality benchmarks.

How We Assessed Each Manufacturing Method

Our evaluation process mirrors the rigorous testing procedures used by automotive industry leaders. According to ZwickRoell's automotive testing protocols, steering systems face "high dynamic loads during driving" and "must function reliably in order to ensure safety and driving comfort." We applied similar principles by examining mechanical, dynamic, and tribological properties under realistic conditions.

For tensile testing, we compared published specifications for forged vs cast components handling equivalent loads. Fatigue analysis considered cyclic stress patterns—the repeated turning, braking, and impact forces that accumulate over a vehicle's lifetime. Much like how a fuel pump relay either works or fails without warning, we paid special attention to components where sudden failure could prove catastrophic.

The Criteria That Matter for Steering Applications

Why can't you simply apply generic forged versus cast comparisons to steering components? Consider the unique demands: a steering knuckle simultaneously manages steering input, suspension articulation, braking forces, and wheel bearing loads—all while enduring road impacts and temperature extremes. This multi-axis loading environment differs dramatically from components experiencing simple unidirectional stress.

The IATF 16949 standard specifically addresses these concerns by requiring manufacturers to implement "strict inspection of critical parts" and maintain "careful assembly and testing" throughout the production process. This automotive-specific quality management system ensures that forging strength claims are backed by documented evidence and traceable manufacturing processes. Organizations certified to this standard must demonstrate "continuous improvement" and maintain "accurate documentation"—providing the transparency you need when selecting safety-critical steering components.

With this evaluation methodology established, let's apply these criteria to specific steering component categories, starting with forged steering knuckles and spindles where maximum strength is non-negotiable.

Forged Steering Knuckles and Spindles for Maximum Strength

Ever wonder what happens to metal when you squeeze it under thousands of pounds of pressure at extreme temperatures? The answer explains why forged versus cast steering knuckles represent fundamentally different safety propositions. When you're working under a vehicle—whether using a portable car lift in your shop or a 3 ton floor jack in your driveway—you're trusting your life to components that must perform flawlessly under tremendous stress. Understanding why forged spindles deliver superior performance starts with understanding what happens at the molecular level during manufacturing.

Forged Steering Knuckles and Spindles Explained

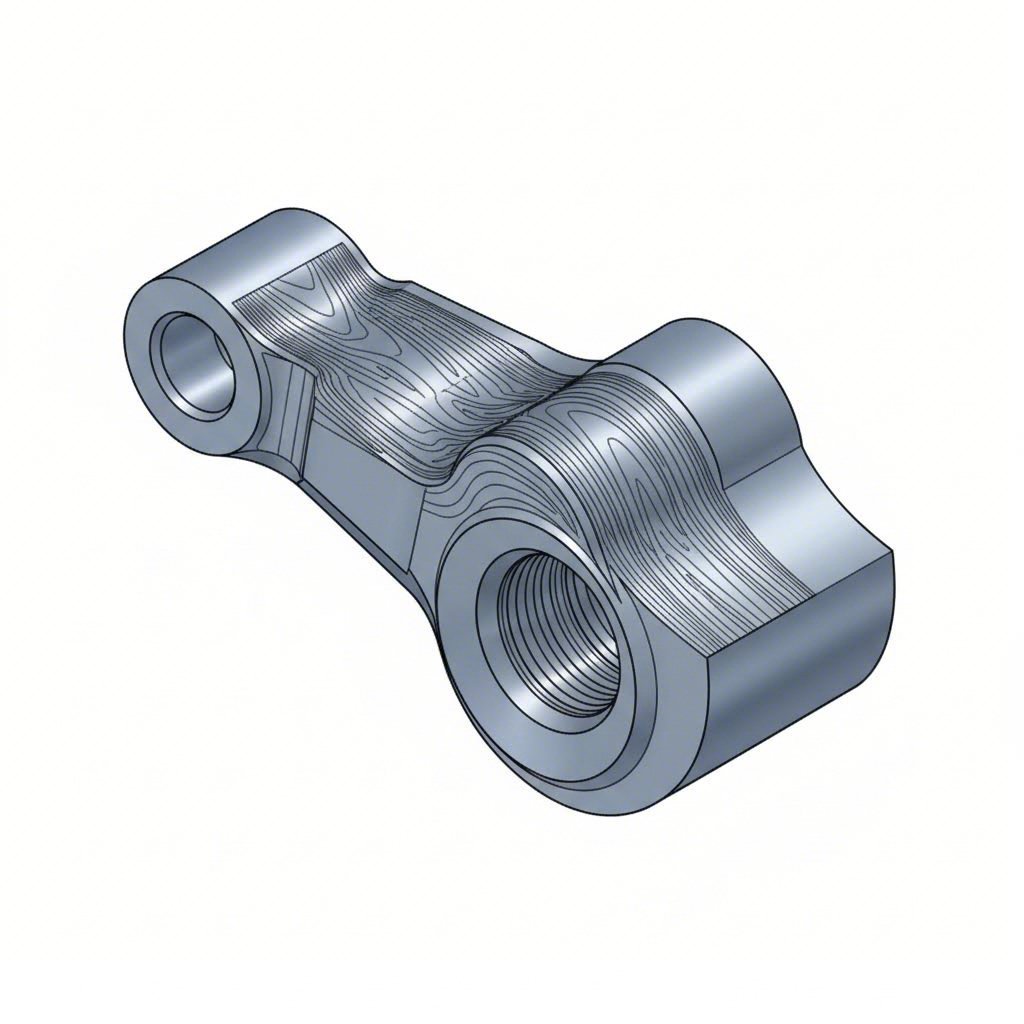

The forging process transforms heated metal billets into steering components through controlled compressive forces. According to KST Casting's technical analysis, "forging involves applying compressive force to shape heated metal into the desired configuration," which "refines the metal's internal grain structure." This refinement creates a continuous grain flow that follows the component's contours—imagine wood grain wrapping around curves rather than being cut across at weak points.

When comparing casted vs forged components, the grain structure difference proves critical. A forged steering knuckle's aligned grain acts like reinforcing fibers running throughout the entire part. Cast components, by contrast, develop random crystalline structures during solidification—creating potential weak points where stress can concentrate. For a component that serves as "the crucial pivot point for the wheels, connecting the suspension and steering system together," this structural integrity isn't optional—it's essential.

Strength Characteristics Under Dynamic Loading

Your steering knuckles don't just sit there holding weight. Every turn, every pothole, every hard brake creates dynamic loading patterns that test the component's fatigue resistance thousands of times daily. The forge vs casting debate becomes especially relevant here because fatigue failure—metal breaking after repeated stress cycles—accounts for a significant percentage of steering component failures.

Forged steering knuckles deliver three critical advantages under these conditions:

- Superior Strength: Forged parts exhibit outstanding toughness, making them ideal for carrying the heavy loads typical of steering applications—often 1,000 to 1,500 pounds per front corner on standard vehicles.

- Longer Lifecycle: With better fatigue resistance, forged steering knuckles maintain performance over extended periods, reducing the risk of age-related failures.

- Enhanced Safety: Properly manufactured forged knuckles help stabilize the vehicle's steering and reduce the risk of sudden catastrophic failures.

The king pin areas of steering knuckles require special attention to hardness and wear resistance. Induction hardening specifications for these critical zones typically achieve 58-63 HRC hardness with case depths of 0.03-0.05 inches for ball pin sockets. This surface hardening process "avoids cracks, oxidation, decarburization and uneven quenching defects caused by traditional heat treatment," ensuring the forged substrate receives optimal surface protection without compromising core ductility.

When Forged Spindles Are Non-Negotiable

Sounds complex? Think of it this way—certain applications simply cannot tolerate the compromises inherent in forged vs cast aluminum or cast steel alternatives. When you're pulling an engine with a harbor freight engine hoist, you trust the lifting equipment to handle the load. The same principle applies to steering components, but with your safety directly at stake.

Forged spindles become mandatory in these scenarios:

- High-Performance Vehicles: Track-driven cars experience lateral forces that multiply the stress on steering components far beyond normal driving conditions.

- Heavy-Duty Trucks: Commercial and towing applications place sustained high loads on steering geometry that demand forged component durability.

- Racing Applications: Competition environments combine extreme stress, heat cycling, and zero tolerance for component failure.

- Authentic Restoration Projects: Classic car enthusiasts seeking period-correct specifications often find that original equipment steering components were forged—and replacements should match that standard.

Pros of Forged Steering Knuckles and Spindles

- Superior tensile and yield strength compared to equivalent cast parts

- Excellent fatigue resistance under repeated stress cycles

- Greater safety margin through predictable failure modes

- Continuous grain flow following component contours

- Better impact resistance for harsh driving conditions

Cons of Forged Steering Knuckles and Spindles

- Higher per-unit cost compared to cast alternatives

- Longer lead times due to specialized tooling and processes

- Limited design flexibility for complex internal geometries

- Fewer aftermarket sources for specialty applications

For restoration enthusiasts particularly concerned about authenticity, the difference between cast and forged parts matters beyond mere performance. Many classic vehicles left the factory with forged steering components that met specific engineering requirements of their era. Installing cast replacements—even if dimensionally identical—changes the safety characteristics the original engineers intended. When sourcing replacement parts for valuable restorations, verifying manufacturing method ensures both authenticity and appropriate safety margins.

While forged components clearly excel in demanding applications, cast steering arms and control arms serve legitimate purposes in appropriate contexts. Understanding where casting makes economic and engineering sense helps you make balanced decisions across your entire steering system.

Cast Steering Arms and Control Arms for Cost-Effective Solutions

Not every steering component needs to withstand race-track abuse or carry a heavy-duty truck's front end. For millions of vehicles operating under normal driving conditions, cast steering arms and control arms deliver reliable performance at a fraction of forged component costs. Understanding when cast forge solutions make sense—and when they don't—helps you allocate your budget where it matters most while maintaining appropriate safety margins.

Cast Steering Arms and Control Arms Analyzed

The casting process creates steering components by pouring molten metal into molds, allowing complex shapes that would be difficult or impossible to achieve through forging. According to CZC Industry's technical documentation, aluminum alloys represent "one of the most common materials for die-cast control arms, usually used in passenger and commercial vehicles." This manufacturing approach enables engineers to integrate multiple functions into single components, "diminish joints, and improve overall strength and reliability."

When examining cast forging alternatives, you'll encounter three primary material options for steering applications:

- Cast Aluminum: Lightweight with excellent corrosion resistance—ideal for passenger vehicles prioritizing fuel efficiency. Aluminum castings "can withstand rain, mud, and road salt with less maintenance and lower operating costs."

- Cast Iron (Ductile Iron): Heavier but exceptionally cost-effective. GF Casting Solutions reports that ductile iron steering knuckles can reduce costs "by up to 30%" compared to aluminum alternatives while maintaining impressive performance through "bionic design" and "topology optimization."

- Cast Steel: Offers a middle ground between aluminum's weight advantages and iron's cost benefits, commonly used in medium-duty applications.

Where Casting Makes Economic Sense

Imagine you're restoring a classic daily driver on a budget. You've already spent considerable time addressing rust with por 15 rust preventive coating and smoothing body panels with bondo body filler. Does every steering component require the premium price of forged parts? The honest answer: probably not.

Cast steering arms and control arms prove perfectly adequate in these scenarios:

- Standard Passenger Vehicles: OEM manufacturers specify cast components for millions of vehicles because they meet safety requirements under normal driving conditions.

- Low-Stress Applications: Vehicles that primarily see highway cruising and light city driving rarely approach the stress limits where the difference between cast and forged becomes critical.

- Budget Restorations: When authenticity isn't paramount and the vehicle won't see performance driving, cast replacements offer significant savings.

- High-Volume Replacement: For fleet vehicles or shops performing frequent repairs, cast components reduce per-vehicle costs substantially.

The economic argument strengthens further when considering production realities. Casting requires less specialized tooling than forging, enables faster production cycles, and allows manufacturers to create intricate geometries in single operations. These efficiencies translate directly into lower consumer prices—sometimes 40-50% less than equivalent forged components.

Understanding Cast Component Limitations

Here's where honest assessment becomes crucial. While cast components serve legitimate purposes, they carry inherent limitations that buyers must understand. The difference between cast and forged parts isn't just about strength numbers on paper—it's about how these components behave under stress and, critically, how they fail.

The most significant concern with cast steering components involves porosity—small voids or cavities that can form during solidification. These microscopic defects create stress concentration points that "can significantly impact the mechanical properties and overall quality of castings, reducing strength, compromising integrity, and potentially leading to failure in critical applications."

Two types of porosity affect cast steering components:

- Gas Porosity: Forms when gases become trapped during casting, appearing as "small, rounded holes within the casting" that compromise structural integrity.

- Shrinkage Porosity: Occurs when metal contracts during cooling without adequate feed material, creating "larger, irregular cavities" that can significantly weaken the component.

Quality manufacturers address these issues through enhanced mold venting, degassing treatments, and vacuum-assisted casting techniques. However, budget-oriented castings may skip these steps, creating components that look identical but perform differently under stress.

Pros of Cast Steering Arms and Control Arms

- Significantly lower purchase price—often 40-50% less than forged equivalents

- Superior design flexibility for complex geometries and integrated features

- Faster production enabling better parts availability

- Adequate performance for stock applications under normal driving conditions

- Lightweight options available through aluminum casting

Cons of Cast Steering Arms and Control Arms

- Potential porosity issues creating internal weak points

- Lower fatigue strength limiting longevity under repeated stress

- Random grain structure rather than aligned directional strength

- Less predictable failure modes—may crack suddenly rather than showing warning signs

- Reduced safety margins for high-stress or high-performance applications

Forum discussions across automotive communities consistently echo a practical consensus: OEM cast components work perfectly fine for stock applications. Problems typically emerge when owners push vehicles beyond original design parameters—adding substantial weight, significantly increasing horsepower, or subjecting suspension components to aggressive driving. In these elevated-stress scenarios, the crank cast limitations that were acceptable for stock performance become potential failure points.

The key takeaway? Cast steering components aren't inherently inferior—they're appropriate for different applications than forged alternatives. Your job is matching manufacturing method to actual use case. For demanding applications requiring documented quality assurance and maximum strength, precision hot forging from certified manufacturers offers the solution we'll examine next.

Precision Hot Forged Components from Certified Manufacturers

When you're upgrading a performance build with components like a holley sniper efi system or swapping an edelbrock carburetor for fuel injection, you expect precision engineering backed by quality documentation. Why should your steering components receive any less scrutiny? For demanding applications where cast vs forge decisions carry safety-critical consequences, precision hot forging from IATF 16949 certified manufacturers represents the gold standard—delivering documented quality assurance, engineering support, and rapid development capabilities that generic aftermarket suppliers simply cannot match.

Precision Hot Forging for Critical Steering Applications

Precision hot forging elevates the traditional forging process through tighter tolerances, advanced die design, and comprehensive quality control at every production stage. According to AL Forge's technical documentation, "under immense pressure, the metal's internal micro-voids are compacted and eliminated," creating "a continuous, unbroken grain flow that follows the contour of the part." This refined grain structure delivers "exceptional resistance to fatigue and cracking under repeated stress"—exactly what steering components demand.

The quick performance gains from precision hot forging become apparent across multiple steering component categories:

- Suspension Arms: These load-bearing components benefit tremendously from forging's superior strength-to-weight ratio. Forged aluminum suspension arms can "offer strength comparable to medium-carbon steel at only a third of the weight," enabling lighter designs that improve handling without sacrificing durability.

- Tie Rod Ends: Critical connections between your steering rack and knuckles require absolute reliability. Precision forging ensures consistent material properties throughout the component, eliminating porosity concerns that plague cast alternatives.

- Pitman Arms: The direct link between your steering gearbox and steering linkage experiences tremendous leverage forces. Forged pitman arms maintain dimensional stability under loads that would fatigue lesser components.

- Idler Arms: Supporting the opposite end of your center link from the pitman arm, forged idler arms provide the structural backbone for precise steering geometry maintenance.

What makes precision hot forging particularly valuable for steering applications? The process allows engineers to achieve "near-net shape" components that "significantly reduce the need for secondary machining." This means tighter tolerances from the forge, less material removal weakening the grain structure, and more consistent performance across production runs—similar to how a quality electric fuel pump delivers consistent flow compared to mechanical alternatives.

IATF 16949 Certified Manufacturing Excellence

Certification matters when lives depend on component performance. IATF 16949 represents the international quality management system standard specifically developed for the automotive industry. According to Carbo Forge's certification documentation, this standard demands "comprehensive understanding of process and quality control" and implementation of "Zero-Defect Policy" ensuring customers "receive the highest quality forgings possible."

When you source steering components from IATF 16949 certified manufacturers, you're getting more than just metal shaped to specification. The certification requires:

- Documented Process Control: Every production step from raw material procurement through final inspection follows standardized procedures with complete traceability.

- Continuous Improvement: Certified facilities must demonstrate ongoing efforts to reduce defects, improve efficiency, and enhance product quality.

- Strict Inspection Protocols: Critical steering components undergo rigorous testing to verify mechanical properties, dimensional accuracy, and surface integrity.

- Material Traceability: Complete documentation tracks each component's material origin, processing history, and quality verification results.

Think of IATF 16949 certification like atk engines remanufacturing standards—it establishes minimum quality thresholds that separate professional-grade components from unknown-quality alternatives. For safety-critical steering parts, this documentation provides the peace of mind that no amount of marketing claims can substitute.

From Prototype to Production in Record Time

Traditional forging development cycles presented significant barriers for custom applications. According to Frigate's rapid prototyping analysis, conventional tooling preparation could span "12-20 weeks, with validation cycles adding several months." For performance builders and restoration specialists needing specific steering geometry, these timelines proved prohibitive.

Modern precision hot forging operations have revolutionized this timeline through several key innovations:

- Hybrid Tooling: Combining additive manufacturing for rapid die creation with CNC machining for precise finishing reduces tooling lead times by "up to 60%."

- Digital Validation: Finite element analysis tools simulate material flow, stress distribution, and thermal behavior before cutting any steel—identifying potential issues before physical trials begin.

- Production-Grade Prototyping: Prototypes forged from the same alloys as final production parts ensure mechanical properties remain consistent from development through high-volume manufacturing.

Leading manufacturers now offer rapid prototyping capabilities that compress development from months to weeks. Shaoyi (Ningbo) Metal Technology exemplifies this capability, delivering rapid prototyping in as little as 10 days while maintaining IATF 16949 certification standards. Their in-house engineering team supports custom specifications for suspension arms, drive shafts, and steering components—ensuring your exact requirements translate into production-ready forgings.

Pros of Precision Hot Forged Steering Components from Certified Manufacturers

- IATF 16949 certification ensuring automotive-grade quality management and traceability

- In-house engineering support for custom specifications and design optimization

- Rapid prototyping capabilities—from concept to sample in as few as 10 days

- Seamless scaling from prototype to high-volume mass production

- Global logistics infrastructure with strategic port access for fast international delivery

- Complete documentation satisfying OEM and regulatory requirements

Cons of Precision Hot Forged Steering Components from Certified Manufacturers

- Minimum order quantities may apply for custom tooling amortization

- International shipping timelines require advance planning for overseas manufacturers

- Higher initial tooling investment compared to off-the-shelf cast alternatives

- Engineering consultation needed for optimal specification development

For automotive professionals, performance builders, and restoration specialists requiring forged steering components with documented quality assurance, certified precision hot forging delivers the engineering support, rapid development, and production scalability that demanding applications require.

The forged vs cast irons debate ultimately resolves around application requirements. For standard replacements in stock vehicles, quality castings serve their purpose. But when specifications demand maximum strength, complete traceability, and engineering partnership throughout development, certified precision hot forging manufacturers provide solutions that generic suppliers cannot match. With evaluation methodology established and manufacturing options understood, the next step involves matching specific steering component types to appropriate manufacturing recommendations based on your application requirements.

Complete Steering Component Comparison by Type and Application

You've learned the metallurgical differences between forged and cast manufacturing. You understand when each method excels. But when you're staring at a parts catalog with seven different steering components needing replacement, how do you decide which ones justify forged pricing and which can safely use cast alternatives? This component-by-component breakdown eliminates the guesswork—giving you specific recommendations based on real-world stress demands, safety criticality, and practical budget considerations.

Component-by-Component Manufacturing Recommendations

Every steering component in your vehicle serves a distinct function and experiences unique loading patterns. A tie rod end handles different stresses than a steering knuckle, which operates under completely different conditions than a control arm. Understanding these distinctions helps you prioritize your investment where it matters most.

According to automotive steering system documentation, steering components must work together seamlessly because "the system is a set of components of different designs, material makeup, and functions that combine to translate a driver's input into vehicle control." This integrated nature means that one weak link—whether from poor material selection or inappropriate manufacturing method—can compromise your entire steering system's reliability.

The following table presents each major steering component type with specific manufacturing recommendations. Precision hot-forged certified components occupy the premium benchmark position, representing the optimal choice when budget permits and application demands maximum performance.

| Component Type | Recommended Manufacturing | Typical Application | Strength Requirements | Cost Considerations | Availability |

|---|---|---|---|---|---|

| Steering Knuckles | Precision Hot Forged (Certified) | All vehicles; mandatory for performance/heavy-duty | Very High—supports 1,000-1,500 lbs per corner with dynamic loading | Premium investment justified by safety criticality | Specialty suppliers; certified manufacturers |

| Spindles | Precision Hot Forged (Certified) | Performance vehicles, trucks, authentic restorations | Very High—wheel bearing mounting surface requires exceptional fatigue resistance | Higher upfront cost; extended service life reduces long-term expense | OEM dealers; certified forging suppliers |

| Pitman Arms | Forged Steel | Trucks, SUVs, recirculating ball steering systems | High—direct connection to steering gearbox experiences maximum leverage forces | Moderate premium over cast; critical failure point justifies investment | Widely available from quality aftermarket suppliers |

| Idler Arms | Forged Steel | Vehicles with parallelogram steering linkage | High—supports center link opposite pitman arm under steering loads | Moderate; often sold as matched set with pitman arm | Common replacement item; multiple quality sources |

| Tie Rod Ends | Forged (inner); Forged or Quality Cast (outer) | All vehicles with rack-and-pinion or conventional steering | Moderate-High—ball joint design requires fatigue resistance | Inner tie rods justify forged premium; outer ends vary by application | Excellent availability across price points |

| Control Arms | Forged Aluminum or Quality Cast (application-dependent) | Passenger vehicles, performance applications | Moderate—suspension geometry maintenance with lower peak loads than knuckles | Cast acceptable for stock applications; forged for performance | Extensive aftermarket options |

| Steering Arms | Quality Cast or Forged (application-dependent) | Vehicles with separate steering arm components | Moderate—transfers steering input to knuckle | Cast sufficient for most passenger vehicles; forged for trucks/performance | Application-specific; check OEM specifications |

Matching Method to Application Requirements

The table above provides general guidance, but your specific situation may demand different priorities. Think about figuring out wheel offset for custom wheels—the right answer depends entirely on your specific vehicle, tire combination, and intended use. Manufacturing method selection follows similar logic.

Consider these application-based decision factors:

- Vehicle Weight Class: Heavier vehicles generate proportionally greater steering component stress. A compact sedan's cast control arms may perform flawlessly for 200,000 miles, while the same design on a full-size truck could fail prematurely. Trucks, SUVs, and vehicles frequently carrying heavy loads should prioritize forged components throughout the steering system.

- Performance Requirements: Track driving, autocross, and spirited canyon runs multiply lateral loads far beyond normal driving. Vehicles set up with negative camber for improved cornering grip experience asymmetric loading patterns that accelerate fatigue in components not designed for such stress. Performance applications benefit from forged components across all steering positions.

- Safety Criticality: Some components fail more dangerously than others. A worn control arm bushing creates vague handling but rarely causes immediate loss of control. A fractured steering knuckle or spindle can mean instantaneous, complete steering failure. Prioritize forged manufacturing for the highest-consequence failure points first.

- Budget Constraints: Limited budgets require strategic allocation. If you cannot afford forged components throughout your steering system, prioritize them for knuckles and spindles while using quality castings for less critical positions. A mixed approach—forged where failure consequences are severe, cast where adequate—delivers better overall safety than uniformly cheap castings.

The Decision Matrix for Steering Components

When facing component selection decisions, work through this systematic evaluation:

- Identify the component's failure consequences. Would sudden failure cause complete steering loss? If yes, specify forged from a certified manufacturer.

- Assess your vehicle's stress profile. Heavy vehicles, performance use, towing, or off-road applications push components harder than standard passenger car duty cycles.

- Evaluate your driving patterns. Daily highway commuting differs dramatically from weekend track days. Match component specification to actual use.

- Consider total cost of ownership. A forged steering knuckle costing 50% more upfront but lasting twice as long actually saves money—plus delivers superior safety throughout its service life.

- Verify supplier quality. A cheap "forged" component from an unknown source may perform worse than a quality casting from a reputable manufacturer. Certification matters.

The difference between cast and forged wheels weight illustrates this principle clearly—forged wheels cost more but deliver measurable performance advantages that justify their premium. The same logic applies throughout your steering system, though with safety stakes far higher than wheel aesthetics.

When uncertain between forged and cast for any steering component, ask yourself: would I bet my family's safety on the less expensive option? The answer usually clarifies the right choice.

With specific component recommendations established, the final critical step involves verifying that your chosen supplier actually delivers the quality their marketing promises. Not all forgings are created equal, and not all casting suppliers maintain consistent standards. The next section covers essential supplier vetting criteria that separate genuine quality from marketing hype.

How to Vet Steering Component Suppliers and Verify Quality

You've identified which steering components need forged manufacturing and which can safely use castings. But here's the uncomfortable truth—a "forged" stamp on packaging means nothing if the supplier cuts corners on material quality, heat treatment, or quality control. Just as knowing how to test alternator output helps diagnose electrical issues before they strand you, understanding supplier vetting criteria helps identify quality problems before they compromise your safety.

Vetting Your Steering Component Supplier

Whether you're sourcing OEM replacements for a fleet operation, tracking down NORS (New Old Replacement Stock) parts for a classic restoration, or specifying components for a performance build, supplier verification follows the same fundamental principles. The goal is establishing confidence that what arrives in the box matches what the documentation promises.

According to Saky Steel's material verification guide, proper quality control ensures "correct material grade and composition, compliance with standards, internal soundness and cleanliness, traceability for audits and customer verification, and prevention of forging defects." Without proper checks, the risk of receiving non-conforming products increases significantly.

Start your supplier evaluation with these essential criteria:

- Manufacturing Facility Verification: Request documentation of where components are actually manufactured. Some suppliers rebrand products from unknown sources. Legitimate manufacturers readily identify their production facilities.

- Quality Management Certification: Demand evidence of current ISO 9001 or IATF 16949 certification. These aren't just paperwork—they require regular third-party audits confirming quality system compliance.

- Material Test Certificates (MTC): Every batch of steering components should trace back to documented material specifications. MTCs following EN10204 3.1 or 3.2 standards provide third-party verification of chemical composition and mechanical properties.

- Heat Number Traceability: For forged components especially, the ability to trace any part back to its original material batch ensures accountability and enables targeted recalls if problems emerge.

For restoration enthusiasts searching for correct parts using Ford vehicle VIN decoders or Chevrolet truck VIN codes to identify original specifications, supplier verification becomes doubly important. The classic car market unfortunately attracts counterfeit and substandard parts marketed as authentic replacements.

Certification and Quality Markers to Demand

Think of certifications as a supplier's credentials—they establish minimum competency thresholds. According to PDM Automotive's certification analysis, "certifications serve as a stamp of approval from respected industry bodies, indicating that a manufacturer's products meet high standards for quality and safety."

The hierarchy of relevant certifications for steering component suppliers includes:

- IATF 16949: The gold standard for automotive component manufacturers. This certification specifically addresses automotive quality management, requiring defect prevention, variation reduction, and continuous improvement throughout the supply chain.

- ISO 9001: The globally recognized quality management foundation. While less automotive-specific than IATF 16949, ISO 9001 certification indicates documented processes and trained personnel committed to quality output.

- CAPA Certification: For collision repair parts, the Certified Automotive Parts Association provides independent verification that aftermarket components meet or exceed OEM specifications.

- SAE Standards Compliance: The Society of Automotive Engineers establishes benchmarks for dimensions, strength, durability, and material specifications that quality manufacturers follow.

Beyond certifications, demand specific testing documentation for steering components:

- Tensile Testing Results: Yield strength, ultimate tensile strength, and elongation values should match material specifications.

- Hardness Testing: Brinell, Rockwell, or Vickers measurements confirm proper heat treatment.

- Ultrasonic Testing (UT) for Forged Components: UT detects internal cracks, porosity, shrinkage cavities, and inclusions that visual inspection misses. This non-destructive testing is essential for verifying the internal soundness of safety-critical forgings.

- Porosity Testing for Castings: Quality cast components undergo inspection to verify acceptable void levels and absence of significant shrinkage defects.

Understanding how to test an alternator involves checking output against specifications—similarly, verifying steering component quality requires checking test results against published standards. Reputable suppliers provide this documentation without hesitation.

Red Flags in Component Sourcing

Experience teaches that certain warning signs reliably indicate potential quality problems. Much like recognizing signs of bad alternator performance before complete failure, identifying supplier red flags early prevents dangerous component installations.

Watch for these concerning indicators:

- Missing or Incomplete Documentation: Legitimate manufacturers maintain comprehensive records. If a supplier cannot produce material certificates, test reports, or traceability documentation, question why.

- Unusually Low Pricing: When a "forged" steering knuckle costs less than competitors' cast alternatives, something is wrong. Either the material isn't what's claimed, quality control is absent, or both.

- Vague Origin Information: Phrases like "manufactured to OEM specifications" without identifying the actual manufacturer suggest rebranded products of unknown quality.

- No Certification Evidence: Claims of ISO or IATF certification without certificate numbers, expiration dates, and certifying body identification deserve skepticism.

- Inconsistent Part Appearance: Legitimate production runs produce consistent components. Significant variations in finish, markings, or dimensions across supposedly identical parts indicate quality control problems.

For those sourcing filtration components alongside steering parts—whether specifying a Purolator oil filter or other maintenance items—the same verification principles apply. Quality suppliers maintain consistent standards across their product lines.

A steering component is only as reliable as the weakest link in its manufacturing chain. Verify every claim before trusting your safety to any supplier.

The investment in supplier verification pays dividends beyond immediate safety. Documented quality enables warranty claims if problems emerge, provides evidence for insurance purposes, and ensures that performance modifications deliver their intended benefits rather than introducing new failure modes. With supplier vetting criteria established, the final step involves synthesizing everything covered into actionable recommendations matched to your specific application requirements.

Final Recommendations for Choosing Your Steering Components

You've absorbed the metallurgical science, examined specific component categories, and learned how to separate quality suppliers from questionable sources. Now comes the moment of decision—translating all that knowledge into purchases that match your exact needs. Whether you're maintaining a daily driver, building a track weapon, or restoring a classic to concours standards, these ranked recommendations cut through complexity to deliver clear action steps.

Your Steering Component Decision Simplified

The forged vs cast steering components debate ultimately resolves around a single question: what does your application actually demand? A weekend grocery-getter and a tow-heavy pickup hauling 10,000 pounds face fundamentally different stress profiles. Your component selection should reflect that reality rather than defaulting to either the cheapest option or unnecessary overkill.

Think about it this way—just as you'd choose the best car battery brand based on your vehicle's electrical demands rather than grabbing whatever's on sale, steering component selection requires matching manufacturing method to actual use case. An agm car battery makes sense for vehicles with high electrical loads; similarly, forged steering knuckles make sense for vehicles experiencing high mechanical loads.

Matching Your Needs to the Right Manufacturing Method

Based on everything covered throughout this guide, here are ranked recommendations organized by application type. Start with your primary use case, then adjust based on budget constraints and specific priorities:

- Heavy-Duty and Commercial Applications: Specify precision hot-forged components from IATF 16949 certified manufacturers for all steering positions. Trucks regularly carrying maximum payload, towing near capacity, or operating in demanding commercial environments cannot afford steering component failures. The premium cost represents appropriate insurance against catastrophic consequences. Certified suppliers like Shaoyi (Ningbo) Metal Technology deliver the documented quality assurance, material traceability, and engineering support these applications require.

- Performance and Track Vehicles: Prioritize forged steering knuckles, spindles, and pitman/idler arms without exception. Control arms and tie rod ends should also be forged for vehicles seeing regular track time. The lateral forces generated during aggressive driving multiply stress far beyond street driving levels. Engineering support from certified manufacturers helps optimize specifications for your specific performance goals—whether that's autocross agility or high-speed circuit stability.

- Authentic Restorations: Research original equipment specifications carefully. Many classic vehicles left factories with forged steering components that period-correct restorations should replicate. For concours-quality builds, precision hot forging with rapid prototyping capabilities enables recreation of specifications no longer available through standard aftermarket channels. The 10-day prototype turnaround offered by advanced manufacturers means custom specifications needn't delay project timelines.

- Modified Street Vehicles: Evaluate modifications realistically. Added weight from audio systems, significant power increases, or suspension modifications altering geometry all increase steering component stress. If your vehicle departs substantially from stock specifications, upgrade at least knuckles and spindles to forged alternatives. Think of it like choosing an Optima battery for a vehicle with aftermarket electronics—matching component capability to actual demands.

- Standard Passenger Vehicles (Stock Configuration): Quality castings from reputable suppliers serve perfectly well for vehicles operating within original design parameters. Focus your budget on verified quality rather than manufacturing method—a properly manufactured cast component from a certified supplier outperforms a poorly made "forged" part from an unknown source. Verify supplier credentials using the criteria covered in the previous section.

- Budget-Conscious Replacements: When funds are limited, prioritize strategically. Invest in forged components for steering knuckles and spindles—the highest-consequence failure points—while using quality castings elsewhere. This mixed approach delivers better overall safety than uniformly cheap components across all positions. Maintain your investment properly, just as you'd use a smart battery charger to extend battery life rather than replacing prematurely.

The Bottom Line on Forged vs Cast Steering

After examining metallurgical differences, specific component categories, certified manufacturing capabilities, and supplier verification criteria, the core principles crystallize clearly:

- Safety-critical applications demand forged components from certified manufacturers. When steering failure means potential loss of vehicle control, the forging premium represents reasonable insurance. IATF 16949 certification provides the documented quality assurance that transforms marketing claims into verified performance.

- Standard passenger vehicle replacements can use quality castings—but "quality" requires verification. Supplier credentials, material documentation, and testing certificates separate legitimate products from counterfeits. Never assume packaging claims reflect actual content.

- Performance and restoration projects benefit from precision hot forging with engineering support. Custom specifications, rapid prototyping, and seamless scaling from development to production enable solutions that generic aftermarket suppliers cannot match.

The difference between forged and cast steering components isn't merely academic—it's the difference between components designed to survive stress and components designed to meet a price point. Your application determines which priority should prevail.

Every steering component represents a decision point between cost savings today and reliability tomorrow. Choose based on consequences, not just price tags.

For automotive professionals, performance builders, and restoration specialists requiring forged steering components with documented quality assurance, certified precision hot forging manufacturers offer the complete solution. Shaoyi (Ningbo) Metal Technology's IATF 16949 certified operation delivers rapid prototyping in as little as 10 days, in-house engineering support for custom specifications, and strategic location near Ningbo Port enabling fast global delivery. Whether you need prototype quantities for development or high-volume production runs, their precision hot forging solutions transform your specifications into reliable steering components backed by complete documentation and rigorous quality control.

Your steering system connects your intentions to your vehicle's direction. Make that connection count by specifying components manufactured to match your actual demands—and verifying that suppliers deliver what they promise.

Frequently Asked Questions About Forged vs Cast Steering Components

1. What is the difference between cast and forged steering parts?

Cast steering parts are created by pouring molten metal into molds, resulting in random grain structures and potential porosity. Forged parts are shaped under extreme pressure while solid, creating continuous grain flow that follows component contours. This fundamental difference gives forged steering components approximately 37% higher fatigue strength and 26% greater tensile strength, making them significantly more durable for safety-critical applications like steering knuckles and spindles.

2. How can I tell if a steering component is forged or cast?

Forged components typically display wider parting line seams (where die halves meet) compared to the narrow seams on castings. Cast parts often show smoother surfaces with potential for slight dimensional variations, while forged parts exhibit refined surface textures from the compressive forming process. For definitive verification, request material test certificates and manufacturing documentation from your supplier, especially for safety-critical steering components.

3. Which is better for steering components, forged or cast?

Forged steering components are superior for high-stress applications including performance vehicles, heavy-duty trucks, and safety-critical positions like steering knuckles and spindles. However, quality cast components are adequate for standard passenger vehicles under normal driving conditions. The best choice depends on your vehicle weight, driving style, and safety requirements. For maximum safety assurance, IATF 16949 certified manufacturers provide documented quality control for both methods.

4. What are the disadvantages of forged steering components?

Forged steering components carry higher per-unit costs, longer lead times due to specialized tooling, and limited design flexibility for complex internal geometries. They also have fewer aftermarket sources for specialty applications. However, their superior fatigue resistance often results in longer service life, potentially offsetting the initial investment through reduced replacement frequency and enhanced safety margins.

5. Are OEM cast steering components safe to use?

Yes, OEM cast steering components are engineered to meet safety requirements for vehicles operating within original design parameters. Manufacturers design these components for the specific stress profiles of stock configurations. However, cast components may be inadequate when vehicles are modified with added weight, increased power, or aggressive suspension setups. Quality and supplier verification remain essential regardless of manufacturing method.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —